Subject: Global Reporting Format (GRF) for Runway Surface Conditions

| Issuing Office: | Civil Aviation, Standards |

|---|---|

| Document No.: | AC 300-019 |

| File Classification No.: | Z 5000-34 |

| Issue No.: | 02 |

| RDIMS No.: | 15565688-V62 |

| Effective Date: | 2021-02-21 |

Table of contents

- 1.0 Introduction

- 2.0 References and requirements

- 3.0 Background

- 4.0 Components of the global reporting format (GRF) in Canada

- 5.0 Reporting criteria for aircraft movement surface condition report (AMSCR)

- 5.1 General

- 5.2 Direction of report

- 5.3 Reporting by runway thirds

- 5.4 Runway surface descriptions

- 5.5 Percent coverage

- 5.6 Depth assessments

- 5.7 Number of runway surface descriptions that may be reported

- 5.8 Wet runways

- 5.9 Standing water

- 5.10 Slippery when wet

- 5.11 Unpaved and partially paved runways

- 5.12 Cleared width

- 5.13 Conditions on remaining width of runway

- 6.0 Runway condition assessment matrix (RCAM)

- 7.0 Process to determine the RWYCC

- 8.0 Other reported runway condition information

- 9.0 Additional non-GRF/TALPA information

- 10.0 Taxiway and apron information

- 11.0 General remarks

- 12.0 Order of reported runway condition information

- 13.0 Requirements to issue an AMSCR

- 14.0 Validity period

- 15.0 Examples of runway surface condition (RSC) NOTAM

- 16.0 Conclusion

- 17.0 Information management

- 18.0 Document history

- 19.0 Contact us

- Appendix A — Preliminary RWYCC single contaminant decision process

- Appendix B — Preliminary RWYCC multiple contaminant decision process

- Appendix C — Full process to determine the RWYCC

- Appendix D — Example illustrating significant change

- Appendix E — Training

1.0 Introduction

(1) This Advisory Circular (AC) is provided for information and guidance purposes. It provides guidance with respect to section 302.417 of the Canadian Aviation Regulations (CARs) – Movement Area Inspections and Reports and section 322.417 of the Airport Standards — Airport Winter Maintenance in consideration of upcoming changes related to the Canadian implementation of the International Civil Aviation Organization (ICAO) Global Reporting Format (GRF). This AC on its own does not change, create, amend or permit deviations from regulatory requirements, nor does it establish minimum standards.

1.1 Purpose

(1) The purpose of this document is to introduce and explain the forthcoming Canadian implementation of the GRF for runway surface condition reporting. The Canadian implementation of GRF is based on the Take-off and Landing Performance Assessment (TALPA) methodology which was developed by the United States Federal Aviation Administration (FAA).

(2) This document is also being made available to the aviation industry for the purpose of conveying flight safety information. All aerodrome personnel involved with runway condition assessment should be aware of the forthcoming implementation of the new GRF for runway condition reporting. These personnel are encouraged to utilize this AC to assist them in reviewing this topic and to determine the applicability to their specific operations.

1.2 Applicability

(1) This document is applicable to:

- (a) Canadian airport operators holding an Airport Certificate issued pursuant to Part 3 of the Canadian Aviation Regulations (CARs);

- (b) Canadian aerodrome operators;

- (c) Transport Canada Civil Aviation (TCCA) inspectors with certification and safety oversight responsibilities; and

- (d) This document is also available to the aviation industry at large for information purposes. Its contents is of particular interest to:

- (i) Canadian pilots, flight dispatchers, air operators and private operators as well as foreign air operators, and

- (ii) Individuals and organizations that exercise privileges granted to them under an External Ministerial Delegation of Authority.

1.3 Description of changes

(1) The guidance in this document has been extensively modified in consideration of feedback from industry stakeholders, including NAV Canada, resulting from the GRF winter trials which occurred during the winter of 2019-2020. These changes are numerous and affect all parts of the document and therefore are not itemized individually here. Airport and aerodrome operators should review this document in its entirety to ensure familiarity with all changes.

2.0 References and requirements

2.1 Reference documents

(1) It is intended that the following reference materials be used in conjunction with this document:

- (a) Aeronautics Act (R.S.C., 1985, c. A-2)

- (b) Part III, Subpart 01 of the Canadian Aviation Regulations (CARs) — Aerodromes;

- (c) Part III, Subpart 02 of the CARs — Airports;

- (d) Transport Canada Publication, TP 312, 5th Edition — Aerodrome Standards and Recommended Practices;

- (e) Advisory Circular (AC) 300-005 — Changes to Runway Surface Condition Reporting;

- (f) AC 302-017 — Runway Friction Measurement;

- (g) NAV CANADA - Canadian NOTAM Operating Procedures; (CNOP)

- (h) Federal Aviation Administration AC 150/5200-28F, 2016-12-30 — Notices to Airmen (NOTAMs) for Airport Operators;

- (i) FAA AC 150/5200-30D, 2018-03-08 — Airport Field Condition Assessments and Winter Operations Safety;

- (j) International Civil Aviation Organization (ICAO) Annex 14 to the Convention on International Civil Aviation — International Standards and Recommend Practices: Aerodromes – Volume I Aerodrome Design and Operations (Eighth Edition, July 2018);

- (k) ICAO Circular 355– Assessment, Measurement and Reporting of Runway Surface Conditions;

- (l) ICAO Doc 9981 Procedures for Air Navigation Services – Aerodromes (Second Edition, 2016); and

- (m) ICAO Amendment 2 to Doc 9981 Procedures for Air Navigation Services, 2018-11-08 — Aerodromes.

- (n) ASTM 3188 – Standard Terminology for Aircraft Braking Performance

2.2 Cancelled documents

(1) Not applicable.

(2) By default, it is understood that the publication of a new issue of a document automatically renders any earlier issues of the same document null and void.

2.3 Definitions and abbreviations

(1) The following definitions are used in this document:

- (a) Aircraft Movement Surface Condition Report: means a report that details the surface conditions of all movement areas at an airport, including runways and taxiways.

- (b) Canadian Runway Friction Index: means the average of the friction measurements taken on runway surfaces on which freezing or frozen contaminants are present.

- (c) Cleared width: means the narrowest portion of the runway width that has been cleared of loose contaminants. (See remaining width.)

- (d) Compacted snow: means snow that has been compacted into a solid mass such that aeroplane tires, at operating pressures and loadings, will run on the surface without significant further compaction or rutting of the surface.

- (e) Contaminant: means material that collects on a surface, including standing water, snow, slush, compacted snow, ice, frost, sand, and ice control chemicals.

- (f) Contaminated runway: A runway is contaminated when a significant portion of the runway surface area (whether in isolated areas or not) within the length and width being used is covered by one or more of the following substances: compacted snow, dry snow, frost, ice, slush, standing water, wet ice or wet snow.

- Note: Sand and ice control chemicals are also contaminants but are not included in the definition of contaminated runway because their effect on runway surface friction characteristics and the runway condition code cannot be evaluated in a standardized manner.

- (g) Dry: means a surface condition that is free of visible moisture, and has no observed contaminants.

- (h) Dry snow: means snow that does not contain sufficient water to allow the crystals to stick together or bond to a surface. (Dry snow, when compressed, falls apart, and a snowball cannot readily be made from it.)

- (i) Frost: means ice crystals formed from airborne moisture on a surface whose temperature is below freezing. Frost differs from ice in that the frost crystals grow independently and therefore have a more granular texture.

- Note 1: Below freezing refers to air temperature equal to or less than the freezing point of water (0°C).

- Note 2: Heavy frost that has noticeable depth may have friction qualities similar to ice and downgrading the runway condition code accordingly should be considered. If driving a vehicle over the frost does not result in tire tracks down to bare pavement, the frost may be of sufficient depth to consider a downgrade of the runway condition code.

- (j) Ice: means water that has frozen on a surface and includes the condition commonly known as black ice as well as the condition in which compacted snow has turned into a polished ice surface.

- (k) Ice control chemicals: means chemicals used to prevent ice formation, to prevent ice from bonding to a surface, or to break up or melt ice on a surface.

- (l) Paved surface: means a surface of asphaltic concrete (flexible) or Portland cement concrete (rigid).

- (m) Percent coverage: means the estimated amount of a condition or contaminant present on the surface of the runway.

- (n) Remaining width: means the un-cleared portion of the runway. (See cleared width.)

- (o) Runway Condition Assessment Matrix: means a matrix allowing for the assessment of runway condition code from a set of observed runway surface condition(s).

- (p) Runway Condition Code: means a number describing the runway surface condition.

- (q) Runway Surface Condition: means the portion of the AMSCR which reports the surface condition of the runway.

- (r) Sand: means small particles of crushed angular mineral aggregates or natural sand material used to improve runway surface friction levels.

- (s) Significant change: means a material change to the runway surface condition which may impact the operational performance of the surface. Significant changes can include: changes in type of condition or contaminant, such as from dry snow to wet snow; measurable changes in depth of condition or contaminant; following the application or removal of sand or chemicals; following snow removal or sweeping; changes in conditions caused by rapid increases or decreases in temperature.

- (t) Slippery when wet runway: means a wet runway where the surface friction characteristics of the runway have been determined to be degraded.

- Note: A runway or any portion of a runway is deemed as having low friction (e.g. due to rubber accumulation, surface texture degradation, etc.) when the friction measurements (as measured by a continuous friction measuring device in accordance with AC 302-017) are below the minimum coefficient of friction specified in TP 312.

- (u) Slush: means partially melted snow or ice, with a high water content, from which water readily flows. (Slush will spatter if stepped on forcefully, and water will drain from slush when a handful is picked up.)

- (v) Snowbank: means a heap or mound of snow created mechanically that is higher than the surrounding snow cover, and is located:

- (i) next to or on the edge of a runway or taxiway; and/or

- (ii) next to or on the edge of the cleared area of a runway or taxiway

- Note: ‘Snowbank’ is used to describe accumulations which will remain over longer time periods; see ‘Windrow’ for shorter-term accumulations, such as those resulting from clearing operations in progress.

- (w) Snow drift: A heap or mound of snow created by action of the wind.

- (x) Standing water: means water of depth greater than 1/8 inch (3mm).

- (y) Take-off and Landing Performance Assessment: means a method of reporting runway conditions (which relates to aeroplane performance), developed by the US FAA, which is intended to reduce the risk of runway excursions.

- (z) Wet: means a surface condition where there is any visible dampness or water up to and including 1/8 inch (3mm) deep.

- (aa) Wet ice: means ice with water on top of it or ice that is melting.

- (bb) Wet snow: means snow that will stick together when compressed but will not readily allow water to flow from it if squeezed. (Wet snow contains enough water to be able to make a well-compacted, solid snowball, but water will not squeeze out.)

- (cc) Windrow: means a ridge of material, such as snow or gravel, created by airside maintenance equipment.

- Note: A windrow is typically temporary in nature, having been formed during clearing operations with the intent of subsequent removal in the near-term (either ploughed/swept to the runway edge or graded for gravel runways).

(2) The following abbreviations are used in this document:

- (a) AC: Advisory Circular

- (b) AMSCR: Aircraft Movement Surface Condition Report

- (c) ASTM: American Society for Testing and Materials

- (d) ATS: Air Traffic Services

- (e) AWMS: Airport Winter Maintenance Standard

- (f) CARs: Canadian Aviation Regulations

- (g) CL: Centreline

- (h) CRFI: Canadian Runway Friction Index

- (i) FAA: Federal Aviation Administration

- (j) GRF: Global Reporting Format

- (k) ICAO: International Civil Aviation Organization

- (l) NOTAM: Notice to Airmen

- (m) NR: Not Reported (applies to CRFI reports)

- (n) PIREP: For the purpose of this AC, PIREP means a pilot report of braking action which reflects the pilots' assessment of the available wheel braking.

- (o) RCAM: Runway Condition Assessment Matrix

- (p) RSC: Runway Surface Condition

- (q) RVR: Runway Visual Range

- (r) RWY: Runway

- (s) RWYCC: Runway Condition Code

- (t) TALPA: Takeoff and Landing Performance Assessment

- (u) TCCA: Transport Canada Civil Aviation

- (v) TP: Transport Canada Publication

- (w) TWY: Taxiway

3.0 Background

(1) The International Civil Aviation Organization (ICAO) has developed a new globally harmonized methodology for runway condition assessment and reporting. This internationally accepted methodology is called the Global Reporting Format (GRF). The implementation date for GRF in Canada is August 12th, 2021.

(2) The philosophy of the GRF is that the airport operator assesses the runway surface conditions whenever water, snow, slush, ice or frost are present on an operational runway. From this assessment, a runway condition code (RWYCC) and a description of the runway surface are reported which can be used by the flight crew for aeroplane performance calculations. This format, based on the type, depth and coverage of contaminants is the best assessment of the runway surface condition by the airport operator. All other pertinent information should also be taken into consideration. When changes in conditions occur, they should be reported without delay.

(3) The RWYCC reflects the expected braking capability as a function of the surface conditions. With this information, the flight crews can derive, from the performance information provided by the aeroplane manufacturer, the landing distance of an aeroplane under the existing conditions. When a RWYCC is not provided, pilots reference the reported runway surface description (condition or type and depth of contaminant) to determine expected landing performance.

(4) Flight crews utilize the reported runway surface description (condition or type and depth of contaminant) when determining their aeroplane’s expected take-off performance.

(5) In preparation for the implementation of GRF in Canada, Transport Canada Civil Aviation (TCCA) has developed the new runway condition reporting methods which are described in this AC.

(6) Canadian implementation will meet the intent and important safety elements of the GRF and will also provide some enhancements. One of the main differences from the ICAO format is the ability to report two runway surface descriptions (condition or type and depth of contaminant) per runway third. The option to report two runway surface descriptions will harmonize the reporting in North America. This approach provides more flexibility for airports or aerodromes, where RWYCCs will not be reported. It also gives pilots more detailed information for the purpose of making take-off performance calculations.

(7) NAV CANADA is updating its technology and software to meet these new TCCA requirements.

4.0 Components of the global reporting format (GRF) in Canada

4.1 General

(1) The Global Reporting Format (GRF) is an internationally accepted concept which utilizes a consistent method to report runway surface conditions. The GRF consists of five fundamental elements:

- (a) Aircraft movement surface condition report (AMSCR) and Runway Surface Condition (RSC) NOTAM;

- (b) Runway condition assessment matrix (RCAM);

- (c) Runway condition code (RWYCC);

- (d) Runway surface conditions and

- (e) Runway surface descriptions.

4.2 Aircraft movement surface condition report (AMSCR) and runway surface condition (RSC) NOTAM

(1) Consistent with the principles of the GRF, the AMSCR and RSC NOTAM have been specially designed to align with the aeroplane performance information (based on TALPA methods) which is used by pilots.

4.3 Runway condition assessment matrix (RCAM)

(1) The RCAM is used to determine a runway condition code from a set of observed runway surface condition(s).

(2) Details respecting the RCAM are provided in Section 6 of this AC.

4.4 Runway condition code (RWYCC)

(1) The Assessment Criteria consist of Runway Surface Descriptions which are used to determine the Runway Condition Code (RWYCC).

(2) Flight crews use the final RWYCC for determining the landing performance of their aeroplane. (The RWYCC is not utilized for determining aeroplane takeoff performance.)

(3) The process for determining the RWYCC is provided in Section 6 of this AC.

4.5 Runway surface conditions

(1) There are four defined runway surface conditions:

- (a) Dry runway;

- (b) Wet runway;

- (c) Slippery when wet runway; and

- (d) Contaminated runway.

(2) The runway surface conditions are further sub-divided into runway surface descriptions, which describe the specific details of a runway surface.

(3) The runway surface descriptions, including depth and temperature (when applicable), are used to determine the preliminary RWYCC

(4) Information on runway surface descriptions is provided in Section 5.4.

5.0 Reporting criteria for aircraft movement surface condition report (AMSCR)

5.1 General

(1) The following sections describe the data fields for the runway condition information to be included in the new Aircraft Movement Surface Condition Report (AMSCR) format.

(2) To harmonize the data being entered into the software, each data field has a range of acceptable entries (parameters). This results in some constraints for some of the items reported by the individual inspecting the runway.

5.2 Direction of report

(1) When runway condition information is reported for each third of the runway, as described in Section 5.3, the RSC NOTAM will include two reports; one for each runway direction (i.e. RSC RWY 07 and RSC RWY 25). This provides information to pilots which is oriented in their direction of flight.

(2) When runway condition information is reported by full runway length (i.e. not in thirds), the NOTAM will provide a single report for the runway pair, as per the previous practice (e.g. RSC RWY 07/25).

(3) The airport or aerodrome operator will only complete one AMSCR per runway pair (e.g. RWY 07/25), regardless of whether or not the NOTAM will present this information by:

- (a) runway thirds (with two reports; one for each runway direction); or

- (b) full runway length (with a single report for the runway pair).

5.3 Reporting by runway thirds

(1) The runway condition information will normally be entered for each third of the runway. Reporting the runway condition information in thirds provides useful information for pilots. This format allows pilots to identify where conditions or contaminants are located on a runway and where the biggest impact on aeroplane performance may exist.

(2) In consideration of the types of aircraft operating at airports or aerodromes, the operator may choose to report full runway length (i.e. not to report by runway thirds). All other input parameters will be the same.

(3) The decision whether or not to report by runway thirds or by full runway length should be made in consultation with the airport/aerodrome users. To minimize confusion, the reporting methodology needs to remain consistent within the season.

Note: Subsections 302.406(1) and 302.410(1) of the CARs require airport operators to consult with a representative sample of the air operators that use the airport.

(4) An airport or aerodrome operator may choose to report a runway(s) in thirds and choose to report another runway(s) by full runway length. This would typically be the case where:

- (a) longer runways serving larger aircraft would normally be reported in thirds; and

- (b) shorter runways serving smaller aircraft would normally be reported by full runway length.

(5) When runway condition information is reported in thirds a RWYCC is to be reported. Conversely, if the runway condition information reported by full runway length, then the RWYCC will not be reported.

(6) Reporting by runway thirds is not applicable for unpaved runways (gravel, turf, etc.).

(7) There is no specific regulatory link between the requirements for reporting CRFI in thirds and the criteria for reporting runway surface conditions in thirds. Information on Canadian Runway Friction Index (CFRI) reports, including an explanation of the circumstances when CRFI reports must be provided in thirds, are detailed in Section 9.

5.4 Runway surface descriptions

(1) The following terms will be used to describe the runway surface condition for each runway third or for the full runway length:

- (a) COMPACTED SNOW

- (b) DRY

- (c) DRY SNOW

- (d) DRY SNOW ON TOP OF COMPACTED SNOW

- (e) DRY SNOW ON TOP OF ICE

- (f) FROST

- (g) ICE

- (h) SLIPPERY WHEN WET

- (i) SLUSH

- (j) SLUSH ON TOP OF ICE

- (k) STANDING WATER

- (l) WATER ON TOP OF COMPACTED SNOW

- (m) WET

- (n) WET ICE

- (o) WET SNOW

- (p) WET SNOW ON TOP OF COMPACTED SNOW

- (q) WET SNOW ON TOP OF ICE

5.5 Percent coverage

(1) The percent coverage is reported using the increments listed in Table 1. If the assessed percent coverage is between increments, it should be rounded up as indicated.

| Assessed Percent Coverage | Reported Percent Coverage |

|---|---|

| 1 - 10 | 10 PCT |

| 11 – 20 | 20 PCT |

| 21 – 25 | 25 PCT |

| 26 – 30 | 30 PCT |

| 31 – 40 | 40 PCT |

| 41 – 50 | 50 PCT |

| 51 – 60 | 60 PCT |

| 61 – 70 | 70 PCT |

| 71 – 75 | 75 PCT |

| 76 – 80 | 80 PCT |

| 81 – 90 | 90 PCT |

| 91- 100 | 100 PCT |

Note: When assessing percentage of coverage, airport and aerodrome operators should be aware that the NAV CANADA software limits the total percentage of contaminants from exceeding 100%.

(2) Where some sections of the runway or sections of a runway third are not wet or contaminated (i.e. are DRY), the reported runway conditions and contaminants are not required to add up to 100%. For example:

- (a) If 50% of the runway third is covered with half an inch of DRY SNOW and the other 50% is DRY, this will be reported as “50 PCT 1/2IN DRY SNOW”.

- (b) If 50% of the runway third is covered with half an inch DRY SNOW, 25% is covered with ICE, and the remaining 25% is DRY, this will be reported as “50 PCT 1/2IN DRY SNOW AND 25 PCT ICE.”

Notes:

- 1) In both of the above examples DRY is not reported; this is a change from the previous practice.

- 2) The reasons for reporting DRY conditions are provided in 5.7(3).

5.6 Depth assessments

(1) Contaminant depths will continue to be reported in inches and fractions of inches, as illustrated in Table 2, below.

| Assessed Depth | Reported Depth |

|---|---|

| 1/8 inch or less | 1/8IN |

| > 1/8 inch to and including 1/4 inch | 1/4IN |

| > 1/4 inch to and including 1/2 inch | 1/2IN |

| > 1/2 inch to and including 3/4 inch | 3/4IN |

| > 3/4 inch to and including 1 inch | 1IN |

| > 1 inch to and including 1 ½ inches | 1 1/2IN |

| > 1 ½ inch to and including 2 inches | 2IN |

Note: At depths greater than two inches, the depth is rounded up and reported as the nearest whole number (e.g. an actual depth of two and a half inches is reported as 3IN).

(2) When the depth of contaminant(s) is variable:

- (a) the maximum depth should be entered, since only one value may be entered in this field, and the maximum depth is the most important information for pilots; and

- (b) the remarks section may be used to report a range of values for depth.

(3) Contaminant depths will be reported for:

- (a) STANDING WATER;

- (b) SLUSH;

- (c) DRY SNOW;

- (d) WET SNOW; and

- (e) Combinations of contaminants where a loose contaminant (DRY SNOW, WET SNOW, SLUSH or STANDING WATER) overlies a hard contaminant (COMPACTED SNOW or ICE). In these cases, the depth of the loose contaminant is to be reported.

(4) For STANDING WATER, 1/4 inch is the minimum depth which can be reported. When the water depth is 1/8 inch or less, the runway is reported to be WET.

5.7 Number of runway surface descriptions that may be reported

(1) The number of runway surface descriptions that may be reported for each runway third is limited to two. Similarly, when the runway is reported by full runway length, the number of runway surface descriptions reported for the entire runway is also limited to two.

(2) If more than two conditions or contaminants are present, only the two most prevalent are reported. Other factors that may be taken into consideration in determining which two runway surface descriptions to report, include:

- (a) the location of the condition or contaminant on the runway; and

- (b) the slipperiness of the condition or contaminant, which is reflected in the corresponding RWYCC.

(3) A “DRY” runway surface condition should be reported:

- (a) when there is need to report wet or contaminated conditions on the remainder of the surface. This would be the case when a runway third(s) is 100% DRY and:

- (i) there are contaminants in other runway third(s), or

- (ii) the other runway third(s) is wet; or

- (b) the cleared width is less than the published width and the cleared portion of the runway is 100% DRY;

- (c) when a significant change has occurred. For example when a runway third(s) reported as RWYCC 5 is now RWYCC 6; and

- (d) when a runway(s) at an aerodrome is DRY and another runway(s) at the same aerodrome is reported to be wet or contaminated.

5.8 Wet runways

(1) As per the previous practice, airport and aerodrome operators are to report “WET” conditions associated with winter contaminants. Additionally, when a runway has been treated with chemicals to mitigate a specific contaminant and the resulting surface is now “WET,” this condition is also to be reported.

Note: Section 6.4 provides information on RWYCCs.

(2) The timely and accurate reporting of conditions when water or moisture is present on the runway is recognized to be challenging. For example, during an active thunderstorm a runway may rapidly transition from dry, to wet (water 1/8 inch or less) to contaminated with standing water (water greater than 1/8 inch), in a very short period of time. In addition, variations in the drainage capabilities of a runway and/or portions of a runway further complicate accurate reporting. Therefore, airport or aerodrome operators may not be able to report these conditions.

Text version - Figure 1

Figure 1 is a photo taken at an airport that displays an active, passing thunderstorm. The photo illustrates that during an active thunderstorm, a runway may rapidly transition from dry, to wet, to contaminated with standing water in a very short period of time. The photo displays the accumulation of standing water on an airport’s paved surface, a portion of clearing blue sky and the presence of passing cumulonimbus clouds.

(3) Where practicable, the reporting of wet runway conditions (which are not associated with winter contaminants and/or chemical treatments) is encouraged.

(4) When an airport or aerodrome operator reports water or moisture on a runway, the following should be considered:

- (a) A surface condition where there is any visible dampness or water up to and including 1/8 inch (3mm) is reported as “WET.”

- Note: A damp runway that meets this definition is considered wet, regardless of whether or not the surface appears reflective. This is a change from past practices, where a distinction was made for runways which were not dry, but were not reflective.

- (b) A surface condition where there is water of depth greater than 1/8 inch (3mm) is reported as “STANDING WATER” as described in Section 5.9, below .

(5) The reporting of “SLIPPERY WHEN WET” runway conditions is described in Section 5.10, below.

(6) The reporting of standing water patches (localized standing water conditions – such as puddles or pools of water) is described in Section 8.3.

5.9 Standing water

(1) Water on a runway at a depth greater than 1/8 of an inch (3mm) is reported as “STANDING WATER.”

Note: Section 6.4 provides information on RWYCCs.

(2) As discussed in Section 5.8, due to the dynamic nature of rainfall conditions, the timely and accurate reporting of conditions when water or moisture is present on the runway, is recognized to be challenging.

(3) Where practicable, the reporting of standing water is encouraged.

(4) To facilitate the accurate reporting of standing water, airport and aerodrome operators should also be aware of the conditions which would lead to the accumulation of standing water including:

- (a) the drainage characteristics of their runways, and

- (b) the rate and amount of precipitation.

5.10 Slippery when wet

(1) A runway or any portion of a runway is deemed as having low friction (e.g. due to rubber accumulation, surface texture degradation, etc.) when the friction measurements (as measured by a continuous friction measuring device in accordance with AC 302-017) are below the minimum coefficient of friction specified in TP 312 – Aerodrome Standards and Recommended Practices.

(2) A normal NOTAM (as opposed to a RSC report) which states that a runway may be “slippery when wet” is issued whenever the surface friction characteristics of a runway fall below the minimum standard, as described above in paragraph (1).

Note: The designation “slippery when wet” – when applied to a normal NOTAM – is a function of the friction characteristics of the pavement.

(3) The airport or aerodrome operator may cancel this normal “slippery when wet” NOTAM only when the runway friction level meets or exceeds the minimum standard.

(4) When there is a “slippery when wet” normal NOTAM in effect, runway conditions and contaminants on a runway are reported in the following manner:

- (a) for any visible dampness or water up to and including 1/8 inch (3mm) present on the runway, an AMSCR is issued with a runway condition of "SLIPPERY WHEN WET;”

- (b) with more than 1/8 inch (3mm) of water present on the runway, an AMSCR is issued with a runway condition of "STANDING WATER” with the corresponding percentage of coverage and depth (e.g. 25 PCT 1/4IN STANDING WATER); and

- (c) for all conditions and contaminants other than wet or standing water, an AMSCR is issued with the type of contaminant, with the percentage of coverage and depth (e.g. 25 PCT 3IN DRY SNOW).

- Note: As outlined in Sections 5.8 and 5.9, the reporting of water on a runway is acknowledged to be challenging; where practicable, the reporting of these conditions is encouraged.

(5) When there is a “slippery when wet” normal NOTAM in effect and there is a need to report a dry runway condition as outlined in Paragraph 5.7 (3), an AMSCR is issued with a runway condition of “DRY.”

(6) As per paragraph (5) above, when reporting in thirds and there is a “slippery when wet” normal NOTAM in effect, the runway surface conditions for each third will be reported as shown in the following examples:

- (a) If the first third of a runway had twenty percent coverage of an 1/8 inch or less water and the remaining runway thirds were dry, this would be reported as:

- SLIPPERY WHEN WET, DRY, DRY

- (b) If the first third of a runway had thirty percent coverage of 1/2 inch of water (more than 1/8 inch of water) and the last two thirds were wet, this would be reported as:

- 30 PCT 1/2IN STANDING WATER, SLIPPERY WHEN WET, SLIPPERY WHEN WET

- (c) If the first third of a runway had thirty percent coverage of a contaminant other than standing water such as 1/2 inch dry snow and the remaining thirds were dry, this would be reported as:

- 30 PCT 1/2IN DRY SNOW, DRY, DRY

(7) When reporting by full runway length (i.e. not by thirds) and there is a “slippery when wet” normal NOTAM in effect, the runway surface conditions for the runway will be reported as shown in the following examples:

- (a) If there is 1/8 of an inch or less water on any portion of the runway, this would be reported as:

- SLIPPERY WHEN WET

- (b) If there is thirty percent coverage of 1/2 inch of water (more than 1/8 inch of water) this would be reported as:

- 30 PCT 1/2IN STANDING WATER

- (c) If there is thirty percent coverage of a contaminant other than standing water such as 1/2 inch dry snow and the remainder of the runway is dry, this would be reported as:

- 30 PCT 1/2IN DRY SNOW

(8) The processes used to determine a RWYCC when there is a “slippery when wet” normal NOTAM in effect are described in Section 7.4.

5.11 Unpaved and partially paved runways

(1) RWYCCs will not be provided for unpaved or partially paved runways.

(2) The following additional information can be reported for unpaved and partially paved runways:

- (a) Graded (levelling of the runway surface);

- (b) Packed (compaction of the runway surface); and/or

- (c) Scarified (cutting of longitudinal grooves in the ice or compacted snow surface to improve directional control).

Note: A paved runway which is covered by ice may also be scarified, In this case, this information is entered as free text in Runway Remarks.

(3) Where applicable, airport and aerodrome operators should ensure that their facility’s entry in Canada Flight Supplement (CFS) includes the following information:

- (a) “Compacted snow and gravel mix during winter conditions” as a runway surface description; and/or

- (b) “Surface may be soft during freeze and thaw periods”

5.12 Cleared width

(1) If the cleared width is less than the published width, the width for which the runway conditions and RWYCCs apply is reported in feet.

Example: RSC 32 … 160FT WIDTH.

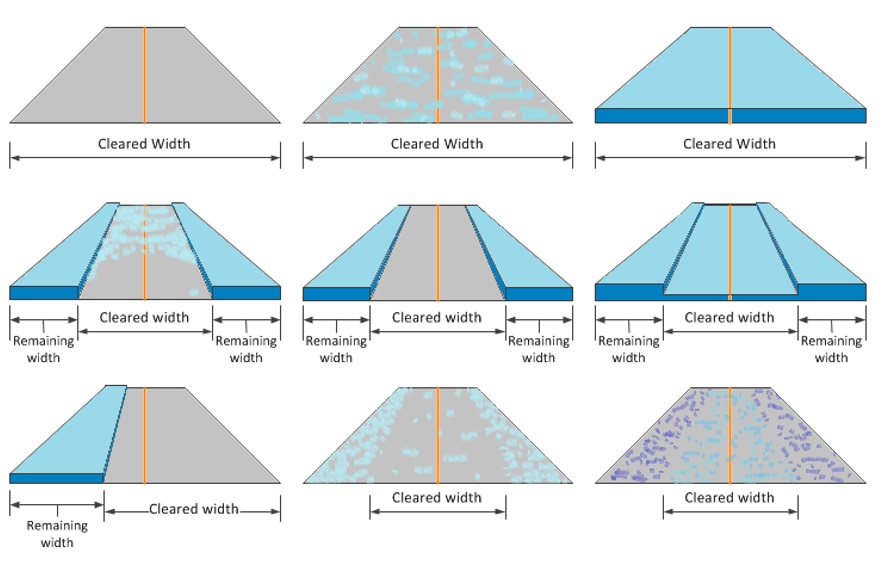

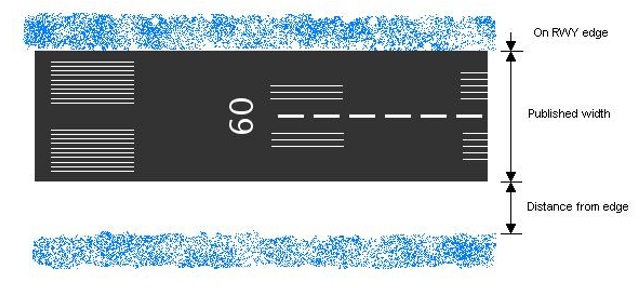

(2) Figure 2 illustrates various possibilities for cleared width.

Text version - Figure 2

Various cleared width and remaining width runway contamination scenarios are depicted.

(3) If the cleared width is not symmetrical about the runway centreline, the cardinal (or inter-cardinal) direction of the offset from the runway’s centreline is to be included in the RSC report.

Example: RSC 32 … 160FT WIDTH OFFSET NORTH.

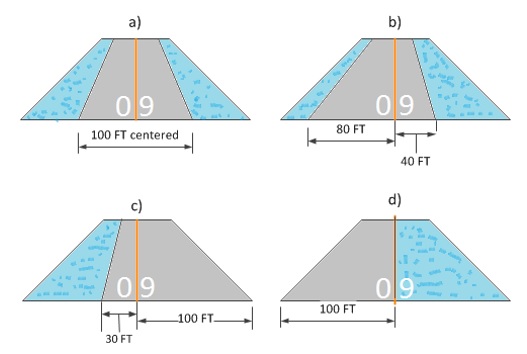

(4) Figure 3 depicts runways with an asymmetric cleared width. (Example a) is provided for comparison purposes.)

Text version - Figure 3

Various cleared width offset scenarios are depicted.

(5) Examples of reports corresponding to the illustrations in Figure 3 appear below:

- (a) RSC 09… 100FT WIDTH.

- (b) RSC 09… 120FT WIDTH OFFSET NORTH.

- (c) RSC 09… 130FT WIDTH OFFSET SOUTH.

- (d) RSC 09… 100FT WIDTH OFFSET NORTH.

5.13 Conditions on remaining width of runway

(1) The conditions on the un-cleared portion of the runway (i.e. remaining width) will continue to be reported by full runway length (i.e. not by runway thirds).

(2) Only one type of surface condition and corresponding depth, should be reported for the un-cleared width of the runway, where applicable.

Example: RSC 07… REMAINING WIDTH COMPACTED SNOW

(3) While contaminant depths may vary from the centre cleared portion to the remaining portions or edges of the runway, the condition of the outlying portions should not present an operational hazard.

6.0 Runway condition assessment matrix (RCAM)

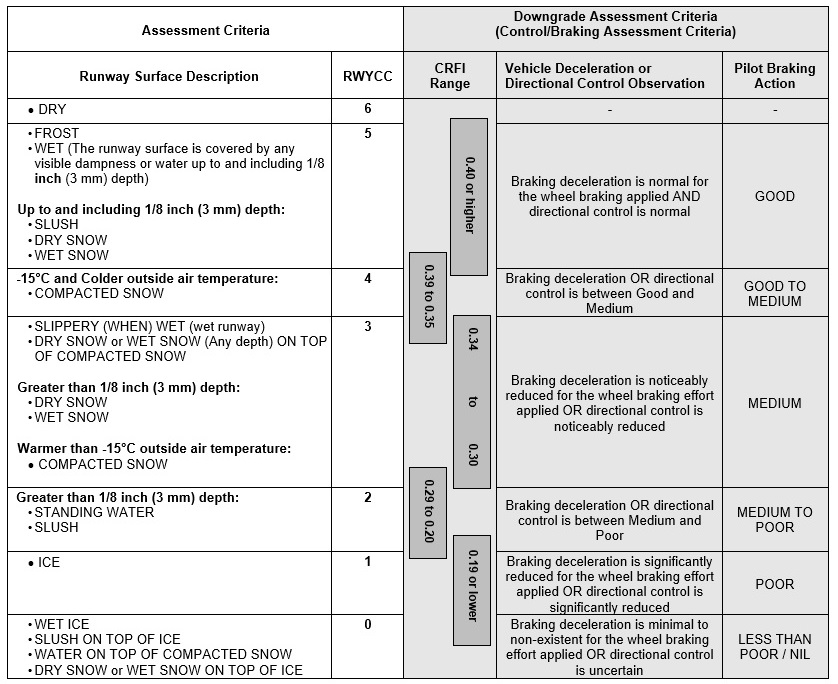

6.1 General

(1) The Runway Condition Assessment Matrix (RCAM) (Table 3) is the method by which the airport or aerodrome operator determines a preliminary Runway Condition Code (RWYCC) for each runway third, whenever water, snow, slush, ice or frost is present on the runway surface.

(2) The RCAM applies only to paved (asphalt and concrete) runway surfaces, and does not apply to unpaved or partially paved surfaces.

(3) When runway condition information is reported in thirds a RWYCC is to be reported. Conversely, if the runway condition information is not entered for each runway third, then the RWYCC will not be reported.

6.2 Assessment criteria

(1) This section of the RCAM consists of a Runway Surface Description and a Runway Condition Code. The Runway Surface Descriptions in each category are linked to the corresponding Runway Condition Code based on their effect on aeroplane braking performance.

6.3 Runway surface description

(1) The Runway Surface Description column of the RCAM lists:

- (a) the contaminants on the runway (e.g. slush, dry snow, wet snow, etc.); and

- (b) runway surface conditions, if a runway is dry, wet or slippery when wet.

(2) These runway surface descriptions are directly correlated to aeroplane landing performance and are listed in order of slipperiness (i.e. from least slippery to most slippery).

6.4 Runway condition code (RWYCC)

(1) Runway Condition Codes (Format: X/X/X) represent the runway condition description based on defined terms and increments. Use of these codes harmonizes with ICAO Annex 14, providing a standardized “shorthand” format for reporting runway condition, which can be used by pilots to determine landing performance parameters.

(2) A preliminary RWYCC is determined using the RCAM based on type and depth of contaminant and outside air temperature (where applicable); or the runway condition, when the runway is dry, wet, or slippery when wet. The preliminary RWYCC must be confirmed, downgraded or upgraded. The full process to determine the final RWYCC is outlined in Section 7.

(3) In the event the full width of the runway is not cleared, the runway condition code will be determined based on the contaminants present in the cleared portion of the runway (typically centre 100 feet).

Text version - Table 3

The Runway Condition Assessment Matrix is shown, whose components are discussed in section 6.0.

Notes (1 to 4):

- 1) Refer to Section 6.5 – CRFI Information Presented in the RCAM, for an explanation of the relationship between CRFI and RWYCCs.

- 2) When available, the runway surface temperature should be used.

- 3) CAUTION: At temperatures near and above freezing (i.e. at -3°C and warmer), the runway surface condition may be more slippery than indicated by the preliminary RWYCC determined with reference to the RCAM assessment criteria. At these temperatures, airport and aerodrome operators should exercise vigilance and should downgrade the runway condition code if appropriate.

- 4) CAUTION: Heavy frost that has noticeable depth may have friction qualities similar to ice and downgrading the runway condition code accordingly should be considered. If driving a vehicle over the frost does not result in tire tracks exposing bare pavement, the frost should be considered to have sufficient depth to consider a downgrade of the runway condition code.

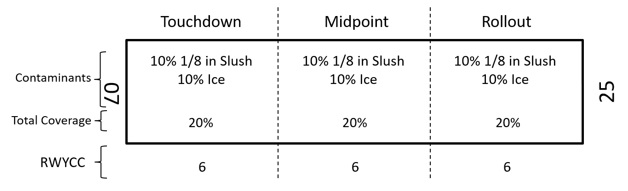

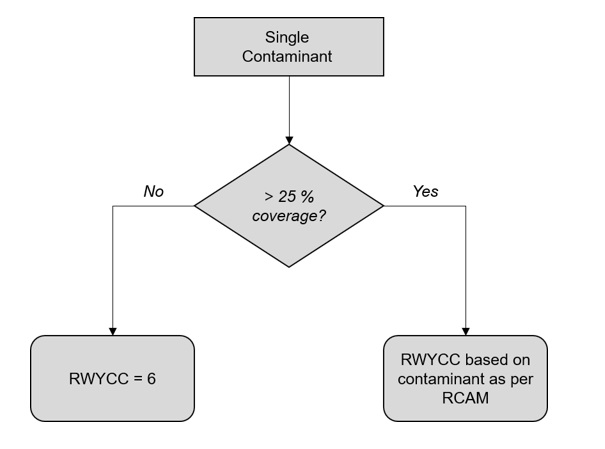

(4) The processes used to determine the preliminary RWYCC are described and illustrated below:

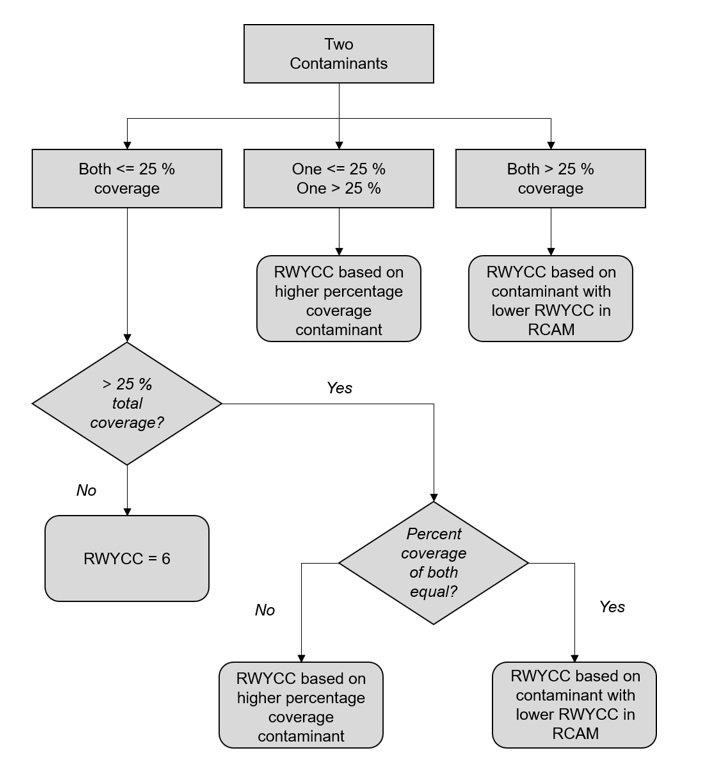

Note: These processes are summarized in flowcharts which appear in Appendix A for a single contaminant and in Appendix B for two contaminants.

- (a) When the runway third contains a single contaminant, the preliminary RWYCC for that third is based directly on that contaminant in the RCAM (Table 3) as follows:

- (i) If the percent coverage of contaminant for the runway third is less than or equal to 25%, a RWYCC of 6 is reported for that third;

-

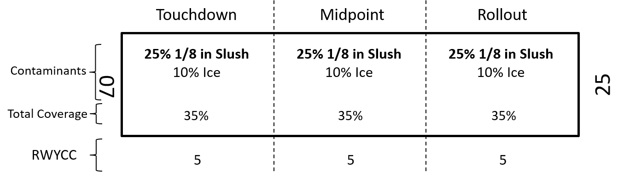

Figure 4 – Single contaminant, less than or equal to 25% coverage per runway third Text version - Figure 4

RWYCC by third illustrated for a single contaminant with 25 percent or less coverage.

- (ii) If the percent coverage of contaminant for the runway third is greater than 25%, the preliminary RWYCC for that third is based on the code for that contaminant that is specified in the RCAM.

Figure 5 – Single contaminant, greater than 25% coverage per runway third Text version - Figure 6

Two contaminants, less than or equal to 25% total coverage per runway third

- (b) When two contaminants are present in a runway third and the percent coverage for each individual contaminant is less than or equal to 25%, the preliminary RWYCC is determined as follows:

- (i) If the total of the percent coverage of contaminant for the runway third is less than or equal to 25%, a RWYCC of 6 is reported for that third;

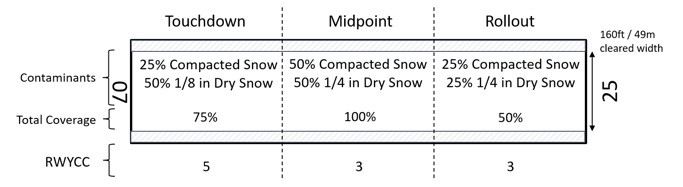

Figure 6 – Two contaminants, less than or equal to 25% total coverage per runway third Text version - Figure 7

RWYCC by third illustrated for a two contaminants with 25 percent or less total coverage.

- (ii) If the total of the percent coverage of contaminant for the runway third is greater than 25%, and the percent coverage of both contaminants is not equal, the preliminary RWYCC for that third is based on the contaminant with the higher percentage of coverage in that third.

Figure7 – Two contaminants, greater than 25% total coverage (but unequal between contaminants) per runway third Text version - Figure 7

RWYCC by third illustrated for a two contaminants with greater than 25 percent total coverage, but unequal coverage between contaminants.

- (i) If the total of the percent coverage of contaminant for the runway third is less than or equal to 25%, a RWYCC of 6 is reported for that third;

- (c) If the total of the percent coverage of contaminant for the runway third is greater than 25%, and the percent coverage of both contaminants is equal, the preliminary RWYCC is based on the contaminant with the lower RWYCC in the RCAM.

-

Figure 8 – Two contaminants, greater than 25% total coverage (but unequal between contaminants) per runway third Text version - Figure 8

RWYCC by third illustrated for a two contaminants with greater than 25 percent total coverage, but unequal coverage between contaminants.

- (d) When two contaminants are present in a runway third and the percent coverage of only one of the contaminants is greater than 25%, the preliminary RWYCC for that third is based on the contaminant with the higher percent coverage for that third.

-

Figure 9 – Two contaminants, greater than 25% total coverage (unequal between contaminants) per runway third Text version - Figure 9

RWYCC by third illustrated for a two contaminants with greater than 25 percent total coverage, but unequal coverage between contaminants.

- (e) When two contaminants are present in a runway third and the percent coverage of both of the contaminants is greater than 25%, the preliminary RWYCC for that third will be based on the contaminant with the lower RWYCC in the RCAM.

-

Figure 10 – Two contaminants, both greater than 25% coverage (and equal) per runway third Text version - Figure 10

RWYCC by third illustrated for a two contaminants with greater than 25 percent coverage, and equal coverage between contaminants.

6.5 CRFI information presented in the RCAM

(1) CRFI is a valuable tool which provides an objective measure of the runway friction that will allow the airport or aerodrome operator to:

- (a) validate the preliminary RWYCCs determined through the use of the RCAM,

- (b) downgrade the RWYCC, when appropriate, and

- (c) upgrade the RWYCC, when appropriate.

(2) An approximate range of CRFI values correspond to various RWYCCs. These CRFI ranges are used to downgrade a RWYCC, as described in Section 6.6.

Note: Due the variability of conditions these CRFI ranges may span more than one RWYCC.

(3) In contrast, a specific minimum CRFI value – as opposed to a range of CRFI values – is required to upgrade a RWYCC. The associated criteria and limitations for upgrading a RWYCC are provided in Section 6.8.

6.6 RWYCC downgrade assessment criteria

(1) As described in Section 6.4, the preliminary RWYCC is initially determined using the RCAM based on type and depth of contaminant and outside air temperature (where applicable); or the runway condition, when the runway is dry, wet, or slippery when wet.

(2) The airport or aerodrome operator should consider downgrading a RWYCC when CRFI measurements (if available), vehicle deceleration or directional control observations, pilot report(s), local knowledge and/or other information reveal that the runway surface is more slippery than the preliminary RWYCC indicated.

(3) The airport or aerodrome operator should exercise vigilance and downgrade the RWYCC when appropriate – so that flight crews are provided with a RWYCC that best reflects the actual slipperiness of the runway.

(4) The shaded area of the RCAM provides Downgrade Assessment Criteria, as detailed below:

- (a) Subject to the limitations for the use of a decelerometer to measure CRFI (see 322.416 of the Airport Standards – Airport Winter Maintenance), the airport or aerodrome operator should utilize CRFI readings, when available, to assess slipperiness of the runway.

- (b) Pilot reports may also provide useful information. These reports may relate to the specific sections of the runway in which wheel braking was applied, and should be considered for the applicable runway third (information on pilot reported braking action is provided in Section 6.7).

- (c) Vehicle control or deceleration observations are another source of useful information. As with pilot reports, vehicle control or deceleration observations may relate to specific sections of the runway and should be considered for the applicable runway third.

(5) CAUTION: At temperatures near and above freezing (i.e. at -3°C and warmer), the runway surface condition may be more slippery than indicated by the preliminary RWYCC determined with reference to the RCAM assessment criteria. At these temperatures, airport or aerodrome operators should exercise vigilance and should downgrade the runway condition code if appropriate.

(6) Figure 11, below provides an example of a situation where a RWYCC downgrade should be considered.

(7) When a RWYCC has been downgraded this information needs to be included in the runway remarks. For further information on runway remarks see Section 8.5.

6.7 Pilot reported braking action

(1) A pilot report (PIREP) of braking action reflects the pilots’ assessment of the available wheel braking.

(2) Where available, pilot reports of braking action should be taken into consideration as part of the ongoing monitoring process, using the following principles:

- (a) A pilot report of braking action should be taken into consideration for downgrading purposes; and

- (b) A pilot report of runway braking action can also prompt the airport or aerodrome operator to consider a RWYCC upgrade providing all of the requirements detailed in Section 6.8 are satisfied.

Notes:

- 1) Airport and aerodrome operators need to ensure that runway surface descriptions (type and depth) are reported in accordance with the pertinent regulatory requirements and the guidance provided in Section 13, regardless of pilot braking action reports.

- 2) Where Air Traffic Services (ATS) are provided, ATS are to notify airport or aerodrome operators of any significant change in surface conditions that they have observed or have been provided knowledge of.

(3) When previous pilot braking action reports have indicated GOOD or MEDIUM braking action, two consecutive pilot braking action reports of POOR indicates that surface conditions may be deteriorating. In this situation, the airport or aerodrome operator should conduct a runway assessment prior to the next aircraft operation.

(4) When one pilot report of runway braking action of LESS THAN POOR (or NIL) is received:

- (a) the information should be disseminated;

- (b) a new assessment should be made; and

- (c) the suspension of aircraft operations on that runway should be considered.

- Note: If considered appropriate, maintenance activities may be performed simultaneously or before a new assessment is made.

6.8 RWYCC upgrade assessment criteria

(1) Under very cold conditions, typically below -15⁰C, frozen contaminants may exhibit a higher degree of friction than indicated in the RCAM. In these circumstances, upgrading the RWYCC may be possible.

(2) A preliminary RWYCC of 2, 3, 4 or 5 cannot be upgraded.

(3) The airport or aerodrome operator may only upgrade a preliminary RWYCC of 0 or 1 up to but no higher than a RWYCC of 3, when all the following requirements are met:

- (a) CRFI values of 0.35 or greater are obtained for the affected third(s) of the runway (subject to limitations for the use of a decelerometer to measure CRFI (see 322.416 of the Airport Standards – Airport Winter Maintenance);

- (b) All other observations support a higher RWYCC as judged by a trained person; and

- (c) When a RWYCC of 0 or 1 is upgraded, the runway surface must be assessed frequently during the period the higher RWYCC is in effect to ensure the runway surface condition does not deteriorate below the assigned code.

- Note: Any process that transfers heat to the surface may make the runway more slippery. Heat sources can come from the aircraft tires, engine exhaust/thrust reverse, atmospheric conditions and precipitation. Runway treatments can also temporarily result in more slippery conditions.

(4) CAUTION: Variables to be considered include, but are not limited to:

- (a) Any precipitation conditions;

- (b) Changing temperatures;

- (c) Effects of wind;

- (d) Frequency of runway use; and

- (e) Type of aircraft using the runway.

(5) CAUTION: If sand or other runway treatments are used to support the upgrading, the runway surface must be assessed frequently to ensure the continued effectiveness of the treatment.

(6) When a RWYCC has been upgraded this information needs to be included in the runway remarks. For further information on runway remarks see Section 8.5.

7.0 Process to determine the RWYCC

(1) To use the Runway Condition Assessment Matrix (RCAM), the airport or aerodrome operator will use similar runway condition assessment practices as they have used in the past. The airport or aerodrome operator will assess surfaces, and report contaminants present on each runway. Based on the reported information, the preliminary RWYCCs will be determined using the RCAM in accordance with the process described in Section 6.4. The airport or aerodrome operator will then be prompted to confirm whether the preliminary RWYCCs are appropriate in consideration of other available information. Details of this process are provided in Sections 7.1 to 7.3, below.

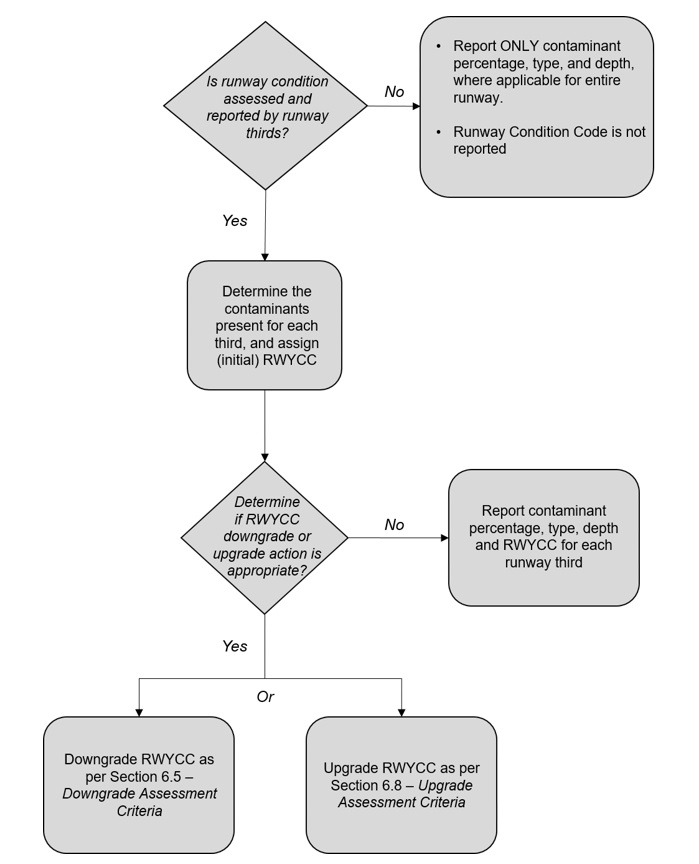

Note: The process described in Sections 7.1 to 7.3 is summarized in a flowchart in Appendix C.

(2) A separate process outlined in Section 7.4 is used to determine the RWYCC for a runway that does not meet the minimum coefficient of friction specified in TP 312, for which a “slippery when wet” normal NOTAM must be issued. (Information on these runways and the corresponding runway condition reporting procedures is found in Section 5.10.)

7.1 Step 1 – determine applicability of RWYCCs

(1) RWYCCs are only applicable if:

- (a) the runway condition information is reported by runway thirds; and

- (b) the runway surface is paved

7.2 Step 2 – apply assessment criteria to determine preliminary RWYCC

(1) Based on the runway surface description, the RCAM is used to determine a preliminary RWYCC for each third of the runway.

(2) NAV CANADA has developed software which will generate the preliminary RWYCC for each third of the runway as applicable, based on the reported runway condition information.

(3) CAUTION: The NAV CANADA software will generate preliminary RWYCCs in accordance with the procedures established in AC 300-019. The RWYCCs generated by this software are only intended to assist the airport or aerodrome operator in their determination of the preliminary RWYCC and conveys no responsibility on NAV CANADA. The determination of the RWYCC remains solely the responsibility of the airport or aerodrome operator, who must ensure that the preliminary RWYCC is confirmed, downgraded or upgraded, as applicable.

(4) For airports or aerodromes that do not have access to the NAV CANADA software, a printable AMSCR is available for runway condition reporting. The airport or aerodrome operator is to include RWYCCs on the printable AMSCR form if applicable (paved runway and reporting in thirds). As the airport and aerodrome operator is responsible for determining and accepting the RWYCC, the information provided is deemed to be correct. Therefore, for information submitted using the printable AMSCR form, the Final RWYCC entered on the AMSCR forms will be entered into the software.

7.3 Step 3 – validate preliminary RWYCCs

(1) After the preliminary RWYCCs have been assigned, the airport or aerodrome operator should determine that the preliminary RWYCCs accurately reflect the runway condition. Through this determination, which should consider CRFI (if available), vehicle deceleration or directional control observations, pilot report(s), local knowledge and/or other information, the preliminary RWYCC will then be:

- (a) Confirmed;

- (b) Downgraded; or

- (c) Upgraded

(2) If the preliminary RWYCCs accurately represent the runway condition, the preliminary RWYCCs will be confirmed and the final RWYCCs may be disseminated.

(3) However, if it is determined – through CRFI, pilot report(s), and/or other information – that the runway is more slippery than indicated by the preliminary RWYCC (determined with reference to the RCAM Assessment Criteria), the RWYCC should be downgraded. Guidance for the downgrade process is provided in Section 6.6 of this AC.

(4) Alternatively, given the variability of certain contaminants, there are circumstances when a RWYCC of “0” or “1” may not be as slippery as the preliminary RWYCC determined with reference to the RCAM assessment criteria. In this case, the airport may upgrade the RWYCC up to but no higher than a RWYCC of “3”, in accordance with the upgrade criteria given in Section 6.8 of this AC.

(5) When a RWYCC has been upgraded or downgraded this information needs to be included in the runway remarks. For further information on runway remarks see Section 8.5.

7.4 RWYCC for slippery when wet runways

(1) The processes used to determine a RWYCC for runways which do not meet the minimum coefficient of friction specified in TP 312 are outlined below. These procedures are applicable for both:

- (a) runway conditions associated with winter contaminants; and

- (b) wet conditions or standing water not associated with winter contaminants, where these conditions are reported.

- Note: Guidance for reporting runway surface conditions for these runways are described in Section 5.10.

(2) For these procedures the percentage of coverage does not factor into the determination of the RWYCC. In addition, when more than one condition or contaminant is present, the lowest corresponding RWYCC is used, regardless of the amount of coverage.

(3) Where any runway third has a runway surface description (for moisture or frozen contamination) which has a corresponding RWYCC that is greater than or equal to 3, a preliminary RWYCC no greater than 3 will be assigned to all three runway thirds (i.e. 3/3/3). This is shown in the following examples:

- (a) Where the first third of a runway has twenty percent coverage of 1/8 of an inch or less water and the remaining runway thirds were dry:

- (i) this will be reported as: “SLIPPERY WHEN WET, DRY, DRY”; and

- (ii) a preliminary RWYCC of 3 will be assigned to all three runway thirds (i.e. 3/3/3).

- (b) Where the first third of a runway has twenty percent coverage of 1/8 of an inch dry snow and the remaining thirds are DRY:

- (i) this will be reported as: “20 PCT 1/8IN DRY SNOW, DRY, DRY”; and

- (ii) a preliminary RWYCC of 3 will be assigned to all three runway thirds (i.e. 3/3/3).

(4) Where any runway third has a runway surface description which has a corresponding RWYCC that is less than 3, this value will be the preliminary RWYCC assigned to all three runway thirds (i.e. 2/2/2; 1/1/1; or 0/0/0). This is shown in the following examples:

- (a) Where the final third of a runway has twenty percent coverage of ice and the remaining runway thirds are dry:

- (i) this will be reported as: “DRY, DRY, 20 PCT ICE”; and

- (ii) a preliminary RWYCC of 1 will be assigned to all three runway thirds (i.e. 1/1/1).

- (b) Where the middle third of a runway has ten percent coverage of 1/4 of an inch of standing water and the remaining runway thirds are dry:

- (i) this will be reported as: “DRY, 10 PCT 1/4IN STANDING WATER, DRY”; and

- (ii) a preliminary RWYCC of 2 will be assigned to all three runway thirds (i.e. 2/2/2).

(5) Where more than one runway condition or contaminant(s) are reported in any runway third, or if there are different conditions or contaminants in various runway thirds:

- (a) the procedures described in (3) and (4) above are used to assess each runway surface description to determine the lowest preliminary RWYCC; and

- (b) the lowest preliminary RWYCC will be assigned to all three runway thirds, regardless of which condition or contaminant has greater coverage.

(6) The reporting of more than one runway condition or contaminant is shown in the following examples:

- (a) Where the first and middle thirds of a runway have twenty percent coverage of 1/8 of an inch or less water and the final runway third has twenty percent coverage of 1/4 of an inch of water:

- (i) this will be reported as: “SLIPPERY WHEN WET, SLIPPERY WHEN WET, 20 PCT 1/4IN STANDING WATER”; and

- (ii) a preliminary RWYCC of 2 (corresponding to 1/4IN STANDING WATER) will be assigned to all three runway thirds (i.e. 2/2/2).

- (b) Where the first and middle thirds of a runway have eighty percent coverage of 1/8 of an inch slush and the final runway third is covered by eighty percent coverage of 1/4 of an inch slush:

- (i) This will be reported as” “80 PCT 1/8IN SLUSH, 80 PCT 1/8IN SLUSH, 80 PCT 1/4IN SLUSH”; and

- (ii) a preliminary RWYCC of 2 (corresponding to 1/4IN SLUSH) will be assigned to all three runway thirds (i.e. 2/2/2).

(7) After the preliminary RWYCC has been assigned, the airport or aerodrome operator should determine that the preliminary RWYCCs accurately reflect the runway condition. Through this determination, which should consider CRFI (if available), vehicle deceleration or directional control observations, pilot report(s), local knowledge and/or other information, the preliminary RWYCC will then be:

- (a) Confirmed; or

- (b) Downgraded

- Note: The RWYCC upgrade process specified in Section 6.8 is not applicable for a runway which does not meet the minimum coefficient of friction specified in TP 312.

(8) If the airport or aerodrome operator deems that a downgrade is necessary, the downgrade will apply to all three runway thirds (i.e. 2/2/2; 1/1/1; or 0/0/0).

(9) When RWYCCs are reported for a runway which does not meet the minimum coefficient of friction specified in TP 312, the following information is to be included in the runway remarks:

- (a) RWYCC DUE RWY SLIPPERY WHEN WET; and

- (b) If the preliminary RWYCCs have also been downgraded, RWYCC DOWNGRADED

- Note: Guidance on runway remarks is provided in Section 8.5.

8.0 Other reported runway condition information

(1) Other reported runway condition information includes:

- (a) Treatments applied to the runway surface;

- (b) Snow drifts, windrows or snowbanks on the runway;

- (c) Other localized conditions;

- (d) Snowbanks adjacent to the runway; and

- (e) Runway remarks

8.1 Treatments applied to the runway surface

(1) Treatments applied to the runway surface are reported using up to two of the following terms as applicable:

- (a) CHEMICALLY TREATED

- (b) LOOSE SAND

(2) The time that the treatment was applied may also be listed, but is not mandatory.

(3) Examples:

- (a) RSC 02 … CHEMICALLY TREATED AT 1200

- (b) RSC 02 … LOOSE SAND APPLIED AT 1200

8.2 Snow drifts, windrows, or snowbanks on the runway

(1) This information is reported using the term “SNOW DRIFTS,” “WINDROWS” or “SNOWBANKS” as applicable.

(2) The maximum snow drift, windrow or snowbank height is to be reported in feet and/or inches, as applicable.

(3) The location of a windrow or snowbank is reported:

- (a) as a distance from the nearest threshold in 100 foot increments (e.g. RSC 07 … 3IN WINDROWS 200FT FROM THR RWY 25);

- (b) by indicating the distance, to the nearest foot, from: the runway edges, the edge of the cleared width or the runway centerline (e.g. RSC 12/30 … 1FT SNOWBANKS 20FT SOUTHEAST FM RWY EDGE); or

- (c) with reference to an intersecting runway (e.g. RSC 07 … 3IN WINDROWS ACROSS INT OF RWY 14/32).

(4) Reporting the location of a snow drift is optional since there may be numerous snow drifts, and may be reported:

- (a) as a distance from the nearest threshold in 100 foot increments (e.g. RSC 07 … 6IN SNOW DRIFTS 200FT FM THR 25);

- (b) by indicating the distance, to the nearest foot, from: the runway edges, the edge of the cleared width or the runway centerline (e.g. RSC 04 … 3IN SNOW DRIFTS 50FT SOUTHEAST FM CL); or

- (c) with reference to an intersecting runway (e.g. RSC 14 … 4IN SNOW DRIFTS ACROSS INT OF RWY 05/23).

(5) When describing a snow drift, windrow or snowbank that is to one side of the centreline or the runway edge, the four cardinal points (North, South, East or West) or four intercardinal (ordinal) points (Northeast, Southeast, Southwest or Northwest) should be used instead of “left” or “right”. This is illustrated in Table 4 below.

| RWY Designators | Cardinal or intercardinal direction right of the runway centerline | Cardinal or intercardinal direction left of the runway centerline |

|---|---|---|

| 01 02 | EAST | WEST |

| 03 04 05 06 | SOUTHEAST | NORTHWEST |

| 07 08 09 10 11 | SOUTH | NORTH |

| 12 13 14 15 | SOUTHWEST | NORTHEAST |

| 16 17 18 19 20 | WEST | EAST |

| 21 22 23 24 | NORTHWEST | SOUTHEAST |

| 25 26 27 28 29 | NORTH | SOUTH |

| 30 31 32 33 | NORTHEAST | SOUTHWEST |

| 34 35 36 | EAST | WEST |

(6) Examples:

- (a) RSC 06 … 3IN SNOW DRIFTS 5FT ALONG INSIDE SOUTHEAST RWY EDGE

- (b) RSC 02 … 10IN WINDROWS 50FT EAST AND WEST FM CL

- (c) RSC 14 … 2FT SNOWBANKS ALONG INSIDE NORTHEAST RWY EDGE

8.3 Other localized conditions

(1) Localized conditions that reduce the friction locally should be reported by indicating the distance in feet from the nearest threshold (in 100 foot increments).

(2) These localized conditions, are separate and distinct from the runway surface conditions that serve as assessment criteria in the RCAM; they include:

- (a) ice patches,

- (b) compacted snow patches, and

- (c) standing water patches.

(3) Examples:

- (a) RSC 04 … ICE PATCHES 1600FT FROM THR 22

- (b) RSC 07 … STANDING WATER PATCHES ACROSS INT OF RWY 14/32

(4) Any other localized conditions not itemized in Paragraph (2) are to be described in the Runway remarks section as described in Section 8.5 of this AC.

8.4 Snowbanks adjacent to the runway

(1) The presence of a runway snowbank, its height (in inches and/or feet) and its distance (in feet) from outside the runway edge is to be reported. For details see the height profile specified in Standard 322 Division IV – Airport Winter Maintenance.

(2) When the height of snowbanks vary, the highest value should be reported.

(3) When the distances from the outer edges vary, the least distance from the runway edge should be reported.

(4) Examples:

- (a) RSC 06 … 3FT SNOWBANKS 5FT OUTSIDE SOUTHEAST RWY EDGE

- (b) RSC 22 … 4FT 6IN SNOWBANKS 10IN OUTSIDE NORTHWEST AND SOUTHEAST RWY EDGE

- (c) RSC 14 … 5FT SNOWBANKS ON SOUTHWEST RWY EDGE

-

Figure 12 – Snowbanks on or adjacent to the runway edge Text version - Figure 12

Figure illustrating snowbank location on and near runway edges.

8.5 Runway remarks

(1) Runway remarks serve to capture any other operationally significant information related to a given runway, which is not otherwise described. These remarks serve an important function by enhancing situational awareness.

(2) Runway remarks need to be kept brief and concise, to ensure that only important safety information is conveyed.

(3) As per paragraph 7.3(4) when a RWYCC has been downgraded or upgraded this information needs to be included in the runway remarks as follows:

- (a) RWYCC DOWNGRADED; or

- (b) RWYCC UPGRADED.

(4) As per paragraph 7.4(9) when RWYCCs are reported for a runway which does not meet the minimum coefficient of friction specified in TP 312 the phrase: “RWYCC DUE RWY SLIPPERY WHEN WET” needs to be included in the runway remarks.

(5) In addition, when applicable, the following predetermined phrases should be used:

- (a) RWY MARKINGS OBSCURED (See note)

- (b) RWY CL LGTS AND MARKINGS OBSCURED (See note)

- (c) HIGH SPEED TAXIWAYS SLIPPERY

- Note: The regulations for pilots require runway markings and/or centreline lights “that are plainly visible to the pilot throughout the take-off run” for conducting take-offs with reported visibility of RVR 1200 (1/4 sm) and RVR 600.

9.0 Additional non-GRF/TALPA information

9.1 Canadian runway friction index (CRFI) – overview

(1) CRFI provides an objective measurement of runway slipperiness. Subject to known limitations, CRFI plays an important role in allowing airport and aerodrome operators to confirm, downgrade or upgrade the preliminary RWYCC.

9.2 Regulatory requirements for CRFI measurement and reporting

(1) CRFI readings are measured and reported in accordance with:

- (a) the requirements specified in:

- (i) Subpart 302– Airports, Division IV of the CARs – Airport Winter Maintenance, and

- (ii) Subpart 322 – Airport Winter Maintenance Standards (AWMS); and

- (b) the guidance provided in AC 300-005 – Changes to Runway Surface Condition Reporting.

(2) The applicability of the above regulations is dependent upon the type of air transport service, if any, being operated at an airport. This is outlined in Subsection 302.402 (2) of the CARs – Applicability, which states:

Sections 302.410 to 302.419 apply in respect of an airport if:

- (a) aeroplanes at the airport are operated in an air transport service under Subpart 4 or 5 of Part VII; or

- (b) aeroplanes at the airport are operated in an air transport service under Subpart 3 of Part VII and the operator of the airport has decided to comply with those sections instead of sections 302.406 and 302.407.

(3) For airports outlined in paragraph (2) above, CRFI is reported as follows:

- (a) For runways greater than or equal to 1829m in length, the measurement of CRFI readings is performed and averaged for each third of the runway length in the report;

- (b) For runways less than 1829m in length, CRFI can be reported as in (3)(a), or CRFI can be measured and averaged for the full runway length in the report.

(4) The regulatory requirements for reporting CRFI in thirds (which are detailed in Paragraphs (1) through (3), above) and the criteria for reporting runway surface conditions in thirds (which are detailed in Section 5.3) are summarized in Table 5.

(5) There is no specific regulatory link between the requirements for reporting CRFI in thirds and the criteria for reporting runway surface conditions in thirds.

| CRFI 1 | Runway Surface Conditions 2 Reported in thirds (with RWYCCs) when: | |

|---|---|---|

| Must be reported in thirds when: | May be reported in thirds when: | |

|

|

|

Notes:

- 1) Reporting requirements for CRFI are stipulated in:

- (a) Sections 302.402(2)(a) and 302.416(1) of the CARs

- (b) Section 322.416 of the AWMS

- 2) See Section 5.3 for guidance respecting reporting by runway thirds.

- 3) A minimum of four CRFI measurements per third are required to report CRFI by runway thirds. A minimum runway length of 1829m (6000ft) is required for reporting in thirds. However, runways of at least 914m (3000ft) can be reported in thirds when measurements are taken on both sides of the runway centreline (down and back method). See AC 300-005 for more information on CRFI reporting.

9.3 Format of CRFI report

(1) Two different formats are used for reporting CRFI; one for reporting in thirds and one for reporting by full runway length, as show in the following examples:

- (a) Reporting CRFI in thirds:

- ADDN NON-GRF/TALPA INFO:

CRFI 09 -3C .40/.32/.28 OBS AT 1909131504

CRFI 27 -3C .28/.32/.40 OBS AT 1909131504 - Note: When reporting CRFI in thirds, each runway end is reported (i.e. 09 and 27)

- (b) Reporting CRFI by full runway length:

- ADDN NON-GRF/TALPA INFO:

CRFI 07/25 -3C .25 OBS AT 1902141408

(2) When reporting CRFI in thirds, in a situation may occur where a CRFI report is required for one third(s), but should not be reported for another third(s). This can happen when an individual runway third(s) are either dry or covered with a condition or contaminant(s) are not conducive to CRFI reporting. (Examples include runways which are wet or covered by slush or standing water). In this case, the applicable runway third is listed as “NR” (not reported) as shown in the example below.

- ADDN NON-GRF/TALPA INFO:

CRFI 09 -3C .32/NR/.28 OBS AT 1909131504

(3) The air temperature in degrees Celsius and time of measurement are included with the CRFI report.

10.0 Taxiway and apron information

(1) Where contaminants are present on taxiways and aprons that may be of “operational significance” to aircrews, the airport operator is required to include these conditions in the report. Aerodrome operators should also report these conditions.

(2) Due to the lower speed at which aircraft move on taxiways and aprons, the originator should take care to only include the information that has an impact on safety and normal operations, such as the risk of becoming stuck, losing control on a slippery surface, or damaging the aircraft.

(3) Only one type of surface condition and corresponding depth, if applicable, should be reported for taxiways and aprons. The percentage of contaminants is not to be reported.

(4) It is important to provide pertinent and concise information. Where possible, the use of approved abbreviations is recommended.

Note: Airport and aerodrome operators are cautioned against providing excessive and overly detailed information regarding the condition of taxiways and aprons. This can be a needless distraction and is a disservice to flight crews as it adds significantly to pilot workload and may contribute to flight crews missing other critical information.

(5) If the same conditions apply to several taxiways or aprons, the information should be grouped together. The term ALL TWY or ALL APN can be used to describe the conditions that apply to all taxiways and/or aprons.

(6) Taxiway and apron information can include but is not limited to:

- (a) type of contaminant and depth,

- (b) qualitative friction (e.g. “BRAKING ACTION POOR”),

- (c) presence of snow drifts, windrows and snowbanks, and

- (d) presence of treatments.

(7) Examples:

- (a) RMK: TWY E AND F: 8IN WET SNOW

- (b) RMK: TWY B BRAKING ACTION POOR

- (c) RMK: TWY A 1FT 6IN SNOWBANKS

- (d) RMK: APN II AND III ICE COVERED. CHEMICALLY TREATED

- (e) RMK: ALL TWY 2IN DRY SNOW

11.0 General remarks

(1) This section is used to record:

- (a) maintenance activities (plowing, sweeping, etc.); or

- (b) any unusual contamination conditions such as a contaminant location that is not otherwise be recorded.

(2) Examples include, but are not necessarily limited to:

- (a) CLEARING/SWEEPING IN PROGRESS; and

- (b) CONDITIONS CHANGING RAPIDLY

- Note: The NAV CANADA software will only permit CONDITIONS CHANGING RAPIDLY to be issued as a part of a RSC NOTAM. It cannot be issued as a stand-alone NOTAM.

(3) These remarks need to be kept brief and concise, to ensure that only important safety information is conveyed.

(4) The next scheduled time of observation is included in general remarks where applicable.

12.0 Order of reported runway condition information

(1) The following order of reporting applies to a complete RSC NOTAM:

- (a) NOTAM information;

- (b) RSC information including:

- (i) Runway in use designator, when reporting by thirds (e.g. RSC 33), or

- (ii) Full runway designator, when reporting by full runway length (e.g. RSC 07/25);

- (c) Surface conditions for each runway, as applicable:

- (i) Runway condition code for each runway third (where applicable);

- (ii) Condition or contaminant(s) within the cleared width: percent coverage, depth (if applicable), and condition or type of contaminant for each third of the runway (if applicable);

- (iii) Condition of unpaved and partially paved runways: graded, packed, and/or scarified (where applicable);

- (iv) Cleared width (if applicable);

- (v) Snow drifts, windrows and/or snowbanks on the runway (where applicable);

- (vi) Localized conditions (where applicable);

- (vii) Treatments (where applicable);

- (viii) Conditions for remaining width (where applicable);

- (ix) Snowbanks adjacent to runway (where applicable); (x) Runway remarks (where applicable);

- (xi) RSC validity time.

- (d) CRFI Header: ADDN NON-GRF/TALPA INFO;

- (e) CRFI readings for each runway as applicable;

- (f) Taxiway conditions;

- (g) Apron conditions;

- (h) General remarks, including next scheduled time of observation (where applicable).

13.0 Requirements to issue an AMSCR

(1) The requirements to conduct movement area inspections and report the surface conditions are described in:

- (a) Subpart 302 of the CARs – Airport Winter Maintenance; and

- (b) Section 322 of the Airport Winter Maintenance Standards (AWMS)

(2) When contaminants are present on a movement area, an AMSCR is to be made available during the published AMSCR hours as follows:

- (a) at the commencement of the published AMSCR hours,

- (b) a minimum of once every eight or twenty-four hours, as applicable, as described in Section 14 of this AC;

- (c) when a significant changes occurs, as described below in (4)

- (d) following every accident or incident in which winter conditions may have been a factor; and

- (e) whenever the cleared width of the runway falls below the full width of the runway.

(3) Reporting of the runway surface conditions should continue until the runway is no longer contaminated. When this occurs, the airport or aerodrome operator will issue an AMSCR that states the runway is wet or dry as appropriate.

(4) A new AMSCR is also issued when a significant change occurs. Significant changes include:

- (a) Any change in the RWYCC;

- (b) Any change in CRFI of 0.05 or more;

- (c) Any change in the contaminant type;

- (d) Any change of 20% or more in the reportable contaminant coverage;

- (e) Any change in contaminant depth as described in Table 6, below; and

- (f) Any other information, which according to assessment techniques, is considered to be significant. For example, following the application or removal of sand or chemicals; following snow removal or sweeping; changes in conditions caused by rapid increases or decreases in temperature.

| Contaminant | Valid depth values to be reported (minimum depth/assessed value) | Significant change |

|---|---|---|

| STANDING WATER | 1/4 inch, then assessed value | 1/8 inch |

| SLUSH | 1/8 inch, then assessed value | 1/8 inch |

| WET SNOW | 1/8 inch, then assessed value | 1/4 inch |

| DRY SNOW | 1/8 inch, then assessed value 3/4 inch | 1/8 inch |

Notes:

- 1) For STANDING WATER, 1/4 inch is the minimum depth which can be reported. (When the water depth is 1/8 inch or less, the runway is reported to be WET).

- 2) For SLUSH, WET SNOW and DRY SNOW, 1/8 inch is the minimum depth which can be reported.

(5) An example illustrating significant change for contaminant depth is given in Appendix D.

14.0 Validity period

(1) The validity period of an AMSCR should not exceed the published operating hours for an airport or aerodrome, unless the surface conditions are being monitored.