ISSN 0828-5039 Vol. 31 No. 1 Agreement Number 40063845

Inside

-

A Word of Warning to All Air Operators Regarding Dangerous Goods

-

Transportation of Dangerous Goods Act 1992, Impact on ERAP program

Accepting US Hazmat Endorsement in Canada

Part 6 of the Transportation of Dangerous Goods Regulations requires anyone who handles, offers for transport or transports dangerous goods (HazMat in the United States) to hold a valid training certificate.

Subsection 6.4(1) of the Transportation of Dangerous Goods Regulations provides for American drivers who hold a document, valid in the United States, that shows they are trained as set out in sections 172.700 to 172.704 of 49 CFR (Code of Federal Regulations).

In the United States, drivers who transport HazMat in quantities that require placards must pass a state-level exam required by Section 383.93 of 49 CFR. The state will then add a HazMat endorsement to their Commercial Driver’s License. In Canada, Canadian drivers are not required to have a HazMat endorsement on their driver’s license when transporting dangerous goods.

An agreement between the United States’ Department of Transportation - Federal Motor Carrier Safety Administration and Transport Canada states that:

- Transport Canada will recognize:

- the HazMat endorsement of the Commercial Driver’s Licence;

- a copy of the certification stipulated in section 172.704(d)(5) of 49 CFR; or

- a Transportation of Dangerous Goods training certificate issued under Part 6 of the Transportation of Dangerous Goods Regulations.

- The United States will accept a Canadian driver’s training certificate in lieu of a HazMat endorsement.

- Canadian transportation of dangerous goods Inspectors can request further verification by contacting the Director, Compliance and Response, Transport Dangerous Goods Directorate within Transport Canada.

To find out more, please contact your regional Transport Dangerous Goods Office or visit the Transport Dangerous Goods website at: www.tc.gc.ca/eng/tdg/safety-menu.htm

Consignor Responsibilities

Section 1.4 of the Transportation of Dangerous Goods Regulations defines the term “consignor” as:

- the person who is named in a shipping document,

- who imports dangerous goods, or

- who has possession of dangerous goods immediately before they are in transport.

When shipping (handling, offering for transport or transporting) dangerous goods under the Transportation of Dangerous Goods Act and Regulations, a consignor has more responsibilities than any other person. Unless the shipment of dangerous goods is exempt from the Transportation of Dangerous Goods Regulations through a “special case”, special provision or an equivalency certificate (formally known as a permit), as a consignor, you must ensure that the dangerous goods are shipped in full compliance with the Regulations. You must do all the preparatory work, or hire someone to do it, before allowing a carrier to take possession of the dangerous goods. This includes:

- classifying the dangerous goods,

- ensuring that you and your employees are trained,

- choosing the right means of containment (i.e. container),

- displaying proper safety marks,

- preparing shipping documents,

- if applicable, preparing an Emergency Response Assistance Plan (ERAP) and getting approval for the plan from Transport Canada, and

- if applicable, reporting dangerous goods involved in a release or anticipated (imminent) release (i.e. spill).

In addition to the above, when dangerous goods are shipped internationally by vessel or aircraft, as a consignor, you must also comply with the requirements of the:

- International Maritime Dangerous Goods (IMDG) Code, or

- International Civil Aviation Organization (ICAO) Technical Instructions

In the upcoming months, we will publish a bulletin on consignor responsibilities, which will provide greater detail on this subject. In the meantime, if you wish to learn more, please contact the regional Transport Dangerous Goods Office in your area, or visit the Transport Dangerous Goods website at: www.tc.gc.ca/tdg/safety/menu.htm

To find out more, please contact your regional Transport Dangerous Goods Office or visit the TDG website at: www.tc.gc.ca/eng/tdg/safety-menu.htm.htm

A Word of Warning to All Air Operators Regarding Dangerous Goods

Transport Canada has identified a potential hazard associated with the carriage of undeclared dangerous goods on Canadian aircraft.

Undeclared dangerous goods take many forms, the classic example being the chemical oxygen generators carried on board in the crash of ValueJet Airlines Flight 592 on May 11, 1996. The U.S. National Transportation Safety Board (NTSB) aircraft accident report of Flight 592 identified the root cause as being a series of decisions that lead to the inadvertent loading of the chemical oxygen generators in the cargo hold. A fire ensued, engulfing combustible materials nearby, and was proliferated by the generation of oxygen gas. The aircraft crashed in the Florida Everglades and everyone on board perished. Measures had not been in place or communicated to ensure that air operator personnel—including third party personnel—were capable of recognizing dangerous goods.

Undeclared dangerous goods are found daily in passenger baggage, company materials, cargo, stores and airmail. A small percentage is reported; however, Transport Canada suspects that a considerable number of items entering the aviation transportation system are not detected for various reasons. To mitigate this hazard, and for the safety of their staff as well as their operations, air operators must ensure that company personnel know how to recognize dangerous goods and the indicators that dangerous goods are being presented for transport.

Are you a dangerous-goods operator?

The Transportation of Dangerous Goods Act, 1992, and the Transportation of Dangerous Goods Regulations apply to you if you handle, offer for transport, import, or transport dangerous goods to, from, or within Canada. The Act and Regulations also apply to aircraft that are registered in Canada but are operated outside Canada. This includes the transportation of replacement parts (i.e. spares) such as fire extinguishers, oxygen cylinders, engines, fuel pumps, fuel control units, first aid kits, life vests, etc. Activities carried out under a regulatory exemption are also subject to the Regulations. Regulatory exemptions allow passengers to bring on board the aircraft articles such as aerosols, toiletry articles, cellular phones, portable computers, cigarette lighters, etc. The exemptions also permit operators to stow electric wheelchairs in the cargo hold and to carry dangerous goods such as aerosols, alcoholic beverages and perfumes for use or sale on board the aircraft during the flight. If any of these regulatory exemptions apply to your operation, you are in fact handling, offering for transport, or transporting dangerous goods.

Training is the key to understanding and complying with the Transportation of Dangerous Goods Regulations. This enables a person to determine whether a product is considered to be dangerous goods, whether the dangerous goods are regulated, and how to use the Regulations efficiently.

International implications for Canadian non-dangerous-goods operators

Air operators who state in their operations manual that they will not conduct dangerous-goods activities and choose not to provide awareness training to their employees may encounter some delays and/or difficulties when operating outside Canada. The International Civil Aviation Organization’s (ICAO) Annex 6 to the Convention on International Civil Aviation contains standards and recommended practices, which are applicable to member States, to regulate the aviation industry. The ICAO standards and recommended practices require that the ground and flight crew member training program include a section on the transport of dangerous goods. In the United States, the Department of Transport has already developed regulations in the Code of Federal Regulations, Title 14 to require awareness training for “will-not-carry” certificate holders. Other ICAO member countries have also included such requirements.

It should be noted that Canada has not yet incorporated the ICAO standards and recommended practices into the Canadian Aviation Regulations; however, this does not relieve Canadian operators from complying with foreign regulations when travelling within their jurisdictions. Foreign authorities check foreign carriers more frequently, and failing to meet ICAO or foreign requirements may be problematic—even if the Canadian operator meets the domestic regulations.

Safety management systems

A safety management system is an explicit, comprehensive and proactive process for managing risks. Since dangerous goods entering the transportation system present a variety of risks to aviation safety, it is important that all air operators establish a comprehensive and proactive process for dealing with dangerous goods in their own contexts. Under the principals of safety management systems, operators must ensure that their system as a whole promotes safe operations.

The general conditions of an air operator certificate stipulate that the holder must conduct flight operations safely and in accordance with the company operation manual. Part of those general conditions is Transport Canada’s approval of procedures for the carriage of dangerous goods in the company operations manual and the dangerous goods training program.

Transport Canada’s position

It is highly unlikely that an air operator is not involved in the transport of dangerous goods in some respect. The great majority of air operators do take advantage of the regulatory exemptions to transport dangerous goods carried by passengers and to transport replacement parts. Thus, they are subject to the regulations, and Transport Canada requires, at a minimum, awareness training for all personnel involved in the processing of passengers, cargo, mail and stores; this includes third party personnel and instructions to be provided to employees in the company operations manual. This training and information assist employees in the recognition of dangerous goods and in understanding their responsibilities in preventing non-compliant or undeclared dangerous goods from entering the aviation transportation system and compromising the safety of the Canadian travelling public.

Air operators wanting to obtain more information should contact their Transport Canada Civil Aviation regional office.

Editorial

Welcome to the Spring 2011 edition of the TDG Newsletter. This Spring, the theme revolves around change and presents itself in 3 forms. First, and most evident to readers, we have made some big changes to the format of our publication. Seven years since the last revision of the layout, we have now opted for a format that we hope will allow for more versatility and also permit the inclusion of more images (graphs, pictures, etc.). The goal is to eventually diversify content by not only bringing important regulatory updates to the industry, but to also offer a wider variety of informational articles. We will surely be making adjustments over the next few issues and would welcome any feedback you have. We hope you enjoy the new format because after all, it is intended to better inform and engage you, our readers.

The second form of change involves the players at the Transport Dangerous Goods Directorate. Indeed, the Directorate has undergone major change in the last 4 years. In fact, there has been a complete turnaround in management since 2007. First, as you may remember, Marie-France Dagenais replaced Dr. John Read, who retired, as Director General in January 2008, while at about the same time, Geoffrey Oliver took on the title of Director, Research, Evaluation and Systems after Doug Dibble retired in the Fall of 2007. Then, Joanne St-Onge joined the Directorate in Spring 2010 as Director of Regulatory Affairs, as Jacques Savard was given a special assignment. And most recently, in Summer 2010, Clive Law came onboard as Director of Compliance and Response, following Edgar Ladouceur’s retirement. Staffing changes have also come about in many more ways in the past year or so, and we are happy to say that the Transport Dangerous Goods Directorate is close to operating at full steam. There are still a few pieces of the puzzle missing but once these are in place, we will prepare a formal introduction, which will be published in the next edition of the Newsletter.

The final form of change is only beginning and will be on going for some time. Following the amendment of the Transportation of Dangerous Goods Act, 1992, in June 2009, much work is being done to align the Regulations to the Act. This also means that our training program is being updated so that the compliance and response aspect of the business reflects new regulatory requirements. Our branches have collectively rolled up their sleeves for the task at hand and awareness is one of our key priorities. With this in mind, this issue contains two articles on what changes to the Act mean for the CBRNE and ERAP programs and we will continue updating you on new developments with each new issue of the TDG Newsletter. Other articles found in this edition touch on various changes that have occurred in the past year, such as Hazmat endorsements and new symbols for stacking loads, while others, like the article regarding the 25th anniversary of the Responsible Care initiative and the TDG colleague who carried the Olympic torch, provide information on notable events.

I do hope you enjoy the new format of the TDG Newsletter and would appreciate your comments and suggestions. Thank you in advance and enjoy your reading!

New symbols for the maximum permitted stacking load applied on Intermediate Bulk Container

The Model Regulations stemming from the UN Recommendations on the Transport of Dangerous Goods, 16th edition, requires that all Intermediate Bulk Containers (IBCs) manufactured as of January 1, 2011 be marked with one of the two following symbols to indicate the maximum permitted stacking load. The symbols must have a minimum size of 100mm by 100mm.

IBC designed for stacking

IBC not designed for stacking

For users of IBCs the new symbols should greatly simplify compliance to the requirements in relation to stacking. In the case symbol A is marked on the IBC, the symbols indicates the maximum total mass of IBCs and their content that may be stacked on top of it. That maximum permitted load is in fact the stacking test load required to be marked in the primary UN marking string divided by 1.8. In the case the IBC is marked with symbol B, stacking of anything on top of it is prohibited.

Please note that these additional markings do not alter the primary marking of the IBC. Consequently, the primary marking will still include:

- The stacking test load in kg if the IBC is designed for stacking or

- The number zero “0” if the IBC is not designed for stacking.

Maximum Permitted Stacking Load

Example of marking on a plywood IBC manufactured in January 2011 and designed for a stacking load of 3600kg

11D / Y / 01 11

CAN / XYZ 4-XXX

6480 / 1800

Example of marking on a plastic fabric flexible IBC manufactured in January 2011 and not designed for stacking

13H3 / Y / 01 11

CAN / XYZ 4-XXX

0 / 1000

The marking of IBCs with these new symbols is not currently required by the standard CAN/CGSB-43.146-2002 “Design, Manufacture and Use of Intermediate Bulk Containers for the Transportation of Dangerous Goods” (CGSB43.146) that sets out the requirements for IBCs in Canada. However, Transport Canada plans to make this new marking mandatory in the next edition of the standard CGSB-43.146 in order to harmonize the domestic regulations with the UN Model Regulations. Until then, Canadian manufacturers of IBCs should consider voluntarily starting to apply these new symbols as soon as possible. This marking will have to be applied on IBCs manufactured after January 1, 2011 if they are to be accepted for international transport. IBCs manufactured before the deadline are not required to be marked and may continue to be used as is.

Transportation of Dangerous Goods Act, 1992, Impact on ERAP Program

The Transportation of Dangerous Goods Act, 1992, was revised significantly in June 2009. A number of changes in the Act impact the Emergency Response Assistance Plan (ERAP) program directly. The goal of the ERAP program is to ensure industry maintains an effective transport related emergency response capability for higher risk dangerous goods. The following article will describe the changes to the Act that are relevant to the ERAP program.

One of the most significant changes that impacts the ERAP program is the ability to revoke a plan that isn’t activated to respond to an actual or anticipated release of dangerous goods to which the plan applies (Paragraph 7.(5)(d)). Although the Act does not distinguish between a major or minor release, subsection 7.(2) clarifies that the ERAP applies to any transport related incident that could endanger public safety. Since the response must also be implemented as described in the approved plan, it is in the best interest of the ERAP holder to describe in detail in their plan how they would respond to events of varying severity.

Paragraph 7.1(a) of the Act allows Transport Canada to direct a person to activate their ERAP for response to an actual or anticipated release of dangerous goods to which the plan applies (for example for product the plan holder has imported or offered for transport). To be clear, Transport Canada can only direct a person to activate their ERAP when that person requires an ERAP under Subsection 7.(1) of the Act. The direction would specify a timeframe for the implementation of the response. If a plan holder refuses to comply with the direction, their plan could be revoked under paragraph 7.(5)(e) of the Act.

Paragraph 20(a) of the Act provides personal liability protection for any act or omission done in good faith and without negligence where an ERAP that is required is implemented in accordance with the plan and CANUTEC is informed of the response.

Prior to the changes to the Act, it was at times difficult to identify an importer in Canada. The importer is the person who is causing the dangerous goods to enter Canada – usually the consignee. If the importer isn’t readily identifiable, Section 2.1 of the Act can be used to identify one. The importer would be “deemed” the person named on the shipping record upon entry into Canada as the person to whom the dangerous goods are to be delivered. Consider also that subparagraphs 9.1(1)(a)(i) and 10.1(1)(a)(i) of the Transport Dangerous Goods Regulations for road and rail, respectively, require the identification of the consignee in Canada (i.e. the consignor) on the shipping record for product imported into Canada. A similar requirement also exists for air and marine shipments.

When product requiring an ERAP is transiting through Canada, the person who handles or transports the dangerous goods (i.e. the carrier) is responsible for the ERAP as per paragraph 7.(1)(c) of the Act. Where there are multiple carriers involved, each carrier is responsible for the ERAP for the portion of the movement where they are handling or transporting the dangerous goods. Paragraph 7.1(7)(a) of the Transport Dangerous Goods Regulations allows the carriers to use someone else’s ERAP. For example, the carriers could use the ERAP of one of the carriers or of anyone else as long as they have permission and the ERAP is valid for the product, the mode of transport and the geographical area of coverage. Although the words in the Act have changed, this requirement is not new. Prior to the change to the Act, each carrier that transported the dangerous goods became an importer by definition and was responsible for the ERAP. The Act was changed to improve clarity.

As of June 2009, all ERAP approvals are issued for a specified period of time (including interim approvals and the former “indefinite” approvals). The interim approvals are issued following a preliminary evaluation of an application to confirm that a response capability exists. Interim approvals do not usually involve site assessments. The specified period approvals (formerly indefinite approvals) are issued following a detailed evaluation of the plan, including site assessments that consider available response equipment, personnel, training, exercises, equipment maintenance, etc. Since ERAP approvals are now time sensitive, it is in the plan holder’s best interest to provide information to the inspector reviewing the plan in a timely fashion to ensure the assessment is completed prior to the ERAP’s expiration.

The Impact of Changes to the Transportation of Dangerous Goods Act, 1992, on the Transport Canada Chemical, Biological, Radiological, Nuclear, Explosives (CBRNE) Response Program

The Transportation of Dangerous Goods Act, 1992, has been amended and received Royal Assent in June of 2009. The amendments deal mainly with introducing security requirements and safety aspects of the Act. Certain changes to the Act have accelerated the CBRNE Response Program and made the final phases of the program possible to implement.

The Transport Canada CBRNE Response Program is progressing well. This program was initiated in 2001 in order to enhance preparedness and response to CBRNE incidents within Canada. The threat that dangerous goods could be utilized or implicated in a CBRNE incident is well recognized. The objective of the Transport Canada CBRNE Response Program remains to ensure that, in the event of incidents involving dangerous goods in a CBRNE incident in Canada, specialized assistance is available to appropriate authorities.

Background

According to Public Safety Canada, a CBRNE incident can be categorized as either an accidental or an intentional incident. “An accidental CBRN incident refers to an event caused by human error or natural or technological reasons. This could include spills, accidental releases or leakages. These are generally referred to as DG or HAZMAT accidents. An intentional CBRN incident is criminal in nature and can include acts of terrorism, the deliberate dumping or release of hazardous materials to avoid regulatory requirements or the malicious, but non-politically motivated poisoning of one or more individuals.”

The Transport Canada CBRNE Response Program is based on utilizing existing resources that are in place as a result of the regulatory requirement for Emergency Response Assistance Plans (or ERAPs). The legal requirement for having an ERAP before offering for transport or importing certain dangerous goods is stated in section 7 of the Transportation of Dangerous Goods Act, described in Part 7 of the Transportation of Dangerous Goods Regulations. The dangerous goods that require an ERAP are those that pose a greater risk of exposure and those that require specialized handling and equipment. The dangerous goods necessitating an ERAP are listed by its quantity or concentration indicated in the ERAP index of column 7 of Schedule 3 in the Regulations.

The impact of this requirement has resulted in a Canada-wide network of response capability for all types of dangerous goods. This response capability comes from the transportation industry, chemical manufacturers and emergency response contractors. The ERAP infrastructure has produced a network of verified industry emergency responders that are normally trained and equipped to respond to dangerous goods accidents in the course of transport.

Although the Transport Canada CBRNE Response Program is progressing, gaps in ensuring that response capability could be made available were identified for dangerous goods in certain situations. For instance, an incident necessitating response involving an “erapable” dangerous goods for which the ownership of the dangerous goods could not be determined, is an example of a problematic situation where response to the dangerous goods could not be assured because there was no ERAP associated to those dangerous goods involved. It was also a concern that the provisions of the Act prior to the 2009 amendment were based on accidental or unplanned releases of dangerous goods only. Emergency responders from industry (ERAP holders) were reluctant at best to respond in an incident dealing with an apprehended release, even if it was their product, due to a lack of liability protection coverage. The success and full implementation of the Transport Canada CBRNE Response Program lies in the changes to the Act.

Safety aspects of the amendments to the Transportation of Dangerous Goods Act have been made to reinforce and strengthen the ERAP Program. These changes will enhance public safety and domestic preparedness by enabling response capability to dangerous goods and CBRN incidents, along with providing liability protection to those responding. The scope of the Act is broadened by elaborating on the interpretation of a dangerous goods release “to be an actual or anticipated release”, rather than “an unplanned or accidental release” from previous. As a result, section 20 of the Act dealing with liability protection would apply for any person who responds to an actual or anticipated release in accordance with 20(a)(b)(c), whether accidental or not, and would not be personally liable either civilly or criminally. The Minister, or designate, also has the authority to direct a person with an approved plan to implement the plan within a reasonable time frame in order to respond to an actual or anticipated release of the dangerous goods to which the plan applies under subsection 7(1)(a). This means that an ERAP can be activated to respond to an actual or anticipated release of dangerous goods to which the plan applies, in the event of a CBRNE incident with the benefit of liability protection coverage. Subsection 7(1)(b) states that “The Minister, or designate, may also authorize a person with an approved plan in order to respond to an actual or anticipated release of the dangerous goods if the Minister does not know the identity of any person required under subsection 7(1) to have an emergency response assistance plan in respect of the release.” This is self-explanatory and is especially useful for response capability to exist in situations where the source of the dangerous goods is known but the release is a non-accidental, apprehended release.

The new security requirements include security plans, security training and transportation security clearances and are governed by such legal instruments as interim orders, security measures and regulations. Persons importing, offering for transport, handling or transporting dangerous goods in a quantity or concentration specified by regulations or that is within a range of quantities or concentrations that is specified by the regulations must have a security plan in accordance to the regulations. They must also have undergone security training to implement the security plan in accordance to the Regulations. The Act further establishes authority to track the movement of dangerous goods.

The legislative changes officially provide Transport Canada with the mandate of implementing the CBRNE Program. An important outcome, as explained, is closing the gap on the ability for industry emergency responders to enable them to respond to a CBRNE incident involving dangerous goods. In addition to liability protection provisions, the new Act mentions a funding envelope in the event that an ERAP under 7(1)(b) is implemented. The compensation shall be paid out of the Consolidated Revenue Fund.

The Transport Dangerous Goods Directorate has thus far provided interested parties and stakeholders with key learning opportunities. In March 2004, Transport Canada hosted five CBRNE Awareness sessions across Canada. A practical training session involving program participants was held in Morrisburg, Ontario, in March 2005. Another CBRNE session took place in Calgary, in 2009, aiming to bring appropriate government entities and industry representatives to the table and share their roles and capabilities in the event of a CBRNE incident in Canada. In January 2010, a radiological workshop was organized and involved stakeholders, including program participants demonstrating capabilities relating to class 7 dangerous goods, namely radioactive materials. Verification of participant’s capabilities has begun, in parallel with ERAP audits.

Transport Canada maintains an up-to-date database with a list of participants along with their scope of response and capabilities. Participation to the Transport Canada CBRNE Response Program remains voluntary. There are currently approximately 35 organizations that have demonstrated their interest in providing response capabilities to Transport Canada in a CBRNE incident.

The next steps are to continue soliciting interested participants in light of the new provisions for liability protection, to continue CBRNE capability response verification for the program participants, to meet with other government agencies to discuss the Transport Dangerous Goods Directorate’s modified mandate and the limitations it may have. We also intend to provide stakeholders and participants with appropriate learning opportunities. Those interested in participating in Transport Canada’s CBRNE Response Program can communicate with either Fred Scaffidi at 613-998-9394 (Fred.Scaffidi@tc.gc.ca) or Kathleen Corriveau at 613-998-6276 (Kathleen.Corriveau@tc.gc.ca).

25 Years of Responsible Care®: The Chemistry Industry’s Bold Initiative of Self-Monitoring and Public Outreach Celebrated its Silver Anniversary in 2010

Last year marked the 25th anniversary of Responsible Care® – the chemistry industry’s global voluntary initiative, under which companies continuously work to improve their health, safety and environmental performance, and to communicate with communities about their products and processes.

In 1985, Canada’s chemistry CEOs began developing Responsible Care because they recognized that the industry could not continue in a “business as usual” fashion. Calls for more government regulation of the industry had increased since the late 1970s, when a dangerous goods train derailed in Mississauga, Ont., causing the evacuation of the nation’s fifth-largest city.

“The leaders of the chemistry industry found themselves at a difficult crossroads,” recalls Jean Bélanger, former president of the Chemistry Industry Association of Canada (then known as the Canadian Chemical Producers’ Association). “They had to accept the fact that the public did not trust their industry.”

“The public believed that we were more concerned about profits and secrecy than about our employees, neighbours and customers,” says Brian Wastle, who worked as a plant manager in the 1980s and was the association’s vice-president of Responsible Care until his retirement in December 2010.

“Incidents happened that got away from us. The federal government was threatening to regulate us. So ultimately, the industry was looking for a way to move from that victim complex to becoming a master of its own destiny.”

Responsible Care offered Canadian chemistry companies a greater sense of control over their operations, but also led to a profound cultural shift within the industry. Early on in Responsible Care’s development, industry CEOs recognized that building public trust must be their priority, and that would require a commitment to doing the right thing, and going beyond the letter of the law. Committing to this principle radically changed the way the chemistry industry operated – from companies focused on regulatory compliance, to ones that were ethically oriented.

Between 1985 and 1988, the first Responsible Care codes were developed – their writing accelerated by the industrial disaster in Bhopal, India, which underlined the need for stringent guidelines on the safe and environmentally sound management of chemicals. Feedback from environmentalists informed the writing of the final six Responsible Care codes: Research & Development, Manufacturing, Community Awareness & Emergency Response, Transportation, Distribution, and Hazardous Waste Management. In total, the association spelled out 150 requirements, controlling each step in a chemical’s life cycle.

Despite the industry’s efforts to establish a stringent set of Responsible Care requirements for companies to adhere to, some criticized the initiative as being nothing more than a public relations exercise. For that reason, the association took a critical step towards greater transparency: establishing a National Advisory Panel, composed of activists and others outside the chemistry industry, to challenge its companies to improve their performance. In 1993, the association also introduced the Responsible Care public verification process; teams of public advocates, neighbours and industry experts ventured behind plant gates to verify that member-companies were living up to their promises. All association members are now publicly verified every three years.

By the early 1990s, it was clear that Responsible Care was working. Workplace safety records showed a dramatic improvement and the association’s member-companies substantially reduced their environmental footprints (to date, their overall emissions have been reduced by 87 per cent). The Canadian Responsible Care model was deemed such a success that it was adopted by dozens of countries across the world – a global movement now practised in more than 50 countries.

Despite its success, in 2007, Canada’s Responsible Care initiative began a process of dramatically reinventing itself. Its principles were extensively reviewed and the concept of sustainability was woven into its ethic to address a wave of public concern around issues like health, climate change, conservation and the environmental footprint of the chemistry industry.

Responsible Care’s shift toward sustainability means ever more stringent standards for Chemistry Industry Association of Canada member-companies to live up to – but they wouldn’t have it any other way.

“What I’m looking forward to seeing now are the innovative ways that our industry will put sustainability into practice over the next 25 years,” says Richard Paton, president and CEO of the association. “That’s going to be very exciting to witness.”

This Article was first published in the November/December 2009 edition of the “Pacific Progress”, a newsletter distributed by Transport Canada in the Pacific Region

TDG Carries the Olympic Torch

The Surface Branch located in New Westminster will be the Olympic Surface Coordination Center for Rail Safety, Transportation of Dangerous Goods and Surface Inter- Modal Security communications and coordination with the RCMP-led Integrated Security Unit. Eight inspectors from across Canada will be in Vancouver during the Olympics to assist the Pacific Region inspectors. They came to Vancouver for Exercise Gold, from November 2-6th, for an orientation and learned that one of their own fellow inspectors would be carrying the Olympic Torch in Newfoundland. Colin Howse walked into the coordination center wearing his torch relay uniform and carrying a “torch” cake. Check out Colin’s amazing story below.

Colin Hose Olympic Torch Run – November 13, 2009

“It was even more exciting than I had imagined.” These are the first words out of Colin Howse’s mouth when you ask him the first thing that comes to mind when he reflects on his Olympic Torch Relay 2010 experience.

Colin was chosen as one of over 300 torchbearers in Newfoundland and Labrador to participate in the torch relay. In speaking to Colin about his Torch run, he said he felt extremely proud to have been chosen as a torch bearer, and he was awed and impressed by the stories of the other torch bearers he met in his stage of the relay. He was overwhelmed with the family and friends who came out to cheer him on, including his granddaughter Cassidy who was visiting from Conne River, NL just to see her grandpa run with the torch.

“The energy of the crowd at O’Donnell High School (Mount Pearl) where our group of runners began their day was phenomenal. And to see so many familiar faces at my starting point, and to be able to hoist the torch and run in front of those same supporters was an amazing experience,” said Colin.

Colin’s Day 15 route took him through a section of the City of Mount Pearl, a community adjacent to St. John’s.

When asked about any advice he would give to future torch bearers for these Olympics or future Games, Colin advised that they soak up the energy and excitement and be very proud that they were chosen to take part in such a special event.

Colin Howse is a Regional Remedial Measures Specialist with the Transportation of Dangerous Goods branch of Transport Canada based out of the St. John’s, NL office.

An Excerpt From Colin’s Torch Relay Essay

“The 2010 Olympics have also found their way into my life as a member of the Transport Canada team assigned to ensuring the safe transport of dangerous goods during the 2010 games. Carrying the Olympic torch is a dream I never thought possible yet at 54 years of age I’m feeling like a kid, waiting for the chance to hold the symbol of the worlds greatest athletic event.”

Response to Radiological Emergencies Workshop

Introduction

The Transport Dangerous Goods Directorate, Transport Canada, is pleased to report that a Radiological Workshop “Response to Radiological Emergencies – What services are available from Industry?” was held on January 6 – 7, 2010 at the Government Conference Center in Ottawa.

Background

The “CBRN Strategy of the Government of Canada” (March, 2005, please see www.publicsafety.gc.ca to obtain a copy of the document) assigns responsibilities to government departments in the event of a CBRNE terrorism event in Canada (note that since 2005, the term CBRN has been modified to include explosives; thus the new abbreviation CBRNE). The Transport Dangerous Goods Directorate’s responsibility, as stated in the Strategy, is to provide access to approved emergency response teams and technical information by CANUTEC in the event of a CBRNE terrorism event in Canada. In order to fulfill this responsibility, the Directorate is developing a program known as the TDG CBRNE Response Program. This program provides access to trained emergency response teams from the industry sector to support the first response community (fire and police departments and other officials) in the event of a terrorism incident involving dangerous goods used as CBRNE agents in Canada. Local authorities, through the Transport Dangerous Goods Directorate would be able to call upon these teams to gain the specialized support and extra capacity they possess when needed. The CBRNE Response Program is modeled on our already familiar Emergency Response Assistance Plan (ERAP) program.

Purpose of the Workshop

There are now new authorities under the Transport of Dangerous Goods Act, 1992, that enable Transport Canada to bring industry response capabilities into a CBRNE incident, transport-related or not (please see http://www.tc.gc.ca/eng/acts-regulations/acts-1992c34.htm for the latest version of the Act). These authorities include provision for liability protection and compensation for costs. One of the objectives of the workshop was to present the changes to the Act and solicit input from the participants. Are there concerns from industry? What regulatory changes should follow from the changes to the Act? Please see an article in this newsletter entitled “The Impact of Changes to the Transportation of Dangerous Goods Act, 1992, on the Transport Canada Chemical, Biological, Radiological, Nuclear, Explosives (CBRNE) Response Program” by Kathleen Corriveau for further information on this question.

A further objective was to understand industry response capabilities concerning response to incidents involving radiation. This is obviously a high priority for the CBRNE response community for many reasons but primarily due to the potential to impact many people and structures. This would overwhelm resources at all levels of government. The capabilities of industry would most certainly be needed. The workshop provided a forum for government and industry to reveal the challenges and explore how they could work together.

Workshop Highlights

The workshop’s aim was to provide a forum for interaction between the public and private sectors as these two entities working together it what will make the CBRNE Response Program a success. Therefore, the event provided an opportunity for government officials and industry representatives to become more familiar with each other’s capabilities and expectations during a radiological incident. A wide range of speakers and subjects were presented including:

- TDG CBRNE Response Program Overview and, Changes to the Transportation of Dangerous Goods Act that impact on terrorism response in Canada (includes new authorities and security sections), by Transport Canada;

- Discussion on CRTI model and lessons learned from exercises, by Defense Research and Development Canada – Center for Security Science (DRDC-CSS);

- FNEP (Federal Nuclear Emergency Plan) and technical issues surrounding consequence management + Polonium -210 Lessons from the Contamination of Individual Canadians, by Health Canada;

- Regulatory overview of response capabilities from industry/ERAP teams, by Canadian Nuclear Safety Commission (CNSC);

- National Strategy and Action Plan for Critical Infrastructure, by Public Safety Canada;

- Capabilities, role and responsibilities of NRCAN, by Natural Resources Canada (NRCAN);

- Dealing with radiological contamination on buildings, by DRDC – Ottawa;

- Capabilities in a radiological emergency, by Atomic Energy of Canada Limited (AECL – Chalk River, ON);

- Capabilities in a radiological emergency, by CAMECO – Port Hope, ON;

- Capabilities in a radiological emergency, by Stuart Hunt and Associates – St. Albert, AB;

- Role of the Fire Services in CBRNE response, by Office of the Ontario Fire Marshal.

In addition, 2 exercise scenarios were presented. Participants were divided into small groups and asked to assess the scenario and explain what a response to a given scenario would look like based on the following high level response categories: Prevention, Initial Response, Verification, Setup of Incident Command, Communications, Monitoring, Human Impact, Response and Recovery

Results

The workshop generated much discussion and ideas the following are some of the higher-level points:

- Changes to the Transport Dangerous Goods Act were well received by industry – Transport Canada is working on the development of a regulatory framework around these changes.

- The capabilities and expertise of the industry would be indispensable in a large-scale radiological response.

- The response contractor community who are not necessarily shippers or receivers of dangerous goods (do not require an ERAP) need to be brought into the ERAP framework.

- Industry can play an important role during any phase of an incident but would most probably play the biggest role during recovery from a radiological incident.

It is our hope that industry response teams that have not already done so would consider adding their organizations to our list of CBRNE response teams (please contact Kathleen Corriveau at Kathleen.Corriveau@tc.gc.ca or Fred Scaffidi at Fred.Scaffidi@tc.gc.ca, for more information about participating in the CBRNE Response Program or if you would like further information about the Radiological Workshop discussed here).

Thanks

The Transport Dangerous Goods Directorate wishes to thank our speakers for volunteering, preparing and presenting to our workshop participants. We are especially grateful for this as the workshop occurred near the height of preparations for the 2010 Olympic Games.

And finally we would like to thank our participants. We hope that the workshop was beneficial for you. We appreciate the commitment demonstrated by the attendance at our seminar and look forward to working with you in further developing our CBRNE Response Program.

Sample of Reportable Accidents Across Canada in 2010

This article highlights some reportable accidents that were reported to the Transport Dangerous Goods Directorate in 2010. Every effort was made to vary this sample of accidents by choosing different provinces/territories, classes of dangerous goods, modes of transport and means of containment, as well as taking into account the accident severity. A similar article was produced for 2009 reportable accidents, but never published in the TDG Newsletter. If you would like a copy, please contact Lindsay Jones at Lindsay.Jones@tc.gc.ca.

Severity Level 2

Edmundston, New Brunswick

METHANOL – Class 3(6.1)

During rail yard operations, a rail tank car (DOT111A100 W1) containing METHANOL was discovered leaking 100 litres of product from the bottom valve. There were no injuries. Emergency response personnel closed the valve to stop the leak. They also cleaned up the released product. This release was considered reportable and required the submission of a 30-Day Follow-Up Report, because the release exceeded the amount set in the table appearing in subsection 8.1(1) for METHANOL’s subsidiary class (Class 6.1 – 5-litre threshold), but not the primary class (Class 3 – 200-litre threshold).

Severity Level 4

Trois-Rivières, Quebec

SODIUM DITHIONITE; SODIUM HYDROSULFITE;

or SODIUM HYDROSULPHITE – Class 4.2

During transport in a tractor-trailer, a bulk tote container (DOT spec 56/20343/tsg638/6000/2722/462/2100/498/226/02-1984/Aluminum/AL-ASTM 209//R 01-2008) containing 1,800 kilograms of SODIUM HYDROSULFITE leaked a small amount of product onto the trailer’s floor. A fire started on the trailer’s floor due to a thermal reaction, thus heating up the container. There were no injuries. Emergency response personnel extinguished the fire. The bulk tote container was removed from the trailer, placed into a basin, and doused with large amounts of water to lower its temperature. The product was emptied from the container and diluted.

Severity Level 0

Enfield, Nova Scotia

CARBON DIOXIDE, SOLID; or DRY ICE – Class 9

After being transported by air in the cargo hold of an airplane, a box (UN4G/Fibreboard Box) containing DRY ICE was delivered to the consignee. At that time, it was discovered that the box had been transported without the proper dangerous goods shipping documents. There was no release of product, no injuries and no damage to the box. The “dangerous goods incident” (as defined in the International Civil Air Organization’s (ICAO) “Technical Instructions for the Safe Transport of Dangerous Goods by Air”) was reported to the proper authorities.

Severity Level 0

Dorval, Quebec

RADIOACTIVE MATERIAL, TYPE A PACKAGE,

non-special form, non-fissile or fissile excepted – Class 7

During transport in a cargo truck from a cargo building to an airport ramp for loading, three drums (UN1A2) of RADIOACTIVE MATERIAL, TYPE A PACKAGE that were loaded in a cargo tub cart were jostled. This caused two of the drums to fall over and pop their lids and for the third to sustain a puncture. There was no release of product and no injuries. The three drums were placed in a designated radioactive storage area until the consignor’s emergency response personnel were able to inspect and repackage them. They were then delivered to their destination.

Severity Level 2

Etobicoke, Ontario

SODIUM HYDROXIDE SOLUTION – Class 8

During switching operations at a plant siding, a rail tank car (DOT111A100 W1) containing SODIUM HYDROXIDE SOLUTION was moved away from the offloaded rack with the hoses still attached. As a result, one of the hoses separated from the tank car and 13,650 litres of product was released into a containment area. There were no injuries. A vacuum truck was dispatched to the site for clean up.

Severity Level 4

Redwater, Alberta

AMMONIA, ANHYDROUS; or ANHYDROUS AMMONIA – Class 2.3(8)

During a farm field application, 1,800 kilograms of ANHYDROUS AMMONIA was released from a nurse tank (TC-51/Canada/Q-3002/A 2873-4213/Yes/265 psi/398 psi/-20ºF - +110ºF/3400kg/ Annual/08-2010/265 psi//Master Tank & Welding/06-1984) when the hitch broke and the breakaway coupler failed. This caused the hose to disconnect from the tank. There were no injuries. The consignor’s emergency response personnel went to the scene to shut off the tank valve, which stopped the leak.

Severity Level 2

Hope, British Columbia

TOXIC LIQUID, ORGANIC, N.O.S. – Class 6.1

While being transported in a road tractor-trailer, a drum (UN1A1/Y1.2/100/09) containing waste TOXIC LIQUID, ORGANIC, N.O.S. (Diazinon) leaked 200 litres of product inside the trailer and on the roadway. There were no injuries. Emergency response personnel were on site to clean up the released product and to remove the leaking drum from the trailer for proper disposal.

Severity Level 4

Halbrite, Saskatchewan

PETROLEUM CRUDE OIL – Class 3

During transport, a tractor tank trailer (DOT 407/Advance/6692-3/2006/2AEASXBH56R000204/44000L/03-10 VK 707/3 axle semi trailer) containing PETROLEUM CRUDE OIL experienced a wheel failure. The wheels on the #2 passenger side axel of the unit came loose and subsequently disengaged themselves from the trailer. The free wheels then came into contact with the piping on the trailer and broke parts of the piping along the side of the trailer. There were 238 litres of fluid that sprayed from the piping onto the highway where it then ignited. There were no injuries. Emergency response personnel were on site to extinguish the fire and to clean up the released product. The remaining product was then transferred into another tank trailer and the damaged unit was placed on a flatbed and transported to a repair facility.

Severity Level 3

Souris, Manitoba

DIESEL FUEL; FUEL OIL; GAS OIL; or HEATING OIL LIGHT – Class 3

During transport, a tractor tank trailer (TC 306 AL Petroleum/Advance/ /02-2002/2AEABSAH91R000218/18500-5000-12000L/03-10 VK 707, 02-08 PI 707/Petroleum Tank Trailer - Lead) and pup (TC306 AL Petroleum/Advance//02-2002/2AEARPAE41R000223/ 6500-5000-18500L/03-10 VK 707, 02-08 PI 707/Petroleum Tank Trailer - Pup) (b-train) containing DIESEL FUEL was overturned while turning a corner. The tractor tank trailer and pup slid across the highway and came to rest in a ditch. Both of the tanks were severely damaged and released the entire 50,223-litre shipment. There were no injuries. Emergency response personnel were on site to clean up the released product and to remove the damaged unit from the ditch.

Severity Level 1

Enterprise, Northwest Territories

GASOLINE; MOTOR SPIRIT; or PETROL – Class 3

PETROLEUM CRUDE OIL – Class 3

During transport, a tractor tank trailer (TC 406/Columbia Remtec/43003167/10-2006/2C9LAA35071026006/6000-14000L//Lead trailer) and pup (TC406/Columbia Remtec/52702167/10-2006/2C9LBA25471026007/27000L//Pup trailer) containing GASOLINE caught fire. The entire consignment of 52,316 litres was burned and the unit was severely damaged. There were no injuries. Emergency response personnel were on site to monitor the scene until the entire amount of product had burned off and then to extinguish the fire within the structure of the unit.

Severity Level 6

Burbank, Alberta

LIQUEFIED PETROLEUM GASES; or PETROLEUM GASES, LIQUEFIED – Class 2.1

While in transit, a train derailed five rail tank cars containing LIQUIEFIED PETROLEUM GAS. Three of these rail tank cars overturned, and one overturned rail tank car (DOT112J340 W) sustained a puncture and released 60,000 litres of product. There were no injuries. Emergency response personnel were on site and set up a 1.6 kilometre radius evacuation zone, which included 5 residences. A freeze patch was applied to the hole on the punctured rail tank car, which stopped the leak. The remaining product was then transferred into a Super B tanker truck and the residue was flared off. Product transfers were performed on the remaining overturned rail tank cars, and then the derailed cars were righted, re-railed and moved under temporary certificates to a repair facility. There were three Emergency Response Assistance Plan’s (ERAP) activated during this release.

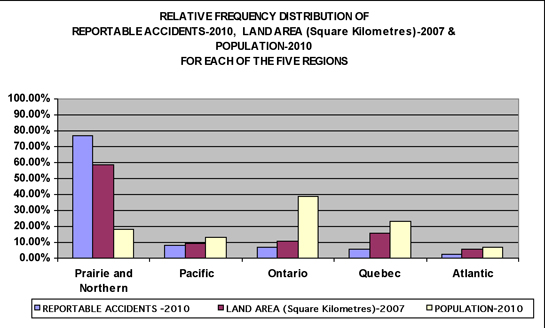

Reportable accident Statistics for 2010 by Regions

This article presents a brief overview of reportable dangerous goods accident statistics by region for 2010. The figures in this article include the number of 30-day follow-up reports received as of December 31, 2010 and an estimate for the number of 30-day follow-up reports expected to be received during the 30-day grace period ending January 31, 2011. A reportable accident is defined as an accident where a release of dangerous goods exceeds the quantity determined in Part 8 of the Regulations.

The Transport Dangerous Goods regions are defined as follows:

Atlantic Region: Newfoundland and Labrador (NL), Prince Edward Island (PE), Nova Scotia (NS) and New Brunswick (NB)

Quebec Region: Quebec (QC)

Ontario Region: Ontario (ON)

Prairie & Northern Region: Manitoba (MB), Saskatchewan (SK), Alberta (AB), Yukon (YT), Northwest Territories (NT) and Nunavut (NU)

Pacific Region: British Columbia (BC)

Highlights of 2010 Reportable Accidents:

- 342 reportable accidents in 2010 in Canada

- 61% of the reportable accidents occurred in Alberta

- 62% of all reportable accidents occurred during handling operations

- 94% of the reportable accidents were minor in severity

- 20.9 days average time to file 30-day follow-up report for reportable accidents

Regional Statistics: Reportable accidents, geographic land area and population size

The chart below presents a regional percentage comparison between the number of reportable accidents reported to the Transport Dangerous Goods Directorate in 2010, the land area measured in square kilometers (figures exclude freshwater and are current as of April 1, 2007) and the population, based on Statistics Canada estimates as of January 1, 2010.

Prairie and Northern is the largest region in Canada based on geographical land area. It represents almost sixty (60%) percent of the entire country, seventy seven (77%) percent of the reportable accidents and eighteen (18%) percent of the population. Sixty one (61%) percent of the reportable accidents submitted to the Transport Dangerous Goods Directorate occurred in the province of Alberta. This is primarily due to the increased activities in the natural resources sector. The Province of Alberta diligently enforces the 30-day follow-up reporting requirements. As a result, companies are more aware of and fully understand the requirement to report. Prairie and Northern is the only region where the accident percentage exceeds both the geographical land area and population percentage. In comparison, the four remaining regions have larger population percentages associated with both smaller geographical land area and number of reportable accident percentages. It would be interesting to compare the number of reportable accidents with the number of shipments or the numbers of millions-kilometres but unfortunately, these statistics are not available.

Submission of mandatory 30-day follow-up reports

Companies are required to complete and file 30-day follow-up reports within 30 days of an accident. On average, across all regions, almost 66% of 30-day follow-up reports were received within the 30-day grace period. As of December 31, 2010 there were no late reports received for the Atlantic Region. However, this region presents the largest percentage of outstanding reports and consequently, the number of late reports received after 30 days will obviously increase. For 2010, the number of outstanding 30-day follow-up reports remains in the low double digit across the country. This has been accomplished with the cooperation of both federal and provincial inspectors who conducted follow-up activities for companies in non-compliance with the reporting requirements.

Companies are given 30 days to gather the required information and file the follow-up report with the Transport Dangerous Goods Directorate. The number of days to report is calculated as the difference measured in days between the accident and report dates. The accident date represents the day the accident occurred and the report date is the date the 30-day follow-up report was completed and signed by the company. In 2010, on average, when a 30-day follow-up report was completed for a reportable accident, it was submitted within 20.9 days of the accident date.

In 2010 on average, 30-day follow-up reports for accidents in the Prairie & Northern, Pacific and Atlantic regions were submitted before the deadline. This is quite an accomplishment considering the number of 30-day follow-up reports received for accidents in the Prairie & Northern region. On average, 30-day follow-up reports for accidents in the Ontario and Quebec regions were submitted late. Note however that the outstanding reports are not included in these statistics.

The Transport Dangerous Goods Directorate pursues the collection of outstanding “30-Day Follow-Up Reports”, with the assistance of regional inspectors who conduct follow-up investigations. Letters requesting the filing of outstanding reports are sent to the companies who had charge, management or control of the dangerous goods at the time of the accidental release. We would like to thank everyone involved in this process for their collaboration.

If you would like an update on this article once the 2010 accident reporting 30-day grace period expires January 30, 2011 please contact Jonathan Rose at Jonathan.Rose@tc.gc.ca.

CANUTEC

January 1, 2010 to December 31, 2010

The Dangerous Goods Newsletter is published twice yearly in both official languages by the Transport Dangerous Goods Directorate, Transport Canada, and is distributed to government and industry organizations in fields related to dangerous goods.

Subscriptions are free of charge and available to anyone on request by calling 613-990-1148 or by visiting the TDG website at http://www.tc.gc.ca/eng/tdg/newsletter-menu-268.htm and clicking on Request. This newsletter is also available at the same internet address. Please address comments and inquiries regarding additional information or publications to:

The Editor,

Dangerous Goods Newsletter

Transport Dangerous Goods

Transport Canada

330 Sparks Street, Tower C, 9th floor

Ottawa, Ontario, Canada

K1A 0N5

Editor

Véronique Tessier

(veronique.tessier@tc.gc.ca)

Graphics and Design

Yvan Meloche

(yvan.meloche@tc.gc.ca)

Writers/Contributors to this issue

Danny Bechamp - Compliance and Response Branch, TDG Directorate

Donna McLean - Compliance and Response Branch,

TDG Directorate

France Bernier - Regulatory Affairs Branch,

TDG Directorate

Fred Scaffidi - Compliance and Response Branch,

TDG Directorate

Jonathan Rose - Research, Evaluation and Systems Branch,

TDG Directorate

Julie McGuire - Communication and Marketing,

Atlantic Region

John Tomaselli - Compliance and Response Branch,

TDG Directorate

Kathleen Corriveau - Compliance and Response Branch,

TDG Directorate

Lindsay Jones - Research, Evaluation and Systems Branch,

TDG Directorate

Harvey Chartrand - Writer- Researcher

for Chemistry Industry Association of Canada

Micheline Paquette - Acting Program Manager

Dangerous Goods, Standards, Civil Aviation, Transport Canada

Susan Williams - Research, Evaluation and Systems Branch,

TDG Directorate

Contacts

Transport Dangerous Goods Directorate

Director General

M.-F. Dagenais 613-990-1147

(Marie-France.Dagenais@tc.gc.ca)

Regulatory Affairs

J. St. Onge, Director 613-998-6540 (Joanne.St-Onge@tc.gc.ca)

Compliance and Response

C. Law, Director 613-998-6540 (Clive.Law@tc.gc.ca)

Research, Evaluation and Systems

G. Oliver, Director 613-990-1139 (Geoffrey.Oliver@tc.gc.ca)

TDG Secretariat

N. Belliveau, Director 613-998-6540 (Nathalie.Belliveau@tc.gc.ca)

CANUTEC

Information 613-992-4624

Emergency 613-996-6666

Fax 613-954-5101

(Canutec@tc.gc.ca)

Atlantic Region

Dartmouth 902-426-9461

Fax: 902-426-6921

St. John's 709-772-3994

Fax: 709-772-5127

Moncton 1 866-814-1477

Fax: 506-851-7042

E-mail: Tdg-TmdAtlantic@tc.gc.ca

Quebec Region

514-283-5722 Fax: 514-283-8234

E-mail: tmd-tdg.Quebec@tc.gc.ca

Ontario Region

416-973-1868 Fax: 416-973-9907

E-mail: tdg-tmdOntario@tc.gc.ca

Prairie and Northern Region

Winnipeg 204-983-5969

Fax: 204-983-8992

Saskatoon 306-975-5105

Fax: 306-975-4555

E-mail: Tdg-TmdPnr@tc.gc.ca

Pacific Region

New Westminster 604-666-2955

Fax: 604-666-7747

Kelowna 250-491-3712

Fax: 250-491-3710

E-mail: TDGPacific-TMDPacifique@tc.gc.ca

Transport Canada Dangerous Goods Directorate

Internet address - www.tc.gc.ca/eng/tdg/menu.htm

We welcome news, comments or highlights of transportation of dangerous goods activities, announcements of meetings, conferences or workshops. The Newsletter carries signed articles from various sources. Such articles do not necessarily represent the views of the Directorate, nor does publishing them imply any endorsement. Material from the Newsletter may be used freely with customary credit.