On this page

- 1. Executive summary

- 2. Ammonium nitrate - A dangerous goods

- 3. Canadian regulatory landscape

- 4. International landscape of ammonium nitrate

- 4.1 United Nations Recommendations

- 4.2 International Maritime Organization (IMO)

- 4.3 European Agreement Concerning the International Carriage of Dangerous Goods by Road (ADR)

- 4.4 Comparison between Canada and international requirements

- 4.5 Comparison between Canada and other countries regarding ammonium nitrate storage requirements

- 5. Canadian and international best practices for the storage, handling and transport of ammonium nitrate

- 6. Analysis of findings

- 7. Conclusion

- 8. Next steps

- 9. References

- 10. List of Acronyms

- 11. ANNEXE A - Classification and economics

1. Executive summary

Transport Canada (TC) is the federal department responsible for regulations, policies, and programs that pertain to transportation across all modes (rail, road, marine, and air). TC also promotes a safe, secure, efficient, and environmentally responsible transportation system and supports innovation and a competitive economy.

The Transportation of Dangerous Goods (TDG) Program develops safety standards and regulations, provides risk-based oversight and gives expert advice on dangerous goods (DGs) to promote public safety in the transportation of DGs by all modes of transport regulated by TC.

In light of the devastating explosion at the Port of Beirut in Lebanon on August 4, 2020 which involved over two thousand tonnes of ammonium nitrate (AN), the TDG Directorate at TC conducted a review of the current regulatory landscape and best practices, both domestic and international, regarding the storage, handling, and transport of ammonium nitrate. While the AN used in the explosives industry has a well-defined regulatory framework, efforts should be made to better understand the role of federal, provincial, and municipal authorities in establishing the requirements pertaining to the management of AN used as fertilizer in Canada.

In Canada, the storage, handling, and transport of AN are subject to a robust regulatory framework at the federal level that is shared between TC, Natural Resources Canada (NRCan), Environment and Climate Change Canada (ECCC), and the Canadian Border Services Agency (CBSA).

Land planning and zoning, building structure, construction design, and fire prevention requirements are enforced by provinces, territories, and municipalities through Building and Fire Codes. This creates variability among the multitude of existing codes.

At the industrial level, the Canadian ammonium nitrate industry has implemented numerous best practices and models. An analysis of international practices also identified possible options that could be adapted in Canada to enhance the safety and security of activities pertaining to AN.

Overall, findings revealed that the multijurisdictional approach may create challenges for regulated parties in terms of identifying and complying with applicable storage requirements. Moreover, the analysis of federal regulations indicates that enhanced clarification could further ensure that requirements are clear and consistent across all modes.

2. Ammonium nitrate - A dangerous goods

2.1 Properties of ammonium nitrate

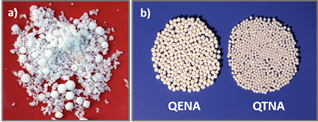

Ammonium nitrate (AN) is an odorless white salt that dissolves easily in water to form a clear solution (see Figure 2-1). It also absorbs moisture from the air, which can lead to the formation of a large solid mass with potentially explosive capabilities under extreme temperatures.

Gases evolved in the decomposition reactions include toxic gases which are irritating and corrosive to the respiratory system and skin.

AN is also a strong oxidizer which means that when it decomposes, it supplies oxygen that can accelerate the burning of combustible and organic substances.

For commercial purposes, AN is typically prepared in a solid form as granules or prills. There are two grades:

- a technical grade referred to as Ammonium Nitrate Technical Grade (TGAN)

- a fertilizer grade referred to as Ammonium Nitrate Fertilizer Grade (FGAN)

Although visually similar, TGAN is usually smaller in size than FGAN and porous to facilitate absorption of other materials, such as fuel oil, so that it can be manufactured into an explosive.Footnote 1

AN can also be manufactured in liquid form, which is used extensively in the mining industry to create explosives. However, it is outside the scope of this report, which will focus on AN in its solid form.

Terminology

Pure AN: a compound that contains only one substance, in this case ammonium nitrate.

TGAN: low density ammonium nitrate (prills containing large pores).

FGAN: high density ammonium nitrate (granules or prills with small pores).

Prills: small porous spheres of ammonium nitrate formed by allowing the melted liquid to dry.

Oxidizer/oxidizing: a chemical which has the capability to provide oxygen, thereby helping combustible materials to burn more readily.

Organic substances: a solid, liquid, or gas compound that contains carbon, and which burn easily when exposed to a heat source.

Figure 2-1 Forms of Ammonium Nitrate a) Crystals b) Prills

Pure AN can be handled safely under normal room temperature and pressure conditions. However, there are three factors that could increase the likelihood of it exploding:

- Heat: when heated to its decomposition temperature of approximately 210°C, it becomes very sensitive to shockFootnote 1 and detonation

- Contamination: when mixed or contaminated with other materials such as diesel, charcoal, or acids, AN becomes more vulnerable to detonation. This means that it is more sensitive to heat and can explode at a lower temperature

- Confinement: if undergoing decomposition, heat and gases are released which creates a pressure. This means boiling is suppressed and the temperature in the molten AN raises. As such, if it is contained in a confined space, an explosion may occurFootnote 2Footnote 3

In Canada, AN is listed as a dangerous goods in the Transportation of Dangerous Goods Regulations (TDGR). A dangerous goods is any substance or product that is capable of posing a significant risk to health, safety, property, and the environment when they are not handled, transported, or stored properly. Dangerous goods may be corrosive, explosive, flammable, or oxidizing and, as such, are restricted or regulated. In regulations, they are classified on the basis of their composition and hazardous behavior according to internationally agreed-upon tests and criteria that are outlined in the United Nations (UN) Recommendations on the TDG Model Regulations.Footnote 4

Of the nine classes of dangerous goods, AN-based products fall under the following three (3):

- Explosives (Class 1), in which AN is mixed with more than 0.2% of combustible or organic substances

- Oxidizers (Class 5.1), in which AN is mixed with less than 0.2 % of combustible or organic substances, as well as AN based fertilizers with a concentration of AN that is ≥ 70 %

- Miscellaneous Dangerous Goods (Class 9), in which AN-based fertilizers have a concentration of AN that is ≤70 %

Table 2-1 below illustrates these nine (9) classes of dangerous goods, highlighting the ones that are specific to AN.

| Class | Description | Examples |

|---|---|---|

|

Specific to AN: 1 |

Specific to AN: Explosive |

Specific to AN: Fireworks, Firecrackers, Ammunition |

|

2.1 |

Flammable Gases |

Lighter Fuel, Camping Gas, BBQ propane tank |

|

2.2 |

Non-flammable, Non-toxic Gases |

Fire extinguishers, Helium Gas |

|

2.3 |

Toxic Gases |

Carbon monoxide, Chlorine Gas |

|

3 |

Flammable Liquids |

Perfume, Paint, Alcoholic Beverages |

|

4.1 |

Flammable Solids |

Matches |

|

4.2 |

Spontaneously combustible |

Charcoal, White phosphorus |

|

4.3 |

Dangerous when wet |

Potassium, Calcium carbide |

|

Specific to AN: 5.1 |

Specific to AN: Oxidizing agent |

Specific to AN: Fertilizer containing ammonium nitrate, Bleach |

|

5.2 |

Organic peroxide |

Plastic adhesive |

|

6.1 |

Toxic substances |

Pesticides |

|

6.2 |

Infectious substances |

Clinical or Hospital waste |

|

7 |

Radioactive substances |

Nuclear waste, Uranium |

|

8 |

Corrosive |

Liquid batteries |

|

Specific to AN: 9 |

Specific to AN: Miscellaneous Dangerous Goods |

Specific to AN: Lithium Batteries, Electronic cigarettes, Dry ice, Fertilizers |

AN is also described in terms of a UN Number, which conveys standardized information for the safe handling, storage, and transport of dangerous goods. However, for the purposes of this paper, ammonium nitrate will be referred to as TGAN and FGAN. For more detailed information on UN specific classifications, please refer to the Table 11-1 in Annex A.

2.2 Main uses of ammonium nitrate

Globally, AN is primarily used as a source of nitrogen in fertilizers for the agricultural industry, as well as an oxidizer in some explosive mixtures for the mining, quarrying, and construction industries.

FGAN is mainly used in fertilizers due to its high nitrogen content, which is a key nutrient that plants need to grow. In the early 1900s, the lack of nitrogen availability was identified as one of the key factors limiting plant growth. During that time, high demand to increase agricultural production resulted in the search for other inexpensive, efficient, and readily available sources of nitrogen, which led to the discovery of AN. In the 1940s, AN became one of the largest source of nitrogen for agriculture, which remains its predominant use nowadays in many countries.Footnote 3 However, since 2008 the Canadian fertilizer industry has shifted its production from solid FGAN to other safer nitrogen-based fertilizers, such as calcium ammonium nitrate, that pose less hazards to farmers and surrounding communities.Footnote 5

In recent years, the Canadian fertilizer industry “has made significant efforts to move towards products that are safer to handle and store. This includes efforts at the retail level to convert customer markets to products with less risk to those who handle them and the communities where they are stored and distributed.”

Source: Fertilizer Canada

TGAN is extensively used in some explosives mixtures because of its ability to provide high concentrations of oxygen, which means that it significantly accelerates the burning rate of combustible or organic substances. The faster these substances burn, the stronger the explosion, due to the accelerated release of heat and gas. It accounts for the majority of explosives used in North America and is commonly used due to the inexpensive formulation.Footnote 3

To a lesser extent, AN has applications in various other industrial sectors. For example, it is an active ingredient in cold packs for athletes, rocket propellants for the aerospace industry, air safety bags for automobiles, in the production of “anesthetic gas” for surgery and dentistry, and as a hardening additive for plastics.Footnote 6

2.3 Storage of ammonium nitrate in Canada

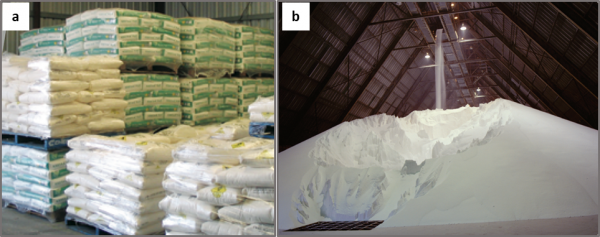

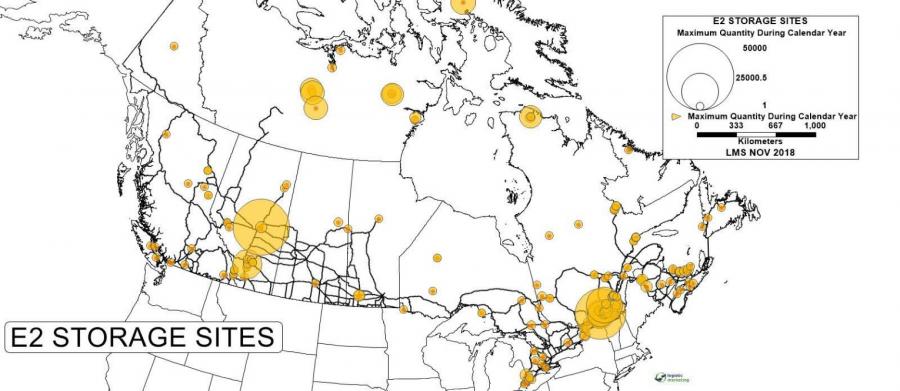

AN is stored in various locations across Canada, ranging from dedicated storage facilities to manufacturing plants, ports, construction sites, farms, greenhouses, and mines. AN can be stored either in bulk (unpackaged materials) or in packages. Regardless of the storage method, ammonium nitrate must be segregated or separated from other chemicals and placed in clean, closed, and dry containers or warehouses.Footnote 2 Figure 2-2 illustrates these two major means of storage. See Figure 11-1, Annex A for the location of various permanent large storage sites across Canada, note their proximity to major cities.

Figure 2-2 Storage of solid ammonium nitrate a) Packaged b) Bulk

2.3.1 Bulk storage

AN can also be stored in bulk (i.e. unpackaged material) at ports prior to being transported by road or rail to processing plants for further storage until it is ready to be blended with other materials and/or packaged. Shipping containers with an anti-corrosive liner are considered acceptable for storing and transferring bulk AN from a ship to a rail car or truck.

At manufacturing sites, mines, and quarries, permanent large storage installations for bulk AN take the form of silos (bins) or specialized domes, which are adapted to resist corrosion due to AN’s oxidizing properties.

At construction sites and in remote locations, road trailers, tankers, and railcars are installed as temporary or permanent storage solutions.Footnote 7 Figure 2-3 illustrates the storage and movement of bulk AN into storage bins, rail cars, trucks and ships.

Figure 2-3 a) Unloading AN solution from Railcar b) Loading of Tanker

c) Loaded onto Vessel d) Loaded from the Plant to Truck e) Railcar unloading prills to Storage Bin.

2.3.2 Storage of packages

Storage facilities (buildings or warehouses) housing packaged AN must follow specific regulatory requirements at the federal, provincial, and municipal levels. These storage facilities can be found at various locations across Canada including ports where they meet the different storage needs of suppliers, distributors, shipping companies, and users along the supply chain (i.e. from manufacturer to end-user).Footnote 8Footnote 9

These packages must comply with specific technical standards outlined in the TDGR, which stipulate the requirements for their design, construction, selection, and use. Furthermore, the packages must be sealed, dustproof, and made of a material that is impermeable to oil and water.

2.4 Ammonium nitrate in a safety and security context

2.4.1 International

On August 4, 2020, a devastating explosion involving thousands of tonnes of AN occurred at the Port of Beirut, Lebanon. The incident resulted in around 200 fatalities and caused extensive damage to infrastructure and property, which left over 300,000 people homeless. For a more in-depth analysis of the incident, please consult Forensic Architecture.

Unfortunately, this is not an isolated event. There are historical examples of AN causing significant loss of life and damage to property due to mishandling, poor storage, or ignoring safety limits.

Figure 2-4 indicates the quantity of ammonium nitrate involved in each incident.Footnote 10

Figure 2-4 Quantity in metric tonnes of ammonium nitrate involved during historical events.

Text version

| Cities, Countries year | Quantity of ammonium nitrate in tonnes |

|---|---|

| Brest, France 1947 | 3000 |

| Texas City, USA 1947 | 2960 |

| Beirut, Lebanon 2020 | 2750 |

| Tianjin, China 2015 | 800 |

| Oppau, Germany 1921 | 450 |

| Toulouse, France 2001 | 300 |

| West, Texas, USA 2013 | 240 |

- In 1921, two (2) consecutive explosions occurred in a silo at a plant in Oppau, Germany, which belonged to BASF, a German multinational chemical company

- In 1947, two (2) ships loaded with AN, exploded at the docks in Galveston Bay, Texas, United States (USA)

- In 1947, an explosion related to AN was reported at the Port of Brest, in France

- In 2001, an explosion related to AN occurred at a fertilizer factory in Toulouse, France

- In 2013, a fire in the warehouse of a fertilizer company in Texas, USA, resulted in the explosion of stored AN. Reports indicated that the warehouse had stored more than the allowed quantity of AN

- In 2015, a fire at a warehouse storing dangerous goods in Tianjin, China, triggered the detonation of AN stored nearby

- In 2020, there was an explosion at the Port of Beirut in Lebanon involving AN. The main contributing factors are not yet fully understood

2.4.2 Safety - Canada

In Canada, data collected from incident reporting show that over the past 20 years, there have been around 165 incidents involving AN, with the majority of these occurring in the provinces of Alberta and Quebec, see Figure 2-5 a. Of the 165 incidents, 102 occurred during the transportation of AN via rail or road modes, while the remaining 63 occurred during the handling AN at a facility.

Figure 2-5 b exhibits one of the most serious accidents in Canada in 1998, near Walden, Ontario. A driver of a commercial vehicle carrying 18,000 Kg of explosives, part of which was AN mixed with Fuel Oil (prill form), lost control and went off the road. The vehicle struck a rock, which created a spark causing a fire. The fire burned for approximately 35 minutes before igniting the solid form of ammonium nitrate. The resulting explosion created a 30-meter long crater in the ground, caused tremors that were felt within a 10 Km radius, and cast fragments of the truck up to 2.7 km away. The injuries sustained during the incident were minor and attributed to exposure to AN. Footnote 11Footnote 12

Ammonium Nitrate Incidents by year

Figure 2-5 a) Ammonium nitrate incidents by year (from 1990 to 2019).

Text version

| Year | Not-intransit | In transit |

|---|---|---|

| 1990 | 0 | 4 |

| 1991 | 1 | 1 |

| 1992 | 0 | 2 |

| 1993 | 0 | 2 |

| 1994 | 1 | 3 |

| 1995 | 2 | 0 |

| 1996 | 7 | 5 |

| 1997 | 0 | 4 |

| 1998 | 3 | 4 |

| 1999 | 15 | 3 |

| 2000 | 3 | 6 |

| 2001 | 4 | 5 |

| 2002 | 2 | 7 |

| 2003 | 3 | 4 |

| 2004 | 0 | 6 |

| 2005 | 2 | 3 |

| 2006 | 1 | 0 |

| 2007 | 0 | 5 |

| 2008 | 4 | 4 |

| 2009 | 1 | 3 |

| 2010 | 2 | 1 |

| 2011 | 4 | 1 |

| 2012 | 0 | 3 |

| 2013 | 3 | 3 |

| 2014 | 2 | 2 |

| 2015 | 1 | 4 |

| 2016 | 0 | 1 |

| 2017 | 0 | 6 |

| 2018 | 2 | 7 |

| 2019 | 0 | 3 |

Figure 2-5 b) Site of explosives truck accident in Walden, Ontario.

Following the Walden explosion, Natural Resources Canada (NRCan) considered reducing the permitted load size of explosives during transport.

2.4.3 Ammonium nitrate in a security context

In addition to the legitimate commercial uses of AN, another aspect for consideration is its malicious use for terrorist attacks. Given the prevalent use of TGAN and FGAN in mining, construction, and agriculture-related operations, AN has been susceptible to theft and unlawful interference by persons who want to make explosive devices.

For instance, in the 1995, a homegrown terrorist group used an AN-based bomb to attack a federal building in downtown Oklahoma City, United States. Between 2011 and 2013, AN-based bombs were used to attack civilians in Oslo, Norway, and Hyderabad, India, as well as government targets in New Delhi, India.Footnote 10

To address this global security issue associated with AN-based bombs, global efforts have been taken to require access control and accountability in the production and use of AN worldwide.

AN is recognized for its potential to be intentionally misused and is classified as a High Consequence Dangerous Goods per the UN. However, for this classification to apply, it must be in bulk and in a quantity greater than 3000 kg.Footnote 4

2.5 Ammonium nitrate in commerce

2.5.1 Global production

With an average production over 650,000 metric tonnes per year, Canada is the 5th largest AN producer in the world after Uzbekistan, Poland, the United States, and Ukraine.Footnote 13 See Figure 2-6.

Canada produces mostly technical grade AN for the industrial mining sector in Western Canada. The TGAN is produced at two manufacturing facilities located in Alberta.Footnote 14

Figure 2-6 Annual Global production of Ammonium Nitrate - total production was estimated at 6.61 million tonnes in 2018. Canada is among the top five (5) producers around the world. (Source: Food and Agriculture Organization)

Text version

| Countries | Production |

|---|---|

| Turkey | 3.90% |

| United States of America | 18.09% |

| Canada | 10.65% |

| Ukraine | 15.84% |

| Croatia | 0.48% |

| Lithuania | 8.35% |

| Poland | 19.56% |

| Uzbeskistan | 23.12% |

2.5.2 Canadian trade in ammonium nitrate

In addition to producing AN, Canada also imports, exports, and re-exports a substantial amount of AN. Re-exports consist of goods that are only in transit through Canada. A review of the trade data for AN was undertaken by TC. See Annex A: Economics and Trade, for additional information regarding how AN is described for this trade analysis.

For imports, 2019 trade volume data indicates that just over 400,000 tonnes of AN entered Canada, of which 70% was comprised of TGAN and 30% was FGAN. The top five (5) countries from which Canada imported AN were the USA (66%), Netherlands (26%), Russia (4%), Germany (1.7%) and Sweden (1.2%).Footnote 14 Please see Figure 2-7 below.

Imports of AN by Country (in Metric Tons), 2019

Figure 2-7 Source and volume (metric tonnes) of imports

Text version

| Countries | Metric tons |

|---|---|

| United States | 274447 |

| Netherlands | 106302 |

| Russia | 17393 |

| Germany | 7158 |

| Sweden | 4796 |

| Others | 2896 |

Ontario and Quebec were the largest importers, comprising approximately 90% of total imports, with Ontario slightly ahead of Quebec, and British Colombia a distant third.

An examination based on the mode of transport for imports revealed that in 2019, over half of AN imports entered Canada by rail, followed by marine, and a much smaller quantity by road. There was very little volume imported via the air mode. Exports are comprised of two (2) categories, “Domestic Exports” and “Re-exports.”

Re-exports of AN accounted for only 1.1% of the total exports. Given its small volume, no further analysis was done for this report. For domestic exports, (i.e. goods originating in Canada that go to another country), trade volumes indicate that around 300,000 tonnes of AN left Canada in 2019, of which 97% comprised of TGAN and 3 % was FGAN. The top five (5) countries for domestic exports of AN were the United States (96%) and Mexico (3.9%), followed by Saudi Arabia, Australia, and Costa Rica. Please see Figure 2-8 below.

Exports of AN by Country (in Metric Tons), 2019

Figure 2-8 Source and volume (in metric tonnes) of domestic exports

Text version

| Countries | Metric Tons |

|---|---|

| United States | 278795 |

| Mexico | 11222 |

| Saudi Arabia | 1 |

In contrast to imports, in which Eastern Canada dominated, the leading provinces for domestic exports were Alberta (86%) and Manitoba (11%), with Quebec a distant third at 3%.Footnote 14

An examination based on the mode of transport revealed that in 2019, the rail mode accounted for more than three-quarters of the domestic export trade, with road being the second most popular mode of transport. This was followed by a very small volume of exports by the marine mode and practically no domestic exports via the air mode.

In summary, imports outweighed domestic exports in 2019 (412,991 metric tonnes versus 290,018 metric tonnes). This is consistent with average trade over the last five years, with Canada’s largest trading partner being the USA. The predominant modes of transport were rail, marine, and road.Footnote 14

3. Canadian regulatory landscape

3.1 Role of federal government

The federal regulatory landscape for the handling, storage, and transport of AN is illustrated in the following Table:

| Federal Department | Regulatory Framework | Regulated Activity | ||

|---|---|---|---|---|

|

Safety |

Transport Canada |

Transportation of Dangerous Goods |

Transportation of Dangerous Goods Act Transportation of Dangerous Goods Regulations |

|

|

Marine |

Canadian Shipping Act Cargo, Fumigation and Tackle Regulations |

|

||

|

Rail |

Railway Safety Act Ammonium Nitrate Storage Facilities Regulations |

|

||

|

Air |

No Specific Acts or Regulations |

|

||

|

Environment & Climate Change Canada |

Canadian Environmental Protection Act Environmental Emergency Regulations |

|

||

|

National Research Council of Canada |

National Building Code National Fire Code of Canada |

|

||

|

Health Canada |

Hazardous Products Act Hazardous Products Regulations |

|

||

|

Security |

Natural Resources Canada |

Explosives Act Explosives Regulations |

|

|

|

Transport Canada |

Transportation of Dangerous Goods Act Transportation of Dangerous by Rail Security Regulations |

|

||

|

Canada Border Services Agency |

Canadian Border Services Agency Act |

|

||

Of particular interest to this report is the role played by NRCan, who regulates all aspects regarding the safety and security of explosives in Canada through the Explosives Act and the Explosives Regulations, 2013.Footnote 15

The requirements prescribe special provisions for the management of TGAN. The security requirements focus on suppliers and control access, sale, and inventory to ensure that AN is not intentionally misused. The safety requirements ensure that workers are adequately trainedFootnote a for their tasks and that storage installations have safety plans in place with emergency procedures that reduce the likelihood of harm to people or property is minimized.

Terminology

Magazines: “any building, storehouse, structure, or place in which any explosive is kept or stored” as defined in the Explosives Act (some exceptions exist).

Applicable standards: These standards apply only to licensed explosion sites.

Additional safety requirements, such as minimum separation distance between AN storage facilities and explosives, as well as the proper storage of explosives, are prescribed in the regulations and detailed in the following specific standards within the National Standards of Canada: Footnote 16 Footnote 17

- Quantity-Distances CAN / BNQ 2910-510 / 2015

- Magazines for industrial explosives CAN / BNQ 2910-500 / 2015

NRCan also provides Guidelines for Bulk Explosives Installations (2018) to be used as a guide to meet regulatory requirements.Footnote 18 Examples of these storage requirements are shown in Table 3-2.

| Requirements | Applicable NRCan Standard or Guidelines | Description |

|---|---|---|

|

Storage ambient temperature |

|

|

|

Special building particularities |

|

|

CAN/BNQ 2910-500/2015 |

|

|

|

Minimal ventilation systems |

CAN/BNQ 2910-500/2015 |

|

|

Fire Protection and Security Features |

|

|

|

|

|

|

Stacking limit |

CAN/BNQ 2910-500/2015 |

|

|

Separation distance explosion sites and AN storage locations |

|

|

AN is not, itself, considered an explosive, but rather a restricted component. The guidelines and best practices provided by NRCan are reflective of industry and international best practices. As such, the information is comprehensive and covers all relevant safety and security considerations for temporary and permanent storage. The most recent update to the Guidelines to Bulk Explosive Facilities occurred in 2018.Footnote 18

3.2 Multi-jurisdictional practices covering ammonium nitrate.

In Canada, provinces and their municipalities rely on multiple models and best practices to ensure safe storage, handling, and transport of dangerous goods, including AN. However, examining areas of jurisdiction between the levels of governments reveals some differences.

Looking at federal jurisdiction, there are Acts and regulations which must be followed for specific modes. For example, the Railway Safety Act and the subsequent regulations prescribe rail activities that federally regulated railways must follow. However, when no federal authority exists, such as in the case of fire or building codes, federal models and guidelines have been developed to guide provincial and municipal practices. These federal models do not prescribe requirements, but rather, articulate best practices and provide example regulations which may be adopted. In instances where provincial authority is shared with the municipalities, again using the example of fire or building codes, provinces put in place model codes which a municipality may adopt, but are free to add additional safety requirements. Moreover, a municipality may adopt the federal fire code model and adapt/modify it according to specific needs. In terms of fire or building codes, this means a municipality may reference federal or provincial models and add or remove elements based on their needs. Footnote 19Footnote 20

The following areas are more closely examined to illustrate how the supply chain of AN is impacted by these different levels of jurisdiction:

- land-use planning and control

- construction planning and fire planning

- road transportation

- occupational health and safety regulations

3.2.1 Land-use planning and control

The location of AN manufacturing or storage facilities across Canada including ports are determined through land-use planning and zoning requirements. Land-use planning is governed by provincial/territorial legislation and implemented by municipalities. The latter are responsible for preparing and adopting planning instruments in their respective jurisdictions, such as official plans and by-laws.

Official planning allows municipalities to control use of their territory and provides them with a regulatory zoning framework, which includes details pertaining to lot size, suitable use, and the height of buildings. In this way, municipalities regulate the location of AN within its jurisdiction and specify the conditions under which AN related activities may be undertaken. By separating AN related activities from housing, schools, libraries, sporting arenas, or other community facilities, the potential negative impacts from fires or explosions are minimized.

3.2.2 Construction planning and fire prevention - building and fire codes

Storage facilities containing AN Class 5.1, in quantities over 1000 kg are subject to provisions that specify construction standards and fire prevention requirements.

These provisions are administered through different codes that limit the likelihood of incidents. To this end, provinces, territories, or municipalities have adopted, in whole or in part, model codes that are published every five (5) years by the National Research Council of Canada (NRC). These include:

- the National Building Code of Canada (NBC)

- the National Fire Code of Canada (NFC)

- the National Farm Building Code (NFBC)

These codes form the basis for all provincial, territorial, and municipal codes. In order to have legal force, the codes published by NRC have to be adopted by local authorities. Table 3-3 shows the adoption of model codes across Canada. It should be noted that differences occur based on the release date of the edition adopted.Footnote 19

Of particular interest is NRC’s National Farm Building Code of Canada, 1995, which provides specifications for the structural design and safety measures applicable to farm buildings, which may be used for fertilizer storage. This Code refers to the NBC, 1995 for some requirements, but does not address the storage of AN. Since 1995, there has been no substantive updates. Some agricultural associations are of the opinion that building codes have not kept up with the needs of the farming industry in terms of increasing size and complexity of buildings. A review of the NFBC is underway and updated provisions for large farm buildings will be incorporated into the next editions of the NBC and NFC in the near future to meet the needs of modern and complex farming activities. Small farm buildings are still subject to the requirements within the NFBC 1995. Footnote 20Footnote 21

| Edition of the National Building Code and National Fire Code Models | Provinces and Territories that Adopted the National Building Code (NBC) and National Fire Code (NFC) Entirely, or with Modifications and Additions | Provinces that Published their own Codes Based on the National Model Codes |

|---|---|---|

|

2010 |

|

|

|

2015 |

|

|

|

Major municipalities in Prince Edward Island adopt the NBC 2010, however, province-wide fire code is not based on NFC. |

||

Furthermore, aspects specifically related to storage facilities for AN Class 5.1 mixtures have been included in these codes to ensure the safety of the population and to prevent the risk of fire and/or explosion. Examples of these specific requirements are presented in Table 3-4 below.

| Requirements for AN Class 5.1 | Applicable Code | Description |

|---|---|---|

|

AN Storage Quantities |

|

|

|

Storage ambient temperature |

|

|

|

Maximum building height |

|

|

|

Special building particularities |

|

|

|

Minimal ventilation systems |

|

|

|

Fire Protection and Security Features |

|

|

|

Industrial trucks |

|

|

|

Storage placement relative to property lines or other buildings |

|

|

|

|

The table demonstrates the most common practices for the storage of AN Class 5.1. As shown, the 2010 and 2015 Codes for both building and fire prevention address these best practices. However, some differences exist between provinces, most notably in Ontario. The Province of Ontario did not adopt the national codes and instead, issued its own codes which, upon examination, demonstrate a variance in content and scope from the NBC and the NFC. For example, the prescribed distance limits for storage installations from property lines in the Ontario Fire Code are fixed. This means that they do not vary based on factors prescribed in the 2010 and 2015 editions of the NFC, such as building size, or the presence of sprinkler systems. This would suggest that the current fixed limiting distances in Ontario rely on requirements that were established before 2010 (i.e., from an older edition of the NFC). However, there are provisions in the Ontario Fire Code that allow for the approval of alternative measures for prescriptive requirements. Footnote 19Footnote 20

Since such variances exist, a more comprehensive analysis of municipal and provincial codes would be useful in assessing whether the specific AN storage requirements satisfy safety and security best practice for storage. Furthermore, it may be necessary to consider a national update in the adoption of the codes by Provinces and Municipalities to enhance the protection of the population and the environment taking into account the latest developments in technology, design and materials. NRC reported that through the ongoing work conducted under the Regulatory Reconciliation and Cooperation Table (RCT), the national model codes will be harmonized with the provincial. As such, it is anticipated that the provinces and territories will adopt the harmonized codes in the future. However, no specific timeline is available at this point. The Province of Ontario has signed the Reconciliation Agreement on Construction Codes under the Canadian Free Trade Agreement (CFTA), and further analysis of the technical variances between the provincial and national model codes will be conducted as part of the harmonization activities.Footnote 22

3.2.3 Road transportation

Provinces and territories administer their respective regulations regarding the transportation of dangerous goods on highways under their jurisdiction. These are similar to the Federal TDGR. Some also choose to add more stringent requirements, such as in Quebec, where the transport of dangerous goods is prohibited in tunnels, unless they are Class 9 dangerous goods.Footnote 23

Although there are different agreements on the division of responsibilities, provincial and territorial regulations generally apply to the handling and transportation of DGs on highways, as well as on rail vehicles that are within the provincial/territorial jurisdiction.Footnote 24

3.2.4 Occupational health and safety regulations

Hazard communication and workplace requirements for hazardous products stored, handled or used in the workplace in Canada are regulated under federal, provincial and territorial occupational health and safety legislation. This interlocking legislation forms the Workplace Hazardous Materials Information System (WHMIS).Footnote 25

WHMIS laws require employers to ensure that their employees work under safe conditions and receive adequate training pertaining to their duties. Examples of activities under this system include ensuring that controlled or hazardous products used, stored, handled or disposed of in the workplace are properly labelled, safety data sheets are made available to workers, and workers receive adequate education and training to ensure safe storage, handling and use of these products in the workplace.

3.2.5 Jurisdictional responsibilities between Canada and other countries.

The division of jurisdictional responsibilities is not unique to Canada. To illustrate this point, this report examines the regulatory requirements for fertilizer grade AN in Canada and several other countries. When examining explosive grade AN across different countries, a commonality was that it is a highly controlled substance at the national level. In comparison, fertilizer grade AN was found to be controlled by various levels of government, which is the case in Canada. As the greatest difference occurs in the examination of fertilizer grade, this is the focus of the jurisdictional comparison moving forward.

Table 3-5 provides a summary overview of the levels related to FGAN for the following countries, Canada, USA, United Kingdom (UK), Australia, France, Austria, Belgium, Spain and Netherlands.

| Activities | Canada | USA | UK | Australia | France | Austria | Belgium | Spain | Netherlands | |

|---|---|---|---|---|---|---|---|---|---|---|

|

Storage |

Quantities |

Federal |

Provincial |

Federal |

Provincial |

Federal |

Provincial |

Provincial |

Provincial |

Federal |

|

Distances |

Federal |

Provincial |

Federal |

Provincial |

Provincial |

Provincial |

Provincial |

Provincial |

Federal |

|

|

Constructions specifications |

Federal |

Provincial |

Federal |

Provincial |

Provincial |

Provincial |

Provincial |

Provincial |

Federal |

|

|

Environment protection |

Federal |

Provincial |

Federal |

Provincial |

Federal |

Provincial |

Provincial |

Federal |

Provincial |

|

|

Labeling |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

|

|

Packaging |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

|

|

Segregation |

Provincial |

Provincial |

Provincial |

Provincial |

Provincial |

Provincial |

Provincial |

Provincial |

Provincial |

|

|

Land planning & zoning |

Provincial |

Provincial |

Federal |

Provincial |

Provincial |

Provincial |

Provincial |

Federal |

Provincial |

|

|

Handling |

Security |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

Federal |

|

Emergency Planning & response |

Provincial |

Municipal |

Provincial |

Municipal |

Municipal |

Municipal |

Provincial |

Municipal |

Provincial |

|

|

Worker protection |

Federal |

Provincial |

Provincial |

Provincial |

Provincial |

Provincial |

Federal |

Provincial |

Federal |

|

4. International landscape of ammonium nitrate

4.1 United Nations Recommendations

The UN Recommendations on the Transport of Dangerous Goods Model Regulations (UN Model Regulations) are developed by the Sub-committee of Experts on the Transport of Dangerous Goods (TDG Sub-Committee of Experts) of the UN Economic and Social Council (ECOSOC), whose members are comprised of TDG experts from participating countries, including Canada.Footnote 26

The UN Model Regulations establish minimal requirements and a harmonized framework of rules, which govern the transport of dangerous goods across all modes.Footnote 4

According to the Model Regulations, AN can be transported in small packaging and in bulk in containers, as long as the packaging instructions are respected. Only UN-approved packages (i.e. standardized means of containment that have passed specific performance tests and are certified by the respective authorities of each country) are allowed to be used for packaging AN for transport.Footnote 4

Table 4-1 below illustrates the means of containment allowed for the transportation of AN according to the UN Recommendations, as outlined in the Model Regulations. It demonstrates that comprehensive guidance is provided to countries on the packaging requirements for AN.

| AN Type | Permitted UN Standardized Means of Containment | Maximum Capacity or Net Mass | Example |

|---|---|---|---|

|

AN |

Drums, jerricansFootnote *, boxes, bags, compositeFootnote ** packaging, and combination packagingFootnote *** |

≤ 400kg (450 L) depending on the type of outer packaging |

|

|

UN Standardized Intermediate bulk containers (IBCs) made of metalFootnote *, plastic, compositeFootnote **, fiberboard, wooden, or flexible fabric |

3 m3 |

||

|

Large packaging ≤ 3m3 (large packaging containing smaller packaging) |

3 m3 |

||

|

Technical Grade AN |

Combination packagingFootnote *** with outer packaging consisting of either a bag, a box, a drum or a jerricanFootnote * |

≤ 400kg (450L) depending on the type of outer packaging |

|

|

UN Standardized IBCs made of metal, plastic, compositeFootnote **, fiberboard, wooden, or flexible fabric |

3 m3 |

||

|

AN Emulsion, Suspension, or Gel for Blasting Explosives UN 3375 |

Combination packagingFootnote *** (boxes or drums or jerricans with glass, plastics or metal inner packaging) |

Inner packaging 5 L Outer packaging 125 kg |

Forbidden for transport in Canada |

|

Drums, jerricans (60 L), or compositeFootnote * packaging |

60 L to 250 L |

||

Within Canada, the UN packaging requirements are incorporated into safety standards that are referenced in the TDGR. Therefore, any time AN is shipped, there are federal regulations that must be followed, as the transportation of dangerous goods is federally regulated. Due to this prescribed requirement, we can infer that in terms of packaging, AN is safe and secure when being transported. This is the benefit of having a prescribed federal authority over a specific activity, consistency can be assured.

4.2 International Maritime Organization (IMO)

The IMO, a specialized agency within the United Nations governs the transport of AN by vessel, which is regulated through different codes depending on whether it is packaged or in bulk (i.e. loaded directly into the cargo space of a vessel without any intermediate form of containment).Footnote 27

Packaged AN is regulated by the International Maritime Dangerous Goods Code (IMDG Code), while bulk transport is regulated by the International Maritime Solid Bulk Cargoes (IMSBC) Code. Footnote 28Footnote 29 TC references these requirements through the TDGR and the Cargo, Fumigation, and Tackle Regulations (CFTR). Please refer to Table 4-2 below for more information.

4.3 European Agreement Concerning the International Carriage of Dangerous Goods by Road (ADR)

The ADR establishes the requirements for vehicles and means of containment involved in the transport of dangerous goods throughout the European Union (EU) by road. These requirements cover handling, packaging, and training related to the carriage of dangerous goods. Please refer to Table 4-2 below for more information.Footnote 30

4.4 Comparison between Canada and international requirements

Table 4-2 below compares Canadian transportation regulations with international requirements.

| Specified elements | TDGRFootnote * | CFTRFootnote ** | UN Model Regulations | SOLAS/ IMDG Code |

SOLAS/ IMSBC Code |

ADR | |

|---|---|---|---|---|---|---|---|

|

Classification |

Classify dangerous goods based on the type of danger |

Applicable |

N/A |

Applicable | Applicable | Applicable | Applicable |

|

Assign packing group (PG I, II, or III) to indicate the level of hazard. |

Applicable |

N/A |

Applicable | Applicable |

N/A |

Applicable | |

|

FGAN (Class 5.1 and Class 9) can be transported |

Applicable | Applicable | Applicable | Applicable | Applicable | Applicable | |

|

Define AN (Class 1 and Class 5.1) as High Consequence Dangerous Goods, in quantity > 3000 Kg in bulk |

N/A |

N/A |

Applicable | Applicable | Applicable | Applicable | |

|

Segregation and stowage of the cargoes |

N/A |

Applicable |

N/A |

Applicable | Applicable |

N/A |

|

|

Provisions for the classification, marking, and packing, etc. |

Applicable | Applicable | Applicable | Applicable | Applicable | Applicable | |

|

AN (Class 1) is not permitted for transportation in bulk |

N/A |

Applicable |

N/A |

N/A |

Applicable |

N/A |

|

|

Packaging |

Outlines packaging instructions (standardized and certified means of containment) |

Applicable | Applicable | Applicable | Applicable |

N/A |

Applicable |

|

Transport |

Establishes specifications for vehicles transporting dangerous goods |

N/A |

N/A |

N/A |

N/A |

N/A |

Applicable |

|

Requires commercial name and the type of explosive to be marked on packaging of TGAN |

N/A |

N/A |

N/A |

N/A |

N/A |

Applicable | |

|

Prohibits the carriage of TGAN in most tunnels |

N/A |

N/A |

N/A |

N/A |

N/A |

Applicable | |

|

Legend: Applicable = applicable, N/A= Not Applicable SOLAS: The Safety of Life at Sea Convention; |

|||||||

It should be noted that in addition to the general requirement to comply with the IMDG Code and IMSBC Code, the CFTR has specific requirements for AN and AN-based fertilizer (which apply to non-dangerous FGAN, as well as Class 5.1 and Class 9). For instance, loading onto or unloading from a vessel of any types of TGAN in bulk form is prohibited and there is a limit of 10000 tonnes for loading/unloading of FGAN either in packaged or in bulk forms. These additional requirements do not differentiate between the different classes and types of AN and different classes and types of AN-based fertilizer. However, there is a possibility that such differentiation might not be necessary within the activities under the CFTR which are in addition to those covered by the IMDG Code and the IMSBC Code.

4.5 Comparison between Canada and other countries regarding ammonium nitrate storage requirements

Table 4-3 provides us with valuable information on regulatory requirements pertaining to the storage of AN in other countries. The Detonation Resistance Test (DRT), also called the detonability test, illustrates this point.

| Identified RequirementsFootnote 1 | Canada | USA | UK | Australia | France | Austria | Netherlands | ||

|---|---|---|---|---|---|---|---|---|---|

|

Detonation Resistance Test (DRT certificate) |

N/A |

N/A |

A |

N/A |

A |

A |

A |

A |

A |

|

Threshold of AN that requires permit prior to storage |

1450 Kg |

454 Kg |

Any |

3 kgFootnote c |

Unknown |

Unknown |

300 KgFootnote a |

Unknown |

Unknown |

|

Main uses of AN |

Explosives |

Explosives |

Fertilizers |

Explosives |

Fertilizers |

Fertilizers |

Explosives |

Explosives |

Fertilizers |

|

Risk assessment |

TGAN |

TGAN |

A |

A |

A |

A |

A |

A |

A |

|

Federal model for Storage facilities |

TGANFootnote d |

TGAN |

A |

A |

N/A |

N/A |

N/A |

TGAN |

FGAN |

|

Legend: A = Applied, N/A = NOT Applied, Unknown = Information were either unavailable or not able to find. |

|||||||||

The DRT is used to measure the ability of FGAN to withstand exposure to heat and to resist shock without deteriorating or detonating. The test is strongly dependent on the density of the AN, as well as the degree of contamination by organic matter. As such, it can be used to ensure if the quality of the stored FGAN is being maintained and if the imported fertilizer has an appropriate degree of resistance to detonation.

Testing requirements for safety of AN-based products vary between EU countries. For example, in France, the EU detonability test is mandatory and documentation must accompany shipments. Belgium has more stringent tests to determine the porosity and explosivity of AN, as well as its classification when compared to that of the EU. The Netherlands also uses the detonability test to assign FGAN to different storage groups, which allows for the establishment of safety distances between AN storage facilities and other buildings. According to this practice, ammonium nitrate fertilizers are divided into four (4) groups, of which level four (4) corresponds to the greatest risk and the longest prescribed safety distances.

5. Canadian and international best practices for the storage, handling, and transport of ammonium nitrate

Governments, manufacturers and industry associations across the globe have developed codes of practice to assist industry in meeting its regulatory obligations. The association of European farmers, Fertilizers Europe, conveyed this clearly when they said that the objectives of these codes are to:

- promote safety

- preserve the quality of AN in storage, handling, and transport

- safeguard the health of personnel and avoid hazards to the environment

- increase awareness of the existing requirements

- promote compliance

It must be noted that national legislation takes precedence over guidance given in codes of practice.

5.1 Best practices in Canada

5.1.1 Agriculture industry

Fertilizer Canada, an industry association representing members of the agricultural industry, publishes the Ammonium Nitrate Code of Practice (AN Code). As indicated by Fertilizer Canada, the AN Code is an industry-driven initiative developed in coordination with government and other stakeholders, that represents their commitment to the safety and security of AN fertilizer products. Fertilizer Canada believes that the AN Code is essential in ensuring that AN fertilizer is stored and handled according to world-class best management practices that mitigate the associated risks.

Compliance with the AN Code is mandatory for their members and applies to all individuals directly involved with the use, transport, storage, handling, and selling of AN. As such, the AN Code applies to bulk and bagged sales, distribution, and purchases of AN. As a condition of Fertilizer Canada membership, members must be certified as compliant with the AN Code and are therefore audited every two years to confirm their compliance. Agricultural end-users are exempt from this audit process.

The AN Code consolidates existing government (federal and provincial) regulations and best practices to raise awareness and promote compliance among their membership. Members are required to ensure their storage facilities are in compliance with the AN Code at all times, and Fertilizer Canada conducts audits and inspections to ensure compliance. The consequences for non-compliance range from fines, suspension, or even loss of certification, which means an individual is prohibited from conducting commerce.Footnote 31

5.1.2 Best practices for explosives facilities

Special provisions concerning TGAN are included in the Guidelines for Bulk Explosives Facilities, 2018 published by NRCan.Footnote 18 These guidelines outline the minimum requirements for sites and equipment used in the handling of bulk explosives. They provide specifications for storage facilities, as well as a series of procedures to prevent environmental spillage, contamination, and fires. For example, having a catchment area for spilled AN, protecting AN from contamination, using hydraulic or electrically powered equipment (no gasoline engine), and segregating AN from incompatible materials, such as brass and copper, which greatly affect its decomposition temperature and make it more sensitive to heat, shock, and detonation.Footnote 32

Some manufacturer associations or private manufacturers, such as Yara International, have also voluntarily published guidance material on the safe storage, handling and use of technical grade AN.Footnote 33

5.2 International best practices

Similar to Canada, international best practices are published by government authorities, industry associations, or manufacturers.

Agricultural associations such as Fertilizers Europe have developed guidance that is used by manufacturers, importers, retailers, shippers, and farmers across Europe. The USA-based industry association, Fertilizer Institute, has also published similar guidelines for the American agricultural industry. Footnote 34Footnote 35

The International Industry Working Group on Ammonium Nitrate (SAFEX), comprised of global TGAN manufacturers, has produced two guides: Footnote 36Footnote 37

- SAFEX Good Practice Guide: Storage of Solid Technical Ammonium Nitrate and

- SAFEX Good Practice Guide: Transportation of Technical Grade Ammonium Nitrate

These guides provide safety and security guidelines for the storage and transport of AN. They are used by many countries including Canada, USA, UK, Australia, and those of the EU.

Moreover, for countries where storage and handling of AN are under federal jurisdiction, such as Australia and the UK, codes of practice have been published by government authorities to provide safety recommendations and assist industry in meeting its regulatory obligations. These codes of practice are based on the aforementioned guidelines published for the agricultural and explosive industries, such as Fertilizers Europe or SAFEX.38

5.3 Best practices examples

When compared to what is done internationally, the Canadian AN industry has voluntarily implemented numerous best practices and followed regulatory requirements where prescribed. Where international best practices are not followed or adopted in Canada, it would be advisable to consult industry members to determine if it could be implemented to enhance the safety and security of activities pertaining to AN. For example, the establishment of procedures to ensure product compatibility (i.e. segregation of incompatible dangerous goods) during transport by road and rail modes, as well as sampling and testing of stored FGAN to assure its quality and conformity.

Some examples of AN safe storage and handling practices that exist in Canada, as well as internationally are presented in the Table 5-1 below.Footnote 39 The table highlights practices surrounding the two types of AN, TGAN and FGAN.

|

|

Countries |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Categories of Best Practices | Description of Best Practices | Canada | USA | United Kingdom | Australia | France | Austria | Belgium | Spain | Netherlands |

|

Secure and safe Handling |

Ensure dangerous goods training for all personnel: general awareness and job specific training that includes knowledge on site-specific hazards, safety data sheets, evacuation plan, first aid stations and procedures, etc. |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

Wear appropriate personal protective equipment (dust masks, gasmasks, safety glasses, gloves, etc.) |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Produce up to date inventory reports that are be readily available (type, quantity, location) |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Segregate from non-compatible substances (i.e. fuel, combustible materials, organic substances, chemicals, etc.) to avoid contamination |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Keep AN away from possible heat sources (e.g. hot water pipes, steam, radiators, etc.) and control all potential ignition sources |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Respect prescribed stacking instructions including height, quantity, and distance between stacks, walls, lights or heating pipes in order to prevent sympathetic detonation (i.e. propagation of detonation between stacks), to avoid contamination and to facilitate access |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Ensure good housekeeping: keep the entire storage and equipment clean and dry, free of dust to avoid contamination |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Do not use explosives to break up caked fertilizer |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Always discard any discharge/contaminated material in a safe manner for the environment and the workers |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Perform welding or cutting away from the AN and on previously cleaned surface (no residue) |

Applied |

Applied |

Applied |

Not |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Do not store AN for long period of time, and only store quantity necessary to operate (regular turnover) |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Do not use AN storage areas for any other purpose (e.g. storing cleaning products, tools, etc.) |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Do not store AN near explosives |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Implement procedures to promptly identify and handle non-conforming materials (contaminated ammonium nitrate) |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Storage Security and Safety Measures |

Establish a security plan. Install fences and security control measures around storage area (e.g. locks, camera, security lighting, limited access to authorized person and vehicle only, guard, etc.) |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

Establish a fire protection strategy and install an adequate fire suppression system (alarms, adequate fire extinguishers, hoses, sprinklers, etc.) |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Equip storage with heat and gas detectors |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Install appropriate dangerous goods safety placards, and other safety signs such “no smoking”, “no sources of ignition” and “emergency exit” |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Inform local emergency responders of all AN locations, quantities, and storage types |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Report unexplained loss, theft, attempted theft or any other security incident to the authorities |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Provide a draft of the storage facility including location, construction specifications, fire suppression system and security measures to authorities |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Establish an emergency plan that includes an evacuation plan |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Conduct regular emergency drills which may include first responders |

Applied |

Applied |

Not |

Applied |

Not |

Applied |

Applied |

Applied |

Not |

|

|

Conduct regular inspection and audit of storage facilities |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Provide a list of AN compatible and incompatible substances (contaminants) |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Commercial Procedures |

Keep records of all ammonium nitrate purchases/sales (seller and customer information, date, AN type, quantity, etc.) |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

Undertake measures to ensure all ammonium nitrate customers have been vetted |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Inform end-users to only purchase according to their needs |

Applied |

Not Applied |

Not |

Not |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Provide guidance and recommendations to end-users for enhancing the safety and security of ammonium nitrate storage |

Applied |

Applied |

Not |

Not |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Do not sell AN to employees, do not accept cash transactions from manufacturing sites, do not allow internet sales or reselling |

Applied |

Applied |

Not |

Not |

Not |

Not |

Not |

Not |

Not |

|

|

Transportation |

Comply with all applicable dangerous goods transportation regulations and provide an emergency response plan, if applicable |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

Ensure that all shipping services have implemented appropriate security measures and clearances (vetted and dangerous goods trained employees only, proof of proper insurance, etc.) |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Implement measures to ensure traceability and proper receipt acknowledgement by the retailer/ end-user upon arrival of the shipment at destination (e.g. records, bill of lading, tracking systems, etc.). |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Provide security and attend loading and unloading of shipments at all time |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Establish measures to prevent unauthorized access to AN during shipment (security seals, locks, etc.) |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

If any shipper’s security seal is removed or broken, determine whether the product has been tempered with or is missing, inform shipper and carrier, investigate and inform the authorities, as needed |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Retain records as per regulations, and be prepared to present and make available for inspection a statement of fact |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Other Considerations |

Detonation test for fertilizer grade |

Not |

Not |

Applied |

Not |

Applied |

Applied |

Applied |

Applied |

Applied |

|

Sampling and product testing in order to verify the quality is maintained in storage |

TGAN only |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Make sure the building has a sufficient access to water in the vicinity of the building |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

|

Stakeholder participation, i.e. preparing best practices guides |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

Applied |

|

6. Analysis of findings

In Canada, the regulatory framework related to AN is a shared jurisdictional responsibility and requires a strong collaborative approach between federal, provincial, and municipal levels of government. Overall, it was determined that Canada’s AN regulatory framework is robust and is supported by industry’s comprehensive codes of practices and international best practices. Nevertheless, there may be opportunities for further enhancement.

While reviewing the existing regulations related to TGAN, the guidelines provided by NRCan are reflective of industry and international best practices. As such, relevant safety and security considerations are covered and highly controlled at the federal level for both temporary and permanent storage facilities. There were no obvious gaps identified.

6.1 Regulatory overlap

When examining fertilizer grade AN under the existing legislation in TC i.e., under the Railway Safety Act, Ammonium Nitrate Storage Facilities Regulations there appears to be some requirements that are open to interpretation and offer limited guidance to facilitate decision-making amongst regulated parties. For example, there may be opportunities to clarify:

- the classification and identification of AN-based fertilizers, which differ from the TDGR (i.e. the regulations do not provide shipping name and UN numbers)

- temporary storage and security requirements, as well as requirements for maximum amounts of AN permitted for storage

- the rationale behind the prescribed distances from other structures

It is worthwhile to note the following regarding Ammonium Nitrate Storage Facilities Regulations:

- only apply to federally-regulated railway companies and does not include farmers, distributors, or manufacturers

- the safety distances required between storage facilities and the nearest residential structure are not reflective of modern safety approaches

- storage facilities can be made of combustible materials (i.e. materials incompatible with AN)

Thus, a more in-depth review of TC’s regulations and standards for AN could be undertaken to identify any opportunities to promote regulatory alignment where possiblem, and ensure regulations reflect the latest safety standards for handling and storage of AN in Canada.

6.2 Multiple jurisdictions and different versions of code models

As previously indicated, the multijurisdictional approach to AN creates some challenges for the regulated community. For example, when looking at storage facilities, a regulated party must comply with regulations at the federal, provincial, and municipal level. Moreover, some of these regulations only apply in specific situations. Returning to the example of storage facilities, only facilities containing over 1000 kg of AN Class 5.1 are subject to the provisions specified in Provincial or Municipal Building and Fire Codes. Therefore, storage facilities containing less than 1000 kg of AN or AN Class 9 (such as AN with a concentration between 45-70%) have no specific AN related safety or security requirements and may, for example, be located in a densely populated urban area.

Of interest, a municipality may adopt or modify these codes according to their specific needs, which means that amongst Canada’s 5000 municipalities, there may be significant variations. This makes it difficult to compare different requirements. Due to such variance, as outlined in the national building and fire codes, a more comprehensive analysis is being undertaken to assess whether AN storage meets adequate safety and security standards across the country. Under the Canadian Free Trade Agreement, a regulatory reconciliation process has been established to help address barriers to trade – specifically, through the Construction Codes Reconciliation Agreement (2019), where jurisdictions will identify, reduce, or eliminate existing variations between their construction codes and the National Codes by 2025 and minimize new variations in the future. The signature process for this agreement is currently underway.Footnote b

6.3 International best practices

Other members of the international community address the storage of AN in a comprehensive and clear manner. For example, the UK has a one window approach for industry, allowing them to better understand construction specifications, risk management practices, emergency planning, and security provisions, etc. Whereas in Canada, regulated parties must refer to different levels of government to navigate the required provisions. In light of this, consideration could be given to creating an information guide for companies or individuals who engage in commerce with AN.

At the industrial level, Canadian industry has implemented numerous best practices, which have been developed collaboratively with stakeholders and government, it is worthwhile to continuously monitor and examine what is being done by international counterparts to identify potential areas for improvement.

7. Conclusion

The Canadian regulatory framework related to AN is a shared responsibility between all levels of government. At the federal level, storage, handling, and transport of AN is a shared responsibility between Transport Canada, Natural Resources Canada, Environment and Climate Change Canada, Health Canada, and the Canada Border Services Agency whereas, land planning and zoning, building structure, construction designs, fire prevention requirements, and environment protection are enforced by provinces, territories, and municipalities.

Findings revealed that this framework is robust and is supported by industry’s comprehensive codes of practices and international best practices. Findings also revealed that federal regulations could benefit from further clarification to ensure that prescriptions in place are clear and consistent across all modes of transport. Moreover, findings revealed that the multijurisdictional approach may create challenges for regulated parties to identify and comply with applicable requirements.

8. Next steps

Based on the above considerations, TC recognizes that the management of AN is a complex and cross-cutting matter. To that end, TC will:

- examine regulations under its authority to enhance regulatory clarity and maintain alignment with the UN Recommendations on the Transport of Dangerous Goods Model Regulations, the IMDG Code, and IMSBC Code

- collaborate with industry, provinces, and territories, to raise awareness and advise on the safety aspects pertaining to AN activities

- create a one-stop shop to answer questions about the regulatory framework surrounding ammonium nitrate and promote awareness.

9. References

10. List of Acronyms

-

ADR

-

European Agreement Concerning the International Carriage of Dangerous Goods by Road

-

AN

-

Ammonium Nitrate

-

AN Code

-

Ammonium Nitrate Code of Practice

-

FGAN

-

Ammonium Nitrate Fertilizer Grade

-

TGAN

-

Ammonium Nitrate Technical Grade

-

CCOHS

-

Canadian Centre for Occupational Health and Safety

-

CFTA

-

Canadian Free Trade Agreement

-

CFTR

-

Cargo, Fumigation, and Tackle Regulations

-

DG

-

Dangerous Goods

-

DRT

-

Detonation Resistance Test

-

ECOSOC TDG

-

Economic and Social Council’s Committee of Experts on the Transport of Dangerous Goods

-

EU

-

European Union

-

ESDC

-

Employment and Social Development Canada

-

FPT

-

Federal, Provincial and Territorial

-

HS

-

Harmonized System

-

IBC

-

Intermediate Bulk Containers

-

IMDG

-

International Maritime Dangerous Goods

-

IMO

-

International Maritime Organization

-

IMSBC

-

International Maritime Solid Bulk Cargo

-

NBC

-

National Building Code of Canada

-

NFBC

-

National Farm Building Code

-

NFC

-

National Fire Code of Canada

-

NRC

-

Natural Research Council of Canada

-

NRCan

-

Natural Resources Canada

-

OHS

-

Occupational Health and Safety

-

PG

-

Packing Group

-

RCT

-

Regulatory Reconciliation and Cooperation Table

-

SOLAS

-

Safety of Life at Sea Convention

-

TC

-

Transport Canada

-

TDG

-

Transportation of Dangerous Goods

-

TDGR

-

Transportation of Dangerous Goods Regulations

-

UK

-

United Kingdom

-

UN

-

United Nations

-

USA

-

United States of America

-

WHMIS

-

Workplace Hazardous Materials Information System

11. Annexe A - Classification and economics

| Shipping Name | Class/Packing Group | UN Number |

|---|---|---|

|

Ammonium Nitrate |

1.1D |

UN0222 |

|

Ammonium Nitrate with not more than 0.2% combustible substances, including any organic substance calculated as carbon, to the exclusion of any other added substance |

5.1 / PGIII |

UN1942 |

|

Ammonium Nitrate Based Fertilizer |

5.1 / PGIII |

UN2067 |

|

Ammonium Nitrate Based Fertilizer |

9 / PGIII |

UN2071 |

|

Ammonium Nitrate Emulsion, intermediate for blasting explosives |

Forbidden for transport |

UN3375 |

|

Explosive Blasting Agent, Type E |

1.5D |

UN0332 |

|

Explosive, Blasting, Type B |

1.1D |

UN0082 |

|

Explosive, Blasting, Type B |

1.5D |

UN0331 |

|