Unpaved Runway Surfaces

| Issuing Office: | Standards | Document No.: | AC 300-004 |

|---|---|---|---|

| File Classification No.: | Z 5000-34 | Issue No.: | 04 |

| RDIMS No.: | 13454059-V2 | Effective Date: | 2017-12-05 |

Table of Contents

- 1.0 Introduction

- 2.0 References and Requirements

- 3.0 Background

- 4.0 Frost effects on gravel pavements

- 5.0 Soil properties – effect on surface Shear strength

- 6.0 strength measurement and reporting

- 7.0 Condition inspection of gravel surfaces

- 8.0 maintenance and repair of gravel surfaces

- 9.0 Maintenance and repair of turf landing strips

- 10.0 Information Management

- 11.0 Document history

- 12.0 Contact Office

- Appendix A — Table 1

- Appendix B — figures 1 to 3

1.0 Introduction

This Advisory Circular (AC) is provided for information and guidance purposes. It describes an example of an acceptable means, but not the only means, of demonstrating compliance with regulations and standards. This AC on its own does not change, create, amend or permit deviations from regulatory requirements, nor does it establish minimum standards.

1.1 Purpose

The purpose of this document is to outline methodologies for the measurement and reporting of surface shear strength for unpaved runways. In addition, the document outlines recommended practices for condition inspection, maintenance and repair of airport gravel surfaces and turf landing strips.

1.2 Applicability

This document applies to Canadian airport operators and is also available to the aviation industry for information purposes.

1.3 Description of Changes

- Revision to section 6.2.7 (1).

- Other changes of an editorial nature.

2.0 References and Requirements

2.1 Reference Documents

- It is intended that the following reference materials be used in conjunction with this document:

- Part III, Subpart 2 of the Canadian Aviation Regulations (CARs) - Airports;

- Transport Canada Publication (TP) 312 5th Edition — Aerodrome Standards and Recommended Practices;

- Advisory Circular (AC) 302-011 — Airport Pavement Bearing Strength Reporting;

- AC 302-023 – Measurement and Evaluation of Runway Roughness;

- AC 525-006 — Operations From Unpaved Runway Surfaces;

- AC 700-011 — Operations on Runways with Unpaved Surfaces;

- TP 14371 — Transport Canada Aeronautical Information Manual (TC AIM);

- Federal Aviation Administration Advisory Circular (FAA AC) 150-5320-6F, 2016-11-10 — Airport Pavement Design and Evaluation;

- International Civil Aviation Organization (ICAO) Annex 14 to the Convention on International Civil Aviation — International Standards and Recommended Practices: Aerodromes (Seventh Edition, July 2016);

- ICAO Doc 9157-AN/901 – Aerodrome Design Manual, Part 3 Pavements (Second Edition, 1983);

- NAV CANADA – Canada Flight Supplement — Canada and North Atlantic Terminal and Enroute Data (Updated and published every 56 days);

- Boeing Document No. D6-24555, 1984-04-05 — High Load Penetrometer Soil Strength Tester;

- Boeing Document No. D6-45222-1, 1980-10-03 — Airplane Requirements for Operations on Gravel Runways;

- American Society for Testing and Materials (ASTM) D2487, 2011—Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System);

- ASTM D4429, 2009—Standard Test Method for the CBR (California Bearing Ratio) of Soils in Place;

- ASTM D6951/D6951M, 2009 (2015) —Standard Test Method for the Use of the Dynamic Cone Penetrometer in Shallow Pavement Applications.

2.2 Cancelled Documents

- Not applicable.

- By default, it is understood that the publication of a new issue of a document automatically renders any earlier issues of the same document null and void.

2.3 Definitions and Abbreviations

- The following definitions are used in this document:

- Aircraft Classification Number (ACN): a number expressing the relative structural loading effect of an aircraft on a pavement for a specified pavement type and a specified standard subgrade category (ICAO pavement strength reporting format);

- Aircraft Load Rating (ALR): a number expressing the relative structural loading effect of an aircraft on a pavement (historical Transport Canada strength reporting format);

- California Bearing Ratio (CBR): a measure of the load bearing capacity of a given sample of soil expressed as a ratio relative to the load bearing capacity of crushed limestone;

Note: The load bearing capacity of crushed limestone is expressed as a CBR of 100. - Pavement Classification Number (PCN): a number expressing the bearing strength of a pavement for unrestricted operations (ICAO pavement strength reporting format);

- Pavement Load Rating (PLR): a number expressing the bearing strength of a pavement for unrestricted operations (historical Transport Canada strength reporting format);

- Surface Treated Runway: a gravel pavement structure covered with a thin layer of asphalt stabilized material to prevent the penetration of water and facilitate drainage; and

- Unpaved Runway Surface: a runway surface comprised of gravel, turf, clay or hard packed soil mixtures. Unpaved runway surfaces can be manually constructed pavements or naturally occurring unprepared surfaces.

- The following abbreviations are used in this document:

- ACN: Aircraft Classification Number;

- ALR: Aircraft Load Rating;

- ASTM: American Society for Testing and Materials;

- CBR: California Bearing Ratio;

- ICAO: International Civil Aviation Organization;

- PCN: Pavement Classification Number; and

- PLR: Pavement Load Rating.

3.0 Background

- This Advisory Circular (AC) should be used in conjunction with Transport Canada Civil Aviation's AC 700-011 and AC 525-006, which apply to operations on runways with unpaved surfaces and the certification of aeroplanes for unpaved runway operations respectively.

- TP 312 5th Edition – Aerodrome Standards and Recommended Practices gives the following standard with respect to the determination and reporting of surface strength for unpaved runway surfaces:

2.1.4.2 The surface strength of an unpaved surface, such as gravel or grass, is determined using a recognized CBR evaluation method and reported as follows:- CBR number;

- surface type; and

- evaluation method.

- Unpaved runway surfaces can be subject to significant variations in their strength and surface characteristics because of climatic effects and the effects of aircraft operations. Unpaved runways can achieve their design strength and surface characteristics when maintained properly and not subject to excessive moisture.

- Surface treated runways (as defined in section 2.3(1) of this AC) may lack surface shear strength as compared to paved runways and in this respect are more similar to unpaved surfaces rather than paved surfaces.

- Conditions of excessive moisture may occur during heavy precipitation or spring thaw due to inadequate drainage and can result in a significant degradation of surface shear strength. The degradation in surface shear strength may be enough to limit or completely restrict operational use. Conversely, during periods of extended and deep frost, unpaved runway surfaces can have strength characteristics similar to those of paved hard surfaces.

- Gravel surfaces deteriorate with time and under repeated traffic loadings. The most common defects occurring with gravel surfaces are ruts, frost heaves, depressions, potholes, soft spots and loss of aggregates. Periodic grading, compaction and addition of new material are required to maintain the integrity of the gravel surface and to ensure the safe operation of aircraft.

- The recommended practices given for the maintenance and repair of gravel surfaces are provided to assist airport operators in promoting airfield safety. The gravel material specifications given in this AC are not intended to be used as part of a staged construction process whereby the surfaces are to be paved at a later date but rather as a preventative maintenance program to keep these surfaces in good repair under normal weather conditions and traffic loads.

- The recommended practices given for the maintenance and repair of turf landing strips are applicable to turf landing strips suitable for small aircraft with tire pressures not exceeding 0.35 MPa (51 psi) and loading characteristics comparable to those of an automobile. The normal maintenance work required for turf surfaces consists of grass cutting in the summer, minor repairs in the spring and snow compaction and removal in the winter.

4.0 Frost effects on gravel pavements

- Gravel pavements have the advantage of a surface that can be easily re-graded to eliminate roughness arising from frost effects. Consequently, subject to operational requirements, they may be the preferred type of pavement in areas having severe frost effects.

- The detrimental effects of frost heave include surface roughness from non-uniform heave and loss of soil strength during frost melt. Other effects may include loss of compaction, restriction of drainage and deterioration of the surface. Conditions promoting detrimental frost heave are a frost susceptible soil, freezing temperatures penetrating the frost susceptible soil and sufficient moisture to form expansionary ice crystals in the soil.

- Generally, coarse grained soils such as gravels and sands have low frost susceptibility, silts have high frost susceptibility and clays are moderately susceptible. The depth of frost penetration is a function of the thermal properties of the pavement and soil mass and the severity of air/surface temperatures.

- For pavements constructed on frost susceptible subgrade soils and exposed to seasonal frost, pavement roughness resulting from frost heaving is controlled by providing a sufficient depth of non-frost susceptible material to limit frost penetration into the subgrade. Adequate pavement load carrying capacity may also have to be provided during the critical frost melting period when load carrying capacity is reduced.

- Permafrost occurs in arctic regions where soils may be frozen to considerable depth year-round. Seasonal thawing and refreezing of the upper layer (the active layer) can lead to severe loss of bearing strength and differential heave or settlement. The design of pavements in permafrost areas has to consider the depth of the active layer. If the active layer is shallow, pavements constructed on frost susceptible subgrade soils should be of sufficient thickness to prevent thaw from reaching the subgrade. This approach is not economical in areas of deeper active layer where pavement thickness is limited to that needed to support traffic during periods of subgrade thaw. Since pavement construction usually increases the depth of the active layer, the latter design approach will result in the thawing of previously unthawed permafrost, and large and continuous post-construction settlements are possible if the newly thawed soil had a high ice content. Gravel surfaced pavements are particularly advantageous under these circumstances.

5.0 Soil properties – effect on surface Shear strength

- Unpaved runway surfaces are typically non-homogeneous in composition and may contain various types of soils. The standard method of classifying soils for engineering purposes is given in American Society for Testing and Materials (ASTM) D2487 - Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). One of the purposes of soil classification is to predict the probable behaviour of soils under the influence of frost and moisture.

- The Unified System classifies soils first on the basis of grain size (coarse grained and fine grained soils), then further subgroups soils based on the plasticity constants. Soils are expressed by soil group symbols (e.g. GW, which is described as "Well graded gravel and gravel sand mixtures, little or no fines").

- The California Bearing Ratio (CBR) provides a measure of the ability of an unpaved surface to resist shearing under aircraft loads. Appendix A of Federal Aviation Administration (FAA) AC 150-5320-6F – Airport Pavement Design and Evaluation gives an estimated range of field CBR values of 60-80 for well graded gravel soils and 20-40 for well graded sands. The potential for frost action for these soils is minimal, with almost no compressibility and expansion and the drainage characteristics are generally excellent. The presence of clay soils can result in a reduction of the strength values and frost properties of these soils, although with granular surfaced pavements, some clay content is desirable to provide cohesion, and a tighter, more erosion resistant surface.

- The use of a soil classification system may be useful as a check on the validity of specific CBR measurements.

6.0 Strength measurement and reporting

- The subgrade bearing strength and overall thickness of a gravel pavement structure controls the amount of surface deflection under an applied aircraft load and thus the ability of the runway to structurally support the aircraft load. The overall loading capacity of a runway pavement structure is expressed as a historical Pavement Load Rating (PLR) and/or a Pavement Classification Number (PCN) (reference AC 302-011 – Airport Pavement Bearing Strength Reporting).

- While it is the subgrade bearing strength and overall thickness of the pavement structure that controls the amount of surface deflection, the most common cause of operational problems on unpaved runways is the failure of the surface layer due to shear under high aircraft tire pressures. The surface shear strength of an unpaved runway may be measured in terms of a CBR value and this value may be used to determine a tire pressure limitation for the runway surface.

6.1 Pavement Load Ratings for Gravel Surfaced Pavements

- The PLR of a gravel surfaced pavement is determined as described for flexible pavements in AC 302-011. The PLR value can be converted to an equivalent PCN value using Table 8 (Flexible Pavements) in AC 302-011. In addition, a note should be appended to the PCN code to indicate that the surface is gravel as follows "Note: Gravel Surface Construction". The tire pressure limitation for gravel pavements may be determined based on the surface (shear) strength as described subsequently. An example of an International Civil Aviation Organization (ICAO) PCN code for a gravel pavement is as follows:

52/F/D/0.69MPa/T Note: Gravel Surface Construction.

6.2 Unpaved Runway Surface Shear Strength

- The shear strength of a gravel surface depends on the interlock of aggregates, particle friction and cohesion. The surface shear strength also depends on the properties of the surface materials under the influence of moisture. This results in the surfaces of unpaved runways being susceptible to shear failures, particularly in wet conditions.

- The relatively low shear strength of unpaved runway surfaces, especially when wet, may limit aircraft loads imposed on the runway.

6.2.1 CBR (California Bearing Ratio)

- The surface shear strength of an unpaved runway is expressed as a CBR value. The CBR is the ratio of the load bearing capacity of a given sample of soil to that of crushed limestone. The bearing strength of crushed limestone has been adopted as one of the criteria to which other types of soil are compared. Limestone has a CBR value of 100, which is expressed as CBR 100. A soil with CBR 10 has 10% of the bearing strength of crushed limestone.

- ASTM has developed standard test methods for both laboratory and field (in-place) CBR measurements. ASTM D1883, Standard Test Method for CBR of Laboratory Compacted Soils, is the laboratory CBR method. ASTM D4429 - Standard Test Method for CBR of Soils in Place is the field CBR method. The laboratory test method is useful at the design stage of a pavement but is of limited use for operational purposes. For the measurement of unpaved runway surface strength, ASTM D4429 is considered to be the definitive standard CBR test method. The ASTM D4429 method is essentially the determination of the load required to cause the uniform rate of penetration of a piston into the soil. The ASTM D4429 also requires that consideration be given to the moisture content of the soil. The presence of large aggregates or stones may cause inaccurate results if a larger stone is embedded under the penetration piston.

- The set up required for the ASTM D4429 test method can be laborious and time-consuming and thus can be impractical for measurements on unpaved runways. As a result, other methods have been developed to estimate CBR values.

- The CBR value derived from the ASTM D4429 method is considered the standard to which other methods will be compared. Surface shear strength can be estimated by measuring the force required to deflect or penetrate the surface to a specified depth. This force divided by the area over which it is applied can be taken as the soil failure pressure. This pressure can be obtained from penetrometer type devices and is often correlated to CBR.

- The CBR value derived from methods other than the ASTM method should be considered as an estimate or index of CBR rather than an absolute value of CBR. The CBR values measured with these methods will be different from the value derived from the ASTM method. It is important to indicate the methodology used to derive the estimated CBR value.

- Unpaved runways with higher surface shear strengths have higher soil reaction pressures and higher CBR values.

6.2.2 Boeing High Load Penetrometer

- The Boeing High Load Penetrometer (Reference Boeing Document No. D6-24555 - High Load Penetrometer Soil Strength Tester) consists of a hydraulic cylinder with a cone point test probe mounted at the rod end. The hydraulic cylinder is normally positioned against the frame of a heavy vehicle which serves as a reactive load. In the test procedure, the probe is driven at a steady rate to a 100 mm (4 inch) depth into the surface by the application of pressure through a hand pump. Generally a pressure reading is taken about 30 seconds or less after movement of the penetrometer has stopped at the 100 mm (4 inch) depth.

- Soil pressure is derived from the penetrometer force divided by the projected area of the 50.8 mm (2 inch) diameter cone point. Friction and shear forces at the side of the cone point are included in the total force. The CBR value is determined by a formula relating the CBR to the soil failure pressure.

- For this test method, the surface material has to be homogeneous to a depth beyond the cone point tip. The presence of large stones may introduce errors but this should be evident to the operator during measurement. This is indicated by a sudden large increase in penetrometer pressure readings during pressure application. Relocation to another test position several feet away is recommended. Inaccuracies may also result from friction in the jack and sides of the penetrometer if any tilting occurs.

- Boeing has developed a curve of the CBR versus Soil Failure Pressure (Boeing High Load Penetrometer) which indicates that the CBR value derived from the Boeing Penetrometer generally corresponds to that of the ASTM D4429 method at a penetration of 12.7 mm (0.5 inches) (Reference Boeing Document No. D6-24555). However, it should be noted that the ASTM D4429 method requires that the CBR be calculated and reported at a depth of 2.54 or 5.08 mm (0.1 or 0.2 inches). Thus the CBR derived from the Boeing High Load Penetrometer should be considered as an estimate or index of CBR rather than an absolute value of CBR.

6.2.3 Other CBR Measurement Methods

- Some European aircraft manufacturers use a device called the sliding weight shock penetrometer. This device consists of a long rod with a cone and a sliding weight of 3 kg (6.6 lb). The penetrometer is driven into the soil by repeatedly raising and dropping the sliding weight along the rod. The CBR value is derived from the number of drops of the sliding weight required to drive the penetrometer into the surface to a depth of 100 mm (4 inches). Because the sliding weight used in the shock penetrometer is quite small in comparison to the load applied using the ASTM D4429 or the Boeing High Load Penetrometer methods, this device is limited for use on relatively soft surfaces. The Shock Penetrometer may not correlate well to CBR because it is an impact test rather than a constant rate of loading test. A comparison of surface strength measurements using the Shock Penetrometer has identified significant discrepancies in CBR values as compared to the Boeing Penetrometer when measured on the same runway.

- Some manufacturers of military aircraft use a device called the Dynamic Cone Penetrometer. A description of the test method is given in ASTM D6951/D6951M, 2009—Standard Test Method for the Use of the Dynamic Cone Penetrometer in Shallow Pavement Applications. This device consists of a rod with a cone tip, an 8 kg (17.6 lb) hammer which is dropped from a height of 575 mm (22.6 inches), a coupler assembly and a handle. The device is held in a vertical position and the hammer is repeatedly raised and released from the standard drop height. The total penetration for a given number of blows is measured. The estimated CBR is computed using correlation equations based on the penetration per blow. Comparison data of surface strength measurements using the Dynamic Cone Penetrometer and the Boeing High Load Penetrometer conducted on the same runway surface is not currently available.

6.2.4 Selection of CBR Measurement Method

- In general, a reactive load type device, with a steady application of pressure that allows for assessing higher strength runways is the preferred type of measurement device. Ideally, the method used to measure the runway CBR should be the same method that was used to derive the minimum CBR published in the Aircraft Flight Manual or supplement for the aircraft operating on the runway. The most commonly used device in Canada for certifying aircraft on gravel runways and for assessing gravel runways is the Boeing High Load Penetrometer.

6.2.5 Measurement of CBR

- The surface shear strength of unpaved runways (including surface treated runways as defined in section 2.3(1) of this AC) should be determined by trained personnel, experienced in the measurement and analysis of the surface strength of unpaved runways.

- The determination of runway surface shear strength should be made based on the results of in-situ strength tests using an established and industry recognized engineering methodology. The test method should be correlated with sufficient accuracy against the standard ASTM D4429 test method. CBR correlation data should be obtained from equipment manufacturers to qualify their equipment, before performing any tests.

- If applicable, the equipment should be certified and calibrated at a frequency recommended by the manufacturer.

- The manufacturer's instructions for runway surface shear strength measurements should be followed.

- Measurements should be taken on the runway surface to a specified depth as recommended by the manufacturer.

- The presence of large aggregate or rock may introduce errors during a test and as a result the test should be stopped and the device moved to another location.

- Measurements should normally be taken along the length of the runway in the anticipated main gear landing paths and at specific intervals, normally 30 to 60 m (100 to 200 ft). The measurements should be evenly staggered between the two wheel paths. Several measurements should also be conducted on the runway centreline and 8 m (25 ft) from the runway edges (towards runway centreline) which may identify weaker portions of the runway. Spot measurements should also be made on areas suspected to be soft and on taxiways and aprons.

- A minimum number of 20 measurements should be taken on the runway surface to obtain a representative sample of CBR measurements.

- (9) The average (X) of the measurements and their standard deviation (σ) should be determined. The reported CBR value is the average CBR value for the runway surface minus one standard deviation (i.e. CBR = X - σ).

6.2.6 Frequency and Timing of CBR Measurements

- The frequency of CBR measurements depends on several factors including the condition of the runway, aircraft type and frequency of operations. Initially, testing should be conducted annually to establish a trend for the measurements. Once a trend has been established, the minimum recommended frequency of testing is every 3 years.

- The surface strength of an unpaved runway will vary with moisture and time of year. CBR measurements should normally be conducted shortly after the spring thaw to determine the surface strength of the runway at its weakest condition. If the testing is conducted at or near this time of year, the measured runway surface strength will likely remain applicable for the remainder of the year, unless the runway is exposed to prolonged rainfall.

- CBR measurements should be also be conducted when any of the following conditions exist:

- following construction to any portion of the runway surface (excluding normal grading and compaction);

- when there is reason to believe that there has been a degradation in surface shear strength (for example due to rutting, pilot complaints, etc.); or

- when the runway has been inactive and not maintained for one season.

6.2.7 Reporting of CBR

- The CBR test report should indicate clearly the methodology/device used for the measurement since different devices will give different values. Because of the errors associated with using the results of various test equipment and methods to estimate the standard CBR value, it is important that the test method be identified. The surface type is also to be included with the test report

- The Boeing, Shock and Dynamic Cone penetrometer methods do not provide any CBR correction factors to account for soil moisture content. As an unpaved surface may be significantly weaker following spring thaw or heavy precipitation, the conditions under which the measurements were made should be recorded.

- As a minimum, the following information should be recorded and included in the test data report:

- Airport site;

- Test site (e.g. runway, taxiway, etc.);

- Test date;

- Surface type;

- Degree of soil saturation;

- Test location;

- Depth of test;

- CBR values; and

- Test method.

- A listing of all Canadian airport operating authorities and contact phone numbers can be obtained by consulting the latest version of the NAV CANADA – Canada Flight Supplement.

6.2.8 Determination of Tire Pressure Restrictions

- Some aircraft manufacturers may use measured CBR values to determine tire pressure restrictions for operations on a runway. Boeing has derived acceptable tire pressure values against CBR values as measured with the Boeing High Load Penetrometer (Reference Boeing Document No. D6-45222-1 - Airplane Requirements for Operations on Gravel Runways). A curve was developed (Appendix B - Figure 1 of this AC) which indicates that a runway has sufficient surface strength for aircraft operations if the tire pressure in psi is less than or equal to 5 times the CBR as measured with the Boeing High Load Penetrometer.

7.0 Condition inspection of gravel surfaces

- The maintenance work necessary to keep gravel surfaces in a safe operational condition consistent with design requirements is normally determined through periodic condition inspections. The technical features to consider during these inspections include slope gradients, drainage patterns, the identification of soft and wet spots, the presence of large stones on the surface and areas of frost heave.

7.1 Slope Gradients

- (1) For adequate surface drainage and to prevent ponding, gravel runways and taxiways should preferably have a centreline crown with a transverse slope of 2 to 2.5 % (reference section 3.1.2.6 of TP 312 5th Edition). Flatter grades are required on aircraft parking aprons and refuelling areas.

- If possible, a downward slope should be provided along the runway shoulders for a distance of 60 to 75 metres (about 200 to 250 feet) from each side of runway centreline.

7.2 Drainage Patterns

- Drainage patterns should be observed and any low spots in the surface that tend to trap or impede the flow of water should be planned for regrading and levelling. The surface layer should be maintained as impervious as possible by providing good drainage, compacting the surface and minimizing rutting. Any accumulation of moisture on the surface will weaken the structure and should be avoided.

7.3 Frost Heave

- During the winter season, the extremities of frost heave should be observed and marked. These areas should be planned for replacement of unsuitable (frost susceptible) material down to the level of frost penetration. This work should be done when no frost is present.

7.4 Gravel Pavement Surface Defects

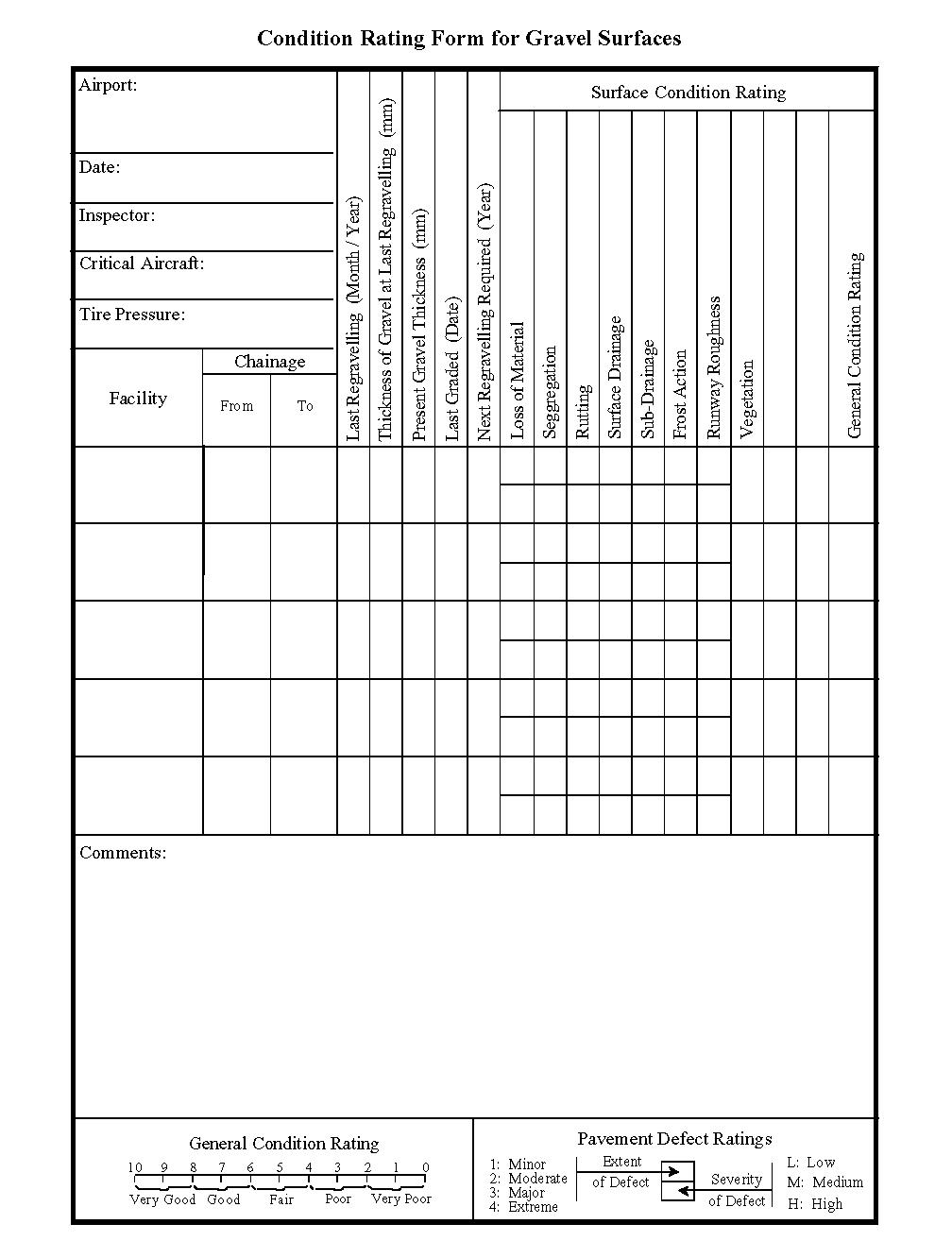

- Appendix B, Figure 2 of this AC gives a sample "Condition Rating Form for Gravel Surfaces" which indicates the type of defects commonly found in gravel surfaces. A description of the defects is given below.

7.4.1 Loss of Material

- Indications of loss of material are bare spots, subgrade material appearing on the surface, and a build-up of granular material on the edge of the runway. Possible causes are loss of material during snow removal, tire action, and infiltration of lower level material into the surface layer.

7.4.2 Segregation

- Segregation is the accumulation on the runway surface of loose, non-cohesive aggregates lacking in fines. Causes are loss of fines due to jet or propeller blast, tire action and weathering.

7.4.3 Rutting

- Rutting is described as longitudinal deformation in the wheel path. Rutting without shoving of adjacent material is an indication of failure in the deeper layers or subgrade due to inadequate thickness or overloading. Rutting with shoving indicates a shear failure in the surface layer due to poor cohesion (low surface shear strength) or excessive tire pressures. Poor cohesion may be the result of high moisture content, poor gradation, segregation or poor compaction.

7.4.4 Surface Drainage

- Poor surface drainage is indicated by damp surface areas persisting after rainfall or snowmelt without rutting. Possible causes include inadequate transverse slope, low spots, or inadequate surface drainage facilities.

7.4.5 Subsurface Drainage

- Soft areas with rutting and shoving during spring thaw or wet conditions and frost heaving during winter are indications of poor subsurface drainage. Similar to rutting but caused by high moisture content instead of inadequate thickness. Persistent wetness not due to inadequate surface drainage is another indication of poor subsurface drainage. Possible causes are inadequate sub-drainage or a high water table.

7.4.6 Frost Action

- Frost action is indicated by differential heaving of the surface or depressions which appear in the same place yearly during the frozen season. Inadequate drainage of the subgrade and inadequate granular thickness over frost susceptible material may be the cause of frost heave.

7.4.7 Roughness

- Roughness is defined as unevenness in the longitudinal profile. Criteria for evaluating runway roughness are given in AC 302-023 – Measurement and Evaluation of Runway Roughness. Roughness may be caused by loss of material, frost action or settlement.

7.4.8 Vegetation

- Uncontrolled vegetation growth may occur on the gravelled operational surface itself and/or in the graded area at the runway edge. Vegetation growth may be caused by poor drainage or accumulation of organic soils (earth) in the surface. Low traffic volume may also encourage vegetation growth.

8.0 Maintenance and Repair of Gravel Surfaces

- Gravel pavement surface maintenance primarily involves periodic grading to remove the surface irregularities developing with time and to re-establish grades for drainage purposes. Occasionally, new gravel has to be added to replace lost material. Dust suppression measures may also be needed during the summer months.

8.1 Gravel Replacement

- Material is gradually lost from gravel surfaces due to grading operations and the erosion effects of traffic, wind and rain, and thickness may be lost from contamination by the subgrade soil. As a rule of thumb and depending on the number of aircraft movements and the type of traffic, runways surfaced with uncrushed gravel lose thickness at an average rate of 25 mm (1 inch) per year and runways surfaced with crushed gravel lose material at about half that rate.

- Depending on the conditions and rate of loss, the periodic addition of new material to the gravel surface is required to replace granular material that has been worn, blown, eroded or driven into the subgrade soil.

- The repair materials should be (natural or artificial) mixtures of gravel, stone, or slag and soil proportioned to meet the requirements specified. The aggregate should consist of clean, hard and durable particles of crushed or uncrushed gravel, stone or slag, and be free from soft, thin elongated or laminated particles, organic or other deleterious substances.

- The gradations of material for re grading and maintaining gravel surfaces historically used by Transport Canada as owner and operator of airports are specified in Appendix A, Table 1 of this AC. If the pavement subgrade and surface are properly shaped and compacted, these gradations should result in a gravel surface requiring minimum maintenance. Other airport operating authorities may have different gradation specifications depending on site conditions. A maintenance stockpile of gravel meeting the specified gradations should normally be available on site where aircraft operational surfaces are gravel.

- The high percentage of fines passing the 0.075 mm sieve (as given in Appendix A, Table 1 of this AC) is for maintenance purposes only, and is intended to compensate for the fine material lost by wind, traffic and/or surface runoff. A lower percentage of fines should be used when specifying aggregates materials for runway construction and/or reconstruction projects.

8.2 Grading and Compaction

- Gravel surfaces should be graded and compacted as soon as conditions permit following the spring thaw and preferably again in the fall in preparation for winter operations. Additional grading and compaction may be required during the summer months depending on the rate of surface degradation experienced under site weather and traffic conditions.

- Maintenance of gravel surfaces should include grading at intervals sufficient to maintain pavement smoothness as well as the longitudinal and transverse slopes. Maintenance activities following the spring thaw should include extensive grading which may involve the cutting to depth of any pothole or ruts and re-shaping and compacting the surface. Grading and re-shaping at other than the springtime should be conducted following a period of precipitation when the surface is moist. Minor grading during dry periods should be used to maintain a uniform gravel thickness.

- Grading should be planned in conjunction with, or following the cleaning and re-shaping of ditches, culvert cleaning, etc. Low spots, trapping or impeding the flow of water should be graded out. These areas should be the first priority for re-grading and levelling.

- Surface grading should not cause any abrupt changes to the gradient and every effort should be made to maintain grades as close to the original design as possible.

- Grading operations should elimi¬nate surface depressions, ruts, soft spots and potholes. During normal grading operations, the surface is scarified to the depth of these depressions and the material blended and re-compacted. Care should be taken to perform the grading operation in such a manner that the blade is always parallel to the desired slope of the surface, thus ensuring that the pavement course being graded will have the necessary slope for run off of surface water.

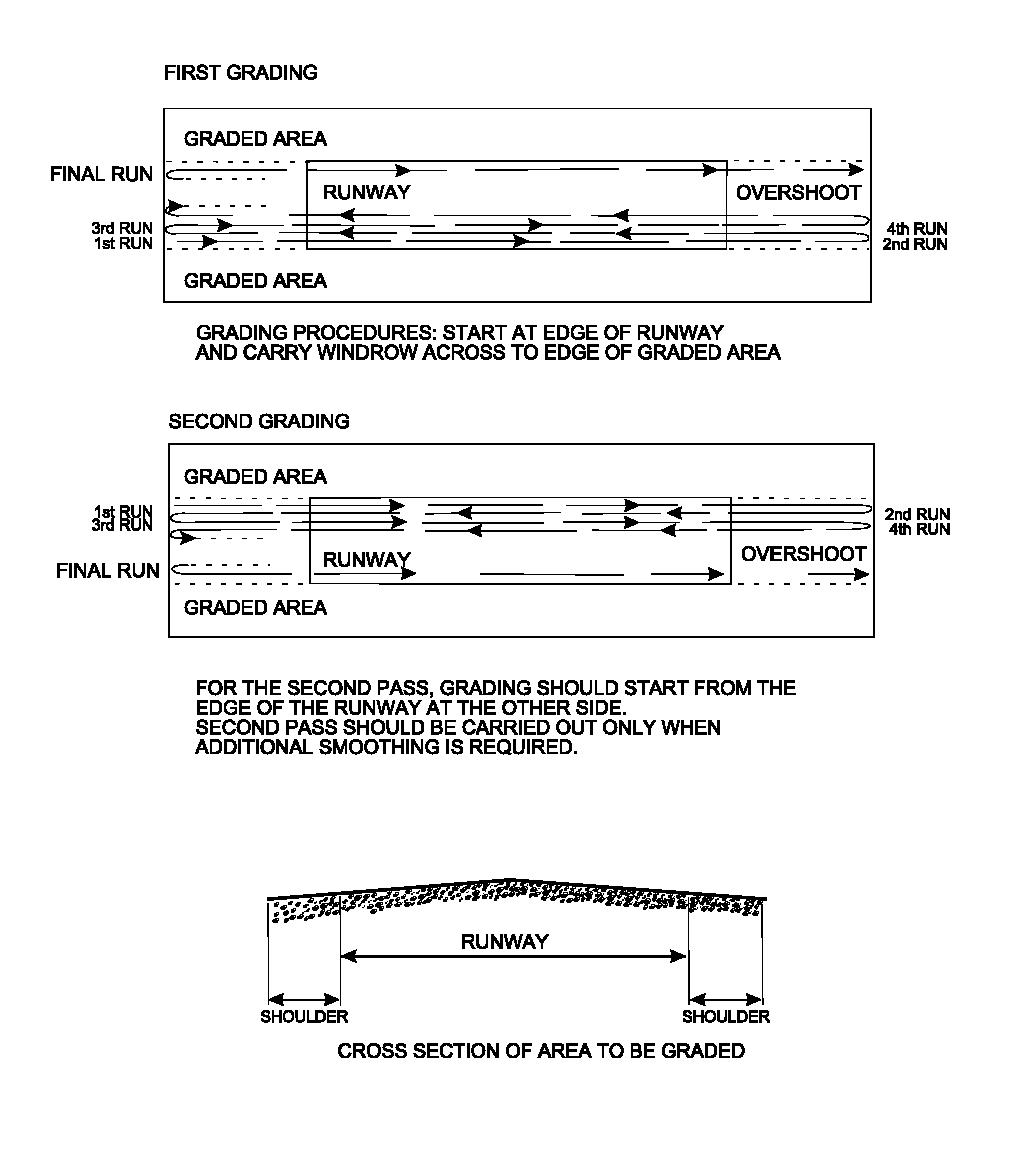

- For runways, the surface should be graded to re establish the design grade with sufficient cross-slope to achieve satisfactory drainage and the smooth surface necessary for safe operation of aircraft. If the surface is graded from the crown to the edge, eventually the crown will diminish. To maintain a correct and full crown, grading should proceed from runway edge to runway edge across the crown. The next grading should be started on the runway side opposite to the previous grading. The final pass with the grader should not leave a windrow but a reasonably level surface (see Appendix B, Figure 3 of this AC for the recommended method of grading gravel runways).

- The amount of surface material removed by the grader should be minimal. Any large stones that are pushed to the edge should be removed. Runway grading should extend beyond the runway lights to include all portions of the graded area where snow removal will be carried out. Stones that are partially uncovered during grading should be dug up and removed.

- New material, when added during the grading operation, should be incorporated into a loosened surface and the resulting mixture compacted in 50 to 75 mm (2 to 3 inch) homogeneous lifts. Because it ensures bonding between layers, this method is preferred as opposed to simply adding new material to an existing surface. The addition of fresh gravel should replace lost fines and fill local depressions such as those frequently experienced in aircraft run up areas near the runway threshold.

- Following grading operations or graveling and grading, the surface should be compacted using a roller when the surface is at its optimum moisture content (i.e., when the material squeezed in the palm of the hand will "cake" without showing any free water). Rolling after a rain shower or spraying the surface with water from a tanker truck will ensure the best results.

- Following compaction, the surface should be smooth, close to line and grade when measured with a 5 metre (16.4 ft) straight edge and free of loose stones greater than 25 mm (1 inch). Depressed areas, which occur during the rolling operations, should be lightly loosened, new material added and compacted.

8.3 Dust Control

- Depending on operational requirements and the severity of dust problems, dust suppression measures may be needed during the summer months.

- Calcium chloride and other salt-based materials used for dust control on roads and highways are not to be used on airside pavements due to the corrosive nature of these chemicals and their potential damaging effect on aircraft components.

- Light asphalt such as slow curing liquid asphalt SC-70 or slow setting emulsified asphalt SS-1 can be sprayed at a rate of 0.5 to 3.0 litres per square metre. When an emulsion is used, it should be diluted with up to 5 parts of water by volume. Local authorities may not permit the use of light asphalt because of its impact on the environment.

- If a high percentage of clay is prevalent in the surface, "road oils" can be applied at a rate of 0.5 litres per square metre to avoid trapping too much moisture and softening the surface. Care should be taken not to apply an excessive quantity of oil that could be washed into adjoining drainage systems and pollute nearby streams. Local pollution control authorities may not permit the use of reclaimed engine oil.

- Other types of dust palliatives are commercially available and their use depends on cost and local experience with respect to effectiveness. Materials used should be demonstrated to be non-corrosive relative to aircraft materials. Information on required test specifications can be obtained from the major aircraft manufacturers.

9.0 Maintenance and repair of turf landing strips

- Turf landing strips should be maintained in a manner consistent with the intent of this section to ensure the safe operation of aircraft. Due to the variety of climatic and soil conditions in Canada, precise detailed maintenance instructions are not provided here.

9.1 Normal Maintenance

- To keep a grass airstrip in good operational condition, a good growth and a uniform grass cover should be maintained to minimize potential damage by erosion. The following preventive maintenance activities should be performed to ensure that these requirements are met:

- Fertilizing and aerating the soil annually;

- Maintaining the grass height in a range of 5 to 10 cm (2 to 4 inches);

- Keeping the grass free of noxious weeds.

9.2 Spring Maintenance

- Turf airstrips should be rolled each spring while the soil is still moist. The roller weight should be selected such that the grass plants displaced by frost heave return to their original position after rolling. The use of the appropriate roller weight at the appropriate soil moisture conditions is important since a heavy roller can inflict serious damage to the grade and soil structure. Over compaction may reduce the ability of the soil to drain water. In addition, a heavy roller may cause rutting and/or displacement of the soil. On the other hand, rolling soil that is too dry will have little or no effect.

- A longitudinal rolling pattern should be used, starting at one end of the strip and proceeding towards the opposite end with successive passes being made parallel to the centreline of the strip.

- Stones or rocks greater than 4 mm (0.2 inches) in size should be raked and removed. Rocks initially below the surface may be raised to the surface by frost action.

- Areas in which there is winter kill, wheel ruts or other irregularities in the grade should be brought to a loose and friable condition. Topsoil added to bring these areas to grade should be mixed with existing soil before rolling, seeding or sod placement is carried out. In areas where large quantities of material are required (due to erosion for example), the replacement of subsoil may be necessary before adding topsoil.

9.3 Seeding

- Seeding and over-seeding are sometimes required to repair damaged areas or to reinforce the grass. The grass mixture to be employed should be selected to meet the following requirements:

- The grass should not grow in tufts;

- The grass should spread rapidly forming a well-knitted turf; and

- The grass should grow under dry, sunny conditions.

- Since the type, variety and mixtures of seed can vary according to site location and climatic conditions, an agricultural representative should be consulted to determine the most appropriate mixture to use. Suggested base seed mixtures are:

- Creeping Red Fescue: 60 to 70%;

- Kentucky Blue Grass: 20 to 30%; and

- Perennial Rye Grass: 10%.

9.4 Drainage

- To provide effective drainage, a definite uniform grade should be maintained. A strip with a centreline crown and a transverse slope of 2 to 2.5 % is preferred (reference section 3.1.2.6 of TP 312 5th Edition). For subsurface drainage, the strip should have a sand or gravel base. In areas of ponding or wet spots, the longitudinal or transverse grade should be re established. Water from areas adjacent to the strip should be prevented from reaching and/or crossing the strip. A good ditching system is recommended and the ditches should be kept free of debris, silt, and weeds.

9.5 Winter Maintenance

- If the landing strip is to be used in winter, a compacted snow surface should be established that is sufficiently hard to support aircraft without rutting. Successive snowfall can then be removed from the compacted surface. Snow compacted airstrips may require the use of a surface edge marking. During the spring run-off, the grass surface has to be allowed to dry. Operations should be curtailed until the surface is dry and able to support an automobile.

9.6 Operations

- Markers for ease of identification from the air should outline turf strips. The type of markers and locations to be used should conform to the standards outlined in TP 312 5th Edition.

10.0 Information Management

- Not applicable.

11.0 Document history

- Advisory Circular (AC) 300-004 Issue 01, RDIMS 6571515 (E), 6836758 (F), dated 2012-03-16 - Unpaved Runway Surfaces.

- Advisory Circular (AC) 300-004 Issue 02, RDIMS 8786183 (E), 8785880 (F), dated 2013-12-02 – Unpaved Runway Surfaces.

- Advisory Circular (AC) 300-004 Issue 03, RDIMS 11300951 (E), 11302845 (F), dated 2016-02-05 – Unpaved Runway Surfaces.

12.0 Contact office

For more information, please contact:

https://tc.canada.ca/en/corporate-services/regions

Suggestions for amendment to this document are invited, and should be submitted via:

TC.FlightStandards-Normsvol.TC@tc.gc.ca

Original signed by

Robert Sincennnes

Director, Standards

Civil Aviation

Appendix A - Table 1

| Gravel Replacement Material Gradation or Mixture | |

|---|---|

| Sieve Size (mm) | Percentage by Weight Passing Sieves |

| 25 | 100 |

| 19 | 70-100 |

| 2.00 | 40-70 |

| 0.425 | 20-45 |

| 0.075 | 10-20 |

Appendix B — Figures 1 to 3

Figure 1: Tire Pressure Restriction vs. CBR Measured with Boeing Penetrometer

(Figure 1 derived from Boeing Document No. D6-45222-1)

Figure 2: Condition Rating Form for Gravel Surfaces

Figure 3: Gravel Runways Recommended Method of Grading

AC 300-004 - Unpaved Runway Surfaces

(PDF, 312 KB)