Service Difficulty Reports about engines that either show a trend or should be known by the airworthiness community.

On this page

- Allison

- Austro Engine

- AVCO Lycoming

- CFM International

- Garrett

- General Electric

- Honeywell

- Pratt & Whitney – Canada

- Pratt & Whitney – USA

- Rolls Royce – USA

- Teledyne Continental

- Turbomeca

- Williams

Allison

250-C47B Engine Outer Combustion Case Cracked Fuel Nozzle Boss

SDR #: 20160505004

Subject:

During aircraft startup, the pilot noticed high turbine outlet temperature and shut down the engine. The aircraft maintenance engineer discovered that the fuel nozzle boss was separated from the can at weld/radius.

Transport Canada Comments:

Rolls Royce has acknowledged additional instances of potential outer combustion case cracking by issuing Revision 3 to M250-C47 CEB A-72-7002. The latest revision decreases the interval of the repetitive visual inspection for the weld size at the fuel nozzle boss. Remain vigilant when inspecting this area. Cracking and separation of the fuel nozzle boss could lead to potential power and performance reduction. Additional Alert Commercial Engine Bulletins have been released to also cover the M250-C28, -C30 & -C40 series Roll Royce engines.

Fuel nozzle boss separated from the engine outer combustion case.

Austro Engine

E4-A - Engine Failure Due To Foreign Object Debris

SDR #20170106003

Subject:

While cruising/descending at 9000 feet, the pilot observed dropping oil pressure and increasing oil temperature. Failure code warnings were also observed. The pilot landed the aircraft, which sustained some minor damage. The lower cowl and underside of the aircraft were contaminated with engine oil.

Transport Canada Comments:

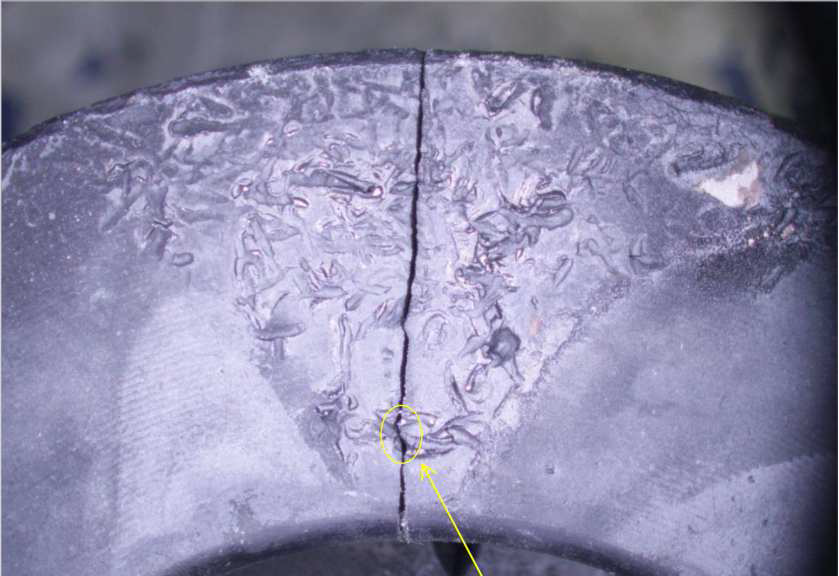

An engine investigation revealed that a foreign object had entered one of the cylinders and damaged the piston. This resulted in the piston cracking and allowing combustion gasses to pressurize the crankcase thereby forcing out the engine oil.

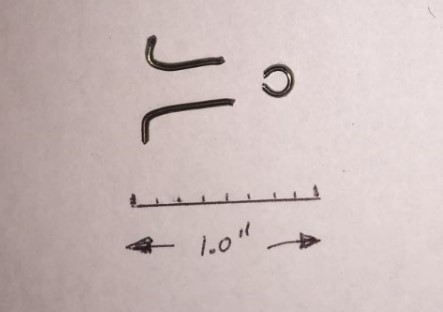

The source of the foreign object was not known however the evidence left behind on the piston indicated that it may have been caused by a piece of lockwire.

It is important for Aircraft Maintenance Engineers to be certain that the areas surrounding critical areas be cleaned of any foreign materials following maintenance activities.

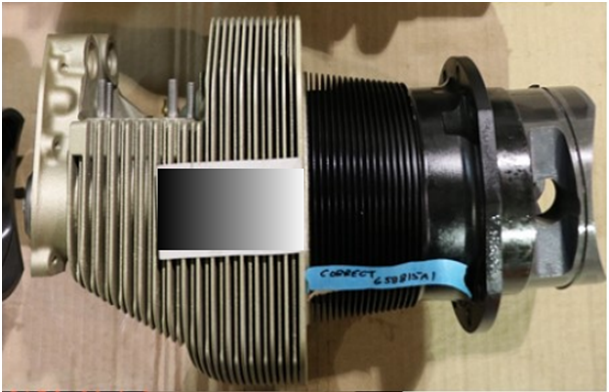

Piston with evidence of foreign object debris damage

AVCO Lycoming

O-320-H2AD - Rocker Arm Failure

SDR #: 20210707007

Subject:

A student pilot was on a solo flight when they experienced a sudden loss of power and a rough running engine. Troubleshooting and attempting to resolve the issue was unsuccessful and the pilot was unable to maintain altitude. As such, the pilot landed the aircraft in a nearby field. They activated the ELT and completed a mayday call before touching down. Upon initial inspection there was no damage to the aircraft from the landing. The mechanical issue was quickly found to be on the cylinder #4. The intake push rod tube was bent, and the exhaust push rod broke through the rocker arm. There were approximately 240 hours on this engine since overhaul with no significant maintenance (besides required inspections) completed prior to the failure. Cylinders were new at overhaul.

Transport Canada Comments:

After conducting an investigation, it was found that Lycoming Mandatory Service Bulletin (MSB) 639 had not been performed at the recommended 50-hour interval following rocker arm replacement during overhaul. To prevent further incidents, Transport Canada Civil Aviation suggests that owners, operators, and maintainers incorporate MSB 639 and continue to file Service Difficulty Reports (SDRs) in the event of rocker arm defects.

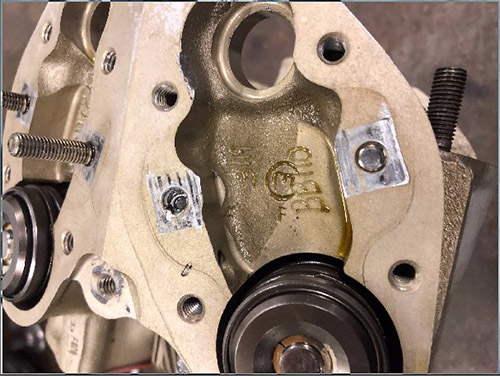

Picture 1 – Rocker Arm failure at pushrod socket

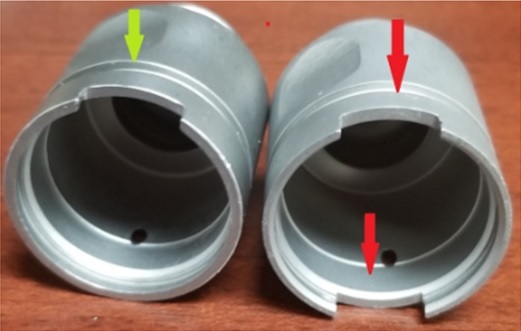

O-320-H2AD - MA-3 and MA-4 Series Carburetor – Liberated Accelerator Pump Discharge Tube

SDR #: 20210923020

Subject:

While landing, the student and flight instructor noticed that they were unable to reduce the engine speed to idle, revolutions per minute (RPM) could only be controlled between 2000-2200 RPM. They declared an emergency, shut down the engine in short final and landed safely. The company’s maintenance technicians inspected the engine throttle control and noticed that it could not be pulled back. The carburetor was removed, and it was found that the accelerator pump discharge tube had detached and stuck in the butterfly.

Transport Canada Comments:

The MA-3 and MA-4 series are updraft style carburetors found on Lycoming, Continental, and other normally aspirated engines. They are currently manufactured by Mavel-Schebler Aircraft Carburetors (MSA) and were previously manufactured by Precision, Facet, and Volare.

The accelerator pump discharges fuel only when the throttle fly is moved toward the open position. In MA4-5, MA-5 and MA-6 series carburetors, this additional fuel is fed through the main discharge nozzle, and in smaller carburetors such as the MA-3 and MA-4 series, a separate discharge tube is utilized. This discharge tube is bonded in the sidewall below the venturi and main discharge nozzle.

Possible indications of a liberated discharge nozzle could include:

- Obstructed throttle fly, jammed throttle control

- Fuel found in airbox

- Cylinder Foreign Object Damage (FOD)

- Failure to start

- Sluggish acceleration during takeoff or other phases of flight

Accelerator pump discharge tubes are bonded in place during assembly or overhaul and undergo a specified torque check to determine serviceability. Transport Canada Civil Aviation (TCCA) recommends that a detailed visual inspection of this area be performed whenever possible to detect a disbonded accelerator pump discharge tube and that such defects continue to be reported by submitting a Service Difficulty Report (SDR).

Picture 1 – Discharge tube lodged beside throttle fly

Picture 2 – Discharge tube

Picture 3 – Left-hand (L/H) unserviceable carburetor without discharge tube, right-hand (R/H) serviceable carburetor with discharge tube bonded in place

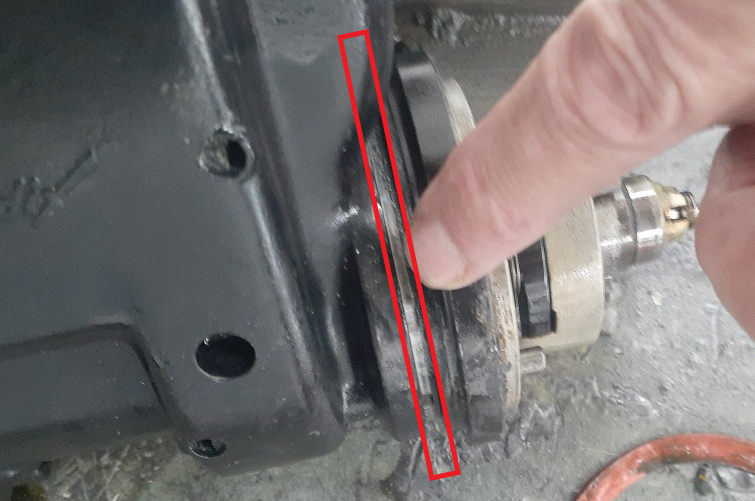

IO-540-K1B5 - Continental Aerospace Technologies (Bendix / TCM) S-1200 Series Magneto Mounting Flange Loose

SDR #: 20210326007

Subject:

After flight, oil was observed to be leaking from the left engine. The Aircraft Maintenance Engineer who inspected the engine found the magneto to still be firmly fastened to the engine, but its case had split at a swaged joint, allowing oil to leak from the resultant gap.

Transport Canada Comments:

It was confirmed that all 3 internal wrenching screws part number (P/N) 10-349652, which secure the flange to the body of the magneto, were found loose. S-1200 series magnetos, which include 4, 6 and 8 cylinder models all use this method of attaching the flange to the body of the magneto.

Possible scenarios involving loose or fully migrated P/N 10-349652 screws include: oil leak, metal contamination of engine oil system or magneto failure.

Service Difficulty Report (SDR) data indicates this event is not a trending defect, the majority of related occurrences were prior to 1997. The inclusion of the following information in the S-1200 Series Service Support Manual may have played a role in mitigating a continuing airworthiness concern.

Multiple notes and warnings are included in the published service manual, stating to remove and discard the flange securing screws and washers, regardless of whether disassembly is for the purpose of inspection, parts replacement, or overhaul. Additionally, adherence to published fastener torque specifications is highlighted.

A daily pre-flight check may not specifically include checking for security of attachment of the magneto, although including such an item may be beneficial.

IO-540-K1G5D - Filter Collapse-Pressure Failure

SDR #: 20210420010

Subject:

The oil filter was removed and cut open for inspection during the annual inspection of the aircraft. After cutting open the filter, it was discovered that the centre tube and media were crushed with no signs of damage to the oil filter can. The oil filter was in service for 46.5 hours at the time of the discovery.

Transport Canada Comments:

The oil filter in this occurrence has experienced a filter collapse-pressure failure. This is most likely due to excessive pressure buildup during a cold start. Unfortunately, as the filter manufacturer suggests “…after the element is crushed, you’ll have little or no oil filtration. You won’t find the crushed element until the next oil change, as oil pressure will appear normal on the engine oil pressure gauge.”

Identifying signs of a filter collapse-pressure failure may be difficult, a domed filter top, an oil leak or a high revolutions per minute (RPM) during a cold start may indicate that the filter has experienced an over-pressurization. Transport Canada, Civil Aviation (TCCA) suggests that owners, operators and maintainers pay close attention and identify the root cause when defects such as these arise.

For additional information on this subject published by the oil filter manufacturer, please refer to Tempest Tech-Tip 0613 – Alaska Cold Starts

Picture 1 – Filter collapse-pressure Failure

Picture 2 – Centre tube collapse

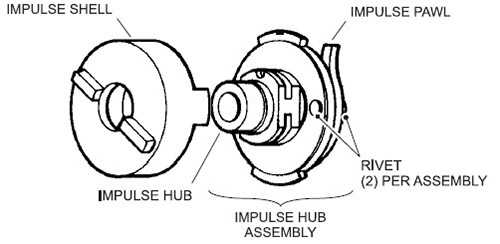

O-320-E2D - Champion Aerospace Slick Magneto Loose or Broken Impulse Coupling Rivets

SDR #: 20180925011

Subject:

During the first 500 hour inspection on the magneto, the rivets on the impulse coupling were found to be loose. The manufacturer was contacted and the impulse coupling was replaced.

Transport Canada Comments:

Champion Aerospace has published Service Bulletin (SB) SB2-19A Mandatory inspection of impulse coupled Slick by Champion magnetos. Engines utilizing Slick 4200, 4300, 4700, 6200, 6300 and 6700 series magnetos, which have had the impulse coupling replaced with a kit dated 26 February 2015 through to 1 February 2019 are affected. Background information in the SB notes: A loose or broken rivet could potentially enter the gear train of the engine resulting in damage to the gear train or damage to engine accessories and could possibly cause catastrophic engine failure.

Transport Canada, Civil Aviation (TCCA) encourages all owners and operators to review the contents of this SB and continue to report service difficulties for any loose rivets found.

Impulse Coupling

IO-540-K1B5 - Connecting Rod Bushing Failure

SDR #20170404111

Subject:

During climb to altitude, the left hand engine sputtered and shutdown. The aircraft returned for landing without further incident. A visual inspection conducted by the pilot revealed a catastrophic failure in the top of the crankcase.

Transport Canada Comments:

The manufacturer, Lycoming, has issued Mandatory Service Bulletin 632B to identify and remove from service certain connecting rods with non-conforming small end bushings. The Federal Aviation Administration (FAA) has issued Airworthiness Directive 2017-16-11 to mandate the inspections and actions listed in the Lycoming Service Bulletin. Transport Canada urges the report of any related service difficulties found on engines not listed in the models affected section of Mandatory Service Bulletin 632B.

Hole in crankcase can be seen following a connecting rod bushing failure.

CFM International

CFM56-7B26/E - Improper Magnetic Chip Detector (MCD) Installation

SDR #: 20230223003

Subject:

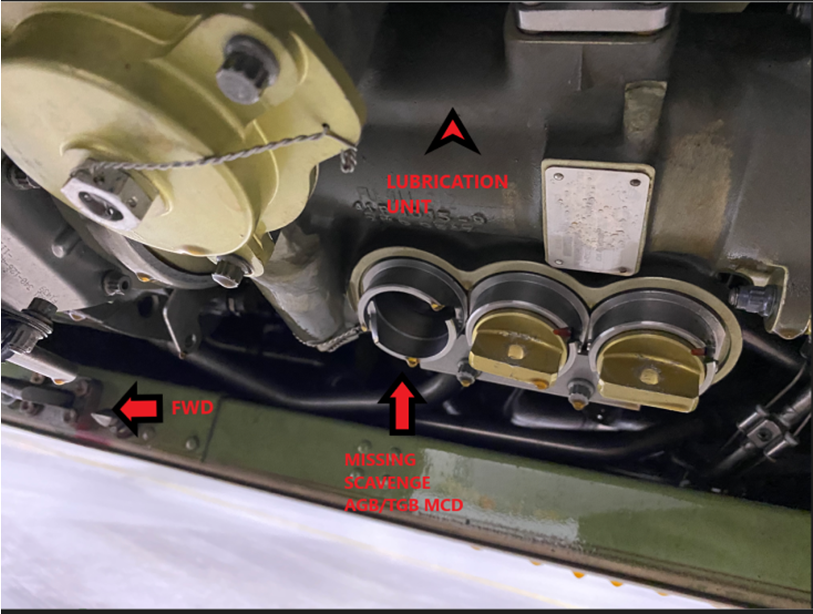

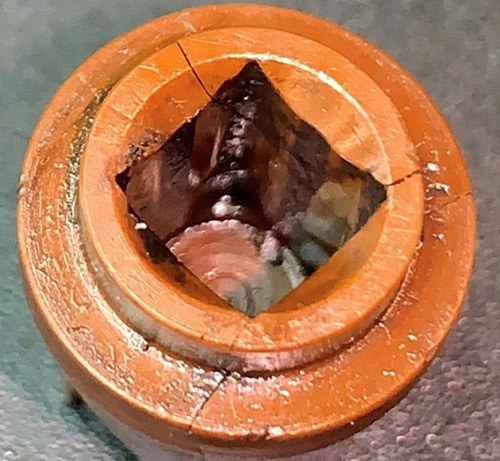

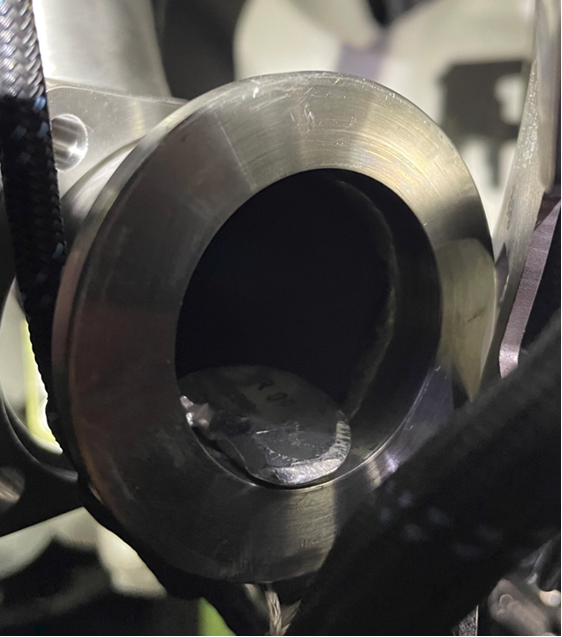

During cruise, on engine number two, low oil quantity was indicated. The quantity soon decreased and an air turnback was initiated. During the turnback, the oil pressure began to fluctuate, exhaust gas temperature and oil temperature began to rise higher than engine number one. Oil pressure fluctuations became more rapid with the indication turning amber, then red. The decision was made to shut down engine number two. The aircraft landed without further incident and towed to the hangar. Maintenance personnel opened the number two engine cowlings and found that an MCD was not in the lubrication unit but was resting on the inside of the cowling. The remaining two MCDs were checked and found secure. All three MCDs on number one engine were checked for correct installation and it was found that the accessory gearbox (AGB) MCD was not locked in the proper detent position. On 13 January 2023, a detailed visual inspection of each engine forward sump, aft sump, and AGB MCDs was carried out as per maintenance task card and installed as per aircraft maintenance manual. The probable cause of the MCD backing out of the lubrication unit was a failure to lock the MCD into position where the bayonet pins fully engage in the slots. It is believed that during the flight of 27 January 2023, the number two engine MCD displaced to the point where the internal cowling structure held it in a position where it still engaged the check valve, allowing the oil to flow out. What contributed to the installation error was the fact that the aircraft maintenance engineer who was performing the task did not use the specified tool as per the maintenance manual.

Transport Canada Comments:

In this event, the published instructions for continued airworthiness (ICAs), specified the use of a special tool for installing the MCDs. The operator suggests that the lack of special tool use contributed to the MCD not being secure and backing out enough to still engage the shut off valve and resulting in oil loss.

It is difficult to speculate why the maintainer did not use the tool to secure the MCDs. Time constraints and pressure to finish the inspection tasks or even tool availability may have been factors.

Transport Canada would like to remind operators and maintainers to follow manufacturers ICAs when accomplishing any task, no matter how straight forward the task may seem. In this event luckily the number one engine MCD, which was found not secure, remained in place and the aircraft landed uneventfully with one engine.

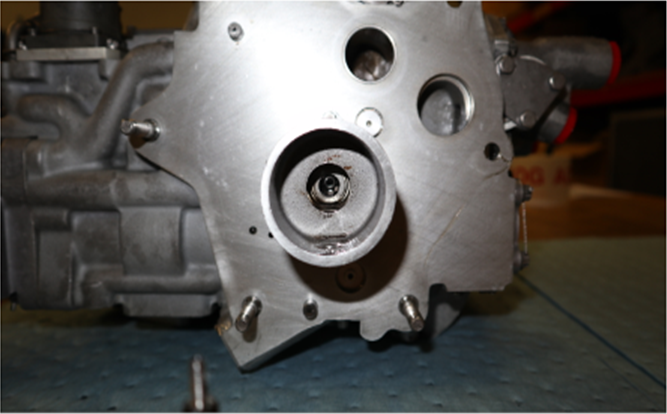

Picture 1 - Lubrication Unit

Text in the picture: Lubrication Unit, FWD, Missing Scavenge AGB/TGB MCD

Picture 2 - MCD

Text in the picture: Displaced MCD Belonging to AGB/TGB Sump

CFM56-5B3/P - Ruptured Fuel Line

SDR #: 20230104008

Subject:

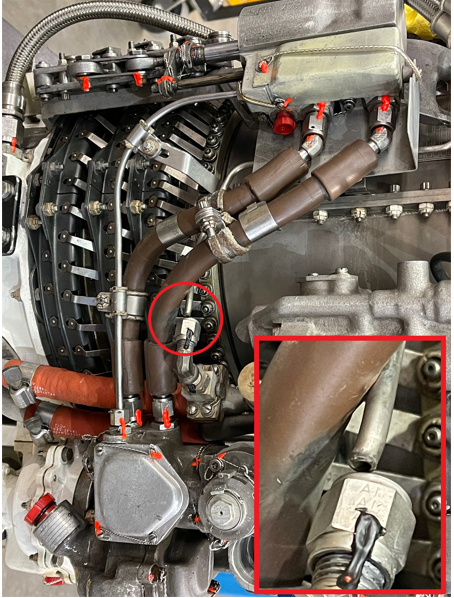

Dripping fuel from right-hand engine fan cowl was found on a walk around. Further inspection of the area showed a ruptured integrated drive generator (IDG) heat exchanger fuel line. The fuel oil heat exchanger tube/line was replaced.

Transport Canada Comments:

Transport Canada Civil Aviation (TCCA) would like to make operators and maintainers of this engine and similar engine models aware of this event and to pay particular attention to this line when accessing or inspecting this area.

The root cause of the ruptured fuel line is still under investigation, however, as seen in the photos, the congestion of lines and hoses and the protective coating on the ruptured line would have made detection of a fuel leak very challenging at best. Luckily, a fuel leak was noticed during a walk around, the ensuing maintenance inspection located the event line, and a possible serious situation was avoided.

Please report any findings similar to this event to TCCA through the Web Service Difficulty Reporting System.

Photo 1: Fuel line location

Photo 2: Ruptured fuel line

CFM56-7B26/E - Loss Of Oil Pressure Event

SDR #20170217010

Subject:

On taxi out, the crew reported a low oil pressure warning for engine number one. The crew shut down the engine and returned to the gate.

The subject engine is being replaced. Maintenance found oil quantity zero, the tank was empty and oil was draining from the forward sump drain port.

Transport Canada Comments:

Investigation revealed foreign material in the tube of the scavenge pump. Analysis revealed the material to be a paper towel. It is not known when this foreign material was introduced to the oil system.

This event was clearly a human factors issue. Transport Canada Civil Aviation (TCCA) continues to see these events occur (see feedback magazine past issues 1/2013: improper use of tooling causing in flight shutdown, 3/2014: oil filler cap left off and 4/2014: improper fuel shipping cap.)

Human factors related events like these continue to be difficult to eliminate, this is in part due to the fact that the aviation industry still relies very heavily on the professionalism and competence of front line individuals to detect and avoid these types of errors and doesn’t necessarily go the extra step to consider the associated organizational factors that may have contributed.

Implementing a formal Safety Management System (SMS) is a good place to start in order to understand organizational factors and their influence on safety. TCCA along with other Civil Aviation Authorities have worked to publish various online tools to aid the aviation industry in these areas. Some examples are:

- TCCA’s Easy Reference Guide of Safety Management System-related Documents

- Safety Management International Collaboration Group (SM ICG)

- Maintenance Workload

- Safety Culture

Although front line staff (ground handlers, Aircraft Maintenance Engineers [AME] and Pilots) can be considered the last line of defense to prevent these types of incidents, organizations should not rely on them to be the only line of defense. TCCA encourages aviation organizations to take the steps necessary to gain an understanding of the organizational factors that exist within their businesses so that they can better understand their influence on the safety outcomes of their operations.

Engine case with oil tube removed revealing paper towel stuck in port

Garrett

TPE331-12UHR-702H - Cracked Tachometer Generator Drive Adapter Inserts

SDR #: 20200911024

Subject:

Upon inspection of an engine for a gearbox repair, it was noted that the adapter insert for the tachometer generator drive was cracked in multiple places.

Transport Canada Comments:

These tachometer generator drive adapter inserts are a common component on numerous engine makes and models. They mate the tachometer generator drive to the engine or gearbox to translate rotating movement into a percentage or rpm displayed on a cockpit instrument.

These inserts are often overlooked due to their location and low failure rate. In this event, the insert was cracked but continued to connect the tachometer generator drive to the accessory gearbox.

Due to the diligence and professionalism of maintenance personnel during the gearbox repair, the cracked insert was discovered and a possible event was averted. Well done to these maintainers for the effort to ensure they were releasing a serviceable product back to the customer.

Picture 1 – Cracked adapter insert top view

Picture 2 – Cracked adapter insert side view

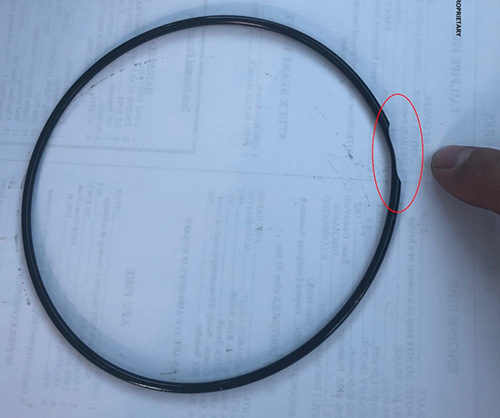

TPE331-11U-612 - Damaged Gasket

SDR #: 20201103021

Subject:

While carrying out a repair on a Garrett engine, we went to get a new gasket to seal the aft turbine oil area. When the gasket was taken out of a new package, it was noted that the gasket was not manufactured properly, it had damage on one of the surfaces. We used another gasket from stores and it was serviceable.

Transport Canada Comments:

Certain tasks such as replacing gaskets, O rings or seals are often considered menial. Inattention to manufacturer’s instructions or standard practices when installing these components, may result in leaks that could have a detrimental result if a fuel leak ignited, or an engine shut down due to lack of lubrication or fuel starvation.

Maintainers are reminded to follow published instructions and verify the condition of these components prior to installing them. Many O rings, for example, have an expiry date or shelf life stated on the packaging, and do not assume a new part is a serviceable part.

In this case, due to this operator’s attention to detail and verification of the condition of this gasket prior to the installation, a potential oil leak was averted.

Transport Canada Civil Aviation (TCCA) requests that owners and maintainers continue to submit Service Difficulty Reports (SDRs) when defective parts, such as this gasket, are discovered.

Picture 1 – Damaged gasket

Picture 2 – Close-up of damaged area of gasket

TPE331-11U-612G - Cracked Engine Mount

SDR #: 20200730008

Subject:

During a routine phase 6 inspection of the engine, the magnesium engine case of the #2 engine at the outboard engine to truss mounting pad was found cracked. After removal of the engine for repair, that portion of the case detached. Review of the history found no recent events or defects that could have caused the failure. In February 2016, the engine had been removed and sent to an approved engine repair facility due to a level 2 propeller strike, this was 2640 hours prior to this failure. The engine had also been removed for a hot section inspection/compressor refurbishment, 1421 hours prior to this failure. No defects in the failure area were found during those major shop visits.

Transport Canada Comments:

Magnesium castings are lightweight and strong, however they are susceptible to cracking due to thermal cycling during manufacture, fatigue failure from vibration, human factors if studs or bolts are over torqued, and corrosion if protective coatings wear or are not properly applied.

In this event, a meticulous inspection detected this failure preventing what may have been a serious incident or accident should the mount have failed altogether.

Transport Canada would like to highlight this event and recommend that maintainers and owners pay particular attention to this area during inspections. Transport Canada Civil Aviation (TCCA) commends the work of these maintainers for their thorough maintenance practices.

Picture 1 – Cracked engine mount

Picture 2 – Detached part of casting

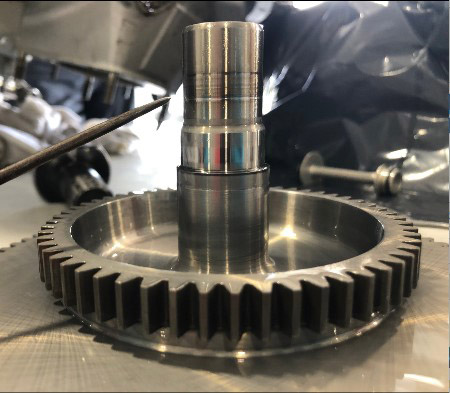

TPE331-12UHR - Idler Gear Bearing Failure

SDR #: 20200908013

Subject:

An engine spectrometric oil analysis program (SOAP) sample result indicated that a bearing was failing. The oil sampling facility lab called to let us know of the sample results. The engine was forwarded to the turbine shop for repair and it was noted that when the gearbox was removed, the idler gear duplex bearing had failed.

Transport Canada Comments:

Oil analysis is an effective tool that can be used by operators and maintainers to monitor the condition of an engine. It assists in the early detection of issues that a minor repair may rectify before costly components are damaged or a major engine failure occurs.

As seen in this event, oil analysis detected deterioration of the idler bearing before a catastrophic failure occurred and may have prevented an expensive repair or a serious incident from an engine shutdown.

Although oil analysis is effective at detecting accelerated wear of internal components over time, it has limited effectiveness in predicting a sudden break or fracture.

Transport Canada encourages the use of these programs by all owners and operators to enhance flight safety through the early detection of failing components.

Idler gear bearing

TPE331-10UA-511G - Engine SOAP (spectrometric oil analysis program) Sample - A Proven Maintenance Tool

SDR #20160926005

Subject:

The pilots reported that a chip light on the aircraft had illuminated during climb for 2 minutes and then went out. Maintenance was advised of the indication when the aircraft returned to base. The chip detector was inspected and a SOAP sample was taken. The sample was rushed out to a lab for inspection and the results revealed that an engine inspection was required immediately. The engine was removed from the aircraft and forwarded to the turbine shop. The gearbox was disassembled and the torque sensor idler bearing was found to have failed.

Transport Canada Comments:

This report proves the effectiveness of good preventative maintenance and how an oil analysis program can help increase safety by preventing possible in flight emergencies and reduce operating cost by catching problems before they become catastrophic.

Idler bearing race showing significant wear

TPE331-10 - Incorrectly Set Turbine Rotor Rivets

SDR #20170113010

Subject:

After routine maintenance at an outside repair station, the propeller was turned to prepare for propeller removal. It was observed that the engine would only rotate slightly due to part of the rotating group getting caught on something internally.

The engine was inspected and it was found that some of the retaining pins (rivets) holding the blades of the second stage turbine (Part Number 3102106-10) had fallen out. After some research it was noted that the rivets were out of dimensions per Honeywell manuals.

The engine is being inspected at an approved overhaul facility and the second stage turbine is in the process of being replaced.

Transport Canada Comments:

Attention to detail is of paramount importance when conducting complex maintenance tasks such as engine assembly. Manufacturers’ recommendations must be followed (CAR 571 Standard 571.02). This is particularly important when the final assembly is hidden from view and not easily inspected.

Fortunately this resulted in a ground incident rather than an inflight emergency.

Rotor assembly with rivets that had fallen out due to incomplete setting

General Electric

CT58-140-2 - Broken P3 Air Line

SDR #: 20210817009

Subject:

During forestry fire-fighting operations, after the load of water was picked-up and the climb was initiated, Engine Number 2 was not providing the required power. When compared with Engine Number 1, the torque was 40% lower and the T5 was 120 to 130 degrees Celsius below the Engine Number 1 T5 indication. The water load was released, the checklist for the low side governor failure was completed, and the helicopter returned safely to the base. An engine inspection revealed a broken P3 air line.

Transport Canada Comments:

The root cause of the broken air line has yet to be determined, however, fatigue and stress may have played a role in this failure. The photo shows the broken air line offset from the B nut, which may suggest a side load from installation.

Due to congestion of lines and bundles on many engines, it is sometimes difficult to have proper alignment when connecting fluid lines. A slight bend of a line to achieve contact, may induce stress and lead to a failure. Another common error is securing and torquing one end of the line before connecting the other end, instead of connecting both ends and then securing and torquing.

Transport Canada Civil Aviation (TCCA) would like to make operators and maintainers of this model and similar models aware of this event. It is also recommended that close attention be paid to this line when inspecting in this area.

Broken P3 air line

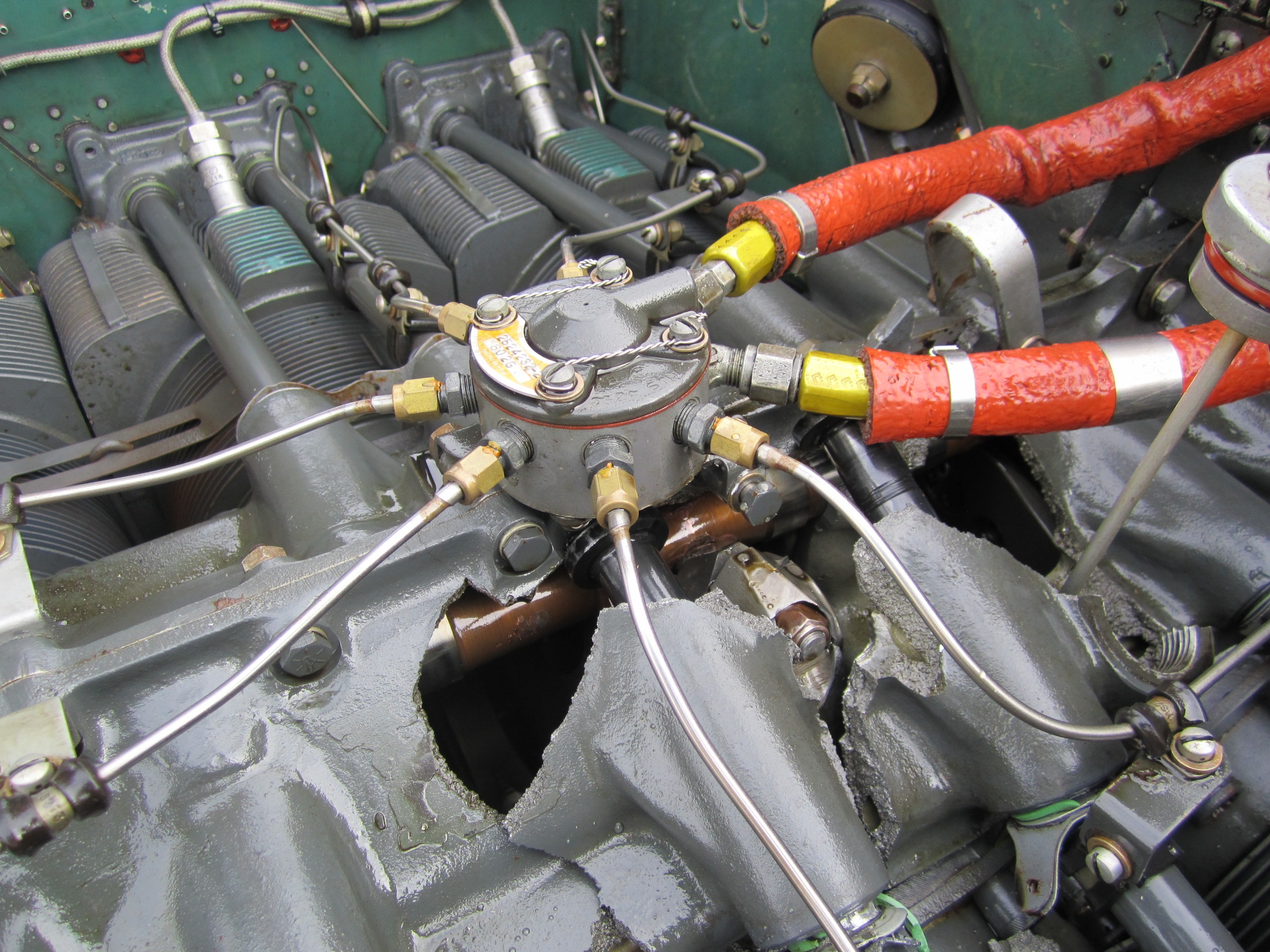

CF34-3B1 - Engine Main Fuel Pump

SDR #: 20220124011

Subject:

During a routine inspection, fuel was discovered in the lower engine cowl. Upon further investigation, it was discovered that the engine-driven fuel pump had developed a small pinhole in the inlet case allowing boost pump pressure to leak from the pump body. The affected pump was replaced, and the aircraft returned to service.

Transport Canada Comments:

We have received several Service Difficulty Reports (SDRs) related to fuel leaks from a pinhole on this particular fuel pump part number. The leakage is attributed to a pinhole on the relief valve wall of the secondary housing as a result of erosion caused by the effect of cavitation over the relief valve cavity threads. These leaks may be barely detectable due to the size of the pinhole.

General Electric added inspection instructions in the component maintenance manual to check for cavitation on the secondary housing and issued Service Bulletin (SB) 73-0050 R00 identifying new spare parts for a redesigned main fuel pump with rerouted passageways.

Transport Canada Civil Aviation (TCCA) would like to make operators and maintainers of similar models aware of these events, and urges everyone to be vigilant while inspecting the fuel pump area for leaks.

Photo 1 – Main fuel pump secondary housing

Photo 2 – Pinhole at secondary housing

CF6-80C2B6 - Main Engine Control Driveshaft Migration

SDR #: 20201111012

Subject:

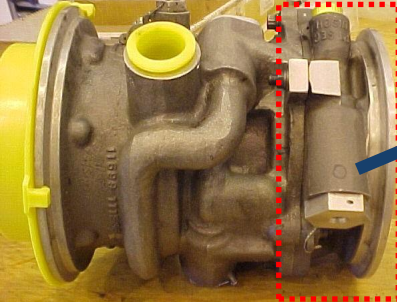

During the left engine start, a hung start condition was observed, with the power turbine speed N2 at 75% and 450 degrees Celsius Exhaust Gas Temperature (EGT), with no response to throttle movement. The engine was shut down for maintenance troubleshooting. Troubleshooting was carried out and identified the Main Engine Control (MEC) as being at fault. Upon maintenance removing the MEC from the accessory gearbox, the driveshaft was found no longer mated to the MEC. The driveshaft had migrated towards the gearbox and was no longer rotating the MEC internal shaft. The nut, attaching the driveshaft within the MEC, had backed off to allow this migration of the shaft. The MEC was replaced, and the aircraft was returned to service.

Transport Canada Comments:

From viewing the MEC driveshaft threads photograph, it appears that the threads were worn or damaged. This condition may have been a factor contributing to the attaching nut backing off. The use of wrong hardware, cross threading or over torque of the securing nut, and thread strength, are a few possible causes of thread damage. Until an investigation is carried out, the root cause of this event remains undetermined.

Although the investigation is still ongoing, Transport Canada Civil Aviation (TCCA) would like to bring this event to the attention of maintainers and operators of the CF6-80C2B6 model or similar models. A verification of the MEC driveshaft condition and security when in this area, or before installation of the MEC, may prevent a similar or more serious incident.

Photo 1 – MEC driveshaft

Photo 2 – MEC

CF34-8E5 - Cracked Fuel Pump Adapter

SDR #: 20200211018

Subject:

During a post engine installation leak check ground run, fuel was noted to be leaking from the number one (1) (left-hand) engine fuel pump. The subsequent investigation found an adapter, which attaches to the fuel pump, to be cracked, which allowed fuel to escape. The adapter was replaced and the engine was returned to service.

Transport Canada Comments:

Post-maintenance functionals, leak checks, ground runs etc. are vital parts of maintenance procedures in the Instructions for Continued Airworthiness. All personnel must be thorough when performing such checks to ensure service difficulties like this one are discovered and rectified before the aircraft is released to service. “Well done” to these diligent maintainers for catching this service difficulty which may have had a potential disastrous outcome if not detected.

Fuel pump adapter with indicated crack area

CF34-8C5 - Chafed Fuel Line

SDR #: 20200603001

Subject:

A fuel smell was present in the cabin during various phases of flight. An investigation found that the 6th stage duct was cracked, making it possible for the fuel line and the duct to rub together. Chafing caused perforation in the fuel line. The right-hand engine will be changed.

Transport Canada Comments:

Performing inspections and maintenance tasks in many sections of an aircraft can be challenging. The routing of lines, wire bundles and hoses in confined spaces makes it difficult to spot every area that may have rubbing or chafing.

Maintainers must be thorough when inspecting or performing tasks in these areas. Always follow the manufacturer’s Instructions for Continued Airworthiness (ICA) when routing lines or wire bundles to ensure that they are secure and that they do not interfere with each other.

Chafing of 6th stage duct and fuel line

CF34-3B1 - Chafed Oil Fill Line

SDR #20190813016

Subject:

A RH OIL PRESSURE warning message appeared while cruising at 33 000 feet. The message was intermittent. Once the message reappeared, we reduced the right-hand engine thrust to idle, performed immediate action and shut the engine down. Maintenance personnel found the oil fill line chafed and a defective check valve at the engine. The small valve unseated from the springs inside the check valve causing the oil pressure to flow back to the chafed fill line, causing oil loss.

Transport Canada Comments:

It is important that maintenance personnel be thorough when installing or inspecting fluid or pneumatic lines with regards to security and the potential for chafing against the airframe, a component or another line/bundle.

Congested areas are prone to such events and maintainers must pay particular attention to the routing of lines and bundles when working in such areas.

Although not the only contributor to this event, had the oil fill line not been chafed it may have been able to contain the engine oil.

Chafed oil fill line

CF6-80C2B7F Fuel Contamination Caused by Superabsorbent Polymers

SDR #: 20170614013

Subject:

A CF6-80C engine’s Hydro Mechanical Unit (HMU) was returned, reporting the aircraft had an inflight shut down with no fuel flow on the left hand engine.

Foreign object damage (FOD) was noted through the area and opened ports. FOD appeared to be all through the overspeed governor bracket and port areas through the bracket as well. The fault was confirmed during analysis of the electrohydraulic servo valves (EHSVs). The substance was identified as superabsorbent polymers (SAP) (polymers that can absorb and retain large amounts of liquid). A common SAP use is in disposable diapers.

Fuel delivery systems at airports around the world use filter monitors with SAP elements to remove water from fuel. SAP may be released into the fuel by improper fuel handling equipment maintenance, cleaning, operation and other scenarios.

SAP particles are typically in the 5 to 20 micron size range and may not be visible, but can be up to 750 microns (0.030 in., visible).

SAP can be identified through black light inspection (SAP will fluoresce in black light) and through chemical testing using sulfate pentahydrate (SAP will turn blue when exposed to this chemical).

The HMU had a contamination overhaul performed, power flushing of main housing and EHSV’s solenoids, and was then returned to service.

The sister HMU from the same aircraft was returned for investigation. There were signs of minor SAP contaminates in some low flow areas and on external surfaces of the HMU, but not as severe.

Transport Canada Comments:

If an operator suspects they have received contaminated fuel, the airframe manufacturer’s instructions must be followed to help ensure safe operation of their aircraft.

Superabsorbent polymer contamination made visible under a black light

CF34-3B1 - Cracked Fan Blade Pins Causing High Engine Vibration

SDR #20170315003

Subject:

During a ground power assurance check, abnormal fan (N1) vibration was noticed on the right hand engine. Inspection revealed severe damage on all the fan blades pins. Three of them were found in very bad condition.

Transport Canada Comments:

This unit is something that is called out for inspection in both the engine and airframe manuals however the airframe manual has lesser inspection requirements. Operators are reminded that when developing maintenance schedules, airframe and engine manufacturer requirements should both be considered. The manufacturers’ recommendations should be thought of as a minimum requirement; operator and industry experience should also be considered.

Damaged fan blade retaining pins

CF6-80C2B6 - Engine failure due to liberated turbine nozzle

SDR #20160913005

Subject:

Crew reported hearing a loud bang from the left engine. Engine vibration was apparent and loss of available power was estimated at about 20% by the crew. Flight was subsequently diverted.

Transport Canada Comments:

The engine teardown revealed that the stage three nozzle had failed. This particular part was the subject of a GE service bulletin (SB) 72-1354 which recommends replacement with an improved unit.

While manufacturer’s SBs are not mandatory unless made so by an Airworthiness Directive, it is good practice to comply with them.

View of engine tail cone after nozzle failure

Honeywell

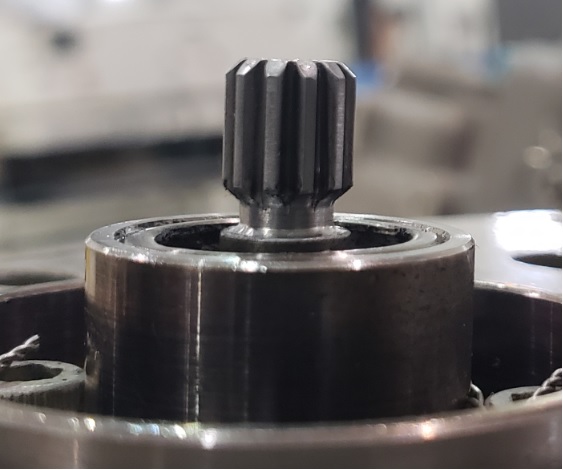

TFE731-20BR-1B Drive Splines and Interconnect Couplings Inspection

SDR #: 20211102014

Subject:

During the pre-flight checks after engine start, the pilots report the engine computer switch is to be set to manual mode, and a slight engine acceleration is noted. When the switch for the left engine was selected to the manual mode position, the engine had an uncontrolled acceleration. The pilots moved the engine computer switch back to auto mode and the engine returned to its normal operating condition, and the engine was then shut down. The Honeywell Maintenance Manual includes a caution for the fuel control unit (FCU) installation, stating that if the coupling between the FCU and fuel pump is not installed, the engine will overspeed rapidly in manual mode. The left engine FCU was removed to inspect the coupling between the FCU and the fuel pump, and the drive splines on the FCU. The inspection revealed that the output shaft from the fuel pump, the interconnect coupling and the FCU drive splines were stripped.

Transport Canada Comments:

It is common practice for many manufacturers to mate components together using interconnect couplings. These couplings are made from a variety of materials depending on the application. Some couplings are designed to shear if a component seizes, to limit the extent of damage to its mated component.

The root cause of these stripped splines has yet to be determined, but improper alignment during installation and material defects are possibilities. As stated in this event, the manufacturer’s Instructions for Continued Airworthiness (ICA) does bring attention to ensuring interconnect couplings are installed to prevent overspeed of the engine. However, maintainers are reminded to inspect the condition of the mating surfaces and to pay attention when installing components to ensure proper engagement.

Photo 1 – Interconnect coupling

Photo 2 – Fuel pump drive spline

Photo 3 – Fuel pump drive spline close-up view

Pratt & Whitney – Canada

PW207D2 - Leaking Triple Function Switch

SDR #: 20230502009

Subject:

During a post flight serviceability check and servicing, fuel was found on the number two engine triple function switch and pooling on top of the number two engine fuel management module (FMM). Aircraft was taken out of service.

Transport Canada Comments:

Transport Canada has received several service difficulty report submissions regarding leaking of the triple function switch. All events reported similar findings of leaks on the FMM. The leaks were typically detected during pre and post flight inspections where there was a noticeable fuel smell and visible wetness around the top of the FMM.

The subject switch is a new version and was introduced with Pratt & Whitney Canada service bulletin (SB) 28332R1 as a result of the previous triple function switches causing incorrect cockpit displays because of electrical contact contamination.

The engine type certificate holder is currently investigating these events. TCCA therefore recommends that operators and maintainers of this engine model and similar models pay particular attention to this area and report any leaks or other findings through their Web Service Difficulty Reporting System.

Picture 1 Triple function switch location

Text in the picture: Right side of engine, Airframe connector

PT6A-34 - Oil Filter Inner Mesh Cone

SDR #: 20230713014

Subject:

During a regularly scheduled inspection of the oil filter, it was noted that the inner mesh cone was split open, just past the end brazing fold (outlet end).

Transport Canada Comments:

The inner mesh screen serves as the secondary filter should the main engine oil filter element go into bypass. In this case, there was no indication that the filter had been bypassed and therefore the secondary inner mesh screen was not being used for oil filtering.

These maintainers are commended for their thorough inspection of this component and detection of the inner screen defect. Had the filter gone into bypass, contaminated oil would have been able to flow through the engine, which could have posed a significant threat to its continued safe operation.

Transport Canada would like to bring this event to the attention of maintainers and operators of this engine and similar models and to encourage reporting of any findings through their Web Service Difficulty Reporting System.

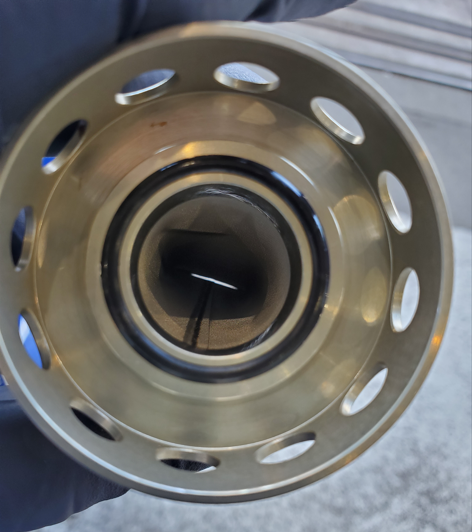

Picture 1 - Oil Filter

Picture 2 - Secondary Mesh Screen

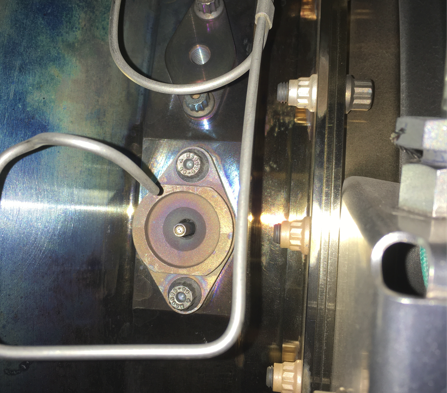

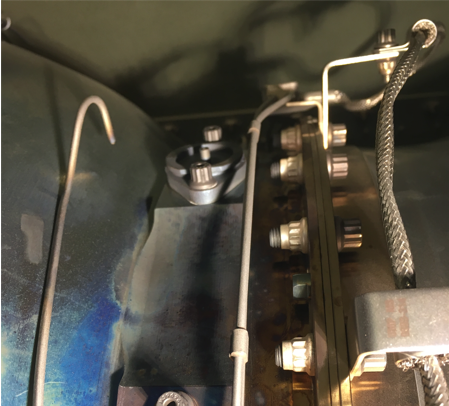

PW150A - Chafed Oil Scavenge Line

SDR #: 20240102006

Subject:

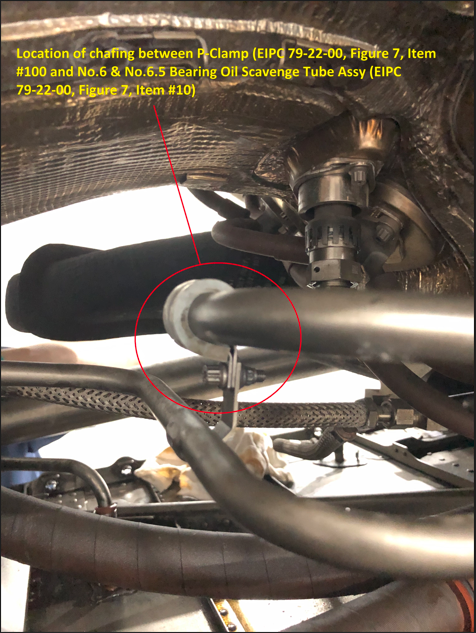

On December 18, during an overnight maintenance check on the aircraft, oil was found dripping from the number two engine cowl at the aft inboard corner near the drain mast. After opening the cowl doors, a significant amount of oil was found on the aft nacelle floor near the oil cooler cover and cooler lines area. Oil was seen dripping from the number two engine 6 and 6.5 bearing oil scavenge tube from underneath a p-clamp. The p-clamp was found to have an unusual amount of play in the fore/aft direction. When removed, it was discovered that the p-clamp cushion had chafed through completely, and the metal portion of the p-clamp had chafed through the oil scavenge tube, causing the oil leak.

Transport Canada Comments:

TCCA received two service difficulty reports with identical problem descriptions. As can be seen in the attached photos, the metal band has worn through the clamp cushion resulting in a chafed scavenge line from metal-to-metal contact.

Like most engine compartments, this area is congested with lines, hoses, cables etc. and the event clamp seems to be secure, but the photo of the removed worn clamp clearly shows that it was moving.

While the investigation continues to determine root cause, TCCA brings this event to the attention of operators and maintainers of this or similar engine models. Take time to check this clamp and all securing hardware when inspecting in this area and report any finding through your Web Service Difficulty Reporting System.

Picture 1 - Engine Bay

Text that appears in the image - Location of chafing between P-Clamp (EIPC 79-22-00, Figure 7, Item #100) and No.6.5 Bearing Oil Scavenge Tube Assy (EIPC 79-22-00, Figure 7, Item #10)

Picture 2 - Chafed Oil Line

Picture 3 - Removed Clamp

PT6A-50 - Damaged Garlock Seal

SDR #: 20230518007

Subject:

On 20 July, 2022, during an inspection, an oil leak was discovered by maintenance coming from the #4 hydraulic pump Garlock seal (plain seal). The Garlock seal for the #4 hydraulic pump was replaced, the engine was leak checked, and found serviceable. On 9 May, 2023 during a flight, the flight crew noticed the #4 low oil pressure caution light illuminate and the #4 oil pressure gauge was indicating low pressure. They shut down the #4 engine and elected to return to the main base. They returned with 3 engines operating and the aircraft landed without incident. Maintenance inspected the engine and found the #4 hydraulic pump Garlock seal damaged. This was allowing oil to bypass the seal and drain overboard. The #4 hydraulic pump Garlock seal was replaced, the engine was leak checked, and found serviceable. The aircraft was returned to service with no further incident.

Transport Canada Comments:

Investigation into this repeat event did not determine a root cause.

A defective seal was not ruled out but given the visual condition of the removed seal it is possible that incorrect maintenance practices may have been a factor. The installation instructions and required tooling are clearly defined in the manufacturer’s instructions for continued airworthiness (ICAs) and their proper use should not result in the type of damage found.

Although the safety implications of this event were low since it occurred on a multi engine aircraft, if this had occurred on a single engine aircraft the outcome may have been much more hazardous. Transport Canada would like to remind maintainers to follow published ICAs when performing maintenance tasks and to report any service difficulty findings.

Picture 1 - Garlock seal side view

Picture 2 - Garlock seal top view

PW150A - Scored Fuel Pump Transfer Tube Bores

SDR #: 20230125017

Subject:

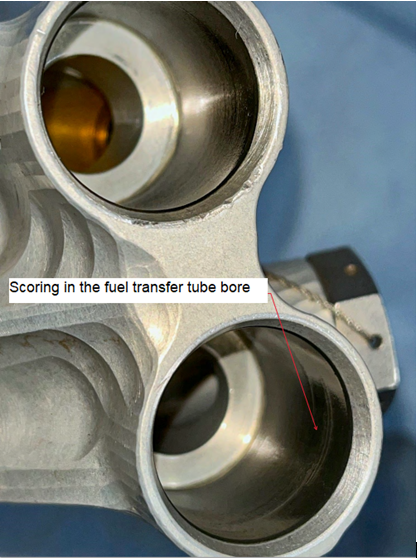

A fuel metering unit (FMU) assembly was issued from stock to be installed on an aircraft and found to have scoring marks in the fuel transfer tube bores, which were beyond the Component Maintenance Manual (CMM) limits. The unit had been received from repair in 2020 and was in stock since that time.

Transport Canada Comments:

Although this event is still being investigated by the manufacturer and a root cause for the scoring has yet to be determined, some possible causes could be a damaged O ring or misalignment of the transfer tube, allowing the transfer tube to contact the bore.

Transport Canada Civil Aviation (TCCA) brings awareness of this event to operators and maintainers of similar models to check these bores prior to installation and report any findings to TCCA through their Service Difficulty Reports (SDR) reporting system.

Well done to this operator and maintainer for performing a meticulous inspection of the FMU and pump before installation.

Picture 1: FMU

Picture 2: Scored transfer tube bores

PW120A - Cracked Fuel Drain Line

SDR #: 20220725001

Subject:

During a scheduled engine fuel nozzle replacement, the combustion chamber fuel drain line was found cracked.

Transport Canada Comments:

Transport Canada would like to inform maintainers and operators of PW120A and similar engine models of this event.

The investigation into the root cause continues, however, corrosion and stress along the weld seam may have been contributing factors.

Please be diligent when inspecting this area and, specifically, this line. Please report any similar findings through the Transport Canada Web Service Difficulty Reporting System.

Picture 1: Broken fuel line

Picture 2: Broken fuel line closeup

PW306D - Broken Thermocouple Harness

SDR #: 20220309008

Subject:

While inspecting the internal ignition lead segments to the igniter plugs, during the first 800-hour interval tasks, broken thermocouples were observed through the bypass access panel. Upon further inspection, it was discovered that there were broken probes on each wiring harness of both engines. All four thermocouple wiring harness assemblies (two per engine) required premature replacement at 818.2 hours total time since new.

Transport Canada Comments:

From the photos provided by the service difficulty report submitter, the thermocouple leads seem to have broken close to the thermocouple probe body where the assembly is attached to the engine case. Some discoloration on the thermocouple leads may indicate corrosion and the offset alignment of the lead to the thermocouple probe after breaking suggests stress or fatigue induced during installation.

The root cause of this event is still being investigated by the manufacturer, however, Transport Canada Civil Aviation (TCCA) would like to highlight this event for operators of PW306D engines and similar models. If performing inspections in this area or carrying out the 800-hour interval task, pay particular attention to the security and serviceability of the thermocouple harnesses and report any findings through the Web Service Difficulty Reporting System.

Picture 1 – Sheared Thermocouple Lead

Picture 2 – Thermocouple Lead Sheared and Rubbing On Case

PW123 - Fuel Line Fitting Under-Torqued

SDR #: 20211129009

Subject:

On take-off while climbing through 1500 feet, the crew identified a loss of torque on the #2 engine accompanied by a loss in propeller Revolutions Per Minute (RPM). The torque went to zero and the crew secured the engine. The aircraft landing was uneventful. An inspection by maintenance determined the loss of power was caused by a fuel leak at the fuel flow divider fuel inlet tube assembly. The affected fuel line and fittings were inspected, O-rings were replaced on the flow divider transfer tube and the line installed in accordance with the maintenance manual. Engine power runs were completed, and the aircraft was released back to service.

Transport Canada Comments:

The occurrence summary in the Transportation Safety Board (TSB) daily notification log of this event states that the maintenance personnel determined that an under-torqued fuel line fitting led to the drop in fuel pressure and subsequent engine power loss.

The fuel, oil and electrical systems of engines are normally housed in very cramped and restricted areas of most aircraft and access can be limited at best. Many “B” nuts for fluid lines may not have clearance to attach a torque wrench in a conventional way and a variety of extensions or adapters may have to be used for access. These extensions or adapters may result in an over or under torque situation. The proper torquing of these lines is vital to ensure they remain secure so maintainers are reminded to be vigilant when installing or inspecting these lines and consult manufacturer’s instructions or standard practices such as AC43.13-1B for proper torque calculations if using extensions or adapters.

This aircraft had an uneventful landing however had the fuel leak ignited, it may have been a very different outcome.

PT6A-27 - Corroded Starter Generator Drive Gear Shaft

SDR #: 20220623027

Subject:

Starter generator drive gear shaft assembly, Part Number 3029567, was received in overhauled condition. During the receiving inspection, it was noted that corrosion was present on the gear shaft once the protective cap was removed.

Transport Canada Comments:

Overhauled components regularly sit on storage shelves for extended periods and may not get inspected before being shipped.

The bearing surface of the gear shaft had numerous pit marks from corrosion, which may have been caused by improper preservation for storage. This corrosion was not detected until the protective cap was removed from the gear shaft assembly.

Transport Canada Civil Aviation reminds maintainers and operators to carry out receiving inspections to ensure serviceability of incoming components. Do not assume parts are serviceable because of the documentation attached. Well done to this operator who caught this issue prior to the gear shaft being installed in an accessory gearbox.

Picture 1 – Corroded gear shaft

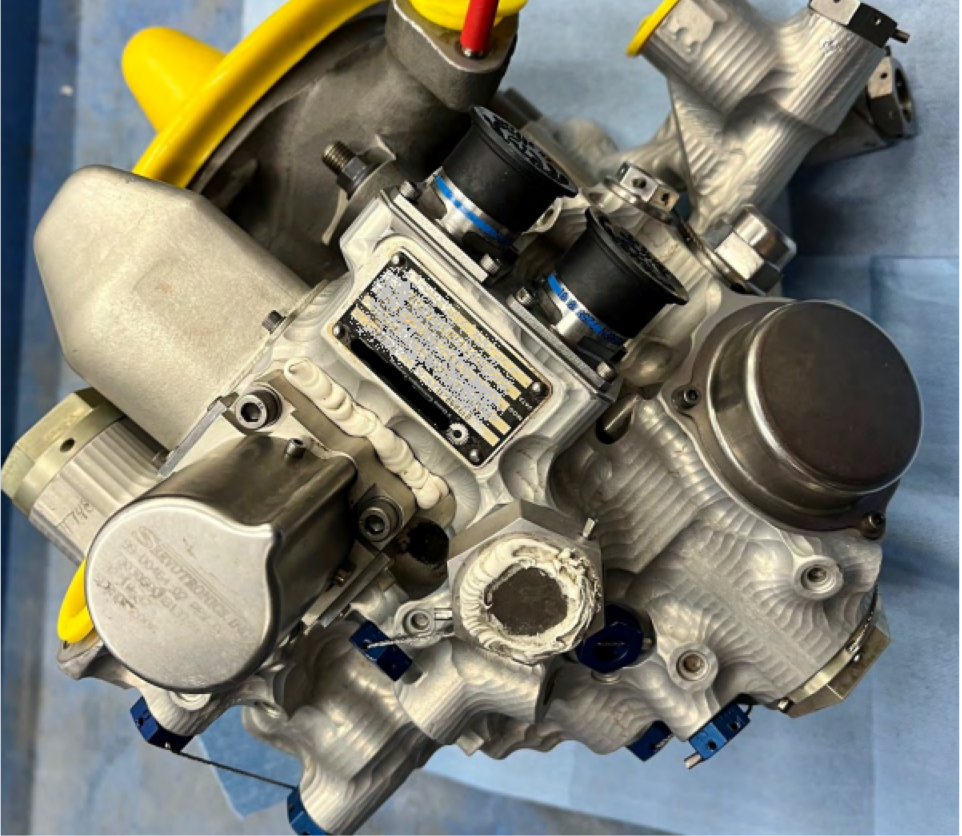

PW210A - Fuel Control Unit (FCU) Casting Defects

SDR #: 20230119005

Subject:

The FCU supplier recently discovered various casting defects within several internal core passages of the inlet housing assembly of the FCU. These defects are mainly excess aluminum material of various shapes (granules, globules, raised ridges, casting flash) resulting from the casting process. The estimated size of these defects ranges from 0.030 to 0.180 inches. There can also be a thin wall thickness condition potentially leading to a fuel leak or affecting the FCU’s functionality. A total of 52 FCUs are affected by this condition. A service bulletin (SB) will be issued to replace the FCU within 150 hours. For helicopters that have two engines affected by this condition, the recommendation is to replace one of the two FCUs before further flight. The affected engine models are PW210A, PW210A1, and PW210S.

Transport Canada Comments:

Transport Canada Civil Aviation (TCCA) would like to raise awareness of this finding to operators and maintainers of the affected engine models. A manufacturing issue may result in a possible blockage of the FCU internal passage affecting fuel flow and may also result in a thin wall thickness condition that could lead to external fuel leakage.

The engine manufacturer, Pratt & Whitney Canada (P&WC), issued SB A57168 which addresses this issue. Please review the SB and component logs or check part numbers and serial numbers of the FCUs on the affected engine models and contact P&WC for disposition.

As TCCA continues to monitor this issue, please report any findings directly to P&WC or to TCCA via the Web Service Difficulty Reporting System.

PT6A-21 - Propeller Governor Flyweight Bearings Insufficient Ball Retention

SDR #: 20230202005

Subject:

During a normal inspection, it was discovered that the right-hand engine magnetic chip detector had a piece of metal attached to one of its magnetic pick-ups. It was a metal ball of 0.039 inch in diameter. We sent the information to the engine manufacturer and after several days, the information came back stating that the ball was probably coming from the propeller governor and possibly also from the overspeed governor. The propeller governor was removed and sent to the overhaul facility who confirmed that one of the four internal flyweight bearings failed. All eight (8) balls and race were missing. On our side, no other metal part has been found so far into the oil filter, on the aft Accessory Gear Box (AGB) pump inlet screen or around the forward AGB magnetic chip opening.

Transport Canada Comments:

Woodward, the propeller governor manufacturer, issued Service Bulletin (SB) 83053-61-027 in 2012. The SB provides instructions for replacing bearings that were assembled with lightly crimped bearing retainers. Engineering analysis, conducted cooperatively by the engine, governor and bearing manufacturers, concluded that the failure was likely caused by a vigorous oscillatory motion of the two-piece, loosely crimped, bearing retainer resulting in fretting wear of the retainer assembly.

Further to their investigation into this Service Difficulty Report (SDR), Pratt & Whitney Canada continues to promote compliance with Woodward SB 83053-61-027. Transport Canada Civil Aviation (TCCA) concurs with this position and would like to highlight the value in assessing and following manufacturers’ recommendations, including those at the component or vendor level.

TCCA encourages submission of SDRs for similar events through the Web Service Difficulty Reporting System.

Figure 1 – Damaged flyweight bearing

Figure 2 – Damaged and serviceable flyweight bearings

PW127M - Disconnected Fuel Line

SDR #: 20211001010

Subject:

During a power assurance check, the left engine caught fire.

Transport Canada Comments:

The investigation of this event determined that the fuel pressure line had been disconnected during the removal of the nacelle lower structure. This is a deviation from the airframe manufacturer's procedures, and disconnection is not required. Following scheduled maintenance, a leak check was not performed before the power assurance check was carried out. A review of the Engine Maintenance Manual (EMM) and Airframe Maintenance Manual (AMM) found nothing wrong with the procedures for the task.

The described event perfectly shows how failure to follow manufacturers' Instructions for Continued Airworthiness (ICA) can lead to very serious situations. Not only did omitting steps lead to problems, but the additional step of disconnecting a fuel pressure line resulted in an engine fire. If a ground run had been performed post-maintenance, this event may have been prevented.

Transport Canada Civil Aviation reminds operators and maintainers to strictly adhere to ICA, perform ground runs after maintenance, and have a colleague check the work performed before closing panels or doors.

Disconnected fuel line

PW150A Improper Generator Installation

SDR #: 20191010008

Subject:

The crew reported that the right-hand direct current (DC) generator caution light was illuminated followed by an oil pressure warning light during flight. The crew commanded shutdown of the engine and landed without any incident. Upon troubleshooting, maintenance found the right-hand DC generator separated from its mount on the reduction gearbox.

Transport Canada Comments:

An investigation by the engine manufacturer found the oil pressure warning was caused by an oil leak from the DC generator that was not seated on its mount. The root cause was determined as improper generator installation.

Generators or starters on most aircraft tend to be heavy, cumbersome to handle or install, and located in an area that is usually difficult to access and congested with lubrication and fuel lines as well as wire bundles. The securing hardware of the generator to its drive varies from basic stud mounts with nuts, to band clamps that encompass the generator and gearbox mounting flanges.

Although these different mounting systems may seem straightforward, you must follow the manufacturer’s instructions to ensure proper installation. Normally, they need to be in a certain orientation for wiring hookup, which may or may not be aided by a locator pin. Many have specific torque procedures for clamps or specific torque sequences for stud mounted, and other components may require removal to facilitate an installation.

In this event, the crew was fortunate to land without incident but had the generator detached from the mount, it may have resulted in a very different outcome. Transport Canada Civil Aviation reminds all maintainers to be diligent and follow the manufacturer’s Instructions for Continued Airworthiness (ICA) regardless of how simple the task may seem.

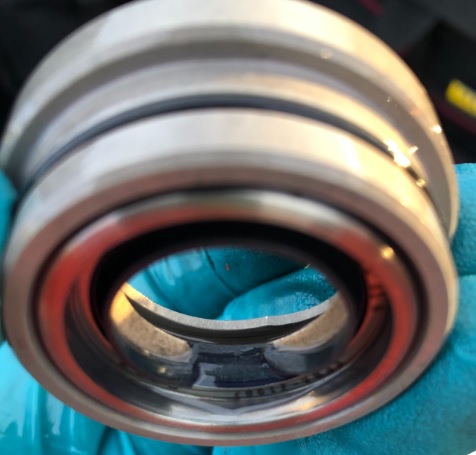

PT6A-67P - Leaking Propeller Shaft Seal

SDR #: 20200716009

Subject:

On July 11, 2020 the propeller shaft seal was replaced due to leaking, and an engine ground run and leak check were completed. On July 13, 2020 the aircraft took off from the airport and completed a turnback due to oil on the windscreen and the engine cowling. Maintenance replaced the faulty propeller shaft seal on July 15, 2020. During the replacement of the faulty shaft seal, a buildup of seal material on the mating surface of the seal was noted and grooves on the aft side of the seal mating surface had worn off.

Transport Canada Comments:

In this event, an oil leak was found, and a seal replacement was carried out by maintenance personnel. Unfortunately, the seal failed on the next flight even though ground runs had been performed after its replacement. Further inspection found a buildup of seal material on the mating surface, which probably resulted in the sealing grooves being worn off and another oil leak.

An investigation into the root cause could not rule out the possibility of both seals being defective. However, it was determined that improper maintenance practices likely contributed to the failure of the second seal. It was found that the replacement seal was not repositioned according to the maintenance manual instructions. A third seal was installed, and the aircraft returned to service.

With the demands of meeting schedules and deadlines in a very competitive market, many tasks are at risk of being rushed to completion. In this circumstance, it appears that a full inspection of the area including mating surfaces may not have been completed prior to installation and repositioning of the propeller shaft seal. Transport Canada Civil Aviation (TCCA) reminds maintenance personnel that they have a responsibility to accomplish tasks in accordance with the appropriate standards of airworthiness and to remain vigilant for human factor issues that may impact the quality of their work.

Picture 1 – Propeller shaft seal

Picture 2 – Buildup of material on seal

PW127M - Re-orientation of Bus-Bar Support Bracket Bolts

SDR #: 20201127003

Subject:

The pilot observed high inter-turbine temperature (ITT) on the left engine during climb and elected to safely return to the airport of origin. During troubleshooting, one thermocouple leg was found touching the mount base. It was isolated and secured, and the aircraft was released back to service.

Transport Canada Comments:

Pratt & Whitney Canada Service Bulletin (SB) 21931 is related to this issue. In summary, the calculated value for the ITT can fluctuate due to intermittent contact between the negative bus-bar support bracket bolts and the turbine support case (TSC) insulation blanket. To eliminate interference, the SB provides instructions to re-orient the negative bus-bar support bracket bolts to increase the clearance with the TSC insulation blanket. Transport Canada, Civil Aviation (TCCA) recommends compliance with this SB.

PW305A - New Bleed Valve Solenoid

SDR #: 20201005017

Subject:

During taxiing for take-off, the crew saw the left engine inter-turbine temperature (ITT) climb to 885oC, the low oil pressure annunciator illuminated, and the crew immediately shut down the engine and taxied back to the fixed base operator (FBO).

Transport Canada Comments:

Transport Canada Civil Aviation (TCCA) has received numerous Service Difficulty Reports (SDRs) related to compressor bleed valves on Pratt & Whitney Canada (P&WC) models PW305A, PW305B and PW306A engines.

The purpose of this Feedback article is to raise awareness of P&WC Service Bulletin (SB) 25401R7 and SB 24645R6. These SBs introduce a new bleed valve solenoid valve to improve the durability of the compressor bleed valve. Reference P&WC Service Information letter (SIL) PW300-198, which advises operators of these SBs.

TCCA encourages operators to follow all manufacturers' recommendations and consider implementing these SBs in the interest of safety.

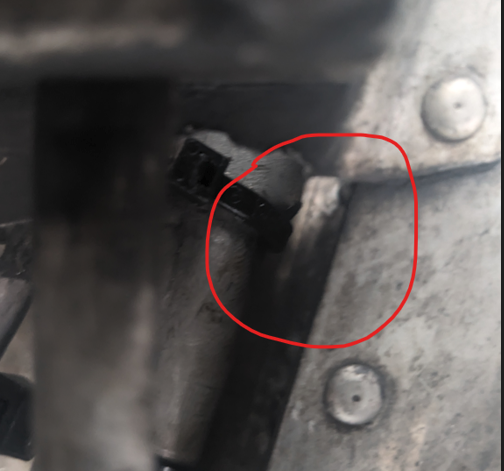

JT15D-4B - Improper Igniter Cable Routing

SDR #: 20201215004

Subject:

At take-off, the crew advanced the throttle, and while adjusting the right-hand engine to the correct power rating, the right-hand throttle lever became jammed. The crew aborted the take-off and vacated the runway normally. The left-hand engine was shut down normally to limit thrust during taxiing. A moment later, the right-hand aircraft brake failed and spun the aircraft off the taxiway. While the crew was trying to unstick the right-hand throttle, the thrust reverser inadvertently deployed, and dust/dirt entered the cabin. The crew had to shut down the right-hand engine using the firewall shut-off valve. The source of the throttle jam was found to be an engine igniter cable not routed properly on the engine, which interfered with the throttle cable.

Transport Canada Comments:

The importance of security and proper routing of lines, cables, bundles etc. cannot be stressed enough. With the confined areas of some aircraft, it may seem impossible to ensure that no chafing or interference of moving parts exist.

In this event, the root cause was determined as improper routing of the ignition cable. This may seem like a human factors error; however, it may have made sense to install the cable in such a way as to avoid interference with other lines or bundles. Luckily this event ended without incident; however, had the event occurred during flight, the outcome may have been much worse.

When carrying out such tasks, please follow the manufacturer’s instructions and if there are doubts or concerns about the security or proper routing, contact the manufacturer for verification. Always check clearance of moving parts when routing bundles, lines or cables to ensure no interference with controls.

PW127M - Fuel Nozzle Transfer Tube Missing O-Ring

SDR #: 20210326013

Subject:

The customer reported an excessive fuel leak from the left engine drain mast after engine start. This happened after the first flight since the fuel nozzles were replaced. The customer identified a missing O-ring from the #4 fuel nozzle transfer tube. The O-ring was installed and the aircraft returned to service after a ground run check.

Transport Canada Comments:

Many maintenance tasks involve mundane procedures that require repetitive actions. The replacement of fuel nozzles is one such task that involves the removal of old and installation of new O-rings on numerous transfer tubes, depending on the engine model.

In this event, an O-ring was found missing from a transfer tube causing a fuel leak. Fortunately, this was detected on engine start prior to flight. Had the leak occurred during flight and ignited, it may have had a much worse outcome.

Complacency caused by repetitive tasks, distraction from the job at hand, fatigue, and the pressure to get the job done are all possible factors that can lead to such events. Aircraft maintainers face significant threats to maintaining diligence when carrying out any type of work, but the threats related to repetitive activities are elevated. Being aware of possible human factor errors, and recognizing when they are most likely to affect one’s performance, are essential skills for any aircraft maintainer to master.

PT6A-67F - Seal Running Surfaces

SDR #: 20200629030

Subject:

Engine accessory gear box (AGB) high pressure fuel pump drive gear is scored causing an oil leak past the drive seal.

Transport Canada Comments:

Seals are often replaced to correct oil leaks, but the seal itself is not always the root cause. As seen in the attached photo, there are visible wear marks in the area of the seal running surface of the gear shaft. Replacing a seal in an attempt to correct an oil leak caused by a worn or damaged seal running surface often results in the leak reoccurring very shortly thereafter.

Limited access to these components often makes it difficult to inspect and verify the amount of wear on the running surface, however, using technology such as inspection cameras, or other similar devices, greatly improves the ability of the maintainer to detect such damage.

Figure 1: Fuel pump drive gear

PT6A-67F - Leaking Fuel Pump Drive Seal

SDR #: 20200623016

Subject:

The engine driven high pressure fuel pump drive seal was leaking oil excessively. The seal was found to be damaged. No lost time.

Transport Canada Comments:

Damaged O-rings and seals are a common root cause for many leaks in oil, fuel and hydraulic systems on aircraft. Many factors, such as limited access and lack of proper tooling, contribute to the possibility of damaging seals on installation. However, in this case, the fuel pump drive gear shaft appears to have been scored, reducing the effectiveness of the oil seal. In cases like this, simply replacing the seal is unlikely to be effective and the shaft would normally require repair or replacement to correct the oil leak.

Picture 1 : Damaged seal

Picture 2 : Damaged drive gear

PT6A-67F - Starter Generator Carbon Seal

SDR #: 20200707012

Subject:

The starter generator seal is leaking oil excessively. The carbon seal appeared to have a worn face. The carbon seal and the runner were replaced. Leak checked was carried out ok.

Transport Canada Comments:

Carbon seals are a proven industry standard in a wide variety of aircraft and engine applications. The seals are ideal for use because of their low coefficient of friction, low wear rate, high thermal conductivity and resistance to oxidation.

Unfortunately, all of these characteristics are ineffectual if the seal is damaged. Installation without proper tooling, insufficient cleaning of sealing surfaces, seal carriers and bores etc. or inattention when installing driven components such as a starter generator are some of the factors that may cause seals to be damaged and leaks to occur.

Inspect both the seal and the seal running surfaces to ensure they are not damaged. Use recommended lubricants and cleaners where applicable and clean thoroughly and always follow manufacturer’s Instructions for Continued Airworthiness (ICA) when installing, removing, inspecting or handling these components.

Seal and Runner

PW123B - Fuel Control Unit Driveshaft Bushing

SDR #: 20201021003

Subject:

Following a fuel control unit (FCU) replacement on the right-hand engine, maintenance found an internal leak between the fuel pump and the FCU. After removal of the FCU, it was noted that the bushing on the FCU driveshaft was improperly installed. The FCU was freshly overhauled.

Transport Canada Comments:

Events such as these are all too familiar to maintainers and operators, where a new or recently overhauled component is installed, and during testing or ground run, they are found to be defective or unserviceable.

The improperly installed bushing may have been the result of incorrect tooling, failure to follow component maintenance manuals, poor maintenance practices or may have been dislodged due to poor handling during shipping or receiving.

Transport Canada Civil Aviation would like to remind maintainers that the certification and serviceability of a component to be installed on an aeronautical product is not only the responsibility of the overhaul shop but also the person who certifies the installation. Do not assume parts bearing certification tags are indeed serviceable, carry out a thorough inspection of components prior to installation.

Photo 1: Properly installed bushing

Photo 2: Improperly installed bushing

PW150A - Cracked Fuel Transfer Tube Bracket

SDR #: 20190524018

Subject:

During the accomplishment of a scheduled maintenance task (replacement of the Fuel Metering Unit (FMU) to the Fuel/Oil Heat Exchanger (FOHE) transfer tubes), an Aircraft Maintenance Engineer (AME) noted that the fuel transfer tube bracket on the left engine was cracked. The assembly was replaced with a serviceable component and the aircraft was returned to service.

Transport Canada Comments:

Pratt & Whitney Canada (P&WC) is aware that cracks develop occasionally on the weld, equally in the pre- and post-mod configurations (see P&WC Service Bulletin No.3533R1) . These cracks typically do not affect the functionality of the bracket and are usually discovered during opportunistic inspections when the tubes/bracket assemblies are replaced.

Transport Canada would like to make maintainers aware of the possibility of these cracks and to pay particular attention to these transfer tubes when circumstances provide access to the FMU as well as during scheduled maintenance.

Photo 1 Transfer tube assembly

PW150A - Oil Pump Leak

SDR #: 20200212008

Subject:

During flight, the right-hand engine experienced fluctuating oil pressure. The pilot proceeded to land the aircraft uneventfully. It was decided to replace the engine and the aircraft returned to service.

Transport Canada Comments:

During cruise, the number two engine oil pressure fluctuated between 40 and 55 psi with the oil pressure light illuminating on and off during the flight. The number two engine was feathered in accordance with the Quick Reference Handbook (QRH) and the oil pressure increased from 50 to 60 psi and was noted as 62 psi on landing. During the troubleshooting, an oil leak was found at the oil pump drain. Further inspection of the area revealed that two bolts holding the oil transfer tube retaining plate had sheared and allowed the retaining plate to vibrate and chafe through the body of the oil pump leading to a hole in the pump casing.

Investigation into the event discovered that a non-mandatory service bulletin (SB) had been issued recommending a periodic visual inspection to check for fretting of the transfer tube retaining plate and ignition support bracket, and to verify the torque on the attaching hardware.

Transport Canada encourages all operators to review SBs issued by manufacturers and recommends adopting these types of inspections as part of their maintenance programs. Although the aircraft landed uneventfully, it could have been much worse and would have likely been avoided had the SB been complied with.

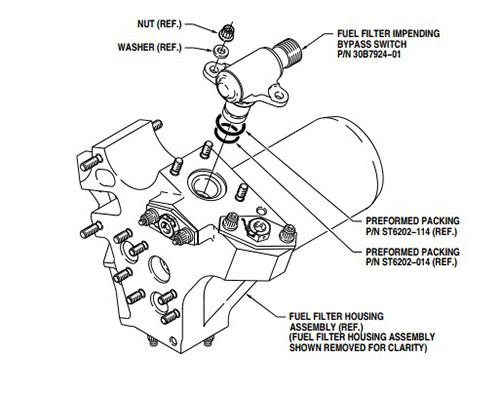

PW306D - Fuel Filter Impending Bypass Switch

SDR #: 20170110013

Subject:

After takeoff, at approximately Flight Level 260, the crew observed a Fuel Filter Bypass Crew Alerting System (CAS) message on the right-hand engine and no other messages were indicated. The crew completed the checklist items, declared an emergency and diverted the flight for an uneventful landing.

Transport Canada Comments:

Transport Canada has received several similar Service Difficulty Reports (SDRs) with the Fuel Filter Impending Bypass Switch identified as the specific part causing difficulty for the illumination of the CAS message.

Pratt &Whitney Canada has published Service Bulletin (SB) SB25455 introducing a replacement switch which annunciates using a normally open contact and has an electrical inverter for interface compatibility purposes. The replacement switch alleviates the existing false annunciations due to the deterioration of the current switch’s normally closed contacts.

It is strongly advised that particular attention be given to the SB’s CAUTION statement which instructs maintainers to NOT remove the bypass valve to facilitate removing the switch.

Figure 1: Fuel Filter Impending Bypass Switch

PW150A - Scavenge Oil Filter Leak

SDR #: 20200320007

Subject:

The flight crew reported that during the approach to the airport, they received a low oil pressure indication on the number one (1) engine. The flight crew followed the Quick Reference Handbook (QRH) and shutdown the engine. A PAN PAN was declared and the aircraft diverted to an alternate airport and landed without further incident. During troubleshooting, maintenance personnel found an oil leak originating from the scavenge oil filter area. The packing and the oil filter were replaced in accordance with Aircraft Maintenance Manual (AMM) 79-22-11-400-801 and a leak check was carried out serviceable. The aircraft returned to service.

Transport Canada Comments:

The operator confirmed that the low oil pressure event occurred on the first flight following the replacement of the scavenge oil filter. An investigation by the operator suggested that the scavenge oil filter cover packing was damaged during the installation and that environmental factors may have diminished the ability to perform an effective inspection during the leak check.

Maintainers often find themselves in situations where factors like weather conditions and accessibility create difficulties in performing certain tasks, however maintainers are reminded to take all necessary steps to perform these tasks, to be thorough when performing maintenance and follow all instructions for continued airworthiness.

PT6A-67D - Cracked fuel line discovered after fuel seen in engine area

SDR #: 20170831016

Subject:

Minor edits have been made to the text below taken from the Service Difficulty Report’s Problem Description. Transport Canada Civil Aviation reserves the right to edit for spelling, grammar and punctuation to increase comprehension.

During a scheduled inspection, maintenance found fuel leaking from the left hand engine. Further investigation revealed that the primary fuel pressure tube assembly (part number 3035618) was cracked at the flange area. The tube assembly was replaced, successful ground runs and leak checks performed. Aircraft was returned to service.

Transport Canada Comments:

This type of failure can be caused by many factors such as mishandling of the line, improper alignment prior to final torqueing or excessive vibration. Maintainers must be careful when working with fluid lines to avoid dangerous situations.

Excessive vibratory loads can be more difficult to detect and diagnose. Propeller balancing is an important step in reducing vibratory loads and should be carried out in accordance with the manufacturer’s recommendations.

Another less obvious source of damaging vibratory loads can come from Starter Generator failures. Often when a Starter Generator bearing fails, it will put a massive vibratory load that can damage many engine components (including fluid lines). After such events, maintainers must use extra care in inspecting the entire engine for secondary damage.

Cracked fuel line

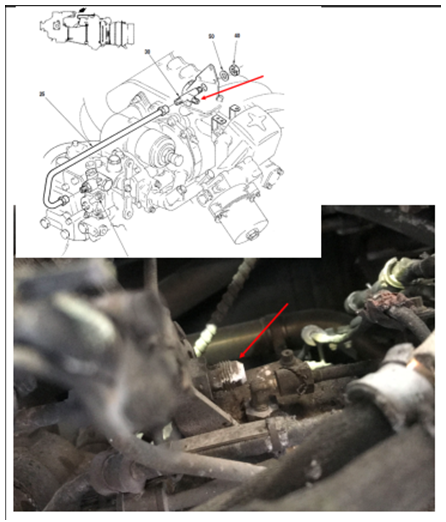

PT6A-60A - Commanded In-flight Shutdown Due to Miss-rigging

SDR #: 20171002008

Subject:

Minor edits have been made to the text below taken from the Service Difficulty Report’s Problem Description. Transport Canada Civil Aviation reserves the right to edit for spelling, grammar and punctuation to increase comprehension.

The aircraft was climbing through eleven thousand five hundred feet with power set at eighty eight percent torque and prop speed at sixteen hundred rotations per minute (rpm). The flight crew heard the propeller rpm changing and observed it dropping back to eight hundred rpm and torque rising. When the torque approached redline, power was reduced to thirty percent. The torque and prop rpm stayed at around eight hundred. The aircraft was levelled off and prop was feathered. The crew elected to leave the engine running. The aircraft returned to base and landed safely. Maintenance performed an inspection and discovered the reversing cable stretched and the prop governor BETA valve was extended (out of rig.). The reversing cable was shortened (re-rigged) and engine ground run carried out. During ground run prop appeared to operate normally however it was indicating in the three to four hundred rpm range at all power settings. Further investigation revealed damage to the prop tach drive gear. The engine was removed from the aircraft and sent to a repair facility.

Transport Canada Comments:

It is believed that the engine may have been repeatedly shutdown with the power lever still in the BETA range. This could cause the reversing cable to stretch and in turn allow the BETA valve to go out of rig.

Evidence of lightning strike was found that may have contributed to the rpm fluctuations (residual magnetism was found in the prop governor).

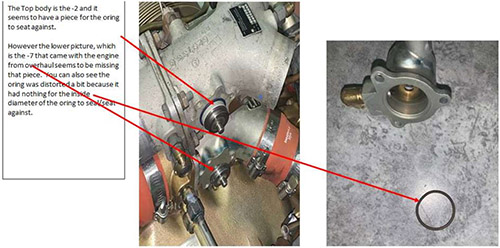

PT6A-114A - Missing or Forgotten Bracket Causes Engine Shutdown

SDR #20170718006

Subject: