TP 11469 - Guide to Structural Fire Protection

(PDF, 5.0 MB)

Title: Guide to Structural Fire Protection

Number: TP 11469 E

Date: 1993

Details: Marine Safety Directorate Transport Canada Ottawa

Table of Contents

- 2.1 Fire zone Plan

- 2.2 Insulation Details

- 2.3 Bulkhead, Ceiling, Lining and Draft Stop Details

- 2.4 Deck Covering Details

- 2.5 Ventilation System Details

- 2.6 List of Doors

- 2.7 Penetration Details

- 2.8 General

Part 3 - Materials of Construction

- 3.1 General

- 3.2 Non-Combustible Materials

- 3.3 Structural Fire Insulations

- 3.4 Bulkhead, Lining and Ceiling Panels

- 3.5 Deck Coverings

- 3.6 Interior Finish Materials

- 3.7 Vapour Barriers

- 3.8 Combustible Materials

Part 4 - Construction and Arrangement

- 4.1 General

- 4.2 'A' Class Insulations

- 4.2.1 'A' Class bulkheads

- 4.2.2 'A' Class decks

- 4.2.3 Mineral wool insulations

- 4.2.4 Securing insulations to structure

- 4.2.5 Board type insulation material

- 4.2.6 Electrical fittings on 'A' Class linings

- 4.2.7 Ceilings which are components of 'A' Class decks

- 4.2.8 Sprayed insulations

- 4.2.9 'A' Class deck coverings

- 4.2.10 Boundaries, intersections and terminal points of thermal barriers

- 4.2.11 Approved manufactured systems for pipes penetrating 'A' Class bulkheads and decks

- 4.2.12 Acceptable non-manufactured systems for pipes penetrating 'A' Class bulkheads and decks

- 4.2.13 Piping penetrating watertight 'A' Class bulkheads and decks

- 4.2.14 Insulating pipe penetrations

- 4.2.15 Electric cables penetrating 'A' Class bulkheads and decks

- 4.2.16 Information required for approval

- 4.3 'A' Class Doors and Shutters

- 4.4 'B' Class Bulkheads, Linings and Ceilings

- 4.4.1 Construction

- 4.4.2 Steel or aluminum alloy 'B' Class bulkheads

- 4.4.3 Termination of 'B' Class bulkheads, ceilings and linings

- 4.4.4 Marking

- 4.4.5 Bottom profiles

- 4.4.6 Top profiles

- 4.4.7 Access panels

- 4.4.8 Lighting and ventilation fittings

- 4.4.9 Cables inside panels or jointing profiles

- 4.4.10 Pipes penetrating 'B' Class bulkheads, ceilings and linings

- 4.4.11 Cables penetrating 'B' Class bulkheads, ceilings and linings

- 4.4.12 Drawings

- 4.5 Draft Stops

- 4.6 'B' Class Doors

- 4.7 Construction of 'C' Class Bulkheads, Linings and Ceilings

- 4.8 Aluminum alloy Structures

- 4.9 Hinged or Portable Decks

- 4.10 False Decks

- 4.11 Separation of Machinery Spaces from Other Spaces

- 4.12 Means of Escape

- 4.13 Ventilation Systems (passenger ships)

- 4.14 Ventilation Systems (cargo ships and tankers)

- 4.15 Window and Sidelight boxes

- 4.16 Restricted Fire Risk Furniture

- 4.17 Special Category Spaces

- 4.18 Combined Galley and Mess Room

- 4.19 Manual Sprinkler Systems on Vehicle Decks

- 4.20 Methods of Fire Protection for Cargo Ships and Tankers

- 4.21 Watertight and Weathertight Doors

- 4.22 Concealed and Inaccessible Spaces

- 4.23 Fire Control Plans

- 4.24 Use of Polyurethane and Other Organic Foam Materials

- 4.25 Windows

- 4.26 Tankers - Protection of Exterior Boundaries

- 4.27 Ships Transferred to Canadian Registry

- Figure 1 - Recommended method of showing fire integrity and insulation values on fire zone plans

- Figure 2 - Details of protective metal sheathing for vapour barriers

- Figure 3 - Section in way of an 'A' class deck showing the termination of the 'A' class bulkhead fire insulation

- Figure 4 - Section in way of the tank top or bottom shell plating showing the termination of the 'A' class bulkhead fire insulation

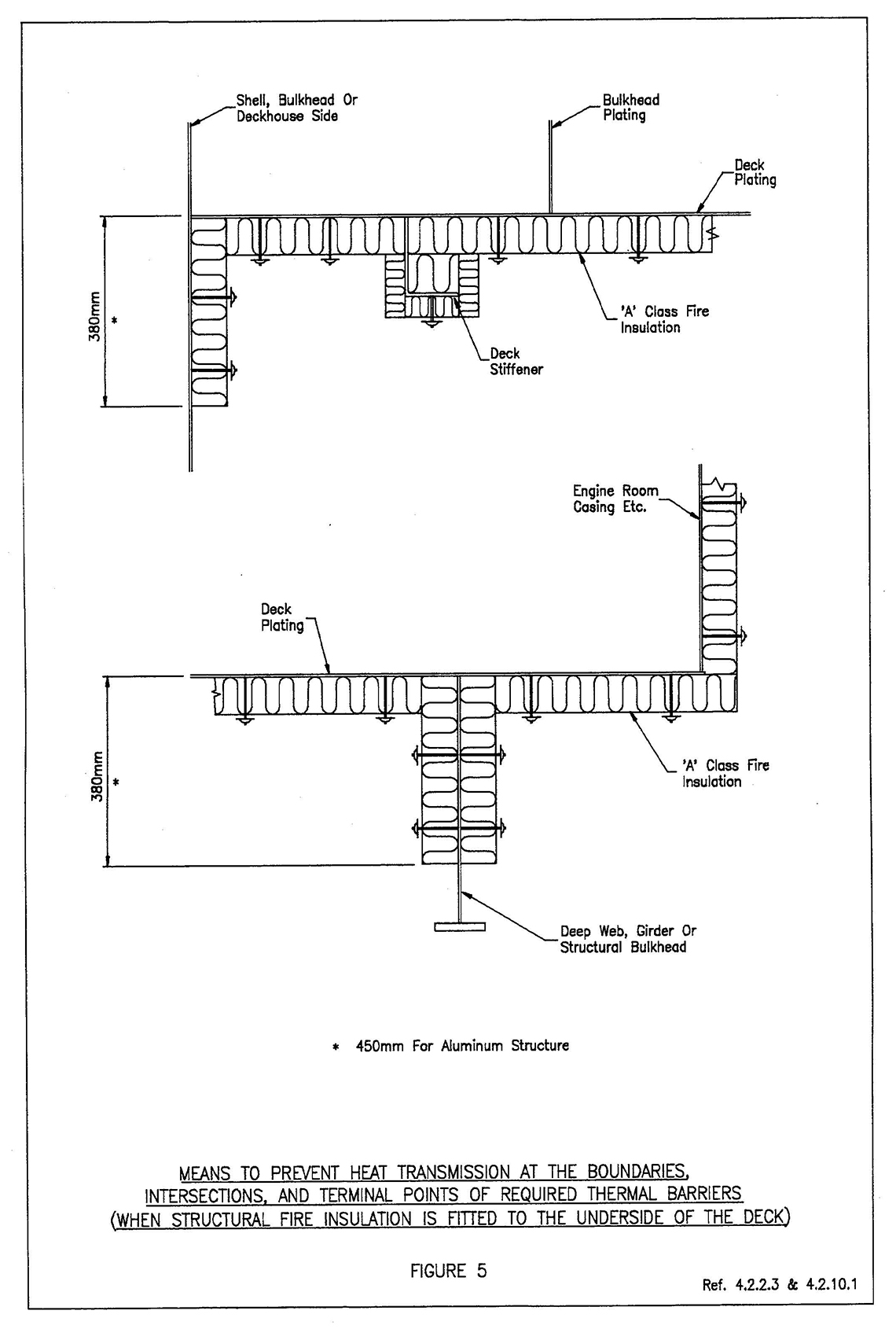

- Figure 5 - Means to prevent heat transmission at the boundaries, intersections and terminal points of required thermal barriers (when the structural fire insulation is fitted to the underside of the deck)

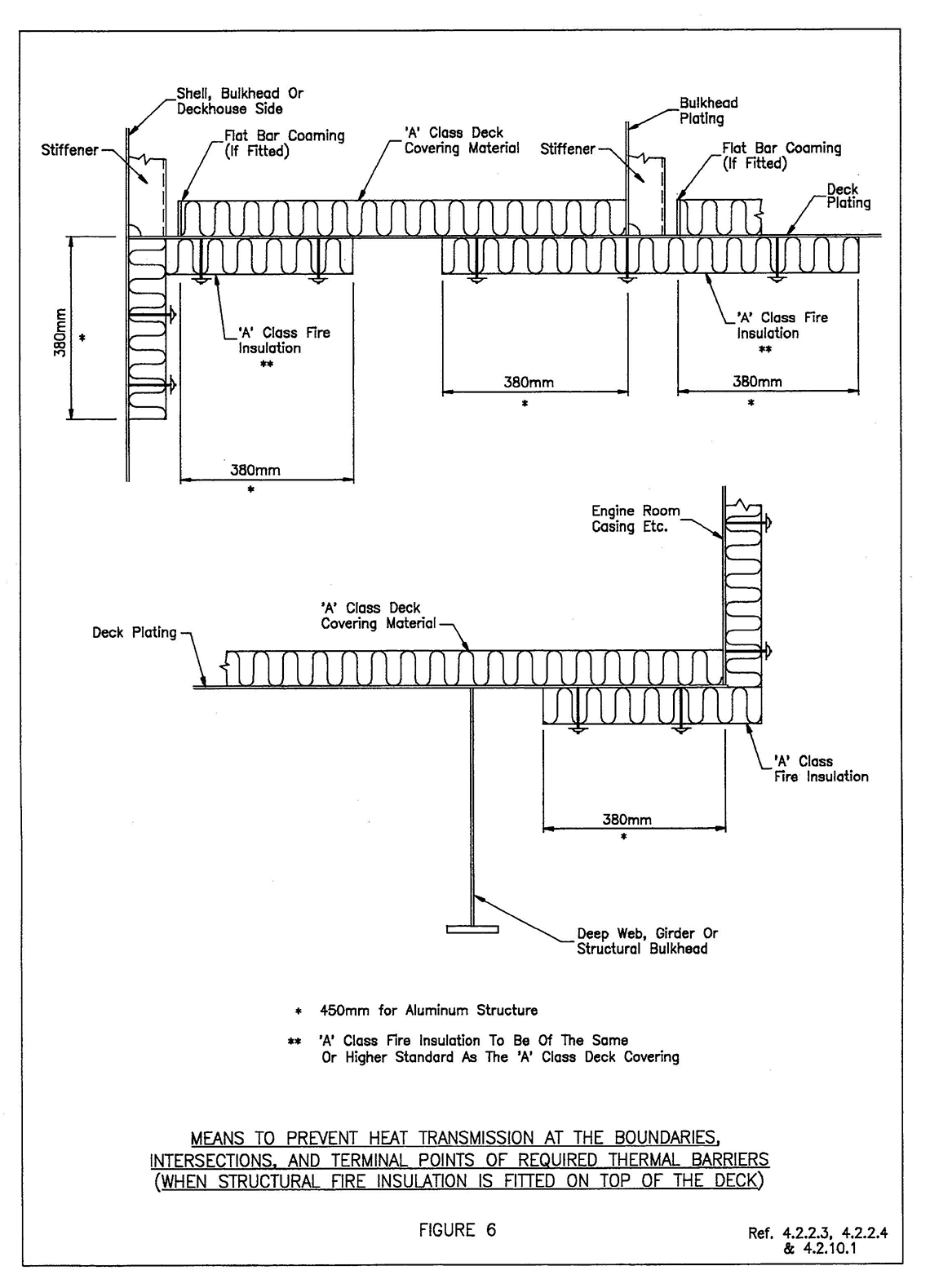

- Figure 6 - Means to prevent heat transmission at the boundaries, intersections and terminal points of required thermal barriers (when structural fire insulation is fitted on top of the deck)

- Figure 7 - Means to prevent heat transmission at the boundaries, intersections and terminal points of required thermal barriers (when structural fire insulation is fitted on top of the deck)

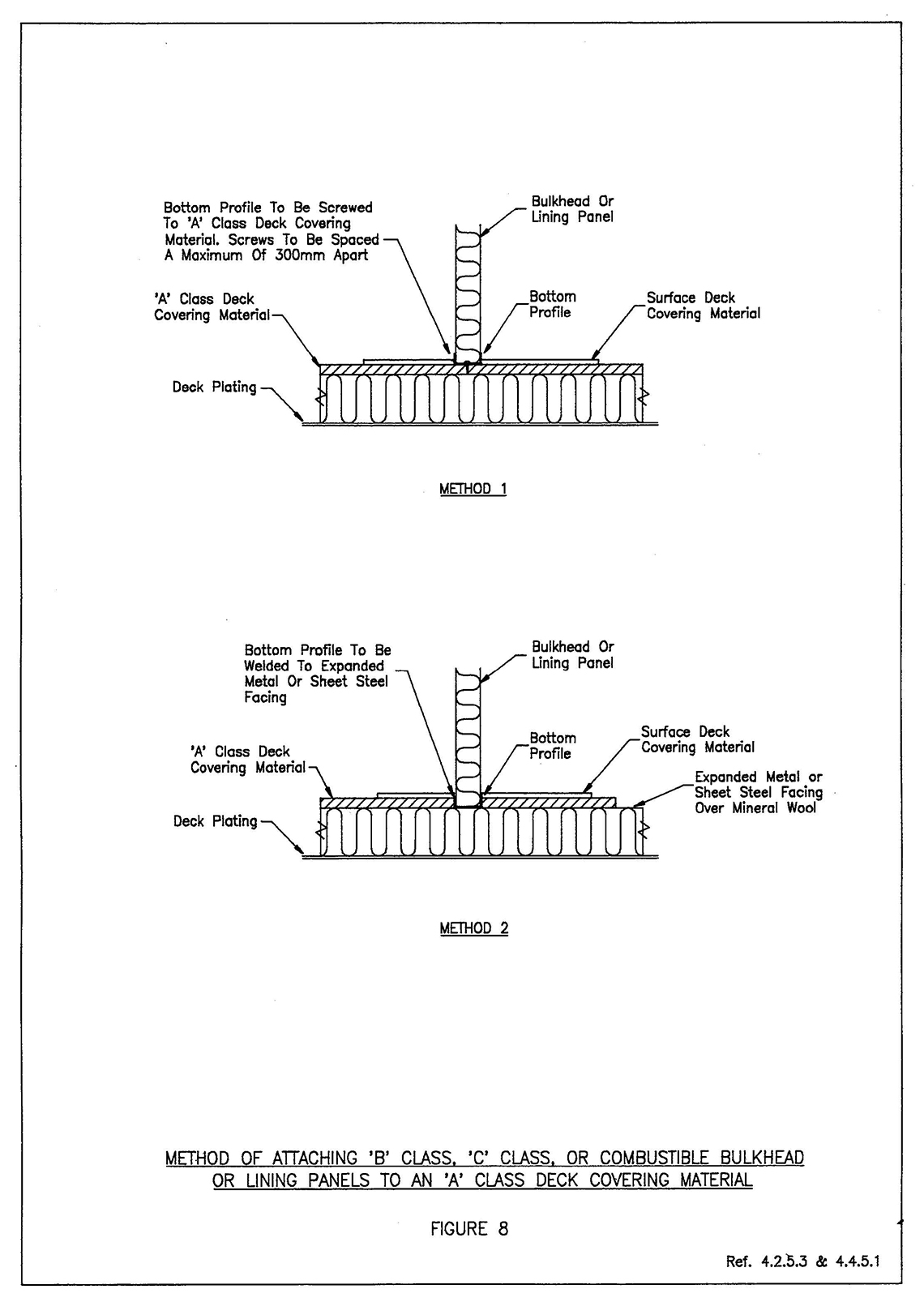

- Figure 8 - Method of attaching 'B' class, 'C' class, or combustible, bulkhead or lining panels to 'A' class deck covering material

- Figure 9 - Termination of 'B' class, 'C' class or combustible, bulkhead or lining panels in way of 'A' class ceilings

- Figure 10 - Details of attachment of mineral wool fire insulation to a steel bulkhead or deck

- Figure 11 - Details of attachment of mineral wool fire insulation to an aluminum bulkhead or deck

- Figure 12 - Arrangement of an 'A' class bulkhead using a 'B' class board type insulation as a component when the board type insulation terminates at the ceiling level

- Figure 13 - Arrangement of an 'A' class bulkhead using a 'B' class board type insulation as a component when the board type insulation extends from deck to deck

- Figure 14 - Methods of insulating a typical machinery casing showing the ribands of insulation at boundaries and intersections

- Figure 15 - Methods of insulating a typical machinery casing showing the ribands of insulation at boundaries and intersections

- Figure 16 - Arrangement when 'B' class bulkheads do not extend deck to deck or to the shell or deckhouse side

- Figure 17 - Arrangement when 'B' class bulkheads extend deck to deck and to the shell or deckhouse side

- Figure 18 - Arrangement when 'B' class bulkheads do not extend deck to deck but do extend to the shell or deckhouse side

- Figure 19 - Attachment of a 'B' class lining panel to the ship's structure

- Figure 20 - Attachment of a 'B' class bulkhead panel to the deck structure

- Figure 21 - Typical arrangement of draft stops

- Figure 22 - Typical draft stop details

- Figure 23 - Construction of corridor bulkheads in passenger ships

- Figure 24 - Arrangement at top of 'B' class bulkhead and lining panels when panels are fitted deck to deck

- Figure 25 - Typical arrangement of stairtowers and stairways

- Figure 26 - Acceptable non-manufactured systems for pipes of steel or any other material having a melting point of 1000° C or more penetrating 'A' class bulkheads or decks

- Figure 27 - Acceptable non-manufactured systems for pipes of steel or any other material having a melting point of 1000° C or more penetrating 'A' class bulkheads or decks

- Figure 28 - Acceptable non-manufactured systems for pipes of a material having a melting point of less than 1000° C penetrating 'A' class bulkheads or decks

- Figure 29 - Acceptable non-manufactured systems for pipes of steel or any other material having a melting point of 1000° C or more penetrating 'A' class bulkheads or decks

- Figure 30 - Penetration of 'A' class bulkheads or decks by electric cables

- Figure 31 - Penetration of 'A' class bulkheads or decks by electric cables when a 'B' class board type insulation is used as an insulation component

- Figure 32 - Penetration of 'A' class bulkheads or decks by vent ducts

- Figure 33 - Penetration of 'A' class bulkheads or decks by vent ducts when a 'B' class board type insulation is used as an insulation component

- Figure 34 - Vent ducts passing through a space surrounded by 'A' class divisions without serving the space

- Figure 35 - Penetration of 'B' class bulkheads, linings or ceilings by pipes constructed of steel or any other material having a melting point of 1000° C or more

- Figure 36 - Penetration of 'B' class bulkheads, linings or ceilings by pipes constructed of steel or any other material having a melting point of 1000° C or more

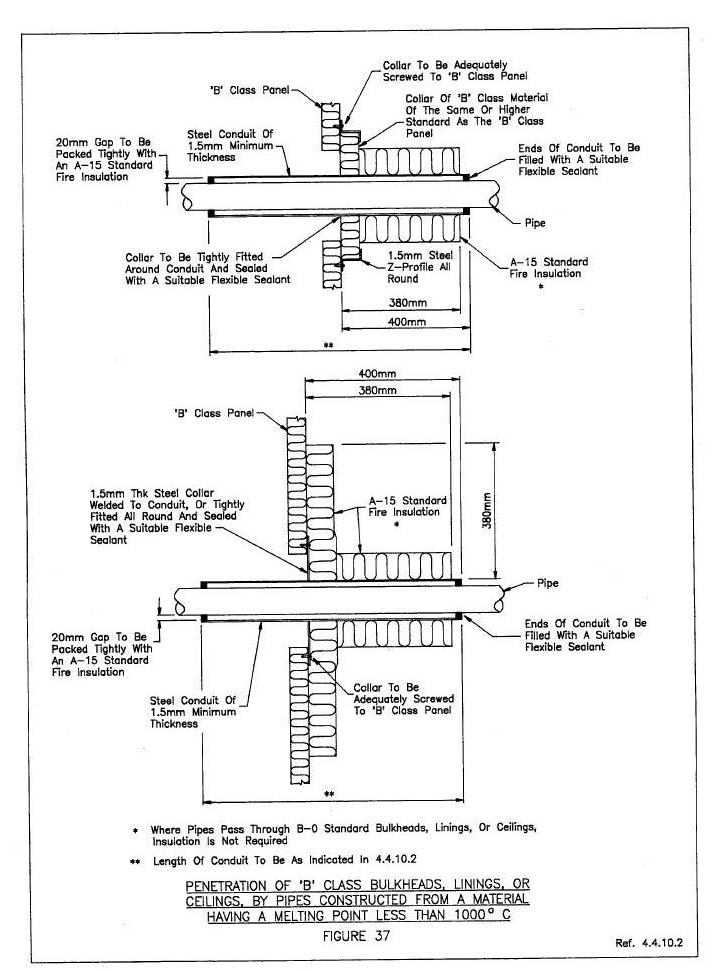

- Figure 37 - Penetration of 'B' class bulkheads, linings or ceilings by pipes constructed from a material having a melting point of less than 1000° C

- Figure 38 - Penetration of 'B' class bulkheads, linings or ceilings by pipes constructed from a material having a melting point of less than 1000° C

- Figure 39 - Penetration of 'B' class bulkheads, linings or ceilings by electric cables

- Figure 40 - Penetration of 'B' class bulkheads, linings or ceilings by electric cables

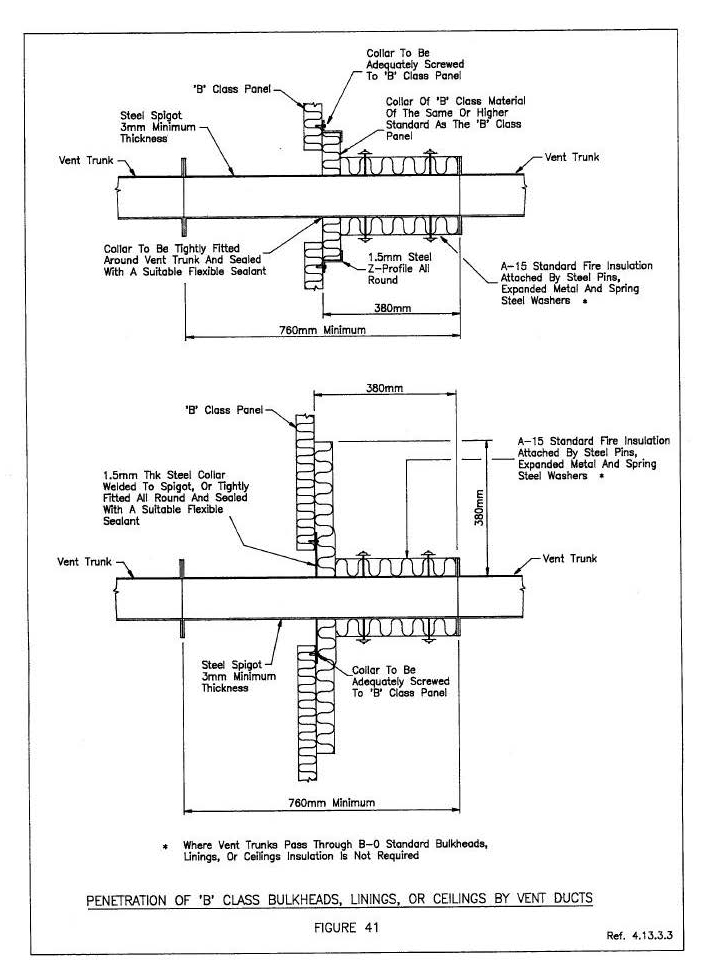

- Figure 41 - Penetration of 'B' class bulkheads, linings or ceilings by vent ducts

- Figure 42 - Penetration of 'B' class bulkheads, linings or ceilings by vent ducts

- Figure 43 - Penetration of 'B' class ceilings by lighting and ventilation fittings when the ceiling is not a component of an 'A' class deck

- Figure 44 - Penetration of 'B' class ceilings by lighting and ventilation fittings when the ceiling is a component of an 'A' class deck

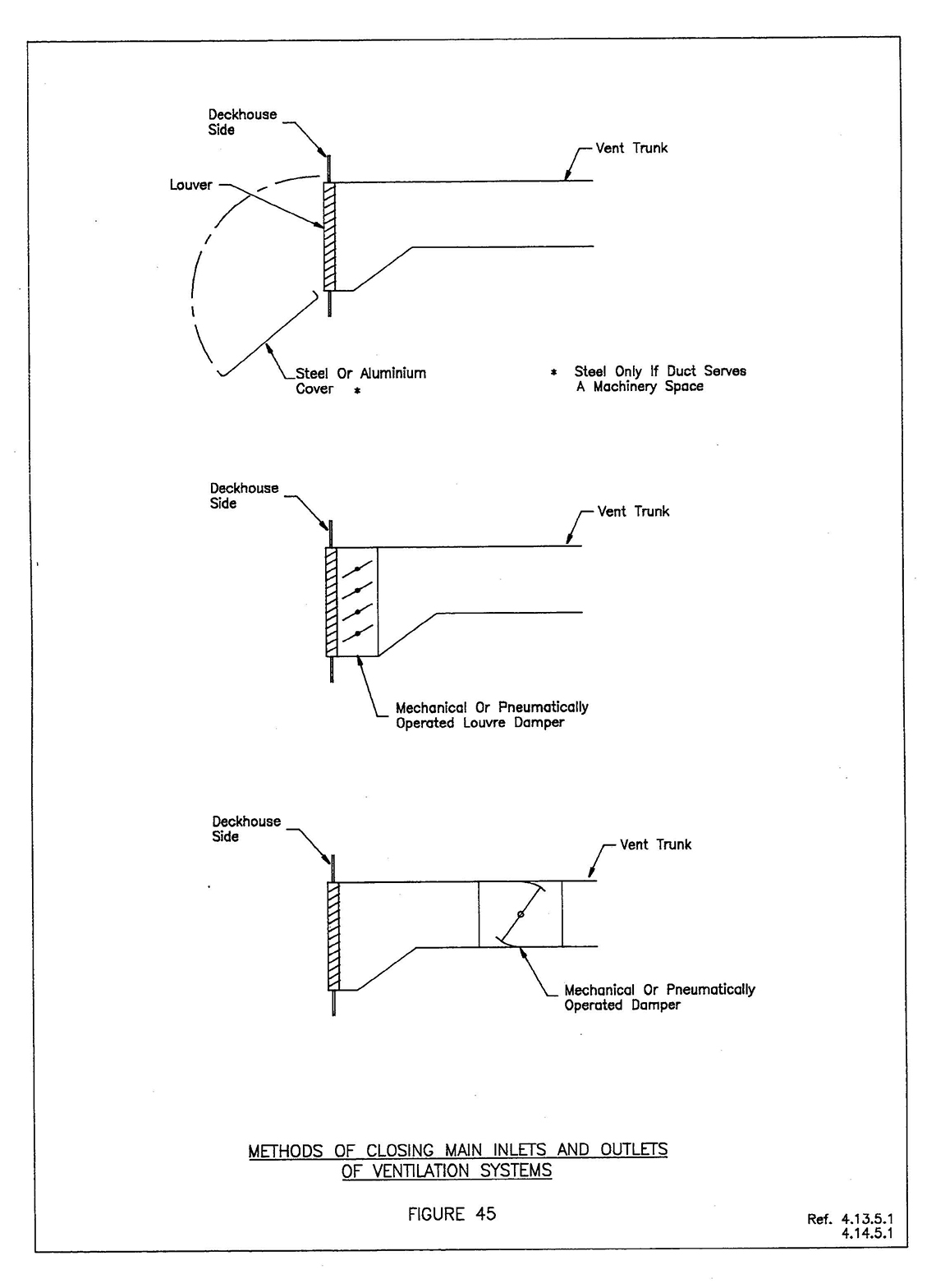

- Figure 45 - Methods of closing main inlets and outlets of ventilation systems

- Figure 46 - Extent of insulation on a superstructure or deckhouse facing the cargo tank area

- Figure 47 - Insulation of an overhanging deck

- Figure 48 - Extent of insulation around a space which is permitted to have access within the area specified in 4.26.6

Foreward

This guide is intended to clarify the structural fire protection requirements contained in the various Regulations and Standards. The Regulations and Standards without explanation may not be sufficient for the comprehension of the total scope and intent of the Canadian Coast Guard's structural fire protection requirements. This guide is a clarification and interpretation of the Regulations and Standards, but in no way changes or modifies the applicable regulatory requirements.

Part 1 - Definitions

Accommodation Spaces

Accommodation spaces include:

- Public spaces

- Corridors and lobbies

- Public washrooms and toilet spaces

- Crew Cabins

- Passenger Cabins

- Offices

- Hospitals

- Dispensaries

- Cinemas

- Games Rooms

- Hairdressing salons and beauty parlours

- Isolated pantries containing no cooking appliances

- Dining rooms

- Lounges

- Shops

- Drying rooms having a deck area of 4 m2 or less

- Isolated lockers and small storerooms having a deck area of 4 m2 or less in which flammable liquids are not stowed

- Cleaning gear lockers in which flammable liquids are not stowed

- Laboratories in which flammable liquids are not stowed

'A' Class Divisions

'A' class divisions are bulkheads and decks constructed of steel or other equivalent material, capable of preventing the passage of smoke and flame to the end of the one-hour standard fire test. They are insulated with approved materials such that the average temperature of the unexposed side will not rise more than 139° C above the original temperature, nor will the temperature at any one point, including any joint, rise more than 180° C above the original temperature, within the time listed below:

Class "A-60" - 60 minutes

Class "A-30" - 30 minutes

Class "A-15" - 15 minutes

Class "A-0" - 0 minutes

'A' Class Fire Doors

The construction of all doors in 'A' Class bulkheads and the means of securing them when closed should provide resistance to fire as well as to the passage of smoke and flame, as far as practicable, equivalent to that of the bulkheads in which the doors are situated. 'A' Class fire doors should be constructed of steel or other equivalent material.

Approved Materials

Approved materials are those which have been approved by the Board of Steamship Inspection and meet the test criteria described in the publication, TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures". A listing of all Canadian Coast Guard approved structural fire protection materials is contained in the publication TP 438, "Structural Fire Protection Standards: List of Approved Products".

'B' Class Divisions

'B' Class divisions are bulkheads, decks, ceilings and linings constructed of approved non-combustible materials, capable of preventing the passage of flame to the end of the first half-hour of the standard fire test. They have an insulation value such that the average temperature of the unexposed side will not rise more than 139° C above the original temperature, nor will the temperature at any one point, including any joint, rise more than 225° C above the original temperature, within the time listed below :

Class "B-15" - 15 minutes

Class "B-0" - 0 minutes

'B' Class Fire Doors

The construction of all doors in 'B' Class bulkheads and the means of securing them when closed should provide resistance to fire as far as practicable equivalent to the bulkheads in which the doors are situated. 'B' Class fire doors should be constructed of approved non-combustible materials.

'C' Class Divisions

'C' Class divisions are bulkheads, decks, ceilings and linings constructed of approved non-combustible materials, which have no requirements relative to the passage of smoke and flame nor the limiting of temperature rise.

'C' Class Doors

'C' Class doors are the type of doors required to be fitted in 'C' Class bulkheads. They must be constructed of approved non-combustible materials.

Cargo Spaces

Cargo spaces are all spaces used for cargo including cargo oil tanks and any trunks leading to and from such spaces.

Ceilings

Ceilings are horizontal divisions fitted near the deckhead of a space for the purpose of decoration, acoustics or fire protection.

Combustible Materials

Combustible materials are materials which do not meet the criteria for non-combustibility.

Continuous 'B' Class Ceilings and Linings

Continuous 'B' Class ceilings and linings are those ceilings and linings which terminate only at a 'A' or 'B' Class division. Continuous 'B' Class ceilings may be used in lieu of fitting 'B' Class bulkheads deck to deck in accommodation and service areas.

Control Stations

Control Stations include:

- Spaces containing emergency sources of power and lighting, including battery rooms

- Spaces containing the ship's radio equipment

- Spaces used for the storage of smothering gas

- Wheelhouse and chart rooms

- Control rooms for propelling machinery when located outside the propelling machinery spaces

- Spaces containing fire control and recording equipment

- Spaces containing the operating controls for sprinkler and water deluge systems

- Spaces containing the emergency fire pumps

- Spaces containing the main navigation equipment

- Spaces containing centralized emergency public address system stations and equipment.

- Trunks leading to and from the above spaces.

Dead End Corridors

Dead end corridors are passageways from which there is only one route of escape.

Draft Stops

Draft stops are divisions installed between ceilings or linings and the ship's structure. The purpose of draft stops is to prevent the spread of smoke and flame in concealed spaces.

Fire Dampers

Fire dampers are devices fitted to vent ducts that penetrate 'A' Class bulkheads and decks, in order to maintain the fire integrity of the division and to prevent the spread of smoke and flame to adjacent compartments through the ventilation system.

Fire Integrity

Fire integrity is the basic fire-resisting ability of a bulkhead or deck to remain intact during a specified period, i.e. , 60 minutes for 'A' Class and 30 minutes for 'B' Class.

Furnishings

Furnishings are the contents of a room, such as desks, chairs, draperies, carpets, etc.

Intumescent Coatings

Intumescent coatings mean coatings which when heated are subject to a chemical reaction called intumescence. This causes the coating to form into a multi-cellular barrier which acts as a partial fire-shield. Intumescent coatings are not structural fire insulations.

Low Flame Spread Characteristics

Low flame spread characteristics means that the surface described will adequately restrict the spread of flame and has been approved by the Canadian Coast Guard as having successfully passed the tests described in TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures."

Machinery Spaces of Category "A"

Machinery spaces of category "A" are spaces and trunks to such spaces which contain internal combustion machinery used for main propulsion, internal combustion machinery for purposes other than main propulsion where such machinery has in the aggregate a total power output of not less than 375 kW , or any oil fired boiler or oil fuel unit.

Machinery Spaces

Machinery spaces include:

- Machinery spaces of category 'A'

- Spaces containing propelling machinery

- Boiler spaces

- Spaces containing fuel oil units, steam or internal combustion machinery

- Spaces containing generators or electrical motors and auxiliaries (spaces containing the emergency source of power are considered control stations)

- Oil fuel filling stations

- Spaces containing refrigeration machinery

- Spaces containing ventilation and air conditioning machinery

- Spaces containing steering gear machinery

- Spaces containing stabilizing machinery

- Trunks leading to and from the above spaces

Main Vertical Zones

Main vertical zones are sections into which the hull, superstructure and deckhouses are divided by 'A' Class divisions the mean length of which on any one deck does not in general exceed 40 metres. Where main vertical zoning is not practicable as in special category spaces, equivalent protection must be obtained on the basis of a horizontal zone concept.

Methods of Fire Protection

In cargo ships, three methods of fire protection are permitted, namely IC, IIC and IIIC. Detailed requirements for each of the three methods are described in Part X of the Hull Construction Regulations.

Non-Combustible Materials

Non-combustible materials are materials approved by the Board of Steamship Inspection that have successfully passed the non-combustibility test described in TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures"

Public Spaces

Public spaces are those spaces in accommodation areas that are used for dining rooms, lounges, recreation rooms, libraries and similar enclosed spaces.

Penetrations

Penetrations are openings made in bulkheads or decks to allow the passage of pipes, electric cables and ventilation ducts. For the purpose of structural fire protection, these openings must be protected to maintain the fire integrity of the bulkhead or deck.

Ro-Ro Cargo Spaces

Ro-Ro cargo spaces are spaces not normally subdivided in any way and extending to either a substantial length or the entire length of the ship in which goods (packaged or in bulk), in or on rail or road cars, vehicles (including road or rail tankers), trailers, containers, pallets, demountable tanks or in or on similar stowage units or other receptacles that can be loaded and unloaded normally in a horizontal direction.

Rooms Containing Furniture and Furnishings of Restricted Fire Risk

Rooms containing furniture and furnishings of restricted fire risk are those rooms (whether cabins, public spaces, offices or other types of accommodation) in which:

- all case furniture such as desks, wardrobes, bureaux, dressers, is constructed entirely of approved non-combustible materials except that a combustible veneer not exceeding 2 mm may be used on the working surface of such articles;

- all free standing furniture such as chairs, sofas,tables is constructed with frames of non-combustible materials;

- all draperies, curtains and other suspended textile materials have, qualities of resistance to flame not inferior to those of wool of mass 0.8 kg / m2 ;

- all soft floor coverings meet the test criteria described in TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures".

- all exposed surfaces of bulkheads, linings and ceilings have low flame spread characteristics; and

- all upholstered furniture meets an approved test criteria.

Service Spaces

Service spaces include:

- Galleys

- Pantries containing cooking appliances

- Storerooms

- Workshops (other than those forming part of a machinery space)

- Laundries

- Drying rooms having a deck area of more than 4 m2

- Mail and baggage rooms

- Paint and lamp rooms

- Trunks leading to and from the above spaces

Special Category Spaces

Special category spaces are enclosed spaces above or below the bulkhead deck intended for the carriage of motor vehicles with fuel in their tanks for their own propulsion, into and from which such vehicles can be driven and to which passengers have access.

Stairways

Stairways are vertical means of escape between two decks. A stairway which penetrates only one deck must be enclosed by bulkheads and a door at least at one level. If it is necessary to have a stairway that penetrates more than one deck, a stairtower is to be provided.

Stairtower

A stairtower is an enclosure which provides continuous fire shelter for a stairway penetrating more than one deck.

Steel or other Equivalent Material

Means steel or any non-combustible material that by itself or when insulated has structural and fire integrity properties equivalent to steel at the end of the applicable exposure to the standard fire test.

Structural Fire Protection

Structural fire protection is a means of minimizing the probability of a major fire and the resulting loss of life by designing the structure of the ship to confine any outbreaks of fire to as small an area as possible. This is accomplished by specifying fire endurance capabilities of structural boundaries. Additional items considered are minor bulkheads and penetrations of structural boundaries.

The following basic principles underline the requirements contained in the Regulations and Standards pertaining to structural fire protection:

- division of the ship into main vertical zones by thermal and structural boundaries (passenger ships);

- separation of accommodation spaces from the remainder of the ship by thermal and structural boundaries;

- restricted use of combustible materials;

- detection of any fire in the zone of origin;

- containment and extinction of any fire in the space of origin;

- protection of the means of escape or access for fire fighting;

- ready availability of fire extinguishing appliances; and

- minimization of possibility of ignition of flammable cargo vapour.

Part 2 - Submission of plans

The following plans are required to be submitted to the Ship Safety Branch to reflect the structural fire protection arrangements of each vessel.

2.1 Fire Zone Plan

2.1.1 The fire zone plan should be in the form of an outline general arrangement drawing, drawn to a scale of not less than 1:100. The regulations being applied and the area of operation should be indicated. Each interior compartment, and exterior decks if designated for the mustering and embarkation of passengers is to be identified by name and classified according to its fire risk into one of the categories described in the tables contained in the applicable regulations. In the case of cargo ships, the method of fire protection which is to be adopted i.e. IC, IIC or IIIC, should be stated on the drawing. Main vertical zone and horizontal zone boundaries should be clearly marked. All bulkhead and deck fire integrity and insulation values are to be shown and the symbols used to indicate such values are to be easily distinguishable. Figure 1 indicates an acceptable method of presenting this information.

2.1.2 This plan should only contain the information described above. Past practice by some shipbuilders and naval architects has been to submit drawings which contain additional information such as installation details of fire insulation, ventilation systems and fire extinguishing equipment. This practice will no longer be accepted. Fire zone plans are not to be confused with fire control plans which are intended for the guidance of ship's officers in a fire emergency.

2.2 Insulation Details

This plan should indicate the location and installation details for all structural fire insulation and other types of insulation fitted, i.e. comfort and acoustic, including details of vapour barriers where fitted. Each product is to be identified and the methods of installation, thicknesses and other details for each product are to be in accordance with the conditions specified on the relevant certificate of approval issued by the Board of Steamship Inspection.

2.3 Bulkhead, Ceiling, Lining and Draft Stop Details

This plan should indicate the location and installation details of all 'A' Class, 'B' Class, and 'C' Class non-combustible bulkheads, ceilings, linings and draft stops. Each product is to be identified and the methods of installation, thicknesses and other details are to be in accordance with the conditions specified on the relevant certificate of approval issued by the Board of Steamship Inspection.

2.4 Deck Covering Details

This plan should indicate the location and installation details for deck coverings both fire-rated and non-fire-rated. Each product is to be identified and the methods of installation, thicknesses and other details are to be in accordance with the conditions specified on the relevant certificate of approval issued by the Board of Steamship Inspection.

2.5 Ventilation System Details

This plan should indicate the arrangement of the ventilation ducts throughout the vessel. It should also indicate the sizes, construction materials and thicknesses of ducts, the extent and type of fire insulation fitted to ducts, location and details of fire dampers and details of the closing devices for the main inlets and outlets.

2.6 List of Doors

This plan should indicate the location, type, dimensions and fire rating of each 'A' and 'B' Class door or shutter which is to be fitted on the ship and an indication of the doors provided with self-closing and central control releasing arrangements. The names of the manufacturers of the doors and the appropriate certificate of approval number should also be indicated.

2.7 Penetration Details

This plan should indicate the detailed arrangements when 'A' Class bulkheads and decks and 'B' Class bulkheads, ceilings and linings are penetrated by pipes, electric cables and ventilation ducts.

2.8 General

2.8.1 The "Fire Zone Plan" should be submitted via a Regional Office to Headquarters for approval. The remaining plans listed above should be submitted to the appropriate Regional Office for their approval.

2.8.2 Plans should contain all the requisite data, clearly substantiate compliance with the regulations and should be submitted prior to construction or installation.

2.8.3 Any plans submitted which are determined to be incomplete or significantly at variance with the regulations will be returned to the submitter unapproved and without detailed comments. The submitter will however be referred to the appropriate regulations and requested to resubmit the plans.

2.8.4 Surveyors should ensure that the texts of all drawings and specifications are legible and in the English or French language or adequate translations are provided.

Part 3 - Materials of Construction

3.1 General

3.1.1 All approved structural fire protection materials for use on Canadian registered ships are listed in TP 438, "Structural Fire Protection Standards: List of Approved Products". In order for a product to be listed as "approved" it must first be tested in accordance with the applicable test procedure described in TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures". After successful testing, and approval of the manufacturer's installation drawings (where required), a certificate of approval will be issued by the Board of Steamship Inspection and the product listed in TP 438.

3.1.2 Methods of construction and installation of such materials must be strictly in accordance with those described in the certificate of approval and shown on the manufacturer's approved drawings. No departure will be permitted without the prior consent of the Board of Steamship Inspection.

3.2 Non-Combustible Materials

3.2.1 One of the basic principles of the Coast Guard's structural fire protection philosophy is that the material from which the vessel is constructed should not add to the fuel load available for combustion.

3.2.2 This requires that the majority of materials of construction within the accommodation and service spaces be non-combustible and must successfully pass the tests described in TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures" except for certain materials which are known to be inherently non-combustible. The following materials fall under this category and are accepted without testing:

- sheet glass, block glass, clay, ceramics and uncoated glass fibres;

- all metals except magnesium and magnesium alloy;

- portland cement, gypsum and magnesite concretes having aggregates of sand, gravel, expanded vermiculite, expanded or vesicular slags, diatomaceous silica, perlite or pumice;

- woven, knitted or needle punched glass fabric containing not more than 2.5% lubricant.

3.3 Structural Fire Insulations

3.3.1 The basic element of bulkhead and deck construction is steel plate. Without additional insulation, steel plate of the required thickness suitably stiffened can be classified as an A-0 or B-0 division. Structural integrity, however, is not the sole parameter upon which the structural fire protection system is dependent. To prevent the spread of fire by radiant or conducted heat, some structural divisions must also act as insulators to prevent the transmission of heat to the unexposed side of the bulkhead or deck.

3.3.2 There are basically three ways to achieve this insulating capability on bare steel:

- application of an approved structural fire insulation;

- application of an approved bulkhead or ceiling panel; or

- a combination of (a) and (b) above.

3.3.3 Materials which have been approved only for use as an insulation for 'A' Class bulkheads should not be used as an insulation for 'A' Class decks and vice versa.

3.3.4 Structural fire insulations are to be tested in accordance with the tests for 'A' Class bulkheads and decks described in TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures".

3.4 Bulkhead, Lining and Ceiling Panels

3.4.1 Generally, bulkhead, lining and ceiling panels are constructed of non-combustible binder board or steel faced mineral wool. These panels may be used in the construction of 'B' Class bulkheads, ceilings and linings or as components in 'A' Class bulkheads and decks when tested in accordance with the tests described in TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures".

3.5 Deck Coverings

3.5.1 Deck coverings fall into two categories, fire rated and non-fire-rated. Fire rated deck coverings are materials which have been approved for use as an insulation material in the construction of 'A' Class decks. Non-fire-rated deck coverings consist of two types, primary and surface. Primary materials are normally in the form of an underlay applied directly to the deck plating and are used for levelling and smoothing. Surface materials are the exposed deck covering materials fitted for decorative purposes. TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures" describe the test requirements for both fire-rated and non-fire-rated deck coverings.

3.5.2 Soft floor coverings such as carpets which are fitted in corridors, stairways and spaces containing furniture and furnishings of restricted fire risk require to be tested in accordance with TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures.

3.5.3 Soft floor coverings which are fitted in spaces other than the type described above should be to the satisfaction of the local surveyor who must satisfy himself that the material fitted does not constitute a hazard.

3.6 Interior Finish Materials

3.6.1 The interior finish applied to shipboard compartments is important because the spread of flame and the generation of smoke is dependent upon the properties of the interior finish materials.

3.6.2 In passenger ships the following surfaces are to have low flame spread characteristics:

- Exposed surfaces of bulkheads, linings, and ceilings in corridors and stairway enclosures;

- Exposed surfaces of bulkheads, linings, and ceilings in all accommodation spaces, service spaces and control stations.

- Surfaces in concealed or inaccessible spaces in accommodation spaces, service spaces and control stations.

3.6.3 In cargo ships and tankers the following surfaces are to have low flame spread characteristics:

- Exposed surfaces of bulkheads, linings and ceilings in corridors and stairway enclosures;

- Exposed surfaces of ceilings in accommodation spaces, service spaces and control stations;

- Surfaces in concealed or inaccessible spaces in accommodation spaces, service spaces and control stations.

3.6.4 The above requirements do not apply to furniture, furnishings, machinery and similar items except where required by a specific regulation e.g. The Towboat Crew Accommodation Regulations.

3.6.5 Where surfaces are required by the regulations to have low flame spread characteristics, they should be tested in accordance with TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures".

3.6.6 Where exposed surfaces of ceilings are required to have low flame spread characteristics plastic light diffusers may be fitted in way of ceiling mounted light fittings provided the fitting is enclosed in a steel housing. The total surface area of the plastic diffusers in any one space should not exceed 20% of the total ceiling area.

3.7 Vapour Barriers

3.7.1 Where insulations are exposed to oil and oil vapours they should be faced with a vapour barrier of impervious material such as aluminum foil or plastic film. Any joints should be sealed with a tape of compatible material having a minimum width of 50 mm . Details of and the method of applying the vapour barrier material should be shown on the plan of insulation details described in Part 2. In no case where a vapour barrier is fitted should the expanded metal used to secure 'A' Class insulation be dispensed with.

3.7.2 Where there is a risk of an 'A' Class insulation becoming damaged by the shipping or unshipping of machinery or similar operations, then the vapour barrier should be protected by a metal sheathing. The metal sheathing should be attached to the structure independently of the 'A' Class insulation with a gap of at least 25 mm and the number and size of the means of securing the metal sheathing should be kept to a minimum. Figure 2 shows an acceptable method of installing the metal sheathing but any other similar method of attachment may be considered.

3.8 Combustible Materials

3.8.1 In passenger ships, the total volume of combustible facings, mouldings, decorations and veneers in any accommodation and service space should not exceed a volume equivalent to a 2.5 mm thick veneer on the combined area of the walls and ceilings.

3.8.2 In cargo ships and tankers, non-combustible bulkheads, linings and ceilings fitted in accommodation and service spaces may have a surface combustible veneer not exceeding 2 mm in thickness within any such space, except corridors and stairway enclosures where the veneer should not exceed 1.5 mm in thickness.

Part 4 - Construction and Arrangement

4.1 General

4.1.1 The effectiveness of structural fire protection is dependent upon each material or fitting being properly fitted and erected in the approved manner so that each 'A' or 'B' Class division is an effective barrier against fire.

4.1.2 Poor workmanship or lack of attention to detail, particularly with respect to boundaries and intersections of 'A' and 'B' Class divisions and penetrations through such divisions, may result in a fire breaking through a division in a very short period of time.

4.2 'A' Class Insulations

4.2.1 'A' Class bulkheads

4.2.1.1 'A' Class bulkheads were originally required on passenger vessels for "fire resisting" boundaries described as main vertical zones, spaced at intervals of 40 metres. Currently, 'A' Class boundaries are also required to contain fires in high fire hazard areas such as machinery spaces, galleys and cargo spaces in passenger ships, cargo ships and tankers. 'A' Class bulkheads are also required to protect spaces such as control stations and stairway enclosures.

4.2.1.2 'A' Class bulkheads, in some locations, are required to have insulating capabilities. There are four types of 'A' Class bulkheads, each type being alpha-numerically designated to indicate its fire integrity and insulation value, i.e. , A-60, A-30, A-15 and A-0.

4.2.1.3 'A' Class bulkheads are constructed of steel or other equivalent material. Subject to any additional requirements for watertight or load bearing structures, the minimum scantlings required for steel and aluminum alloy 'A' Class bulkheads should be derived from the following tables and notes.

4.2.1.4 Scantlings of 'A' Class bulkheads should not be less than those derived from the following tables and notes since these are based on the minimum scantlings of the bulkhead specimens which are used to test 'A' Class insulations. If bulkheads of lesser scantlings were to be used, the insulations may not achieve the 'A' Class standards for which they were approved.

4.2.1.5 Steel 'A' Class bulkheads

| Stiffener Span Metres |

Plating Thickness Millimetres |

Geometrical Properties in Conjunction with Plating 610 mm × Thickness | |

|---|---|---|---|

| Moment of Inertia (I) cm 4 | Section Modulus (I/Y) cm 3 | ||

| 2.4 | 4.0 | 87.5 | 12.0 |

| 2.7 | 4.5 | 130.0 | 17.0 |

| 3.0 | 5.0 | 175.0 | 22.0 |

| 3.3 | 5.5 | 237.5 | 27.0 |

| 3.6 | 6.0 | 305.0 | 32.0 |

- The spacing of stiffeners should not normally exceed 760 mm ;

- Where swedges are used to stiffen 'A' Class bulkheads the spacing should not exceed 760 mm .

- Where stiffeners are spaced other than 760 mm apart, the stiffness and strength should be increased or decreased in direct proportion to their spacing.

4.2.1.6 Where 'A' Class bulkheads are constructed of aluminum alloy, they should have equivalent strength, stiffness and efficiency to that of steel bulkheads having the same length or unsupported span.

4.2.1.7 The following table gives the ratios which may be used to obtain these equivalent values:

Plating thickness of aluminum alloy - 1.4 × thickness of steel of plating

Modulus (I/Y) of aluminum alloy stiffeners - 2.35 × Modulus (I/Y) of steel stiffeners

Inertia (I) of aluminum alloy stiffeners - 2.8 × Inertia (I) of steel stiffeners

4.2.1.8 An insulation for an 'A' Class bulkhead should cover the whole area of the division and adjacent structures as indicated in paragraph 4.2.10 except that it may terminate on top of the expanded metal or equivalent fitted over the insulation incorporated in an 'A' Class deck covering of the same or higher 'A' Class standard provided that the 'A' Class deck insulation is fitted tightly to the bulkhead plating as shown in Figure 3. However when an insulated 'A' Class bulkhead terminates at the tank top or bottom shell plating, the insulation should terminate 380 mm above the tank top or bottom shell plating to prevent the insulation absorbing any oil or water which may be on the tank top or bottom shell plating. The lower edge of the insulation should terminate at a flat bar welded to the bulkhead as shown in Figure 4.

4.2.1.9 Any pipe penetrations situated in the bulkhead below the flat bar need not be insulated provided that the penetrations are constructed in accordance with paragraph 4.2.13.

4.2.1.10 Any cable penetrations situated in the bulkheads below the flat bar need not be insulated except for those which are constructed of heat sensitive materials. These should be insulated in accordance with the conditions specified in the certificate of approval as indicated in paragraph 4.2.15.2 and the insulation protected by an oil and oil vapour barrier.

4.2.2 'A' Class decks

4.2.2.1 The insulation of decks for fire protection purposes can be accomplished by two methods. The first method is to insulate the underside of the deck plating with a structural fire insulation and the second method is to apply an approved fire rated deck covering on the upper side of the deck.

4.2.2.2 'A' Class decks, in some locations, are required to have insulating capabilities. There are four types of 'A' Class decks, each type being alpha-numerically designated to indicate its insulating capability, i.e. , A-60, A-30, A-15 and A-0.

4.2.2.3 When structural fire insulation is installed it should not terminate at the edge of the deck, but should be carried around the adjacent structure for at least 380 mm for steel (450 mm for aluminum alloy) to prevent heat transmissions as shown in Figures 5, 6 and 7.

4.2.2.4 If an approved fire rated deck covering is used as the insulating material, care is to be taken for preventing heat transmission. Where the deck covering is penetrated by steel, aluminum or 'B' Class bulkheads or other structures or where it terminates at a boundary such as the ship's side, deckhouse side or casing, the horizontal and vertical structure underneath and adjacent to such penetrations and boundaries are to be insulated for a distance of 380 mm for steel (450 mm for aluminum alloy) with an approved 'A' Class fire insulation as shown in Figure 6 and 7.

4.2.2.5 'A' Class decks are constructed of steel or other equivalent material. Subject to any additional requirements for watertight or other load bearing structures, the minimum scantlings required for steel and aluminum alloy 'A' Class decks are to be derived from the following tables and notes:

4.2.2.6 Scantlings of 'A' Class decks should not be less than those derived from the following tables and notes since these are based on the minimum scantlings of the deck specimens which are used to test 'A' Class insulations. If decks of lesser scantlings were to be used, the insulations may not achieve the 'A' Class standards for which they were approved.

4.2.2.7 Steel 'A' Class decks

| Beam Span Metres |

Plating Thickness Millimetres |

Geometrical Properties in Conjunction with Plating 610 mm × Thickness | |

|---|---|---|---|

| Moment of Inertia (I) cm 4 | Section Modulus (I/Y) cm 3 | ||

| 2.4 | 4.0 | 87.5 | 12.0 |

| 2.7 | 4.5 | 130.0 | 17.0 |

| 3.0 | 5.0 | 175.0 | 22.0 |

| 3.3 | 5.5 | 237.5 | 27.0 |

| 3.6 | 6.0 | 305.0 | 32.0 |

- The spacing of beams should not normally exceed 760 mm .

- Where beams are spaced other than 760 mm apart, the stiffness and strength should be increased or decreased in direct proportion to their spacing.

4.2.2.8 Where 'A' Class decks are constructed of aluminum alloy, they should have equivalent strength, stiffness and efficiency to that of steel decks having the same length or unsupported span.

4.2.2.9 The following table gives the ratios which may be used to obtain these equivalent values:

Plating thickness of aluminum alloy - 1.4 × thickness of steel of plating

Modulus (I/Y) of aluminum alloy beams - 2.35 × Modulus (I/Y) of steel beams

Inertia (I) of aluminum alloy beams - 2.8 × Inertia (I) of steel beams

4.2.2.10 An insulation for an 'A' Class deck should cover the whole area of the division and adjacent structures as indicated in paragraph 4.2.10. It should not terminate at a ships side lining or deckhouse side lining or a bulkhead lining except that a ceiling which is a component for an 'A' Class deck may terminate at a lining fitted deck to deck which is a component of an 'A' Class bulkhead as shown in Figure 13.

4.2.3 Mineral wool insulations

4.2.3.1 Mineral wool insulations should be stored in dry conditions before use and should be dry when attached to the ships structure.

4.2.3.2 The density of a mineral wool insulation is required to be within the range of ±10% of the density specified by the manufacturer and indicated on the certificate of approval. Surveyors should check from the mass and volume of several slabs or rolls that the density of an insulation lies within this range. A surveyor who finds that the density of an insulation is outside this range should contact Headquarters ( AMSDD ) for advice on what further action should be taken.

4.2.3.3 Although water does not normally affect the insulating properties of 'A' Class mineral wool insulations it could seriously corrode the steel pins and expanded metal which secures the insulations to the structure. Therefore surveyors should examine insulation which has been soaked with water and if there are any signs of deterioration in the pins and expanded metal then the insulation should be removed, the pins renewed as necessary, the insulation replaced when dry if still in good condition or new insulation fitted, and new expanded metal and spring steel washers fitted over the pins.

4.2.3.4 Insulation fitted in boiler rooms should be examined regularly as similar deterioration may occur due to the high humidity in such spaces.

4.2.4 Securing insulations to structure

4.2.4.1 When mineral wool batts are used as the structural fire insulation, the batts should be fitted tightly against all mating surfaces. Steel pins having a diameter of 3 mm and a length of at least 12 mm longer than the thickness of the insulation, are to be welded to the steel bulkhead or deck and the insulation impaled on the pins. In the case of aluminum bulkheads and decks, stainless steel pins screwed into aluminum alloy bosses welded to the structure are to be used. Galvanized steel expanded metal mesh sheets, 18 gauge × 38 mm are to be placed over the surface of the insulation and held in position by 38 mm square or 38 mm diameter spring steel washers pressed firmly over the pins. To ensure that the insulation is anchored tightly against the bulkhead or deck the pins are to be spaced at 300 mm centres maximum. However, adjacent to stiffeners and exposed ends, the spacing is to be as shown in Figures 10 and 11.

4.2.4.2 As an alternative, surveyors may accept the insulation being secured by means of welded steel pins bent at right angles over the expanded metal mesh, the spring washers being dispensed with provided that the pins are at least 40 mm longer than the thickness of the insulation and pins in adjacent rows are bent over in opposite directions. On no account should pins be bent in the same direction since this may result in the expanded metal mesh becoming detached from the insulation. The pins should be bent over at the exposed surfaces of the insulation in order to maintain its thickness and prevent a 'quilted' effect occurring. On aluminum alloy structures, the steel pins should not be bent over at right angles as an alternative method of securing the insulation since the thread in the bosses may be damaged in the process of bending the pins.

4.2.5 Board type insulation material

4.2.5.1 For the purpose of this part, board type insulation material includes panels consisting of mineral wool insulation faced with sheet steel.

4.2.5.2 The density of a board type panel or the core insulation in the case of a panel consisting of mineral wool insulation faced with sheet steel is required to be within the range of ±10% of the density specified by the manufacturer and described on the certificate of approval. Surveyors should check from the mass and volume of the boards or panels that the density of the board or insulation lies within this range. A surveyor who finds that the density of an insulation is outside this range should contact headquarters ( AMSDD ) for advice on what further action should be taken.

4.2.5.3 Each board type insulation which has been approved as a component of an 'A' Class bulkhead should be fitted deck to deck except that it may terminate on top of the insulating component of an 'A' Class deck covering as indicated in 4.2.1.8 and as shown in Figures 8 and 12. In no case should the board insulation terminate on any other type of deck covering. Stopping a board type insulation at ceiling level and insulating the bulkhead between the ceiling and the deckhead is acceptable provided the arrangement is as shown in Figure 12.

4.2.5.4 If a tween deck height exceeds the length of an 'A' Class board insulation the length of the board may be increased by butt strapping an extension board of the same material to it, the joint between the boards being tight. Straps should be fitted in way of the joint on each side of the extended board and should be of steel having a length equal to the width of the board less any jointing profiles and width and thicknesses of 75 mm and 0.07 mm respectively. The butt straps should be screwed and not through bolted.

4.2.5.5 Care should be taken to ensure that the board type panels used as the insulating media for 'A' Class bulkheads are erected in accordance with the approved manufacturer's drawings and in particular that the correct thicknesses of boards and jointing profiles are used. The boards may be faced on their exposed and concealed surfaces with a combustible material of the prescribed thickness having low flame spread characteristics.

4.2.6 Electrical fittings on 'A' class linings

4.2.6.1 Lighting switches, power sockets and other electrical fittings and cables leading to such fittings should be surface mounted on the unconcealed side of linings which are the insulating media for 'A' Class bulkheads in order to ensure that the insulation standards of the bulkhead are not impaired. The cables may be uncovered or fitted in conduits or covered by omega profiles of steel or other materials having surfaces with low flame spread characteristics.

4.2.7 Ceilings which are components of 'A' Class decks

4.2.7.1 Ceilings which have been approved as components of 'A' Class decks should be constructed in accordance with the manufacturer's approved drawings. A ceiling should not be fitted closer to the deck plating than the dimension quoted in the certificate of approval. The panels from which a ceiling is constructed may be faced on their exposed and concealed surfaces with a combustible material of the prescribed thickness having low flame spread characteristics.

4.2.7.2 Hinged panels may be fitted in an 'A' Class ceiling in order to provide access for the control and maintenance of fire dampers located above the ceiling provided that the integrity and insulation standard of the ceiling is not impaired, particularly when the ceiling incorporates an overlay of mineral wool insulation.

4.2.7.3 A ceiling which is a component of an 'A' Class deck should not be penetrated by bulkheads and linings which are 'B' Class or 'C' Class divisions or combustible divisions nor should it rely on support afforded by such bulkheads and linings. The ceiling should be supported in accordance with the approved manufacturer's drawings at the ships side, deckhouse side or 'A' Class bulkheads and also from the deckhead by steel hangers and/or on the flanges of the top profiles of bulkheads and linings, the profiles being supported by steel hangers from the deckhead. Figure 9 illustrates such arrangements.

4.2.8 Sprayed insulations

4.2.8.1 The density of a sprayed insulation in its dried out condition is required to be within the range of ±15% of the density specified by the manufacturer and indicated on the certificate of approval.

4.2.8.2 The thickness of a sprayed insulation indicated in the certificate of approval is a minimum thickness. Surveyors should use their discretion when checking the thickness of a sprayed insulation and may accept small areas in which the minimum thickness has not been achieved provided that the insulation in these areas are deficient by no more than 3 mm and the thickness over the division is generally in excess of the minimum thickness.

4.2.9 'A' Class deck coverings

4.2.9.1 The preparation of the deck plating and the method of installing an approved 'A' Class deck covering are described in the certificate of approval and shown on the approved manufacturer's drawing.

4.2.9.2 Linings which are the insulating media for 'A' Class bulkheads and decks and linings which are 'B' Class or 'C' Class or are combustible should not penetrate an 'A' Class overdeck insulation. In each case the bottom profile should be fitted to the top of the 'A' Class insulation as shown on the appropriate manufacturer's approved drawing. Combustible surfaces fitted to an 'A' Class deck covering should not be laid under any bulkheads or linings. Figure 8 illustrates such arrangements.

4.2.10 Boundaries, intersections and terminal points of thermal barriers

4.2.10.1 It is essential that the fire integrity and insulation value of insulated 'A' Class divisions are maintained at the boundaries and terminal points of the division and where the division is intersected by other structural members. The method by which this may be achieved is by continuing the insulation along the boundaries and intersections for a distance of not less than 380 mm in the case of steel structure and 450 mm in the case of aluminum alloy structure. The thickness of the insulation used in the continuation ribands should be the same as that fitted over the plating of the division which is being insulated and not as that of the insulation fitted over the stiffeners or beams. This should apply to all structures at which the division terminates or which abuts or intersects the division such as bulkheads or decks, ships side or deckhouse side, webs or girders and beams or stiffeners. It may be necessary to fit ribands of insulation on the opposite side of the division to that on which the insulation is fitted. When a division is insulated by means of approved boards or panels, the continuation of the insulation may best be achieved by the use of an approved mineral wool insulation having a thickness corresponding to the same 'A' Class standard as that of the division which is being insulated. Figures 5, 6, 7, 14 and 15 illustrate typical arrangements to prevent heat transmission at boundaries, intersections and terminal points.

4.2.10.2 The continuous ribands may be omitted in the following locations:

- on the underside of a weather deck abutting a bulkhead which is being insulated; and

- on the upper side of a deck intersecting a bulkhead which is being insulated except when the bulkhead is a machinery casing.

4.2.11 Approved manufactured systems for pipes penetrating 'A' Class bulkheads and decks

4.2.11.1 Any approved manufactured system for pipe penetrations may be used for pipes penetrating 'A' Class divisions subject to compliance with the conditions specified in the certificate of approval and the details shown on the manufacturer's approved drawing.

4.2.11.2 Bends in pipes should be arranged sufficiently clear of a bulkhead or deck so as not to interfere with a pipe penetration. Pipe penetration systems are normally tested on straight pipes and consequently they should not be fitted round bends unless the certificate of approval indicates otherwise.

4.2.12 Acceptable non-manufactured systems for pipes penetrating 'A' Class bulkheads and decks

4.2.12.1 When the piping is of steel or any other material having a melting point of 1000° C or more either (a) or (b) should apply:

- The pipe should be welded directly to the bulkhead or deck or joined to a fitting of the same material which should be welded or bolted to the bulkhead or deck. Where practicable, in the case of an insulated bulkhead or deck the fitting should be of sufficient length to ensure that bolted flanges are clear of the insulation which is to be continued along the fitting for a distance of 380 mm from the bulkhead or deck. When compression, push-in or similar joints are used, the length of the portion of the piping or fitting which is welded or bolted to the bulkhead or deck should not be less than 900 mm with at least 400 mm on the insulated side of the bulkhead or deck. Figure 26 illustrates such arrangements.

- When the pipe is not welded or bolted to the bulkhead or deck as indicated in (a) then each pipe should be passed through a steel circular conduit of 5 mm minimum thickness which should be welded to the bulkhead or deck. A nominal 20 mm gap should be provided between the pipe and the conduit which should be packed tightly throughout its length with an A-60 standard insulation approved by the Board of Steamship Inspection and sealed at each end with a suitable flexible sealant.

The minimum length of the spigots should be as follows:

50 mm or less

150 mm or more

400 mm

900 mm

Lengths of conduits for intermediate diameters should be obtained by interpolation.

Compression, push-in or similar types of joints should not be positioned within the spigot and should not be less than 900 mm apart.

The conduit should be positioned such that at least 400 mm of its length is on the insulated side of the insulated bulkhead or deck as shown in Figure 27.

4.2.12.2 When piping is of a material having a melting point less than 1000° C the following should apply:

- Bulkheads

Each pipe should be passed individually through a 900 mm long steel circular conduit of 5 mm minimum thickness which should be welded to the bulkhead. A nominal 20 mm gap should be provided between the pipe and the conduit which should be packed tightly throughout its length with an A-60 standard insulation approved by the Board of Steamship Inspection and sealed at each end with a suitable flexible sealant. There should be no joints in the pipe within the length of the conduit. The conduit should be positioned such that at least 400 mm of its length is on the insulated side of the insulated bulkhead. Figure 28 illustrates such an arrangement. - Decks

Pipes penetrating decks should be treated as indicated in (a) above except that when the piping extends vertically through more than one tweendeck, the vertical piping in alternate tweendecks should be of steel irrespective of whether or not the pipe is offset within its length.

4.2.13 Piping penetrating watertight 'A' Class bulkheads and decks

4.2.13.1 The piping should be of steel or any other material having a melting point of 1000° C or more and should be welded directly to the bulkhead or deck or joined to a bulkhead or deck fitting of the same material which should be welded or bolted to the bulkhead or deck as described in 4.2.12.

4.2.13.2 Compression, push-in or similar joints should not be used in piping systems which penetrate watertight 'A' Class bulkheads and decks.

4.2.13.3 Piping which is of any material having a melting point of less than 1000° C should not be used in piping systems which penetrate watertight 'A' Class bulkheads and decks.

4.2.14 Insulating pipe penetrations

4.2.14.1 When the piping penetrations referred to in 4.2.12 and 4.2.13 pass through insulated 'A' Class bulkheads and decks the insulation on the plating of the bulkhead or deck should be continued along the piping or spigot for a distance of not less than 380 mm . Where a pipe has a bend close to the division the 380 mm should be measured along the inside of the bend. The insulation should be secured effectively in place. See also 4.2.1.8 and 4.2.1.9.

4.2.14.2 When a pipe penetration passes through an 'A' Class bulkhead or deck that is insulated with a 'B' Class panel, the arrangement of insulation should be as illustrated in Figure 29.

4.2.15 Electric cables penetrating 'A' Class bulkheads and decks

4.2.15.1 Any approved manufactured cable transit may be used for electric cables penetrating non-watertight 'A' Class bulkheads and decks subject to compliance with the conditions described in the certificate of approval issued by the Board of Steamship Inspection and the details shown on the manufacturer's approved drawing. Figures 30 and 31 illustrate typical installation arrangements.

4.2.15.2 Alternatively the following procedures may be adopted:

The cables should be passed through steel conduits having a minimum length of 450 mm and a minimum thickness of 5 mm which should be welded to the bulkhead or deck. The internal cross sectional area of the conduits should not exceed 0.05 m2 . A nominal distance of 20 mm should be maintained between the cables and between the cables and conduit. The space between the cables and between the cables and the conduit should be packed tightly throughout the length of the spigot with an A-60 insulation approved by the Board of Steamship Inspection and the ends of the conduit sealed with a suitable flexible sealant. When the bulkhead or deck is insulated the conduit may project up to 400 mm on the insulated side of the division but should not project more than 225 mm on the uninsulated side of the bulkhead or deck. The insulation on the bulkhead or deck should be continued along the conduit and cables where applicable for a distance of not less than 380 mm . Where the bulkhead or deck is uninsulated the conduit may project up to 400 mm on either side. Figure 30 illustrates an acceptable arrangement.

4.2.15.3 Cables which penetrate watertight bulkheads and decks should only be passed through manufactured cable transits which have been approved by the Board of Steamship Inspection for this purpose as indicated in the certificate of approval.

4.2.16 Information required for approval

4.2.16.1 The following information is required to be submitted in order that the Board of Steamship Inspection may issue a certificate of approval for use of a material as the insulating medium for an 'A' Class bulkhead or deck:

- a copy of the test report issued by the testing laboratory for each fire test carried out in accordance with the applicable test procedure described in TP 439, "Structural Fire Protection Standards: Testing and Approval Procedures";

- a sample of the material measuring approximately 100 mm × 100 mm for examination and record;

- any trade literature which the manufacturer may have on the material; and

- two copies of a drawing showing the following information:

- in the case of a mineral wool or ceramic fibre insulation, the drawing should show details of the insulation including its name, reference number and/or letters, thickness and density; an elevation of a part typical bulkhead or upwards view of a part typical deck showing the disposition of the pins; sections through a bulkhead in way of large and small stiffeners or a deck in way of large and small beams; a large scale detail of a welded steel pin or welded aluminum alloy boss and screwed stainless steel pin, the galvanized steel expanded metal and a spring steel washer. In the case of an A-60 standard insulation the drawing should incorporate a section showing the staggering of joints in the two layers of insulation;

- in the case of a board or panel type of bulkhead insulation the drawing should show details of the board or panel including its name, reference number and/or letters, its dimensions and density and in the case of a composite panel details of its components; air gaps between the board or panel and the bulkhead plating and between the board or panel and the stiffeners; connections to the deck and deckhead and shipside or deckhouse side; butt joints and joints for inside and outside corners;

- in the case of panels used in the construction of a ceiling which is the insulating medium for an 'A' Class deck the drawing should show details of a panel including its name, reference number and/or letters, its dimensions and density and, in the case of a composite panel, its components; the hangers and framework supporting the ceiling panels and dimensions of each profile used in their construction; connections to the ship's side or deckhouse side and to 'A','B','C' and combustible bulkheads; the joint across a ceiling which exceeds the maximum length of the panels; and the arrangement in way of the boundary of an 'A' Class deck which is clear of any 'A' Class bulkhead or the ship's side or deckhouse side;

- in the case of a sprayed insulation the drawing should show details of any necessary preparatory work to be carried out on the structure of the bulkhead or deck and the coverage rate in square metres/litre and corresponding dry film thickness of each coating which is to be applied to the structure before the insulation is sprayed; the mechanical retention; and the name reference numbers and/or letters, thickness and density of the insulation. The drawing should also indicate the number of bags of dry mix of the insulation ingredients which when mixed with water will cover one square metre of a bulkhead or deck at the correct thickness and density;

- in the case of a deck covering for use as an insulating medium for an 'A' Class deck the drawing should show a full sized section through the deck covering, detailed sections through the deck covering in way of the ship's side, a steel bulkhead and a 'B','C' or combustible bulkhead, a plan view of the deck covering showing the various layers of the constituent materials cut away in turn and sections through the deck covering in way of penetrations such as pipes and ventilation ducts.

4.3 'A' Class Doors and Shutters

4.3.1 General

4.3.1.1 Doors and shutters

- Every door and shutter assembly which is used to close openings in 'A' Class bulkheads should be of an approved type and its construction and method of installation should be in accordance with the conditions specified in the certificate of approval issued by the Board of Steamship Inspection and the details shown on the manufacturer's approved drawing.

- When a door or shutter is used to close an opening in an 'A' Class bulkhead constructed of aluminum alloy it should be fitted in a stiffened steel panel attached to the aluminum bulkhead by 12 mm diameter steel bolts spaced 300 mm apart. The steel plate should extend 450 mm beyond the sides and top of the frame of the door or shutter. The steel plate and bolts should be suitably isolated from the aluminum alloy to the satisfaction of the attending surveyor.

- In no case should a primary or a surface deck covering be fitted under an 'A' Class door or shutter. The sill plate, sill channel or coaming, whichever is applicable should be welded to the deck plating and such coverings stopped on each side of it.

- Grilles and louvres should not be fitted in 'A' Class doors or shutters. If a hose port is fitted it should be self-closing and constructed of material which is equivalent in fire resistance to that of the door in which it is fitted. The hose port should be 150 mm square and should be inset into the lower edge of the door leaf, opposite the door hinges, or in the case of a sliding door, nearest the opening.

4.3.1.2 Doors only

- A door should have the same or higher 'A' Class standard as the bulkhead in which it is fitted.

- A window having a clear glass area not exceeding 0.02 m2 may be fitted in the upper half of an 'A' Class door provided that:

- it is positioned no closer than 150 mm to any edge of the door leaf;

- the window is of toughened safety glass and the window frame and glazing bar are of steel;

- the door incorporating the window has been successfully fire tested and a certificate of approval issued and details of the window are shown on the manufacturer's approved drawing. In no case should a window be accepted in an 'A' Class door which does not comply with these conditions.

4.3.1.3 Shutters only

- In no case should a shutter be fitted in an 'A' Class bulkhead other than a bulkhead of A-0 standard.

- A drop-rolling shutter should be capable of automatic closure after initial release.

4.3.2 Doors in spaces of high humidity

4.3.2.1 'A' Class doors which are fitted in the boundary bulkheads of boiler rooms, refrigerated machinery spaces and similar spaces having atmospheres of high humidity may be constructed of stainless steel instead of mild steel without the necessity to retest the doors provided that all other materials and details of construction are the same as shown on the manufacturer's approved drawing.

4.3.3 Installation

4.3.3.1 Each door or shutter should be inspected by the attending surveyor to verify as far as it can be determined that the door or shutter and its frame have been constructed in accordance with the drawing referred to on the identification plate and that the 'A' Class standard of the door or shutter is at least the same as that of the bulkhead in which it is fitted.

4.3.3.2 The attending surveyor should satisfy himself that the bulkhead has been faired and adequately stiffened around any opening in which a door or shutter is to be fitted in order to ensure that no stresses will be imposed on the door or shutter and its frame which may cause them to distort and become inoperable. It is not intended that the frame of a door or shutter should form any part of such stiffening.

4.3.3.3 Each door or shutter should be examined after it has been fitted to verify that:

- the door or shutter and its frame have been properly fitted in the bulkhead;

- the clearances between the edges of the door or shutter and its frame correspond reasonably with those shown on the manufacturer's approved drawing; and

- the latches or shootbolts of a door or shutter are properly engaging the frame. The dimensions of the holes in a doorframe in which the top and bottom latches or shootbolts engage should be approximately 5 mm greater than the dimensions of the latches or shootbolts in order to cater for minor movements of the door and its frame during service.

4.3.3.4 Opening and closing tests should be carried out on each door or shutter after the closing devices have been positioned so that the attending surveyor may be satisfied as far as is practicable that the door or shutter complies with the appropriate regulations. These tests should be carried out whilst the ship is in the upright position.

4.3.3.5 Sliding fire doors should have positive means of closing under all conditions. It has become common practice to fit power assist systems to such doors to make their operation easier for passengers, however, the fitting of such systems is not to result in the removal of counterweights which are required to ensure fail-safe operation of the doors.

4.4 'B' Class Bulkheads, Linings and Ceilings

4.4.1 Construction

4.4.1.2 Generally, 'B' Class bulkheads linings and ceilings are constructed of individual panels joined together by a system of steel framing. 'B' Class bulkheads are required by the regulations to extend from deck to deck and to the shell or other boundaries unless continuous 'B' Class ceilings and linings are fitted on both sides of the bulkhead, in which case they may terminate at the ceiling or lining. Figures 16, 17 and 18 illustrate acceptable arrangements. In passenger ships where continuous 'B' Class ceilings or linings are fitted on both sides of the corridor bulkheads, the portion of the bulkhead behind the ceiling or lining should be of a material which in thickness and composition is acceptable in the construction of 'B' Class bulkheads but meets 'B' Class integrity standards only insofar as is practical. Figure 23 shows acceptable methods of compliance with this requirement.

4.4.1.3 'B' Class bulkheads, ceilings and linings are required by the regulations to be constructed of approved non-combustible materials which have been tested and approved by the Board of Steamship Inspection in accordance with the procedures described in TP 439, 'Structural Fire Protection Standards: Testing and Approval Procedures'. The methods of erecting 'B' Class bulkheads, ceilings and linings should be in accordance with the conditions described in the certificate of approval and the details shown on the approved manufacturer's drawing

4.4.1.4 When a 'B' Class bulkhead or lining is required to be fitted deck to deck in a tween deck the height of which exceeds the maximum length of the panel from which the bulkhead or ceiling is constructed, the panels may be increased by butt strapping extension panels of the same material to them, the joint between the panels being tight. Straps should be fitted in way of the joint on each side of an extended panel and should be of steel having a length equal to the width of the panel less any jointing profiles and a width and thickness of 75 mm and 0.7 mm respectively. The butt straps should be

screwed and not through bolted. The jointing profiles should be fitted deck to deck.

4.4.1.5 When a 'B' Class bulkhead or lining is fitted deck to deck, closing arrangements shall be fitted in way of structural members as shown in Figure 24.

4.4.2 Steel or aluminum alloy 'B' Class bulkheads

4.4.2.1 Subject to any additional requirements for load bearing structure, the minimum scantlings required for steel or aluminum alloy 'B' Class bulkheads should be the same as those for steel and aluminum alloy 'A' Class bulkheads as derived from the table and notes in paragraphs 4.2.1.3 to 4.2.1.7.

4.4.2.2 The regulations require that the insulation of aluminum alloy 'B' Class bulkheads should be such that the temperature of the aluminum alloy core does not rise more than 200° C above the ambient temperature at any time during a standard fire test of 30 minutes duration. This requirement applies to 'B' Class bulkheads of both B-15 and B-0 standard.

4.4.2.3 Steel 'B' Class bulkheads of B-15 standard should be insulated to the same standard as steel 'A' Class bulkheads of A-15 standard and aluminum alloy 'B' Class bulkheads of B-15 and B-0 standards should be insulated respectively to the same standards as aluminum alloy 'A' Class bulkheads of A-15 and A-0 standards unless a certificate of approval has been issued by the Board of Steamship Inspection for the appropriate 'B' Class standard.

4.4.3 Termination of 'B' Class bulkheads, ceilings and linings

4.4.3.1 A 'B' Class bulkhead, ceiling or lining should not terminate at another 'B' Class bulkhead, ceiling or lining of lower standard, or a 'C' Class or combustible bulkhead, ceiling or lining.

4.4.4 Marking

4.4.4.1 Each panel used in the construction of a ‘B' Class bulkhead, ceiling or lining should bear the identification marking as indicated on the appropriate

certificate of approval.

4.4.5 Bottom profiles

4.4.5.1 The steel angle or channel profiles which support the bottom edges of the panels from which a "B' Class bulkhead or lining is constructed, should be welded to the deck plating or connected to the expanded metal or equivalent fitted over an 'A' Class deck covering by welding or steel fastenings as shown on the approved manufacturer's drawing for the 'A' Class deck covering. In no case should a 'B' Class bulkhead or lining penetrate an 'A' Class insulation incorporated in an approved deck covering. Primary or surface deck coverings which are combustible should not be laid under 'B' Class bulkheads or linings. Figures 8, 19 and 20 illustrate such arrangements.

4.4.6 Top profiles

4.4.6.1 The top edges of the panels from which a 'B' Class bulkhead or lining is constructed should be housed in steel channel profiles with a gap between the top edges of the panels and the inside of the webs of the channels in order to prevent the panels being effected by any movement in the ship's structure. The channel profiles supporting the top edges of the panels should be welded to either:

- the deckhead;

- the bottom edge of the beams, the gaps between the beams being plated-in or filled-in using the same panels from which the bulkhead or lining is constructed;

- the bottom edge of a continuous steel curtain plate having a minimum thickness of 3 mm . when the depth of curtain a plate exceeds 450 mm its lower edge should be flanged and it should be stiffened to the satisfaction of the attending surveyor. When the bulkhead or lining is of B-15 standard the curtain plate should be insulated on one side with an 'A' Class mineral wool insulation of A-15 standard attached to the curtain plate by means of welded steel pins, expanded metal and spring steel washers; or

- steel hangers welded to the deckhead and having scantlings and a spacing as shown on the approved manufacturer's drawing from which the bulkhead or lining is constructed. When the distance between the top channel profile and the deckhead is in excess of 500 mm , the attending surveyor should consider whether or not it is necessary to increase the scantlings of the steel hangers in order to maintain the stability of the bulkhead or lining particularly in a direction at right angles to the division. The hangers may be omitted in the case of a lining which terminates at a continuous 'B' Class ceiling provided that the top channel profile of the lining is welded to the stringer which connects the ceiling to the ship's side or deckhouse side and 'A' Class bulkheads respectively as shown on the approved manufacturer's drawing for the ceiling panels.

4.4.6.2 In no case should the top channel profile be laid directly on top of the panels from which a 'B' Class bulkhead or lining is constructed i.e. without an air gap.

4.4.6.3 When a shipbuilder wishes to construct a 'B' Class bulkhead or lining by erecting the panels before the steel hangers and channel profile, the gap between the top edge of the panel and the inside of the profile should be maintained by bonding strips of an 'A' Class mineral wool insulation to the top edge of the panels at approximately 600 mm spacing before fitting the top channel profile. The strips of insulation should be bonded in place with their fibres positioned vertically and their length should be 100 mm , their width equal that of the panels and their depth equal to the gap above the top edge of the panels as indicated on the approved manufacturer's drawing.