Summary

This report describes combined heat and mass transfer modelling, as well as crude oil property and reaction modelling to study rail tank cars exposed to fire while containing crude oil. The research explores key factors that affect heating rate, thermal response of the lading (i.e. the crude oil in the tank car), and release of the lading through the pressure release valve (PRV). This information is then used to simulate incident scenarios of a tank car in a pool fire to determine which variables have a significant effect on lading response. The cases simulated in this study consider typical fill levels of a range of crude oils, diluted bitumen (dilbit), and a condensate in a fully engulfing pool fire under different incident scenarios.

The work was commissioned by Transport Canada and done by Natural Resources Canada/CanmetENERGY - Ottawa labs.

Background

Given the complex nature of crude oil, it is difficult to predict how a tank car and lading will behave in an incident. This study focuses on the lading response.

In 2018-19, laboratory experiments were done where crude oil samples underwent a controlled distillation process to study properties and reactions at increased temperatures and pressures. This crude oil analysis work was used in this study, and more details can be found in the publication, “Crude Oil Equation of State Final Report – October 18, 2019”Footnote 1.

A computational fluid dynamics (CFD) analysis of this heat transfer, from the fire through the tank and into the lading, was done using ANSYS CFX. A detailed CFD study of the PRV was also done to determine appropriate PRV discharge coefficients. These are detailed in the appendix of the full report of this study.

Objectives

The main objectives of this study are to answer:

- How does crude oil behave when it is inside a tank car that is exposed to a pool fire?

- Which factors, such as the type of crude oil or how full the tank is, are important when modelling this?

This project provides key thermodynamic modelling inputs for an accompanying project that studies how the tank car structure behaves when exposed to a fire. In that work, Transport Canada plans to assess how a detailed material model compares to a more user-friendly, simplified model for assessing tank car fire performance, such as AFFTAC (Analysis of Fire Effects on Tank Cars).

Methods

The detailed model developed in this study uses a combination of 2-D CFD modelling in ANSYS CFX, Aspen HYSYS, and MATLAB to model a tank car in a fully engulfing pool fire. A general overview of how inputs and outputs flow through the different steps and software, as well as the variables explored in the incident scenarios, can be seen in Figure 1.

Figure 1: General Overview of Project. “AFFTAC validation” was deferred to a later study.

Text version

General Overview of Project

1.0 Crude oil properties from EOS work & Fire conditions

1.1 Forward to 2.0

2.0 ANSYS CFD heat Flux Curves

2.1 Forward to 6.0

3.0 Variables of Interest

3.1 Unordered List

3.1.1 Crude oil type

3.1.2 Chemical reactions

3.1.3 Volatility

3.1.4 PRV orientation (rollovers)

3.1.5 PRV blockage

3.1.6 Fire temperature, tank emissivity

3.1.7 Thermal protection

3.1.8 Fill level

3.2 Forward to 6.0

4.0 Correct PRV Performance in CFD

4.1 Forward to 6.0

5.0 Matlab/EOS (Reaction kinetics)

5.1 Forward to 6.0

6.0 ASPEN HYSYS Modelling

6.1 Back to 5.0

6.2 Forward to 8.0

7.0 AFTAC Validation

7.1 Forward to 8.0

8.0 Fire Scenarios

8.1 Back to 7.0

To elaborate on Figure 1, first a 2-D CFD model of the cross-section of the tank (either thermally protected or not) filled with a crude oil is exposed to a boundary condition representing a fully engulfing fire at 815.6 ⁰C, as specified in section 8.2.7 of TP 14877Footnote 2. This generates the heat flux into the lading and the initial temperature ramp rate. This information is entered into Aspen HYSYS, along with discharge coefficients of the PRV and crude oil properties.

Next, a tank with a PRV and filled with crude oil is simulated in Aspen HYSYS using inputs from CFD. An iterative process with MATLAB is used to update the changing crude oil composition due to evaporation and chemical reactions as the tank heats up, pressurizes, and vents. Variables of interest, such as fill levels or PRV performance, are changed here to generate different scenarios to study crude oil response in fire scenarios over long exposure times and multiple pressure relief discharges. The base case is defined in Table 1.

| Parameter | Initial Value |

|---|---|

| Initial Conditions | 105 kPa, 46.1 ⁰C |

| Fire Properties | 815.6 ⁰C, heat flux curve from CFD |

| Tank Properties | Thermally protected (ceramic blanket), emissivity 0.9 |

| PRV Set Pressure | 85 psi |

| PRV Discharge Coefficient | 0.828 (gas), 0.61 (liquid) |

| Fill Level | 93% |

| Crude Oil Type | Light crude, with reactions |

Once the model was fully developed, it was validated against data from a physical experiment conducted by the United States Department of Transportation (DOT) – Federal Railroad Administration (FRA)Footnote 3, where a 1/3rd scale tank car filled with water was exposed to fire. Temperature, pressure and time to venting was considered, and the model results were comparable.

Results

A detailed model was developed, capable of accounting for the complex nature of crude oil. This includes the temperature-pressure dependent properties of the lading, chemical reactions, evaporation and pressure relief events, and how these combine to change crude oil composition over time.

Heat Transfer Results

Comparison of the model to US DOT-FRA experiments confirmed that the dominant mechanism for heat transfer from the fire to the tank is via radiation.

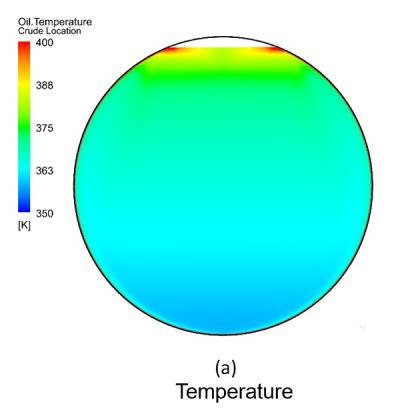

In the initial heating of the lading, the dominant mechanism is convective heat transfer driven by fluid flow, up to 130 ⁰C. Although crude oils are typically characterized by density, viscosity is much more important for heat transfer. The fluid in contact with the tank walls heats up and moves inward (Figure 2), driving the heat transfer.

Figure 2. Colour contour plots for (a) temperature [K], and (b) flow speed [m/s] inside the bare tank for light crude oil near the time the relief pressure was reached.

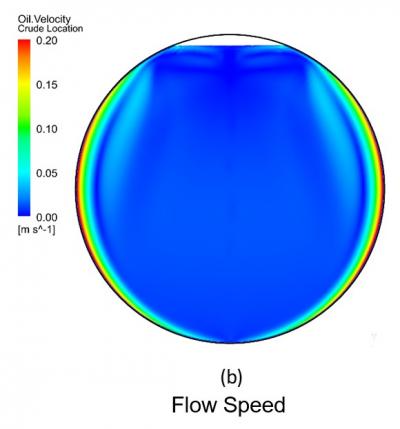

Figure 3 shows the pressure and heat flux curves for light crude oil. The uninsulated, bare shell tank, shown in red, reaches the relief pressure (85 psig) within about 15 minutes. In comparison, the thermally protected tank, shown in blue, has only minor pressurization even one (1) hour into the simulated time of being exposed to the fire. This simulation assumes that the thermal protection remains intact and doesn’t degrade or shift, which may not be the case in reality.

Figure 3. Heat flux curves for light oil for an uninsulated (red) and insulated (blue) tank car.

HYSYS Fire Modelling Results

Based on the modelling of tank car with or without thermal protection, it was determined that thermal cracking (i.e., long hydrocarbon chains breaking down into smaller compounds) can be generally insignificant when the lading is below 425 ⁰C, and can be excluded from analyses if this temperature is not exceeded. In addition, lading temperatures above 425 ⁰C are only expected to occur when adequate insulation is not present (i.e. bare tank).

Different levels of thermal protection resulted in drastic changes on the tank car performance both before and after the initial relief event. Performance assessments at varying levels of thermal protection integrity should be examined to get a better understanding of more ‘realistic’ tank car protection arrangements (pre- and post-incident). Thermal cracking should especially be considered during partial- to no- thermal protection scenarios.

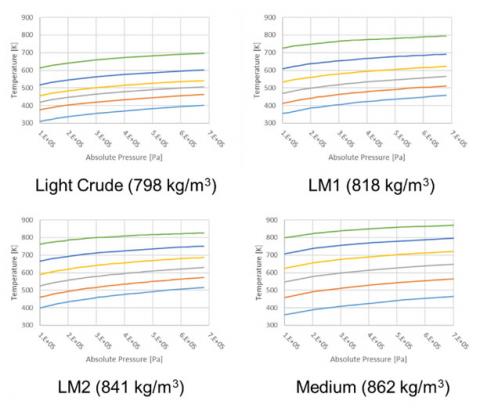

Notable differences were observed for different crude oil types. The lighter crudes do not reach as high of liquid temperatures as the heavier crudes since the lighter crudes vaporize and vent earlier, removing heat periodically from the system.

At high initial fill levels (90%+), time to pressurization is dominated by liquid expansion and less by the crude oil type. Lower initial fill levels can significantly improve tank car performance under fire conditions, such as longer time to pressurization and reduced heat uptake of the lading. Very high fill levels can result in rapid pressurization and a higher likelihood of flammable liquid being vented through the PRV into the fire due to thermal expansion of the liquid.

Flame temperature and tank emissivity are also important when predicting the tank car performance. Note that tank emissivity could be difficult to determine given the potential differences in jacketing and crude oil-specific depositions (soot). The level of thermal protection currently required by TP 14877Footnote 2 for rail tank cars carrying crude oil (Class 117 built after January 2018) appears to provide good heat transfer resistance over a reasonable range of flame temperatures (815.6 ⁰C to 1204.4 ⁰C) and tank emissivity (0.8 to 1.0).

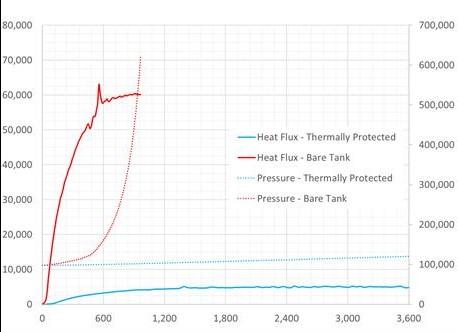

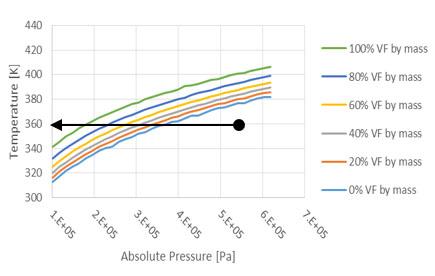

A Note on BLEVEs

When a vessel containing a pressurized liquid fails and instantaneously depressurizes, a BLEVE (boiling liquid expanding vapour explosion) can occur. Reviewing the saturation curves for the condensate and crude oils studied, it was found that condensates can BLEVE due to their low and narrow boiling point range. The black line in Figure 4 represents a tank containing a condensate which has been heated from 27 °C to 87 °C, and reached an internal pressure of 65 psig; a tank rupture under these conditions (with a pressure drop following the direction of the arrow) would cause the contents to go from fully liquid to fully vapour instantaneously. The large boiling point range of the crude oils studied did not exhibit this behaviour (Figure 5).

Figure 4. Saturation curves for condensate studied, showing the narrow boiling point range.

Figure 5. Saturation curves for light and medium crudes showing large boiling point range for each.

Conclusions

Key conclusions related to the heat transfer were:

- Most of the heat from the fire comes into the tank in the form of radiative heat.

- The initial heat transfer of crude oil inside a tank car is primarily driven by convection, which in turn, is mainly driven by the viscosity of the crude oil – lighter crudes tend to be less viscous, and so heat up faster than heavier crudes.

- The vapour space experiences much higher temperatures than the liquid, so the metal touching this vapour space would get much hotter than the rest of the tank.

- When a tank car is thermally protected, the heat flux into the tank is limited by the heat capacity of the thermal protection, and these tanks heat up much more slowly than tanks without any thermal protection.

- Condensates, due to their narrow boiling point range, have the theoretical possibility to experience a BLEVE, whereas crude oils do not.

Factors with a significant effect on tank survivability and modelling impact are:

- Thermal protection: reduces the heating rate of the light crude to less than a tenth of that for the bare tank.

- Crude oil type (lading): heavier crudes reach higher temperatures faster due to lack of venting; lighter crudes heat quickly but also readily vaporize, thus the system pressurizes faster but lading temperatures remain lower.

- Fill levels: lower initial fill levels can significantly improve tank car performance under fire conditions.

- Fire characteristics: Especially important for accurate modelling, since how hot the fire is plays a significant role on how quickly the tank heats up and pressurizes, or more importantly, how long a tank may survive in a pool fire.

Below are the less significant factors:

- Tank car orientation (rollover): PRV is able to prevent over-pressurization even in rollovers; liquid crude oil is vented for cases where tank is rotated 45⁰ and 120⁰, which is problematic for a flammable lading since it can continue to fuel a pool fire.

- PRV blockages: PRV is able to adequately relieve pressure even if partially blocked; only saw over-pressurization in 100% and 99.8% blocked cases.

Future action

To complete the detailed model for studying the fire performance of a tank car in a pool fire, Transport Canada plans to use this data on lading response to model how the tank material and structure may behave using finite element analysis. This study will be published in the future.

The results identifying which factors are important when modeling crude oil will be used to support other research goals.

There is potential for applying a similar approach to model other flammable ladings in fire or incident conditions where there is an identified need to better understand the hazards and risks associated with the transport of these types of dangerous goods.

References

TP 15499E

ISBN: 978-0-660-40730-2

Catalogue Number: T44-3/26-2021E-PDF

Acknowledgements

This study was commissioned by Transport Canada. Experimental testing, modelling, and model validation was performed by Natural Resources Canada/CanmetENERGY - Ottawa. Additional assistance was provided by United States Department of Transportation – Federal Railroad Administration.

Contact

To obtain a copy of the report, please contact us:

TDG Scientific Research Division

Keywords

Flammable lading, Crude Oil, Computational fluid dynamics (CFD) modelling, HYSYS, Process modeling, BLEVE, Reaction kinetics, Pool fire, Fire performance, Tank car