ISSN 0828-5039 Vol. 29 No. 1 Agreement Number 2182971

An Act to amend the Transportation of Dangerous Goods Act, 1992

Inside

- Editorial

- TDG Inspectors' Workshop - October 2008

- An Amended TDG Act, 1992

- North American Inspectors Championship 2008

- Which Edition of a Safety Standard or Requirement do We Need to Comply With?

- Ticketing Update

- Amendment to the Standard on Tank Cars and Other Means of Containment for the TDG by Rail

- Field verification of the Chlorine Institute's pump for autorefrigerated chlorine

- Transportation of UN 1999, Tars, Liquid

- What is Risk, and How can it be Managed?

- Transport Canada's CBRNE Response Seminar

- Training initiative across the country

- Accident Summary Report 2008

- Non-Spec Tank Grandfather Clause Expiring

- Alert

- CANUTEC Stats

TP 2711 E

06/2009

The Dangerous Goods Newsletter is published twice yearly in both official languages by the Transport Dangerous Goods Directorate, Transport Canada, and is distributed to government and industry organizations in fields related to dangerous goods. Subscriptions are free of charge and available to anyone on request by calling 613-998-1834 or by visiting the TDG website at http://www.tc.gc.ca/eng/tdg/newsletter-menu-268.htm and clicking on Request. This newsletter is also available at the same internet address. Please address comments and inquiries regarding additional information or publications to:

The Editor,

Dangerous Goods Newsletter

Transport Dangerous Goods

Transport Canada

330 Sparks Street, Tower C, 9th floor

Ottawa, Ontario, Canada

K1A 0N5

Editor

Véronique Tessier

(veronique.tessier@tc.gc.ca)

Graphics and Design

Yvan Meloche

(yvan.meloche@tc.gc.ca)

Agreement Number 1529021

Writers/Contributors to this issue

Edgar Ladouceur - Compliance and Response Branch,

TDG Directorate

Ray Desjardins - TDG Inspector - PNR Region

Marie-France Dagenais - Director General, TDG Directorate

Marc Grignon - Compliance and Response Branch,

TDG Directorate

Nicole Noccey - Regulatory Affairs Branch,

TDG Directorate

Marc Schram - TDG Inspector - Ontario Region

Jean-Pierre Gagnon - Regulatory Affairs Branch,

TDG Directorate

Manuel Kotchounian - Regulatory Affairs Branch,

TDG Directorate

Eve Poirier - Remedial Mesures Specialist - Quebec Region

Julie Prescott - Regulatory Affairs Branch,

TDG Directorate

David Lamarche - Regulatory Affairs Branch,

TDG Directorate

Michèle Provencher - Research, Evaluation and Systems Branch,,

TDG Directorate

Fred Scaffidi - Compliance and Response Branch,

TDG Directorate

Lindsay Jones - Research, Evaluation and Systems Branch,

TDG Directorate

Susan Williams - Research, Evaluation and Systems Branch,

TDG Directorate

Jonathan Rose - Research, Evaluation and Systems Branch,

TDG Directorate

Zenon Lewycky - Regulatory Affairs Branch,

TDG Directorate

Contacts

Transport Dangerous Goods Directorate

Director General

M.-F. Dagenais 613-990-1147

(Marie-France.Dagenais@tc.gc.ca)

Regulatory Affairs

J. Savard, Director 613-990-1154 (Jacques.Savard@tc.gc.ca)

Compliance and Response

E. Ladouceur, Director 613-998-6540 (Edgar.Ladouceur@tc.gc.ca)

Research, Evaluation and Systems

G. Oliver, Director 613-990-1139 (Geoffrey.Oliver@tc.gc.ca)

Legislation and Regulations

L. Hume-Sastre, Director 613-998-0517 (Linda.Hume-Sastre@tc.gc.ca)

Publications: 613-990-1148

Fax: 613-993-5925

CANUTEC: Information 613-992-4624

Emergency 613-996-6666 Fax 613-954-5101

(Canutec@tc.gc.ca)

Atlantic Region

Dartmouth 902-426-9461 Fax: 902-426-6921

St. John's 709-772-3994 Fax: 709-772-5127

Moncton 1 866-814-1477 Fax: 506-851-7042

E-mail: Tdg-TmdAtlantic@tc.gc.ca

Quebec Region

514-283-5722 Fax: 514-283-8234

E-mail: tmd-tdg.Quebec@tc.gc.ca

Ontario Region

416-973-1868 Fax: 416-973-9907

E-mail: tdg-tmdOntario@tc.gc.ca

Prairie and Northern Region

Winnipeg 204-983-5969 Fax: 204-983-8992

Saskatoon 306-975-5105 Fax: 306-975-4555

E-mail: Tdg-TmdPnr@tc.gc.ca

Pacific Region

New Westminster 604-666-2955 Fax: 604-666-7747

Kelowna 250-491-3712 Fax: 250-491-3710

Transport Canada Dangerous Goods Directorate

Internet address - www.tc.gc.ca/tdg/menu.htm

We welcome news, comments or highlights of transportation of dangerous goods activities, announcements of meetings, conferences or workshops. The Newsletter carries signed articles from various sources. Such articles do not necessarily represent the views of the Directorate, nor does publishing them imply any endorsement. Material from the Newsletter may be used freely with customary credit.

TDG Act Amendments:

On May 14, 2009, the Act to amend the Transportation of Dangerous Goods Act, 1992, was adopted and received Royal Assent in the House of Commons. The coming into force of the legislative provisions, by order in council, is expected to occur by mid June.

Editorial

Welcome to the Summer 2009 edition of the Transport Dangerous Goods Newsletter. First, I would like to announce that our efforts have finally come to fruition: our Bill has passed and as of June 16, 2009, the Act to amend the Transportation of Dangerous Goods Act, 1992 is now in force! That being said, our work is not quite done yet. We now need to roll up our sleeves and prepare for what is to come as the changes brought upon by the law will have repercussions on many aspects of the transportation of dangerous goods. Our feature article gives a brief overview of what the future holds. And stay tuned; we will be keeping you updated on new developments.

I am confident that you will find the other articles of this edition of the Newsletter to also be informative, useful and interesting. This issue highlights important events of the last year and articles on more general topics related to the transportation of dangerous goods as well as articles containing important information of standards and regulatory changes. Happy reading, have a great summer and don't forget, your comments and questions are always welcome!

Véronique Tessier

Transport Dangerous Goods Inspectors' Workshop - Moving Forward, Kelowna, October 2008

by Ray Desjardins and Edgar Ladouceur

The goal of the Transportation of Dangerous Goods Act is to promote public safety in the transportation of dangerous goods. The Act provides the authority to develop requirements and restrictions so that the risks associated with their transport is reduced to an acceptable level. The Act also recognizes there must be compliance with the regulatory requirements for the benefit of these requirements to be realized. This recognition is provided in the form of authorities to be used in achieving compliance, such as inspection authorities to promote compliance, and penalties that can be applied in the event of non-compliance.

The Transport Dangerous Goods Directorate has a team of highly trained and experienced inspectors responsible for monitoring compliance with the Transportation of Dangerous Goods Act and its Regulations, carrying out investigations and taking enforcement action. The inspection force, distributed in five regional offices across Canada, focuses its efforts on shippers, receivers and importers of dangerous goods and federal carriers.

The primary tool used to provide inspectors with the direction and guidance needed to deliver a fair, effective, efficient, consistent and transparent compliance program in a safe and professional manner is the Transport Dangerous Goods Directorate Inspectors' Manual. The Manual defines the powers, duties and functions of an inspector; the organization under which an inspector works; the strategy and policies to implement the compliance program; the necessary prerequisites for obtaining and maintaining inspector credentials; the means and measures put in place to respect the safety and health of an inspector; and the means by which the quality of delivery of the compliance program is assessed. The Manual is a living, breathing document that is subject to continuous review and modification all in an effort not only to ensure that the Manual reflects new or revised government initiatives, strategies, policies and regulatory requirements, but also that it remains relevant in guiding the everyday activities of the Transportation of Dangerous Goods inspectors.

A national inspector workshop took place over a three-day period in October 2008 in Kelowna where updated training on the Transport Dangerous Goods Directorate Inspectors' Manual was provided to ensure that all Transportation of Dangerous Goods inspectors were current and thoroughly familiar with the Manual's purpose and content. The workshop also provided an opportunity to review the results and recommendations of a 2007 internal quality improvement review conducted by the Transport Dangerous Goods Directorate regarding the day-to-day use of the Transport Dangerous Goods Directorate Inspectors' Manual by inspectors across Canada. Subject matter experts also delivered sessions on transportation of dangerous goods case studies and lessons learned as a result of transportation of dangerous goods incidents with the goal of updating inspectors and providing them with the tools and knowledge necessary to keep the Transportation of Dangerous Goods program moving forward.

Feedback from the 63 workshop participants indicated that the workshop was a strong success. As a result, plans are being made for another national inspector workshop in 2010.

FEATURE

An amended Transportation of Dangerous Goods Act, 1992

Marie-France Dagenais

As you may be aware, the amended Transportation of Dangerous Goods Act, 1992, received royal assent on May 14, 2009 and came into force June 16, 2009. The amended Transportation of Dangerous Goods Act, 1992, remains focused on the prevention of incidents when dangerous goods are imported, handled, offered for transport and transported but also expands the response capability of the Canadian Government in the event of a security incident involving dangerous goods.

The main safety amendments include:

- A new definition of dangerous goods release;

- Reinforcing and strengthening the Emergency Response Assistance Plan Program;

- Reconfirming that inspectors are able to inspect anywhere a means of containment is being manufactured, repaired or tested, unless it is a private dwelling, in which case a warrant is required;

- Modifying the concept of importer to clarify who is the person in Canada responsible for the dangerous goods;

- Changing the name of Permits of Equivalent Level of Safety to Equivalency Certificates and adding the notion of a "Temporary Certificate" to replace the use of Estoppels.

The amended Act now provides for security requirements during the importation, handling, offering for transport and transportation of dangerous goods. The legislative provisions on which the prevention and response security program will be based include:

- Requiring security plans and security training;

- Enabling the use of Security Measures and Interim Orders;

- Enabling regulations to be made to require that dangerous goods are tracked during transport or reported if lost or stolen;

- Reinforcing the existing Emergency Response Assistance Program to equally address responses to security incidents and accidents during the transportation of dangerous goods;

- Enabling the development of a program to require transportation security clearances for dangerous goods. (This section will come into effect at a later date)

These enabling authorities will allow the Transport Dangerous Goods' directorate to develop new policies and regulations using our regular consultation process in order to enhance the safety and security for Canadians during the transportation of dangerous goods.

A copy of An Act to amend the Transportation of dangerous Goods Act, 1992, can be found at this address: http://www2.parl.gc.ca/HousePublications/Publication.aspx?Docid=3944893&file=4

As always, we would be glad to answer any questions. Please feel free to contact either myself, Marie-France Dagenais, Director General, Transport Dangerous Goods Directorate at 613-990-1147, or by email at marie-france.dagenais@tc.gc.ca or Peter Coyles, at 613-990-1156 or by email at peter.coyles@tc.gc.ca.

North American Inspectors Championship 2008

by Marc Grignon

Inspectors representing 52 jurisdictions across North America vied for the top spot at last year's North American Inspectors Championship in Houston, held from August 18th to the 24th, 2008. At the 2008 Championship, Daniel Slick, a Commercial Vehicle Safety Alliance certified North American Standard Level I inspector from Wisconsin, was awarded the Jimmy K. Ammonds Grand Champion Award for his combined performances in seven competition elements including the North American Standard Level I Inspection, Level V Passenger Vehicle Inspection, and HAZMAT/Transportation of Dangerous Goods Inspection.

Mr. Dan Armstrong, an inspector representing the Ontario Ministry of Transportation, took top honors as the highest Canadian point participant.

To the men and women whose job title is “CMV inspector”, inspecting commercial motor vehicles (CMV) and motor coaches daily is much more than going through a checklist, they are the front line of highway safety. Of the 52 Commercial Vehicle Safety Alliance certified North American Standard Level I roadside inspectors who competed in the 16th annual Championship, there were 7 inspectors representing Canada, 3 inspectors representing Mexico-SCT, and 42 representing the United States.

Every year, the NAIC honors the vitally important contributions to safety made every single day by thousands of dedicated and skilled inspectors. Through the North American Inspectors Championship, the Commercial Vehicle Safety Alliance salutes all commercial vehicle inspectors who are working to make our roads and highways safer for travelers. The event also allows inspectors to improve their knowledge and skills through training sessions touching almost every aspect of their complex daily tasks.

The North American Inspectors Championship is managed by the Commercial Vehicle Safety Alliance and is funded in part by government agencies. Its success is mainly due to strong industry participation and sponsorship. The Commercial Vehicle Safety Alliance is an international not-for-profit organization comprised of local, state, provincial, territorial and federal motor carrier safety officials and industry representatives from the United States, Canada, and Mexico. Its mission is to promote commercial motor vehicle safety and security by providing leadership to enforcement, industry and policy makers. For more on Commercial Vehicle Safety Alliance, visit www.cvsa.org.

Which Edition of a Safety Standard or Requirement do We Need to Comply With?

by Nicole Noccey

The Transportation of Dangerous Goods Regulations require compliance to a number of CSA and CGSB safety standards and requirements. The table set out in section 1.3.1 of the Regulations lists these standards and requirements and includes a date of publication for each one. Other sections of the Regulations specify when compliance with each standard or requirement is required. (A copy of the Transportation of Dangerous Goods Regulations is available on the Transport Canada website at www.tc.gc.ca/tdg/clear/menu.htm.)

Periodically, these safety standards and requirements are updated to address safety concerns or important changes in industry or regulations.

If the revisions to the standard or requirement are not extensive, the standards writing organization may choose to publish an update or amendment, rather than a new edition. These updates and amendments replace certain pages in the standard or requirement and are available from the standards writing organization.

If the revisions to the standard or requirement are extensive, or if a number of years have passed since the last edition of the standard or requirement was published, the standards writing organization will publish a new edition, rather than an update or amendment.

Copies of updates, amendments and new editions are available from the standards writing organization once they are published. It is important to note, however, that the edition of the standard or requirement that is referenced in section 1.3.1 of the Transportation of Dangerous Goods Regulations is the edition that is enforced, and that updates and amendments that are not cited in section 1.3.1 of the Regulations are not mandatory.

To give an example: If the 2002 version of a standard is cited in section 1.3.1 of the Transportation of Dangerous Goods Regulations, then compliance with the 2002 edition is mandatory even if the 2008 edition is available from the standards writing organization.

For more information regarding this subject, please contact a Means of containment specialist by fax at 613-993-5925 or by email at tdgcontainers-tmdcontenants@tc.gc.ca. Insert the word “Standards” in the subject line.

Ticketing Update - First Convictions Registered

by Marc Schram

Since the publication of the last article on Federal Dangerous Goods violations in the Transport Dangerous Goods Newsletter (Fall 2007 – Volume. 27 No.2 http://www.tc.gc.ca/tdg/newsletter/fall2007.pdf), significant events have taken place. Indeed, the first notices of infraction have been issued with convictions being registered against two separate companies.

The Contraventions Act establishes a simplified procedure for prosecuting certain federal offences. The Act provides that offences designated as “contraventions” may be prosecuted by means of a ticket.

In November 2007, with the amendments to the Contraventions Regulations, several offences under the Transportation of Dangerous Goods Act, 1992, were designated as contraventions under the Contraventions Act. Transport Dangerous Goods inspectors can now issue a ticket to an individual or corporation that handles, offers for transport, transports or imports dangerous goods in a manner that is non compliant to the Act.

Obviously, proceeding by way of a ticket is not always the most appropriate or desired enforcement action to be taken. Many factors such as the circumstances surrounding the occurrence, history, likelihood of achieving compliance, and other factors must be taken into account. However, issuing a ticket, instead of proceeding by way of summary conviction, is another option available to dangerous goods inspectors. Receiving a ticket allows defendants to enter a guilty plea without having to appear in court. This process reduces costs for the public, courts and government. Offences that are more serious in nature, where a greater penalty is sought, will continue to be prosecuted under the Transportation of Dangerous Goods Act, 1992. It should be noted that convictions registered via this avenue could be used at future proceedings for sentencing purposes should further violations take place. In all there are only 21 offence types listed in the schedule for the Transportation of Dangerous Goods Act, 1992, under the regulations of the Contraventions Act. That does not mean however that there are only 21 violations or different circumstances under which a ticket can be issued. Each wording references a specific section of the Transportation of Dangerous Goods Act, 1992, that, in turn applies to many different sections of the regulations and well over 200 violations are captured.

The Contraventions Act and regulations, along with the short form descriptions and associated fines can be found online at:

http://laws.justice.gc.ca/en/c-38.7/index.html.

Set fines start at $500 to a maximum of $1,000. This does not include court costs and applicable victim fine surcharges, which are added to the set fine.

In the two matters previously mentioned, the tickets were not contested and the companies involved paid the set fines within the prescribed time. The total payable for one company was in excess of $1,000 while the other was $1,890. The matters involved similar circumstances where, during the course of a routine inspection, the inspector identified problems relating to non-compliances under Parts 4 and 5 of the Transportation of Dangerous Goods Regulations. In both cases the large means of containment (a highway tank) being used were not displaying prescribed safety marks. Issues involved faded and misleading placards. Further, both highway tanks were not in compliance with CSA B620-03, which is referenced in Part 5, Means of containment, as they had not undergone the required periodic inspections and testing. Transport Canada inspectors had previously warned both companies involved for similar violations during routine inspections. Obviously, had these violations been discovered under different circumstances, such as a motor vehicle collision, release of product or personal injury, enforcement action would not have been by way of ticketing.

Undoubtedly, ticketing will prove to be a valuable method of ensuring compliance with the Act and Regulations and promoting public safety in the transportation of dangerous goods.

Amendment to the Standard on Tank Cars and Other Means of Containment

for the Transport of Dangerous Goods by Rail

by Jean-Pierre Gagnon and Manuel Kotchounian

In Canada, the regulatory requirements for the construction, modification, qualification, maintenance, and selection &use of means of containment for the handling, offering for transport, or transport of dangerous goods by rail are found in Standard CAN/CGSB 43.147-2005. That edition of the standard was adopted by reference in the Transportation of Dangerous Goods Regulations on 20 February 2008, by way of Amendment No. 6.

Following meetings of the Canadian General Standards Board (CGSB) Committee responsible for developing and updating the CGSB 43.147 Standard, a number of changes to the 2005 version have been made, and CGSB published Amendment 1 to CAN/CGSB 43.147-2005 in July 2008. Transport Canada plans to propose adoption of the July 2008 amended standard by way of an amendment to the Transportation of Dangerous Goods Regulations. As always, the proposal to amend the Transportation of Dangerous Goods Regulations will be published for comment in Canada Gazette, Part I before taking effect.

The following is a summary of the important changes introduced by CAN/CGSB 43.147-2005-Am. 1:

| Section(s) | Topic | Description of Change |

|---|---|---|

| 4.6.2 | Venting | Clarify tank car venting provisions for pressure-regulating devices that operate as intended |

| 5.4.7 | Quality Management System | Clarify that procedures must be available to document maintenance / modifications involving welding to the tank |

| 6.1 | Marking | Remove the adoption by reference of the commodity name marking requirements in 49CFR §172.330 |

| 15.2 &16.7 | Attachment to Tanks | Update support attachment requirements and require pads for all air brake equipment support attachments, consistent with the Association of American Railroad (AAR) Manual of Standards and Recommended Practices (AAR M-1002) Appendix E, section 15 |

| 25.5.4 | Qualification of cryogenic cars | Add requirements for the qualification of tank cars used for cryogenic liquids |

| 25.5.7 | Structural Integrity Inspection | Exempt the inspection of the body bolster pad attachment welds from the structural integrity inspection requirements at time of tank car qualification. This aligns the regulations with Canadian permits as well as US DOT Special Permit 12095 |

| 25.5.10.1 | Thermal Protection Inspection | Establish acceptable level of defects in tank car thermal protection systems, consistent with the recommendations of a AAR Tank Car Committee task force (see Figure 1) |

| 25.5.13 | Adjustments in Inspection and Test Protocols | Allow the use of service reliability assessment for adjusting inspection and test protocols if it is supported by analysis of systematically collected data |

| 25.5.14 | Qualification of 113 and AAR 204W cars | Establish requirements for the first qualification for specification 113 and AAR 204W tank cars |

| 25.7.3 | Leak Testing | Clarify that leak tests relative to service equipment qualification, modification or maintenance are considered “non-destructive tests” (NDT) and must therefore conform to AAR M-1002 Appendix T |

| 25.7.5 | Opening in Jackets | Require that access openings in jackets and tank head puncture-resistance systems be restored to “original” condition |

| 30.8.4 | Bottom-discontinuity Protection | Exempt molten sulfur and elevated temperature dangerous goods from the bottom discontinuity protection requirements |

| 30.14.2 | Tank Car Loading &Unloading |

|

| 30.16.2 | Hydrogen Peroxide Vent | Exempt the inspection of hydrogen peroxide ceramic venting devices for cars being returned after unloading |

| 31.1 | Tank Car Loading Limits |

|

| 7 &Appendix E | Tank Container Impact Test | Clarify the administrative provisions of the Dynamic Longitudinal Impact Test and update the technical requirements to align with ISO standard 1496-3 Am. 1, in particular the “permitted design variations” |

As part of the amendment to the Transportation of Dangerous Goods Regulations, it is Transport Canada's intention that the regulatory requirements differ from those of CAN/CGSB 43.147-2005-Am. 1 in the following two respects:

| Section(s) | Topic | Description of Change |

|---|---|---|

| 4.11.3 c. | Registration of Tank Car Facilities | Remove the requirement for an applicant to provide evidence of holding an AAR registration or certification (as applicable). The Transport Canada registration requirement for tank car facilities would thus operate independent of any AAR requirements in that respect |

| New Para. 4.6.4 | Tank Car Tank Defects | Quantify the limits and extent beyond which some type of defects to tank car tanks (such as dents and buckles) would be considered a danger to public safety if tank cars were to be transported with those defects present. This will address a safety concern recently identified by Transport Canada that has not been adequately addressed in the Standard. |

The full text of the proposed amendment to the Transportation of Dangerous Goods Regulations will be posted on our website once it has been published in Canada Gazette, Part 1. In the meantime, do not hesitate to contact Jean-Pierre Gagnon, Superintendent, Rail Tank Cars (jean-pierre.gagnon@tc.gc.ca) if you have any comments on the proposed changes.

FIGURE 1: Transport Canada inspectors use thermal imaging cameras to evaluate the integrity of tank car thermal protection. This thermographic image of a tank car used for liquefied petroleum gas shows areas of defects in the thermal protection system.

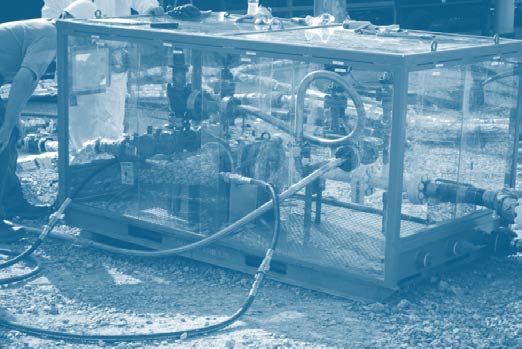

Field verification of the Chlorine Institute's pump for autorefrigerated chlorine

by Eve Poirier

Until recently, there wasn't any technology available in the industry to safely remove autorefrigerated chlorine from a breached tank car without spending weeks at an incident site.

Following the Montana derailment in 1996, where a 90 ton chlorine tank car was damaged and chlorine gas was release into the atmosphere, the Chlorine Institute formed a task group responsible for identifying specialized equipment and techniques.

This task group has since evolved and a lot of work has been done regarding new technologies and proven techniques for handling incidents involving a breach or a badly damaged chlorine tank car.

After several months of brainstorming and few possibilities on the horizon, the pump task group finally found a site that would allow a field transfer with live product, i.e. liquid chlorine! In the end, it was a member of the Chlorine Institute, PPG, who came forward and decided to host the pump verification exercise, at their Natrium plant located in West Virginia, in September 2008.

Chlorine pump

One of the main objectives of the pump field verification was going through the pump standard operating procedure so the Chlorine Institute would have a thorough and updated document for future use.

Of course, it was also important to gather as much technical information as possible about the pump, such as operating pressure, flow rate, packing material, etc. for a better understanding of its performance and capacity.

It was essential to document the behavior of the pump so we could address the proper changes, if needed.

The first pump trial was not as successful as expected. One of the problems was the seal at the head plate of the pump, which was frustrating for some people, as similar difficulties had surfaced in Mercury, Nevada, in 2000. Given that modifications had been made to the pump, identifying the problem was not easy. In light of this, further testing will be performed on o-ring and/or gasket materials to identify components that can withstand the operating conditions of the pump.

Pump being pulled apart after the first trial

Face plate of the pump and o-ring

The second pump trial was another experience all together. We could of heard a pin drop in the documentation team's tent. When the time came to obtain pump readings, it felt like asking for the vital signs of an open heart surgery patient laying on the operating table!

The pump verification was a SUCCESS.

The Chlorine Institute has proven the technology. They now have technical data and can move forward to make this specialized equipment available in the near future.

Once the Chlorine Institute's final report is published, an article outlining its content will be prepared for the Transport Dangerous Goods Newsletter.

In closing, I must mention the dedication of those involved in the pump field verification. People were and still are committed to this project. You may remember that September is hurricane season in some parts of the United States. Despite the fact that many in the group were affected by hurricane Ike, all showed up in the hope of making this piece of specialized equipment work to help keep people safer when incidents occur.

Thank you for letting me be part of this once in a lifetime experience. It was a great learning opportunity.

Transportation of UN 1999, TARS, LIQUID, including road asphalt and oils, bitumen and cutbacks

by Julie Prescott &David Lamarche

Regulatory amendments are usually made to clarify and simplify regulatory requirements or in order to better ensure public safety during the transportation of dangerous goods. Due to modifications to the Transportation of Dangerous Goods Regulations, Permits for Equivalent Level of Safety issued to authorize the use of a non-specification means of containment for the transportation of liquid tars (UN1999), used mainly as road sealants, are no longer required.

Permits for the transportation of UN1999, TARS, LIQUID, including road asphalt and oils, bitumen and cutbacks will no longer be issued or renewed. Amendments No. 6 and No. 7 to the Transportation of Dangerous Goods Regulations now allow the selection of non-standardized means of containment for the transportation of these dangerous goods while remaining in conformity with the Regulations.

Though Permits for Equivalent Level of Safety are no longer required or issued for the selection of non-standardized means of containment, certain requirements must nonetheless be met. These requirements are described as follows for both small and large means of containment.

Small Means of Containment (capacity up to and including 450 litres)

Special Provision 89 of the Transportation of Dangerous Goods Regulations, effective February 7, 2008, now applies to the transportation of UN1999, TARS, LIQUID, when the means of containment used for transport has a capacity of 450 litres or less.

Special Provision 89

Despite subsection 5.12(1) of Part 5, Means of containment, until January 1, 2010, these dangerous goods may be transported on a road vehicle or a ship on a domestic voyage in a small means of containment if the small means of containment:

- is a welded metal tank;

- is used for the application of liquid tar to pavement, concrete or metallic structures and is fitted with the appropriate application equipment; and

- is designed, constructed, filled, closed, secured and maintained so that under normal conditions of transport, including handling, there will be no accidental release of the dangerous goods that could endanger public safety.

As mentioned, Special Provision 89 will expire on January 1st, 2010. An equivalent provision will therefore be included in a new standard on small containers, which will be referenced in Part 5, Means of containment, of the Transportation of Dangerous Goods Regulations following a regulatory amendment in 2010.

Furthermore, if the UN 1999, TARS, LIQUID, is included in packing group III AND has a flash point over 37.8 °C, it can be transported in a non-standardized means of containment even after January 1st, 2010. This exemption is defined in Section 1.33 of the Transportation of Dangerous Goods Regulations. To find out the exact classification or the tar product used, it is recommended to contact the supplier or manufacturer of the product directly.

Large Means of Containment (capacity over 450 litres)

Through Amendment No. 7 to the Transportation of Dangerous Goods Regulations, which came into effect in August 2007, Specific Requirement 23 of the National Standard of Canada CAN/CSA-B621-03, Selection and Use of Highway Tanks, Portable Tanks, Cargo Compartments and Containers for the Transportation of Dangerous Goods, Classes 3, 4, 5, 6.1, 8 and 9, now applies to the selection of a large means of containment for the transportation of UN 1999, TARS, LIQUID.

Specific Requirement 23

23 Tanks shall be:

- TC 406 Crude, TC 406, TC 407, TC 412, or TC 331 tanks; or

- until 1 January 2016, non-specification tanks meeting the requirements of Clause 4, if:

- the tanks were manufactured before 1 January 2007;

- no more than 15 years has elapsed since the date of manufacture of the tank, or if that date is unknown, since 1 January 1996;

- the tanks are inspected, tested, retested, and marked in accordance with the applicable requirements for TC 406 Crude tanks set out in Clause 7 of CSA B620-03, except that a pressure of 21 kPa (3 psi) may be used for the pressure test; and

- a metal identification plate is permanently attached by the registered facility conducting the test, marked with at least the following information:

- the words “Non-spec Flammable Liquids Tank” and “Not for Dangerous Goods Use after January 1, 2016” or “Citerne hors spécification pour liquides inflammables” and “Inutilisable pour les marchandises dangereuses après le 1er janvier 2016”;

- the date of the first inspection or test done in accordance with Item b) iii); and

- the name of the registered facility.

The conditions of this Specific Requirement are equivalent to the conditions of the Permits for Equivalent Level of Safety that were previously issued for the use of large means of containment. Please note that under Specific Requirement 23, the tank must undergo an external visual inspection and a leakage test every 2.5 years, and must also undergo an internal inspection and a pressure test every 5 years. These inspections and tests must be performed by a facility registered with Transport Canada in accordance with the CSA B620-03 Standard. A non-standardized means of containment with a capacity of over 450 litres must meet the requirements of this Specific Requirement in order to be legally used for the transportation of UN 1999, Tars, Liquid, such as pavement sealing products. Permits for Equivalent Level of Safety will no longer be issued or renewed.

It is thus not possible to request or receive a Permit for Equivalent Level of Safety for the selection of non-standardized means of containment (small or large) for the transportation liquid tars including road asphalt and oils, bitumen and cutbacks. Non-standardized means of containment must meet either the conditions of Special Provision 89 Transportation of Dangerous Goods Regulations (for small means of containment) or the conditions of Specific Requirement 23 of the CAN/CSA-B621-03 Standard (for large means of containment).

A list of Highway and TC Portable Tank Facilities - Registered per Standard CSA B620-03 can be found on the Transport Canada website at: https://fdr-ric.tc.canada.ca/en/tdg/registrations

For questions relating to either this requirement of the CAN/CSA-B621-03 Standard or the list of Registered Facilities, please contact Transport Canada's Superintendent, Highway Tanks, Engineering Services, Mr. Kevin Green at 613-998-5270, or by e-mail at kevin.green@tc.gc.ca

For questions relating to the Issuance of Permits for Equivalent Level of Safety, please contact Sue Miner at 613-998-6102 or by e-mail at sue.miner@tc.gc.ca.

What is Risk, and How can it be Managed?

by Michèle Provencher

“Activities undertaken by an individual, organization or government all involve some degree of risk. All activities expose people or groups to a potential loss of something they value: their health, money, property, the environment, etc.”

CAN/CGSB-Q850-97, October 1997

“There will always be risks in transportation. How we manage risk - or what we do to prevent incidents and accidents from occurring in the first place; and what we learn from them when they occur - becomes the logical and necessary focus of our efforts.”

Moving Forward - Changing the safety and security culture – A strategic direction for safety and security management”, Transport Canada 2007(TP 14678)

As the first quote reflects, understanding and managing risks is part of the work of almost all organizations, and the Transport Dangerous Goods Directorate is no exception. As part of the Safety and Security Branch of Transport Canada, we are responsible for reducing the risks associated with transporting and handling dangerous goods to a “reasonable” level. But what is reasonable? How safe is safe enough? And what costs are reasonable to incur to society and industry when reducing risks?

It is clear that answering these questions, and undertaking the cost-benefit analyses required by federal government regulatory policies demands a well-developed understanding of what we mean by risk, and how it can be measured.

Risk is a potential loss: the likelihood of this loss and the magnitude of the loss conveying its importance. In fact people will often quantify risk mathematically as

Risk = Frequency x Consequence

where “frequency” represents the likelihood or probability of the event or loss and “consequence” represents the magnitude of the loss. Multiplying the two makes sense.

The frequency serving as a weight for the consequence: if the event is extremely unlikely (the frequency is extremely small) and if the consequence is large the risk should be low.

In practice it is often difficult to find the frequency or probability of the event because the desired information has not been collected in the past, let alone trying to evaluate the consequence. This expression implies that risk can be expressed in a number of ways depending on how the consequence is measured: the risk could be expressed in terms of money lost, surface contaminated, health effects, etc. An event will often lead to a combination of consequences not all of which can be evaluated by a single unit of measurement, e.g. fatalities, money. Then how do we sum them up? We cannot add apples and oranges.

Everyone would agree though that the lower the frequency and the lower the consequence(s), the lower the risk. Whether we can or cannot measure risk accurately, we do want to make sure the frequency or consequence are acceptable and manageable.

What is an acceptable risk? To a great extent the answer reflects society's knowledge and values – and these can evolve. The criteria used in our parents' times can be very different than the ones used now. Just think of cigarette smoking: we know a lot more now about its health effects than was known then, we also restrict the practice in given areas to protect the public.

The Transport Dangerous Goods Directorate is the focal point for the national program to promote public safety during the transportation of dangerous goods. Risk management is an inherent part of our work. Since the program is a mature program, risk analyses will be made when a concern is raised. Typical triggers are accidents, perceived problems raised by inspectors and engineers, and requests for a Permit for Equivalent Level of Safety, PELS (an exception to the rule). It is not possible to measure all risks completely or accurately –however different options will be compared using all the information at hand. Some analyses can be done very thoroughly and precisely but represent only a piece of the puzzle. Risk analysis is really a decision aid. Once the risk has been evaluated to the best of our knowledge, measures are taken, where appropriate, and considering the costs involved, to diminish or mitigate this risk.

These measures constitute the control mechanisms and management overview that Transport Dangerous Goods chooses to take to promote public safety. A variety of actions can be taken. They can simply be applications of existing tools/rules under the Transportation of Dangerous Goods Act and regulations such as: increasing enforcement in areas of concern, refusing to issue a Permit for Equivalent Level of Safety or even in emergency situations issue an emergency permit and/or a protective direction. They can and often are modifications to regulatory text to reflect the need for reinforcement or attenuation of existing rules or the introduction of new requirements in light of recent studies, international obligations, technological improvements, or demands from federal/provincial partners.

These measures are taken “where appropriate” because the risks that we are willing to take are a reflection of times. Decisions to reduce risk must also consider the distribution of costs and benefits, as well as how we are able to communicate and respond to public perceptions around risks. The choice of instrument, and the roles of government and the private sector must be considered. For these reasons, consultation with all stakeholders is of the utmost importance.

Risk management: an art or a science? Really it is both. Decisions made with respect to risk issues must balance technical knowledge with social and moral considerations. Equilibrium is key.

Transport Canada's CBRNE Response Seminar

by Fred Scaffidi

Transport Canada's Transport Dangerous Goods Directorate held a Chemical, Biological, Radiological, Nuclear and Explosive (CBRNE) Response Seminar for Industry Responders at the Delta Calgary South Hotel, Calgary, Alberta, from March 24 to 26, 2009.

Background

Since the events of September 11, 2001, government departments have been assigned responsibilities in the CBRNE area, summarized in the CBRN Strategy of the Government of Canada (March, 2005, see www.publicsafety.gc.ca for a copy of the document). The Transport Dangerous Goods Directorate's responsibility, as stated in the Strategy, is to provide access to approved emergency response teams and technical information by CANUTEC in the event of a CBRNE terrorism event in Canada. In order to fulfill this responsibility, the Transport Dangerous Goods Directorate was granted funding under the Public Service Anti-Terrorism Initiative to develop the TDG CBRNE Response Program that provides access to trained emergency response teams from the industry sector to support the first response community (fire departments, police services, and other officials) in the event of a terrorist incident involving dangerous goods used as CBRNE agents in Canada. Local authorities would be able to call upon these teams to gain the specialized support and extra capacity they possess when needed.

The TDG CBRNE Response Program is modeled on our already familiar Emergency Response Assistance Plan (ERAP) program. The requirement for an ERAP is pursuant to the Transportation of Dangerous Goods Act, 1992, which mandates the filing of a plan with Transport Canada explaining what is to be done if an accident occurs during transportation of certain more harmful dangerous goods requiring special handling and equipment. The TDG CBRNE Response Program functions similarly with the important caveat that participation is voluntary; program participants would only be asked by authorities in charge to intervene after the site is secured and further threats have been eliminated.

The Transport Dangerous Goods Directorate's role in the CBRNE program includes:

-

verification of the response capability of responders against established criteria currently in use in our current ERAP Program and,

-

providing awareness training to industry to better prepare them should they be called upon in a CBRNE-related terrorist event.

A similar meeting, hosted by the Transport Dangerous Goods Directorate, was held in Morrisburg, Ontario, May 9 to 11, 2006. Our seminar in Calgary was designed to incorporate some of the comments we received from participants in Morrisburg and to discuss upcoming changes to the CBRNE landscape. The primary goals of the 2009 seminar included:

-

informing industry about Transport Canada's evolving role in CBRNE, upcoming changes to the Transport of Dangerous Goods Act and their impact in the CBRNE area;

-

providing an opportunity for government officials and industry representatives to become more familiar with each other's capabilities and expectations during a CBRNE incident and do so ‘in the same room'.

-

providing an opportunity for those that couldn't attend the Morrisburg meeting to benefit from our program.

Seminar Highlights

The design of our seminar was based on the idea of providing a forum for interaction between the public and private sectors, as having these two entities working together will ensure the success of the TDG CBRNE Response Program. The seminar provided an opportunity for government officials and industry representatives to become more familiar with each other's capabilities and expectations during a CBRNE incident. In our view such opportunities are few and far between. Calgary 2009 offered a wide range of speakers and subjects and a busy agenda.

Transport Canada representatives gave presentations on the TDG CBRNE Response Program and on the CANUTEC program. Of particular interest was the presentation entitled the Proposed Amendments to the Transportation of Dangerous Goods Act and Regulations, which described the changes to the Act that have an impact on CBRN issues and the involvement of the private sector. We had a very knowledgeable speaker and this was a valuable opportunity for questions from the audience.

Seminar organizers decided to have presentations on each of the elements of CBRNE to provide the core technical background necessary. Our seminar included some great technical presentations including speakers from the Canadian Counter Terrorism Centre who presented the fundamentals of biological and chemical agents and our speaker from the Canadian Nuclear Safety Commission presented radiological and nuclear fundamentals. The Canadian Counter Terrorism Centre and the Canadian Nuclear Safety Commission also have vital roles that were also presented. The Royal Canadian Mounted Police presented on explosives and on the role of the national police force in CBRNE.

The counter-terrorism area has an undeniable intelligence component. What does the intelligence community have to say about the current threats? Our speaker from The Integrated Threat Assessment Centre gave us his overview.

Organizations from the private sector were also asked to speak in order to give their perspectives on responding to incidents involving CBRNE. There were some excellent technical presentations on chlorine, ammonia and propane. We had several speakers including the Liquefied Petroleum Gas Emergency Response Corporation, Canexus Chemicals (member of the CHLORine Emergency Plan), Agrium Inc. and the Canadian Emergency Response Contractors' Alliance. All these presentations demonstrated the wealth of information and capability that resides in the private sector and that could be brought into a response involving CBRNE.

As the Fire Department would be the most likely group on scene to assess the requirements for a CBRNE response, Calgary Fire Department Hazardous Materials Coordinator presented The Relationship between Fire Departments and Industry Responders at CBRNE incidents.

Federal roles and responsibilities were presented by Public Safety Canada, Public Health Agency of Canada (for infectious substances) and Environment Canada.

One question that we had was the potential role for the armed forces in CBRNE. Our speaker from Canadian Joint Initial Response Unit - Canadian Special Operations Forces Command gave a presentation explaining what the Canadian Joint Initial Response Unit can and cannot do on-scene.

In addition to time spent indoors, participants were able to view response trailers and equipment graciously supplied by the Royal Canadian Mounted Police, Agrium Inc. and Liquefied Petroleum Gas Emergency Response Corporation. Personnel were on hand to give demonstrations and answer questions from the group.

Results

The seminar was valuable in that it provided an opportunity to hear an impressive array of very knowledgeable speakers in their respective areas. That our speakers gave of their valuable time and expertise (particularly in the current economic situation) indicates just how importantly industry is viewed as a component in a CBRNE response. The Transport Dangerous Goods Directorate believes that this seminar improved the knowledge base of the CBRNE community as a whole. It is our hope that industry response teams that have not already done so would consider adding their organizations to our list of CBRNE response teams (please contact Fred Scaffidi at Fred.Scaffidi@tc.gc.ca or Kathleen Corriveau at Kathleen.Corriveau@tc.gc.ca for more information about participating in the TDG CBRNE Response Program).

Thanks

The Transport Dangerous Goods Directorate wishes to thank our speakers for volunteering, preparing and presenting to our seminar participants. I believe their willingness to do so arose from the belief that some value will come of it. Ultimately, the driver for this seminar was the protection of our fellow Canadians who, we believe, were well served by this seminar. We also would like to thank the organizations that stepped forward to provide us with sponsorship assistance, namely:

-

The Liquefied Petroleum Gas Emergency Response Corporation

-

The Canadian Chemical Producers Association

-

The Canadian Association of Chemical Distributors

-

Devon Canada Corporation

-

Husky Energy

And finally we would like to thank our participants. These difficult economic times force people to be selective about where they devote their time and resources. We appreciate the commitment demonstrated by the attendance at our seminar and look forward to working with you in further developing our TDG CBRNE Response Program.

Training initiative across the country

by Marc Grignon

Facing the challenge of keeping up with changes brought on by Amendment No. 6 of the Transportation of Dangerous Goods Regulations, Transport Canada's transportation of dangerous goods instructors, with the help of two senior transportation of dangerous goods inspectors, have traveled around the country since March 2008 in an effort to train federal, provincial and territorial inspectors. To ensure the understanding of all those recent changes, instructors have worked hard during the past year preparing their course material to guaranty proper vulgarization of all those new regulatory requirements.

From March 2008 to March 2009, the Inspector Education and Public Awareness division trained a total of 476 inspectors, the eyes and ears that keep the regulated community on their toes and Canada's population safe. During this period, 31 courses were given, 3 of which served to train new federal inspectors, 9 specifically to address changes brought upon by Amendment No. 6 and 19 to provide Transportation of Dangerous Goods Regulations training to provincial/territorial inspectors and enforcement officers.

It's all about keeping our commitment!

Transport Canada's Transport Dangerous Goods Directorate is keeping its commitment in providing training to provincial/territorial inspectors and enforcement officers. More than 302 provincial/territorial inspectors and enforcement officers, from all over Canada, received training on the Federal Transportation of Dangerous Goods Regulations, and more will be provided in months to come.

This joint effort between the federal government and the provinces and territories is essential to continue promoting public safety in the transportation of dangerous goods.

Thanks to our instructors and all the inspection community for their dedication to our program.

Job well done!

Accident Summary Report 2008

by Lindsay Jones, Susan Williams and Jonathan Rose

The Transport Dangerous Goods Directorate receives hundreds of accident reports each year. Most are submitted to comply with the requirement to complete a “30-Day Follow-Up Report” when the quantity of dangerous goods released in an accident exceeds the amount listed in the table contained in Part 8 of the Transportation of Dangerous Goods Regulations (reportable accidents). However, the Transport Dangerous Goods Directorate also receives many voluntary accident reports.

As of April 2009 a total of six hundred and ninety-eight (698) accidents involving dangerous goods had been identified for 2008. This included four hundred and thirty-two (432) reportable and two hundred and sixty-six (266) non-reportable accidents. This is higher than the actual number of accident reports collected for 2007 (631). The 2008 total will likely change because some accident reports have yet to be received.

Companies submitted five hundred and seventy-nine (579) “30-Day Follow-Up Reports” for accidents, which occurred in 2008. Approximately 72% (421) of these dealt with reportable accidents, and the remaining 28% (158) were voluntary accident reports. Eleven (11) additional reportable accidents identified from Transport Dangerous Goods Inspector and Remedial Measures Specialists reports, newspaper clippings and other sources are still outstanding. The Directorate also added 108 non-reportable accidents of interest to the accident database for analytical purposes.

The Transport Dangerous Goods Directorate pursues the collection of outstanding “30-Day Follow-Up Reports”, with the assistance of regional inspectors who conduct follow-up investigations. Letters requesting the filing of outstanding reports are sent to the companies who had charge, management or control of the dangerous goods at the time of the accidental release. To date, the number of letters sent out to companies is significantly down compared to the same period in previous years.

Accident reports provide the Directorate with valuable and timely information on what took place, how the accident occurred, its severity and what response measures were taken to mitigate the event. Therefore, companies are required to complete the “30-Day Follow-Up Report” within 30-days following an accident with all of the information requested in paragraph 8.3(2) of the Transportation of Dangerous Goods Regulations. The Directorate also encourages companies to continue to provide voluntary accident reports. Accidents involving minor releases, or no release at all, may still highlight trends, or flag potential risks for a more significant event. Reports for accidents where the means of containment sustained damage, imminent accidental releases and where no release occurred, can also assist us in understanding how a means of containment performs during an accident.

When completing the “30-Day Follow-Up Report”, please remember to provide all of the means of containment identification markings and specify the location(s) on the means of containment where damage or releases occurred, as required under paragraph 8.3(2)(f) of the Transportation of Dangerous Goods Regulations. Please also be sure that all information required under paragraph 8.3(2)(a-j) is present in your report in order to minimize the amount of follow-up.

For more information on how to complete a “30-Day Follow-Up Report”, please contact Jonathan Rose at 613-990-1142, or by e-mail: jonathan.rose@tc.gc.ca. Please note that there is now an e-mail address dedicated to receiving 30-Day Follow-Up Reports: dor-rcd@tc.gc.ca or rcd-dor@tc.gc.ca.

The Transport Dangerous Goods Directorate currently assesses the severity of an accident based on the following 10 questions:

- Was there a compressed gas or explosive involved?

- Was there a fire or explosion at the scene?

- Was there a dangerous goods release?

- Was there a death, serious or multiple injuries?

- Was there an evacuation or a road closure?

- Was the accident reported in the press?

- Were TC personnel at the accident scene?

- Was site cleanup required?

- Was property/equipment damage greater than 65 000 $?

- Was there mechanical failure of the vehicle?

One point is assigned for each positive response to each of these questions. The sum of the points for the accidents is shown under “Severity Level” to represent the accident severity. Although rare, a zero severity level can be assigned to an accident, indicating no positive responses to any of the questions. An accident with a level from 0 to 3 is regarded as minor, from 4 to 6 as moderate and from 7 to 10 as major.

The following table presents the distribution of reportable accidents involving dangerous goods in 2008 by severity level. Approximately 81% of the accidents had a severity level of 2. Of the accidents, 95% are considered minor in nature, having received a severity level of 3 or less.

Below is a short selection of accidents that occurred in 2008. Every effort was made to vary this sample of accidents, by choosing different provinces and territories, classes of dangerous goods, modes of transport, means of containments and accident severities.

13/05/2008

Severity Level 2

Port aux Basques, Newfoundland and Labrador

Liquefied Petroleum Gases - Class 2.1

While waiting to be loaded onto a ferry, a Residue Tank Trailer (MC331 LPG) last containing Propane, was discovered leaking product from a seal on the pump located at the bottom of the tank. There were no injuries. A pail was placed under the trailer to collect the leaking Propane. Emergency Response Personnel were on site and waited for the remaining product to drain off into the recovery pail. The product was then allowed to evaporate from the pail and the tanker was secured and sent for repairs.

07/17/2008

Severity Level 2

Truro, Nova Scotia

Ammonium Nitrate - Class 5.1

During rail yard operations, a covered Hopper Rail Car (CGLX001985) containing Ammonium Nitrate was discovered with one of its bottom doors opened. It had leaked 200 litres of product. There were no injuries. The hopper door was secured and the spilled product was cleaned up.

09/23/2008

Severity Level 3

Baie-James, Quebec

Diesel Fuel; Fuel Oil; Gas Oil; or Heating Oil Light – Class 3

Fuel, Aviation, Turbine Engine – Class 3

During transport, a Compartmentalized Tank Truck (A/MAC406) carrying Diesel and Pup Trailer carrying Aviation Fuel went off the road and overturned in a ditch releasing 1,615 litres of both products combined. The driver suffered injuries and was transported to the hospital. Emergency Response Personnel were on site to contain and clean up the spill, to transfer the remaining product into another tanker, and to upright and remove the overturned unit from the ditch.

08/27/2008

Severity Level 6

Lakefield, Ontario

Argon, Refrigerated Liquid – Class 2.2

During transport, while turning a corner, a Tractor Tank Trailer (TC341) containing Argon, Refrigerated Liquid went off the road and overturned in a ditch. The tank was breached releasing 15,500 litres of product to the atmosphere. The driver, who sustained minor injuries, was transported to the hospital for treatment. Emergency Response Personnel were on site and evacuated a few nearby homes until the product had completely vented off. The unit was then righted and removed from the ditch.

09/18/2008

Severity Level 2

Winnipeg, Manitoba

Corrosive Liquid, N.O.S. – Class 8

During railyard operations, a Rail Tank Car GATX01433 (DOT111A100 W) containing Corrosive Liquid, N.O.S. leaked 5 litres of product from the manway. One employee was sprayed with some of the product and immediately showered off before being transported to the hospital for treatment. Railway Emergency Response Personnel were on site to secure the manway bolts which stopped the leak. The tank car was then washed down with water.

06/20/2008

Severity Level 2

Saskatoon, Saskatchewan

Hydrogen Peroxide, Aqueous Solution, Stabilized – Class 5.1(8)

During rail yard operations, a Rail Tank Car TILX200325 (DOT111A 60 W7) containing Hydrogen Peroxide leaked 23 litres of product from the manway cover. Some of the product contacted railway ties under the tank car igniting a fire that quickly burned itself out. There were no injuries. Emergency Response Personnel were on site to tighten the bolts on the manway cover that stopped the leak. The area was washed down with water to ensure the fire was extinguished. This accident was deemed reportable based on the dangerous goods' subsidiary class (class 8) and not it's primary class (class 5.1).

11/19/2008

Severity Level 2

Didsbury, Alberta

Flammable Liquid, Corrosive, N.O.S. – Class 3(8)

During transport on icy roads, a pick-up truck carrying four Plastic Drums (UN1H1/Y18/100/07/USA/M-5123) of Flammable Liquid, Corrosive, N.O.S. went off the road, hit a fence and overturned in a farm field. One drum was damaged releasing 10 litres of product. There were no injuries. Emergency Response Personnel were on site to clean up the spilled product and to upright and tow the truck back onto the roadway.

05/16/2008

Severity Level 3

Worsley, Alberta

Anhydrous Ammonia – Class 2.3(8)

During loading operations from a bulk storage tank, containing Anhydrous Ammonia, into a Nurse Tank (ASME code/Western Rockbit/ E9252.234 /1986 /27380A/ 113.42M3/ABN A227231 2007) 20 kilograms of product was released from a loose connection between the transfer hose and a valve on the Nurse Tank. The operator was sprayed with some of the product while closing the valve. The operator was treated by paramedics at the scene and then transported to the hospital for further treatment. Emergency Response Personnel were on site to ensure the valve was secured properly. The nurse tank was then moved to a repair facility. This accident was deemed reportable based on both the primary class (class 2.3) and subsidiary class (class 8) of the dangerous goods.

10/14/2008

Severity Level 3

Tumbler Ridge, British Columbia

Explosive, Blasting, Type E – Class 1.5D

During unloading operations from a Tank Trailer (TC407SS) containing Explosive, Blasting, Type E into a mine site storage tank, a gasket on the offload pump failed releasing 100 litres of product. There were no injuries. Mine site personnel contained and cleaned up the spilled product.

10/17/2008

Severity Level 2

Big Creek, Yukon

Fuel, Aviation, Turbine Engine – Class 3

During transport, a Tractor Compartmentalized Tank Trailer (TC306AL) and Pup (TC306AL) containing Aviation Fuel ran off the road into a ditch. The tank sustained damage to a valve, the plumbing and the piping. There was a release of 4,772 litres of product from one of the compartments on the lead trailer. There were no injuries. Emergency Response Personnel were on site to contain and clean up the spill, to transfer the remaining product into another set of trailers, and to remove the unit from the ditch.

03/16/2008

Severity Level 2

Marion Lake, Northwest Territories

Diesel Fuel; Fuel Oil; Gas Oil; or Heating Oil Light - Class 3

During transport, a Tractor Tank Trailer (MC306) containing Diesel Fuel went off the road and overturned. The tank was punctured by a tree stump resulting in a release of 7,088 litres of product. There were no injuries. The carrier company's Emergency Response Personnel were on site to contain and clean up the spill, to transfer the remaining product into another tank trailer, and to upright the overturned unit.

08/08/2008

Severity Level 1

Igloolik, Nunavut

Batteries, Wet, Filled with Acid - Class 8

During transport in the cargo hold of an airplane, two Boxes (UN4G) containing Batteries, Wet, Filled with Acid leaked a small amount of product. The packaging contained most of the released product. There were no injuries. The spill was discovered when the airplane arrived at its destination and the boxes were being unloaded. The airport fire department was called in to assist in the clean up. Upon further investigation it was discovered that the batteries had been placed into the box with the arrow labelled “Boxes” not right side up. The box was placed into the cargo hold of the airplane with the arrow labelled “Boxes” facing right side up, which allowed the acid to leak out. The consignor and the appropriate authorities were notified of the incident.

Please note:

The Transport Dangerous Goods Directorate is planning several new non-regulatory additions to its accident reporting system. One addition will enable parties to record the accident information, as required by our Act, using an on-line web application. (We are now in a position to move forward on this development.) The other addition is to refine the accident severity index discussed here, to make it more subtle and better reflect individual intuitions on the relative seriousness of different factors. This index, orginally derived from a private sector model, is only used for a better understanding and description of dangerous goods accidents in Canada - it does not play directly into decisions with respect to enforcement and prosecutions.

Diesel Fuel, Heating Oil and Jet A Fuel Oil Non-Spec Tank Grandfather Clause Expiring

by Zenon Lewycky

Diesel fuel (UN 1202)1 is a dangerous goods within the scope of the Transportation of Dangerous Goods Act, 1992, and the Transportation of Dangerous Goods Regulations.

Since the August 2002 amendment, the Regulations require that when diesel fuel is transported in a container of greater than 450L capacity (a “large” container), that container must meet one of the safety standards prescribed in Part 5 of the Regulations. This requirement continues to apply even if a large container of over 450L capacity is underfilled.

Along with implementation of this new requirement for diesel fuel to be transported in standardized large containers, existing non-standardized tanks manufactured before 2003 were grandfathered for continued use for transport of diesel fuel by road until the end of 2009, under the conditions in specific requirement 5(b) of the CAN/CSA B621 Standard.

The grandfather provision for non-standardized diesel transport tanks expires at the end of 2009. As a result, starting January 1, 2010 all diesel fuel transport tanks of over 450L capacity will be required to meet one of the standards prescribed in Part 5 of the Transportation of Dangerous Goods Regulations. Non-standardized (non-spec) large containers will no longer be allowed for transport of diesel fuel after January 1, 2010.

The following standardized large container types are and will remain acceptable for diesel fuel transport beyond January 1, 2010:

-

Railroad tank cars in accordance with the CAN/CGSB 43.147 standard;

-

TC 406 and TC 306 tank trucks and trailers in accordance with the CAN/CSA B621 standard;

-

UN code 31A and 31B standardized intermediate bulk containers; including UN standardized ‘mobile' intermediate bulk containers slip tanks, in accordance with the CAN/CGSB 43.146 standard. Intermediate bulk containers are limited to 3000L capacity but some of up to 5000L capacity have been approved by exception; and

-

TC or DOT 57 portable tanks used in accordance with the CAN/CGSB 43.146 standard.

In addition, the Canadian Standards Association has recently published standards for two new large container types suitable for diesel fuel transport:

-

TC 44 portable tanks are specified in the CSA B626-09 standard. TC 44 portable tanks may be rectangular or may be of round or oval cross section; and

-

UN standardized portable tanks are specified in the CSA B625-08 standard. UN portable tanks are internationally accepted and may or may not be enclosed in an ISO tank container frame.

Both the CSA B625 and CSA B626 are now available from CSAhttp://www.tc.gc.ca/eng/tdg/newsletter-menu-268.htm in English. Once the French editions are published, we will propose these new standards for adoption in the Regulations. Until that time, persons wishing to manufacture or use UN portable tanks or TC 44 tanks in Canada must do so under the authority of a Permit for Equivalent Level of Safety issued under Chapter 14 of the Transportation of Dangerous Goods Regulations.

Diesel fuel may still continue to be transported in non-standardized small containers having a capacity of 450L or less. Please also note that none of the Transport Canada transportation of dangerous goods safety standards requires the use of double-walled tanks for diesel fuel transport. The transportation of dangerous goods safety standards detail design, manufacturing, periodic retesting, approval and use requirements for dangerous goods transport containers, but they do not require nor recommend the use of double-walled tanks. For more on double-walled tanks please refer to the summer 2008 edition of the Transport Dangerous Goods Newsletter. http://www.tc.gc.ca/tdg/newsletter/summer2008.pdf

1 - The container requirements described in this article also apply to similar dangerous goods like heating oil and Jet A-1 fuel that are flammable liquids in Packing Group III, with no subsidiary classification and having a flash point of 37.8°C or higher.

2 - http://www.shopcsa.ca/onlinestore/

Alert

CSA B620 Standard on Highway and Portable Tanks Mandatory in Canada

Changes to the Transportation of Dangerous Goods Regulations in Amendment No. 6 require a person who uses a standardized means of containment required by CAN/CSA B6211 or CAN/CSA B6222 to offer dangerous goods for transport, to use a means of containment:

-

manufactured in accordance with CSA B6203 if the means of containment was manufactured in Canada on or after 31 August 2008; and

-

tested and inspected in accordance with CSA B620 when the most recent periodic re-test or re-inspection is performed in Canada on or after 31 August 2008.

This means that highway tanks manufactured in Canada after 31 August 2008 and used to offer dangerous goods for transport in Canada, must be manufactured to the Canadian standard. Department of Transportation (DOT) specification highway tanks made in the United States continue to be recognized for use in Canada as equivalents to the corresponding Transport Canada specifications.

Similarly, it means that highway tanks undergoing periodic testing in Canada must be inspected and tested to the Canadian standard if they are to be used in Canada to offer dangerous goods for transport. This applies to TC, MC and DOT tanks that are inspected and tested in Canada prior to being loaded in Canada. Periodic testing and inspection of highway tanks performed in the United States in accordance with the 49 CFR continues to be recognized in Canada as before. There is no change for tanks that are not loaded in Canada.

While it will remain permissible to manufacture highway tanks in Canada for export, to the 49 CFR4 or to any other foreign standard, such tanks would then not be acceptable for use in Canada unless they were also manufactured in compliance with CSA B620. Tanks that comply with both 49 CFR and CSA B620 would be dual marked.

As of the HM-215F amendments to 49 CFR in 2007, CSA B620 tanks are acceptable for use in the United States as equivalents to the corresponding US DOT specification tanks. Therefore, while it is permissible to dual mark tanks, it is not necessary because tanks that comply with CSA B620 can be used in Canada and in the United States. For further information concerning the use of TC tanks in United States, you may contact the United States Department of Transport, Federal Motor Carriers Safety Authority using the contact information at the following link: http://www.fmcsa.dot.gov/about/contact/hq/hq.htm.

1 CSA Standard B620-03, "Highway Tanks and Portable Tanks for the Transportation of Dangerous Goods", July 2003, as amended in February 2006, published by the Canadian Standards Association (CSA).

2 CAN/CSA B621-03, "Selection and Use of Highway Tanks, Portable Tanks, Cargo Compartments, and Containers for the Transportation of Dangerous Goods, Classes 3, 4, 5, 6.1, 8, and 9", July 2003, as amended in May 2004 and February 2006, published by the Canadian Standards Association (CSA).

3 CAN/CSA B622-03, "Selection and Use of Highway Tanks, Multi-unit Tank Car Tanks, and Portable Tanks for the Transportation of Dangerous Goods, Class 2", July 2003, as amended in September 2004 and February 2006, published by the Canadian Standards Association (CSA).

4 Title 49 of the "Code of Federal Regulations" of the United States, 2006.

Sending in your Completed 30-Day Follow-up Reports

All completed 30-day follow-up reports should be sent within 30 days of the accidental release. Companies may send in completed 30-day follow-up reports by mail, fax and email. Please note there have been a few changes in our fax numbers and email addresses.

Mailing address remains the same:

Transport Canada

Transport Dangerous Goods Directorate

Place de Ville, Tower C

330 Sparks St, 9th floor

Ottawa, Ontario

Canada

K1A 0N5

Fax numbers:

613-990-2917 receives an electronic copy of your 30-day follow-up report.

613-993-5925 receives a paper copy of your 30-day follow-up report.

613-952-1340 is No Longer available to receive any correspondence.

Email addresses:

dor-rcd@tc.gc.ca and rcd-dor@tc.gc.ca were created specifically for 30-day follow-up reports.

Source of Emergency Calls

CANUTEC

June 1, 2008 to April 30, 2009