This page explains the requirements related to the transportation of produced water. It does not change, create, amend or suggest deviations to the Transportation of Dangerous Goods (TDG) Regulations.

On this page

- Description of produced water

- Determine if produced water is regulated as dangerous goods

- Transporting produced water as non-regulated dangerous goods

- Potential danger with the transport of produced water

- Identifying produced water with a residue of petroleum crude oil on a shipping document

- Potential impact of not identifying residual petroleum crude oil

- Handling produced water in a highway tank that previously contained petroleum crude oil

- Compliance with the Transportation of Dangerous Goods Act and Regulations

- Contact us

- Related links

Description of produced water

Produced water is a term used in the oil and gas industry to describe water produced as a byproduct when oil and gas are extracted.

Produced water can be injected:

- to stimulate a formation

- in a well to enhance oil recovery

It can be reused several times, depending on the availability of water in a particular region.

Produced water is disposed of in deep injection wells or stored temporarily, both which are subject to regulations. This water is generally highly saline and not suited for domestic purposes.

Determine if produced water is regulated as a dangerous goods

It is difficult to determine, on a consistent basis, if produced water is regulated as dangerous goods. Why? The composition of produced water varies from well to well. Also, produced water is often reused during the extraction of oil and gas, which further affects its composition. Produced water has varying quantities of oil, metals and minerals (zinc, lead, manganese, iron and barium).

Produced water must be classified through testing to determine if it is regulated.

If it meets the classification criteria of a dangerous goods in accordance with Part 2 of the TDG Regulations, the consignor (i.e. shipper) must follow the TDG Regulations such as, but not limited to, the requirements of:

- Classification (Part 2)

- Documentation (Part 3)

- Dangerous Goods Safety Marks (Part 4)

- Means of Containment (Part 5)

- Training (Part 6)

- Reporting Requirements (Part 8)

Transporting produced water as non-regulated dangerous goods

The requirements of the TDG Regulations do not apply to produced water when:

- testing determines that produced water is NOT classified as dangerous goods, and

- transported in a highway tank that was cleaned and purged prior to loading

For example, the carrier, or consignor (shipper), does not need to display the placards and UN numbers (safety marks) on the highway tank or have a shipping document.

For the remainder of this bulletin, we assume that produced water is:

- not classified as dangerous goods; and

- being transported in a highway tank that previously contained petroleum crude oil but was NOT cleaned and purged prior to loading

Note: This bulletin does NOT address provincial, environmental or any additional regulations that may apply.

Potential danger with the transport of produced water

Highway tanks used to transport produced water are often also used to transport petroleum crude oil, condensate and other oil and gas products.

However, there are currently no regulatory requirements to clean and purge a highway tank, which previously contained petroleum crude oil or any other dangerous goods, prior to filling it with produced water. As such, there is often a residue of petroleum crude oil in the highway tank. This residue coats the inside walls of the tank and typically floats on top of the produced water.

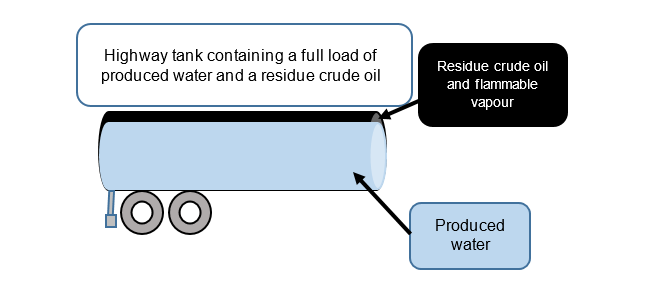

In this unique situation, petroleum crude oil and water don't mix, so the highway tank contains two distinct products (petroleum crude oil and produced water).

Even though most of the load in the highway tank is non-regulated produced water, the petroleum crude oil residue still represents a potential danger. The top of the tank (i.e., the “vapour space”) can be filled with flammable vapours.

Since the potential danger associated with the petroleum crude oil is still present, the Class 3 safety marks must remain displayed on the highway tank until it is cleaned and purged.

Below are drawings to help illustrate this scenario.

Text version

An image displaying a highway tank containing a full load of produced water and a residue of petroleum crude oil. Arrow pointing to the residue of petroleum crude oil and flammable vapour disposed at the top of the highway tank, and arrow pointing to the produced water, under the residue.

Even when produced water, which is not classified as dangerous goods, is of a greater quantity than petroleum crude oil in the highway tank, consignors (i.e. shippers) must still identify the dangerous goods (Class 3):

- using placards displayed on the highway tank, and

- on a shipping document

Text version

A flowchart to determine if produced water must be transported as per TDG Regulations: Is the produced water a dangerous goods? If yes, then transport as per TDG Regulations. If no, then is the highway tank cleaned and purged of dangerous goods? If yes, then the TDG Regulations do not apply. If no, then transport the residue of petroleum crude oil as per the TDG Regulations.

Identifying produced water with a residue of petroleum crude oil on a shipping document

Once a highway tank delivers its load of petroleum crude oil, the carrier must show the change in quantity on the shipping document, as per Subsection 3.5(5) of the TDG Regulations.

As a minimum, a shipping document must identify the residue of petroleum crude oil, even if the shipment contains a full load of unregulated produced water. However, as per Subsection 3.5(4) of the TDG Regulations, when the highway tank contains a residue, the words “Residue – Last Contained” may be added before or after the description of the dangerous goods. These optional words are used instead of listing the actual remaining quantity of petroleum crude oil, in liters.

To avoid confusion, the highway tank should be accompanied by another document (meter ticket, invoice ticket, bill of lading, manifest, etc.) that identifies the load of produced water. This helps inspectors clearly understand that the highway tank contains residue of petroleum crude oil and a full load of produced water. Also, the consignor of the petroleum crude oil and produced water are usually not the same, which is why separate documents should be used to identify both the produced water and petroleum crude oil.

The shipping document used to identify the residue of petroleum crude oil must stay in the vehicle until the highway tank:

- has been cleaned and purged, or

- is filled with a new load of dangerous goods

Potential impact of not identifying residual petroleum crude oil

This could cause confusion and mislead:

- first responders attending the scene of an accident, or

- anyone inspecting or servicing the highway tank

If the shipping document does not identify the petroleum crude oil, anyone could mistakenly assume the placards and UN numbers are displayed in error and thus, not take the appropriate precautions.

Handling produced water in a highway tank that previously contained petroleum crude oil

When transporting a load of produced water that is not classified as a dangerous goods, with a residue of petroleum crude oil, you must:

- use a specification highway tank

- keep the Class 3 safety marks on the highway tank until it is cleaned and purged

-

identify the petroleum crude oil on a shipping document

Note: To avoid confusion, it is suggested to identify the produced water on a separate document, otherwise inspectors may assume that the highway tank contains a full load of petroleum crude oil.

- ensure the driver of the vehicle has TDG training

Compliance with the Transportation of Dangerous Goods Act and Regulations

Failure to comply with the TDG Act and TDG Regulations may lead to fines and/or imprisonment.

Contact us

For questions about the TDG Regulations, contact a Transport Canada dangerous goods inspector in your region:

|

Region |

Phone number |

|

|---|---|---|

|

Atlantic Region |

1-866-814-1477 |

|

|

Quebec Region |

514-633-3400 |

|

|

Ontario Region |

416-973-1868 |

|

|

Prairie & Northern Region |

1-888-463-0521 |

|

|

Pacific Region |

604-666-2955 |

Related links

TDG Bulletin – Produced water

(PDF, 364 KB)