TP 13822 E - Survival in Cold Waters (2003)

(PDF, 9.7 MB)

Table of Contents

- Executive Summary

- Introduction

- Chapter 1: The problem

- Chapter 2: How can we protect from the four physiological stages of cold water immersion

- Chapter 3: Key physical issues in the design and testing of immersion suits

- Chapter 4: Key issues in the construction of the immersion suit

- Chapter 5: Inter-relationship between the immersion suit and the lifejacket

- Chapter 6: Who needs protection and what regulations are required?

- References

Executive Summary

- It is quite astonishing that over the centuries, hundreds and thousands of humans have drowned in cold water, and it is only in the last 50 years that anyone has taken this death toll seriously. Death was attributed to drowning from an inability to stay afloat and vague terms, such as exposure. This is because death at sea was, and to some degree still is considered an occupational hazard. Fishermen for instance, who are most at risk, simply considered it as on occupational hazard and fate. Any attempt at protection was to float the person in rather than out of the water.

- It took until the middle of the Second World War for the UK and Germany, and post-Korean war for the US to realize that there was a problem from sudden cold water immersion.

- As a result, internationally over the last half of the 20th century, there has been considerable human experimentation in cold water physiology. The pioneering work was done in the mid- 1940s and 1950s, but by the 1960s, it appears to have been forgotten and needed to be relearned. The advent of the offshore oil industry created a demand for more research to produce better immersion suits. This created a flurry of experimentation in the 1980s and 1990s. A number of these experiments have been cited to give the reader the wide scope of them.

- Although the four stages in which death may occur in the cold water accident were known since the Second World War, stage one (cold shock) and stage two (swimming failure) were considered only of academic interest. As a result, regulators, teaching establishments and survival suit manufacturers all concentrated their efforts on protecting the human from hypothermia. In this regard they have done a very good job.

- Even though there are well established teaching programs, good regulations and much improved life saving equipment, there are still in the order of 140 000 open water deaths each year. What has been overlooked is the significance of the first two stages - cold shock and swimming failure as a cause of death. The severity of the effects of cold shock is directly proportional to the water temperature peaking between 10-15° C .

- The layperson and accident investigators are often surprised that some people do not survive a lengthy immersion. Theoretically they are within the "safe" boundaries of one or more of the survival curves that have been developed to predict death from hypothermia. These people do not die of hypothermia per se. They die from a variety of problems in which moderate hypothermia is enough for them to lose their physical ability and mental determination to keep their backs to the waves. They thus inhale the next wave and die from drowning in spite of wearing a life jacket.

- In regard to immersion suits, Eskimos have used "spring pels" to protect themselves from sudden cold water immersion since they took to the water. Crude suits have been available to mariners since the mid 19th Century. A concentrated effort to produce a practical, commercially available suit did not occur until post 1945. Between the 1950s and the late 1970s, the suits were criticized due to poor design, poor fit, leakage and quality control in the manufacturing process. In the last 20 years, with the introduction of several standards, including the 1983 IMO SOLAS standard, improvement in fabrics, zips and better inspection procedures, the water tightness of the suits has improved, and acceptance has improved.

- Fundamental principles of the immersion suit design and development are discussed, particularly the requirements for a dry suit, the necessity for it to be integrated with the lifejacket, the profound, negative effect of leakage on the immersed Clo insulation value, the difficulty of protecting the hands and the penalties for the use of poor materials and quality control in the manufacturing process.

- Thermal manikin technology for evaluating the thermal protection of an immersion suit moved rapidly forward in the 1980s, but has stagnated basically due to lack of funding. Although there are pros and cons for manikin use, the way ahead is to develop a simple manikin for suit thermal testing against a standard. Humans should only be used for new concepts and major modification to already approved suits. More research is needed to clarify the proportional contribution of torso, head and limbs to the heat equation in order to fine tune the next generation of manikins.

- In regards to who should be protected and what regulations require modification or initiation, there are thirteen professional categories that require either a constant wear suit (Group l), a ship abandonment suit (Group ll), or a passenger immersion suit system (Group lll). Modifications are required to the standards related to the Group l and ll suits, but most important, the Group lll (passengers sailing in water below 15° C ) are currently unprotected. In the next two years, Transport Canada should require the carriage of a Navy style quick don immersion suit, within the next five years, an integrated passenger immersion suit system must be developed.

- In regards to the practical advice regarding the regulations requiring the carriage of liferafts and training of operators of passenger carrying vessels.

- Wherever possible, entry into water below 15° C should be avoided. Direct entry into a life raft should be the objective.

- Transport Canada should use this philosophy in the design, development and implementation of all new legislation in a step wise fashion. All vessels operating in Canadian lakes and rivers at 15° C or below should carry liferafts that can easily be launched and boarded by the entire crew and passengers.

- The only exception to this should be where it is physically or practically impossible to stow a liferaft. Under such conditions the passengers must wear inflatable lifejackets when on board.

- Operating a vessel close to the shore or in groups or the carriage of EPIRB are not reasons for waiving this requirement because death from cold shock will occur within 3-5 minutes, swimming failure in under 30 minutes, and darkness only hampers escape and rescue.

- The Marine Emergency Duties curriculum should be amended to include the two new Canadian videos on cold shock, swimming failure, hypothermia and post-rescue collapse.

- A correctly designed and fitted lifejacket plays a vital role in the effort to protect the human from cold shock. Introduction of legislation and regulations since 1945 have had a dramatic effect on drowning statistics. These are at an all time low in Canada of 1.2 per 100,000 population.

- This does not allow any complacency because work still needs to be done on the nomenclature of flotation devices (lifejacket v. PFD s), improvement in self righting tests, a review of self righting requirements, co-ordination of new standards with the IMO / ISO / CEN standards, and the question of legislation of the wearing of flotation devices on small passenger vessels. More attention should also be paid to how fashion positively or negatively affects the wearing of lifejackets and personal flotation devices.

- If the decision is made to develop new standards for lifejackets (inshore and offshore) and PFD s (generally domestic and recreational) then because there is so much commonality between them, neither must be developed in isolation of each other. Furthermore, it is essential that preferably the committee chairman or senior representative for both standards should both attend each other’s meetings and also international meetings with IMO / ISO / CEN . If this does not happen an incongruous situation may occur where common essential parameters may not be in agreement.

- For those destined to develop the integrated immersion suit system, it must be remembered that:

- getting wet is potentially very dangerous

- a dry system must be provided to achieve protection from the four stages of immersion

- leakage of as little of 1/2 litre of water into the system will reduce insulation by 30%

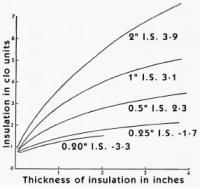

- the maximum insulation that can be added to a suit to prevent heat loss and still be wearable is 4.5 Clo in air

- protection of the hands in the longer term is problematic, but not essential to survival, providing function is maintained for critical tasks

- testing should be as realistic as possible to avoid disappointment with the function of the final product in the survival situation

Frontispiece

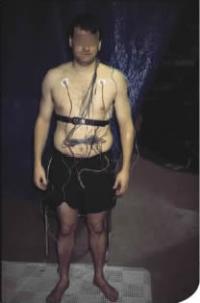

A Thermal Immersion Suit Experiment Using the Latest Technology with Humans and the Manikin in the Laboratory and at Sea.

Heat flow discs applied to skin of subject; inner liner donned and heat flow discs applied to this layer; outer shell immersion suit donned and heat flow discs applied to the external surface.

Thermal manikin prepared in exactly the same manner and ready to be loaded into cradle; manikin loaded in cradle and positioned at correct angle.

Manikin and human floating in the NRC Institute of Marine Dynamics wave tank; manikin loaded in cradle and ready to go to sea; manikin and human riding three metre waves in the Atlantic Ocean offshore in 2 ° C water, Halifax, Nova Scotia.

Introduction

This report was requested by the Marine Safety Directorate of Transport Canada to address the problem of survival in cold waters.

It is divided into six specific chapters:

- a brief introduction to the problem;

- the physiology of cold water immersion;

- the research that has been conducted to protect the human from the dangers of sudden cold water immersion;

- the design and development of current immersion suits;

- the inter-relationship between the immersion suit and the lifejacket, and

- a review of the different groups of people who fly over, work on or play on the water and what protection these groups need.

The report is designed to provide knowledge to a wide variety of people, for instance, on the one hand to pathologists and coroners conducting autopsies and investigations on drowned victims through to young physiologists starting their career in thermal physiology; from manufacturers of immersion suits to cruise ship operators required to provide protective clothing for their ship’s company; and from naval medical officers and marine safety inspectors who need to understand the problems of the dangers of cold water to masters of fishing vessels who also need to know the problem and do not know where to get the answer. Therefore, each chapter has been written as a standalone chapter and can be read on its own. For those who wish to obtain only superficial knowledge and not delve into more detail, there is a summary of the contents at the end of each chapter, then the reader can skip to the next chapter of interest. It also incorporates the contents of the first edition of Transport Canada TP 13822E, published in August 2001, which specifically addressed the new knowledge gained on cold shock and swimming failure.

Chapter 1: The Problem

Currently within Canada, there are hundreds of thousands of persons being transported for business or pleasure over inland waterways, lakes and rivers. Moreover, there are thousands of Canadians who earn their living working on or flying over water. Depending on the local climate, transportation may occur throughout the year or be limited to when the passage is ice free. Irrespective, for a large portion of the year, particularly the winter, spring, and early summer, the water is cold.

Recently, (June 2000), there was an accident in Georgian Bay where two children drowned after the True North ll sank within two minutes (Reference 162). The question has been asked as to what steps should be taken to prevent this from re-occurring. Carriage of lifejackets is already mandatory. Should there be any change in the regulations? Carriage of liferafts or immersion suits within Canada’s internal waterways is not mandatory when operating close to shore. Should a change of policy be made on this requirement? If there are to be any changes in policy on the wearing of immersion suits, lifejackets or carriage of liferafts, should it be related to the physical water temperature at the time the vessel is operating? Finally, are Canadian national immersion suit standards adequate and how do they relate to the lifejacket standards and how do they interrelate to international standards? These questions will be addressed in the following chapters with conclusions and recommendations.

Drowning in Cold Water: How and Why Does it Happen?

Records of death from immersion in cold water date back to ancient times. Circa 450 BC, Herodotus (Reference 77) wrote of the sea borne expedition against Athens by the Persian general Mardonius. He clearly distinguished drowning from hypothermia, when he wrote, "Those who could not swim perished from that cause, others from cold" (Reference 56). In spite of hundreds of thousands of maritime disasters, the precise medical cause of death has been rarely noted. Death has commonly been ascribed to "drowning" or being "overcome by the sea". In the 18th and 19th century, James Lind (1762) mentioned the dangers of collapse after rescue (Reference 102), and James Currie (1797) observed deterioration of his subjects before improvement (Reference 41).

Loss of life at sea was accepted as an occupational hazard and fate. Wrecking was not made illegal until 1807 and the Royal Navy’s use of impressment was not abandoned until 1815. Thus, such items as lifejackets, which could be used to aid escape were not encouraged. Shipwrecked sailors had to cling to wooden spars, and water and rum barrels (Reference 29). Since very early times, the Eskimos understood the dangers of sudden cold water immersion. They used suits called "spring-pels", these consisted of sealskin or seal gut stitched together to form a complete waterproof covering when sailing in their kayaks (Vanggaard, 1988) (Reference 168). A version of this suit is in the Danish National Museum (Willett, 1988), (Reference 172) (Bricket-Smith, 1924), (Reference 26). However, this concept was not adopted by professional mariners and fishermen.

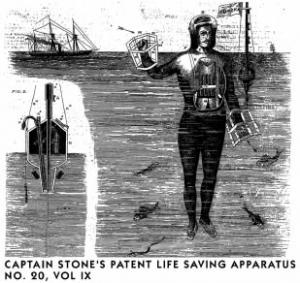

Little specific design of immersion suits was conducted until the middle of the 19th Century. The only work on survival equipment had been the pioneering work of Captain John Ross Ward in the development of a life jacket in 1851 for the National Lifeboat Institution (Reference 99). In 1869, Captain Stoner invented a patent life saving apparatus, which was revolutionary for the time and addressed all the fundamental modern day requirements of a survival suit. It included a waterproof suit, a lifejacket, head protection, a signalling device and paddles for aiding passage through the water (Figure 1) (Reference 44).

Figure 1: Captain Stoner’s Patent Life Saving Apparatus

Lee (1960) reported that: "An exposure suit was brought from America by Merriman in about 1870. It consisted of a complete waterproof dress with the upper part inflated with air, and it protected the body from loss of heat; the face was the only part of the body exposed. When inflated it had a buoyancy of 30 lbsFootnote 1. The Board of Trade bought a number of them in 1872 and supplied one to each of their Lifeboat Stations." (Reference 96). With the advent of iron ships around 1850, not only did the ships sink faster, but also there was less flotsam for flotation. Consequently, there was an increase in the loss of life at sea. In 1871, it was reported that 2740 British seamen lost their lives through drowning (Reference 29).

Aury (1955) reported that: "In 1875, Captain Boyton, wearing an inflatable swimsuit, attempted to cross the English Channel, propelling himself by paddles and a small sail. He had to give up after sixteen hours in the water. In a second attempt two months later, he carried provisions, rockets and a trumpet and successfully crossed from Cape Gris Nez to Dover in 24 hours" (Reference 12).

No one paid attention to the observations by Lawrence Beesley (1912) (Reference 20). He was a survivor from the Titanic who noted that the victims wearing lifebelts and in cold, but calm water had died of cold. The official cause of death was given as drowning. Although the International Safety of Life at Sea ( SOLAS ) Committee was formed directly as a result of this accident, no thought was given to personal protection. Everyone was obsessed with floating in and not on the water. In 1912, Mr Boddy demonstrated his "Boddy" Life Saving jacket in the English Channel off Cowes, but his efforts came to nought even though it was approved by the Board of Trade for aviation (Reference 1).

Following the Empress of Ireland accident in 1914, a Mr Macdonald of Portland, Oregon demonstrated his waterproof rubber survival suit and lifejacket in the harbour in Montreal, but no one paid much attention to it (Reference 29). 12,000 British merchant seamen and 5354 German naval officers and men drowned during World War l, yet again, no one asked why (Gilbert, 1994) (Reference 50). Toward the end of that war, Walter Fry developed a lifesaving suit, which was tested by the US Navy in January 1918 at the Brooklyn Navy Yard, but nothing seems to have come out of that either (Hiscock, 1980) (Reference 79). Ultimately, the US Navy and Coastguard developed a combination flotation and exposure garment for aviators. The "Dreadnaught Safety Suit" made of rubberized material and padded with kapok was reported to be in use at the Naval Air Station Pensacola in the winter of 1918 – 1919 (Reference 29).

After World War I, the British Merchant Advisory Committee met in 1922 to review lifesaving appliances (Reference 112). Their review of passenger ships lost between 1914 and 1922 revealed that, 10,024 (21%) of crew and passengers had lost their lives. The whole report concentrated on the multiple failures that occurred in the mechanics of launching lifeboats into the water. One very small section was devoted to a simple applied cold water physiology experiment conducted by Hill on the effect of clothing on the laboratory assistant Mr. Pergarde, protected by a Macintosh coat or sack, and oil skin coat and waders. He was exposed to water temperatures down to 16° C . The significant conclusion was:

"that the coverings wet or dry, protect a body from cooling down, and also that a rubber skin outside such coverings is a further great protection against such cooling down".

Yet, no one acted on this profound and correct statement, nor did any recommendations pertaining to this discovery appear in the extensive report; it was hidden away in one of the Annexes!

In 1928, the Vestris foundered off Chesapeake Bay and 112 passengers and crew perished. The SOLAS committee was recalled, but no advice was given to do research on personal protection. The only positive step taken in 1928 was the use of a tailor’s dummy or manikin to investigate the performance of the lifejacket and protective oilskins in turbulent seas. This had been precipitated by the loss of all 17 crew of the Rye Harbour lifeboat in the English Channel (Reference 100). The policy, right up the Second World War and the following ten years was still to rely on flotation in rather than on the water using lifeboats, Carley floats and a series of Balsa, Spanner or Denton rafts.

It was the inadequacies of life saving equipment during the Battle of the Atlantic in the Second World War that was the catalyst for scientific examination of the problem. The progress of the design and development of immersion suits will be discussed in Chapter 2.

As Golden (1996) (Reference 57) clearly pointed out, official inquiries in an endeavour to prevent a recurrence, have been more interested in the cause of disaster than the cause of death of the crew and passengers. This is still the case as we enter into the 21st century. The recent issue of the Marine Investigation Report by the Transportation Safety Board of Canada on the sinking of the "True North ll" in Georgian Bay June 2000 extends to 63 pages (Reference 162). There are only five sentences assigned to the fact that two grade seven students died. One of the sentences curtly states: "The bodies were subsequently examined by the coroner who determined that the cause of death was drowning." There has been no thought put into why they drowned or even if they could swim in the first place. Thus, both funding and direction for physiology and human factors research has sadly lagged behind the technological advances in ship design.

The Knowledge: Physiology of the Immersion Incident to 1995

The Medical Research Committee (Reference 110) published a pamphlet in 1943 on "The Guide to the Preservation of Life at Sea After Shipwreck". This was based on the observations of naval medical officers who had treated survivors, and on 279 survivor interviews. This was the basis from which all the modern physiological research has been conducted.Two other reports were to follow after the War that revealed the shocking loss of life at sea which could have been prevented. The first was the Talbot Report (Reference 147) published in 1946.This showed the inadequacy of the RN lifebelt and the Carley type floats. Over 30,000 men died after escaping from their ships, in other words, during the survival phase. The second was the Medical Research Committee report by McCance et al (1956) which investigated "The Hazards to Men in Ships Lost at Sea 1940 – 1944" and examined the cause of death at sea in greater detail (Reference 108).

The pioneering work post-war was conducted under the auspices of the Royal Navy Personnel Research Committee and subsequently the Royal Navy Institute of Naval Medicine. This was basically summarized in Professor Keatinge’s monograph (1969) (Reference 92). As a result of all the aforementioned information, it had become clear that the human body cannot maintain its internal temperature when immersed in water below 25° C when conscious and shivering. The body temperature must progressively fall until death occurs. However, there was much more to the problem than this.

Golden and Hervey (1981) (Reference 56) identified four distinct stages in which a human immersed in cold water may become incapacitated and die. However, what is most important to note is that stages 1, 2 and 4 were largely regarded as of academic interest only; so they did not have a large effect on survival policy, international regulations and survival equipment. All of the effort was concentrated on stage three, that of hypothermia, on predicting the onset and prevention of hypothermia. Thus, there is still no consideration given to the physiological impact resulting from the first two stages of immersion in the design of emergency equipment. For instance, flares are still vacuum packed in polythene bags and as in the Estonia accident were not usable simply because no one had the grip strength or the tactility to open the bags. The bailer in the Estonia liferaft was wrapped in polythene and after attempting to open it with his teeth, one survivor finally gave up after he had lost several teeth!! (Reference 43) Anyone who works, flies or plays over cold water, those who design equipment for emergency use, and coroners and pathologists who investigate deaths in marine accidents must know about these four stages.

Stage 1. Initial immersion responses or cold shock

On initial immersion, there is a large inspiratory gasp followed by a four-fold increase in pulmonary ventilation, i.e. severe hyperventilation. This on its own can cause small muscle spasms and drowning. Along with this, there is a massive increase in heart rate and blood pressure. These latter cardiac responses may cause death, particularly in older, less healthy people. These effects last for the first two to three minutes, just at the critical stage of ship abandonment (Tipton, 1989) (Reference 153), (Tipton et al., 1994) (Reference 157).

Death from cold shock is not uncommon. These are typical examples that continue to be regularly reported in the Canadian press each year and demonstrate the practical evidence that cold shock kills.

Teen drowns after lunch-hour plunge (Globe & Mail, April 16, 1998)

Toronto – A 14-year-old high-school student drowned yesterday after jumping into the frigid water of Lake Ontario. Hours after the incident, police still did not know why Peter Arthur went into the water, which was only about 4 degrees. There were two other teenagers with him at the time. When Peter failed to surface, his friends sought help from nearby construction workers, who called the police. When they arrived they jumped into the lake, which is about 31/2 metres deep at that location, and searched for the missing teen for 10 minutes, until the icy water forced them to shore Sgt. McCann said. As the two officers sat on nearby rocks, huddled in blankets, members of the Toronto police marine unit arrived and took over the search. Dragging the area with a net, they located the teen, who by that time had been in the water for about 30 minutes. Firefighters performed cardiopulmonary resuscitation until paramedics arrived to continue treatment. But Peter was pronounced dead at Toronto East General Hospital at 12:55 p.m.

Reveller drowns after attempting polar bear swim (Globe & Mail, January 3, 2000)

A man celebrating the New Year at a party on a frozen lake drowned when he jumped into a hole cut in the ice. Adrian Weber, 38, was playing hockey with 25 friends on New Year’s Eve on Kingsmere Lake when he attempted a polar bear swim between two holes cut two metres apart in the ice. Mr. Weber dived in at 1:30a.m. When he failed to resurface, friends jumped in but were unable to find him. His body was recovered Saturday by firefighters, close to the spot where he had jumped in. "The water was only about waist deep and he tried to swim between the two holes," his 44-year-old brother Christoph Weber said. "He must have got disoriented." "His friends dove in right away with a rope and tried to find him. They drove a car onto the ice and pointed the headlights of the car toward the hole to get some kind of light onto the lake. It was dark and hard to see anything." Mr. Weber said his brother was healthy and a good swimmer.

Hope fades in Newfoundland for teens swept into ocean in Pouch Cove (Mail Star Chronicle Herald, March 9, 2001)

Hundreds of people lined the shore of this tiny coastal community Thursday night as hope faded for three teens who were swept into the ocean while playing on ice floes. Police said four males between the ages of 16 and 18 were jumping from ice cake to ice cake about 50 metres from shore when one of them fell into the frigid water and slipped under the ice. The others tried to rescue him, but two were knocked into the ocean by a wave. The fourth teen made it back to shore. A woman who didn’t want to be identified said people on shore tried to rescue the teens with a rope. She said one of them tried to grab the rope, but was too weak and couldn’t hold on.

Stage 2. Short-term immersion or swimming failure

Death at this stage, between three and thirty minutes after immersion, appears to affect those who try to swim. It has now become apparent that much more emphasis must be put on swimming failure as a cause of death. It must also be understood that ability to swim in warm water is no indication of how well a human can swim in cold water. The classic testimony heard in the coroner’s court is: "We saw him go over the side, he started to swim and by the time we had the boat turned around and tried to identify where he was lost, he had disappeared. How could that be? He was an excellent swimmer."

The cause was thought to be due to the respiratory and cardiovascular responses already started in the initial immersion. An alternative theory was that the cold water contact with the nose and mouth induced the "diving response". This causes breathing to stop (apnea), a slowing of the heart rate (bradycardia) and even cardiac arrest (asystole).

These are not rare events either and are commonly reported in the newspaper.

A sad start – two accidents in one weekend (Halifax Herald, June 18, 1996)

In Chester Basin, a 37-year-old woman drowned while attempting to swim across Gold River to the Goldwater Marina. About forty people including RCMP , firefighters and Coast Guard personnel undertook a search. Her body was found an hour later.

Michelle Yetman was suntanning with a friend shortly after 5 p.m. when she heard cries for help coming from the water. At first she thought it was just children playing around, she said. But then she realized it was for real. " I guess he lost his breath…so I ran in the water and swam as fast as I could to get out there," said Michelle, who happens to be a junior lifeguard. "It was so cold, I felt like I was hitting ice." When she reached the man, she helped the woman he had been swimming with – who had called for help – keep him above water until another rescuer arrived in a canoe. Then she helped load the man into the canoe, which took him to shore.

Son helpless as mom died (Daily News, June 5, 2002)

A Chester man who can’t swim watched Tuesday as his mother was overcome by frigid, choppy water off Quaker Island, Lunenburg Co. Kathleen Haase, 44, and her son Michael, 25, were spending the day exploring the small grassy island about two kilometers south of Chester. When their small speedboat started to drift away from the island as the tide rose, Kathleen Haase tried swimming after it. She could swim, but the water Tuesday was only about 10° C . Wayne and Geraldine Truck were going past the island in their 11-metre sailboat when they heard the son’s distant screams for help. "We didn’t see anyone splashing in the water," Wayne Truck said. "She undoubtedly had succumbed." They caught the drifting speedboat and were bringing it back to the island when they discovered Kathleen Haase floating face down in the "bitterly cold" water, about 50 metres from the shore. Rescue crews worked to revive her on the boat ride and in the ambulance to South Shore Regional Hospital in Bridgewater. But she never recovered and was pronounced dead in hospital.

There are several common threads in these types of accidents:

- the victims were good swimmers

- the water was cold

- death occurred within a matter of only minutes - much too early for hypothermia to set in

- they were all healthy people

- they were often in shallow water

- the accidents occurred within feet of the shore.

Most important, there was potential help at the scene of the accident, but no one recognized the danger of sudden death from cold shock in an otherwise healthy person. This is the precise reason why standards for wearing lifejackets and/or carriage of liferafts must not be relaxed when operating in cold water. Carriage of EPIRB s (with their 90 minute to 2 hour response time), and the fact that the vessel may be operating in a group or close to shore are not reasons for a waiver.

The clear message is that sudden entry unprotected in cold water is very dangerous and should be avoided wherever possible. This applies to everyone whether commercial operators or recreational boaters.

Stage 3. Long-term immersion or hypothermia

Heat Balance: The Basic Physics

In order to understand the cause of hypothermia, it is important to understand the basic physics of how a human maintains heat balance.

Heat flows down a thermal gradient from high to low temperatures. Thus, in the cold, a thermal gradient is established, down which heat "flows" from the warmer deeper tissues to the cooler tissues near the surface of the body. Heat then escapes from the body to the environment. In normal circumstances in air, the body can exchange heat with the environment via four physical processes: radiation (R), convection (C), conduction (K), and evaporation (E).

- R (Radiation)

- All objects possessing heat, including the body, emit thermal radiation from their surfaces.

- C (Convection)

- This is the process by which heat is exchanged with the environment by the movement of air or water molecules adjacent to the skin, as they move away they are replaced by colder molecules.

- K (Conduction)

- This term is used to describe heat exchange between the skin and surrounding surfaces with which it is in direct contact.

- E (Evaporation)

- Evaporation is the process by which energy transforms liquid to a gas. The heat required to drive this process is removed from the surface of the object on which evaporation is occurring, and it cools.

For body temperature to remain stable in a cool environment, the heat produced by the body at rest or through exercise or shivering (M), must match that lost by R, C, K and E, or combined, R+C+K+E=M.

Several factors influence the amount of heat exchanged by R,C,K, and E. The most common are: the surface area involved in heat exchange; the temperature gradient between the body and the environment; and the relative movement of the fluid (air or water) in which the body is placed. This explains why someone will cool faster if: they are in colder water (gradient); they are partially immersed compared to completely immersed (surface area); they are in fast flowing as opposed to still water (movement of the fluid); they move about compared to staying still (relative movement of the fluid).

In water, heat is conducted to the molecules of water in contact with the skin ("boundary layer"), these molecules are warmed and rise (Convection), and are replaced by cooler ones. Thus, in water only two of the four primary pathways for heat exchange are available, and heat loss is principally by convective and conductive heat exchange. Despite this, a naked individual in cold water will cool approximately four times faster than in air at the same temperature. This is because thermal conductivity of water is 25 times that of air, and its volume-specific heat capacity is approximately 3500 times that of air. Therefore, water has a much greater capacity to extract heat. (The volume-specific heat capacity is obtained by multiplying the specific heat of a substance by its density. It represents the amount of heat required to raise the temperature of a given volume of water by 1° K . At 37° C the volume-specific heat capacity of water is 3431 times that of air.) Furthermore, when in water, unlike air, the surface area available for heat exchange with the environment comes close to 100%. This is the reason why cold water is so dangerous. The corollary to this is that hot water is a very good medium to re-warm hypothermic victims.

After thirty minutes or more of immersion, death may occur from hypothermia. The reason for this is that water has a specific heat 1000 times that of air and a thermal conductivity of about 25 times that of air. Thus, when a body is immersed in water below body temperature (37° C ), it will inevitably cool to hypothermic levels at a rate dependent on:

- Temperature differential

- Clothing insulation

- Rate of agitation of the water

- Body heat production produced by shivering and exercise

- Ratio of body mass to surface area

- Subcutaneous fat thickness

- State of physical fitness

- Diet prior to immersion

- Physical behaviour and body posture in the water

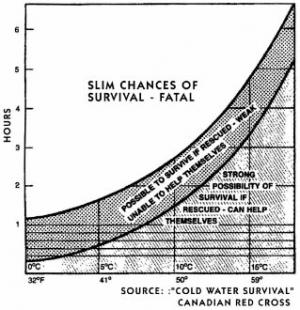

As the deep body temperature falls, humans lapse into unconsciousness. Death may occur in two ways – drowning through incapacitation, and cardiac arrest. Death from drowning will occur in a lightly dressed individual even wearing a lifejacket, approximately one hour after immersion in water at 5° C , or two hours in water at 10° C , or in six hours or less at 15° C (Reference 57).

If the deep body temperature continues to fall, death occurs on average from cardiac arrest somewhere below a body core temperature of 24° C . The lowest recorded survival temperature in an accidental victim is 13.7° C (Reference 51). However, after surgical induction of hypothermia, there has been one reported incident of resuscitation from a body core temperature of 9° C (Reference 122).

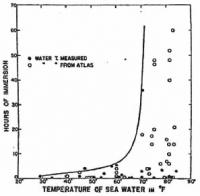

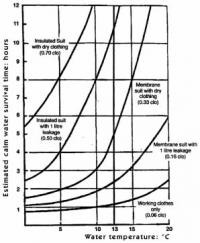

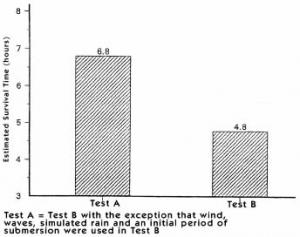

Survival predictions were made from experimental data and case histories from shipwrecks. The first classic survival curve was published by Molnar in 1946 (Figure 2) (Reference 115). Included in here was the data from the Dachau prisoners (Reference 4). Survival predictions were later produced by Hall (1972) (Reference 65), and by the Canadian Red Cross from work conducted by Professor Hayward (1975, 1977, 1984) at the University of Victoria (Figure 3) (References 69, 70, 71 and 73).

A later predicted survival curve was published by Hayes et al (1987) derived from Professor Eugene Wissler’s Cold Water Survival Model (Figure 4) (Reference 67). From this and the combination of previous work, Tikuisis (1995, 1997) has published the latest prediction of survival time at sea level based on observed body cooling rates (References 149 and 150).

Figure 2 (After Molnar 1946) – Duration of immersion of shipwreck survivors in ocean waters of diverse temperatures.

(The data are from the files of the Bureau of Medicine and Surgery, US Navy. Open circles, sea-water temperature was measured at time of rescue. Black dots, sea water temperature was obtained from the World Atlas of Sea Surface Temperatures on the basis of date and location of shipwreck or rescue. Each point represents the survival of at least one person.)

Figure 3 – Cold Water Survival (Canadian Red Cross)

Figure 4: Predicted survival time against sea temperature for different levels of immersed clothing insulation (as derived from Wissler Model, Modified by Hayes, 1987).

A summary of current predictive curves is given in Oakley and Pethybridge (1997) (Figure 5) (Reference 126). From this work, it became possible to give advice that survival times could be extended if the survivors stayed still in the water and did not attempt to swim to keep warm. Furthermore, adopting a fetal position with legs together and arms to the side, or folded across the chest prolonged survival time (References 5, 53, 71, 89 and 125). All of these predictive curves are premised on the fact that the person using the curves is prepared to accept the assumption that death is due to hypothermia. They are all based on time to incapacitation.

| Water Temperature | Molnar, 1946 (Reference 115) | Keatinge 1969 (Reference 92) | Nunnely & Wissler, 1980 (Reference 115) | Allan, 1983 (Reference 5) | Lee & Lee 1989 (Reference 98) |

|---|---|---|---|---|---|

| 5° C | 2.3 | 0.9 | 1.1 | 1.5 | 1 |

| 10° C | 4 | N/A | 2.6 | 2.5 | 3 |

| 15° C | N/A | 4.5 | 3 | 9 | 7 |

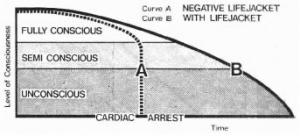

If the immersed person has survived the initial two stages of immersion, i.e. cold shock and swimming failure, then the next hurdle to face is hypothermia. It is now known that this per se may not be the cause of death. These curves must be used with caution. As Golden pointed out in 1996 (Reference 57), the predicted 50% survival times for fully clothed men in water wearing lifejackets are 1 hour at 5° C , 2 hours at 10° C , and 6 hours at 15° C . Yet these figures are difficult to validate in the laboratory where the body temperature only falls about two or three degrees in the equivalent time. There must be another cause of death. Golden explained that a conscious survivor in a seaway will make the physical effort to keep his/her back against the waves, but when physically impaired through muscle cooling, semi-conscious and with a loss of determined will to survive, both of which occur after a body core temperature drop between 2-3° C , then the survivor turns into the waves and drowns. He also emphasized the point that death will occur much quicker from drowning if a lifejacket is not worn (Figure 6) (Reference 54).

Figure 6: Empirical curve correlating deterioration in consciousness to time, in an immersed body with (B) and without (A) a lifejacket. Courtesy of Prof. Frank Golden.

Markle (1991) provides several classic examples of death from hypothermia in water below 15° C in his US Coast Guard Report on lifesaving systems for small passenger vessels (Reference 106).

COMET, May 1973

The COMET had 27 persons on board and sank in Block Island Sound, Rhode Island, about seven miles offshore, in 48°F [9° C ] water. The COMET had no EPIRB and the only lifesaving apparatus was a 20- person buoyant apparatus. About 15 of the survivors held onto the buoyant apparatus at some point, including two of three who set out in a swamped dinghy to get to the buoyant apparatus. Six others were able to use an 8’ X 10’ piece of flotsam for partial support. Almost everyone on board had a lifejacket on when they abandoned ship. The two or three people who were not able to get a lifejacket were able to use either the buoyant apparatus or the flotsam. The first death occurred in the dinghy about 1/2 hour after the sinking. Deaths continued until rescuers happened on the scene 4 hours later. A total of 16 persons died in this time.

JOAN LA RIE lll October, 1982

The JOAN LA RIE lll had 22 persons on board and sank about 8 miles off of the New Jersey coast in 53°F [11.6° C ] water. Life saving apparatus consisted of a 7-person buoyant apparatus and a 15-person life float. Most of the passengers were resting in the deckhouse when the vessel was hit by a rogue wave, heeled over, and began to flood. Two persons are missing as a result of this casualty. They may have drowned in the deckhouse. The remaining 20 persons were able to escape into the water, but none was able to put on a life jacket. Apparently all but two persons made it to the life float and buoyant apparatus, which were secured together. Those two died. Of the remaining 18 gathered at the life float and the buoyant apparatus, 14 survived and 4 died in the 90 minutes it took for the rescue to arrive.

The argument that liferafts are not necessary because vessels operating near shore in day time can expect other vessels to come to the rescue quickly is not supported, nor is the addition of an EPIRB going to speed up rescue to this type of response time. As already stated, death will occur within 3-5 minutes for those who have not donned a life jacket, or from swimming failure within 30 minutes if not clothed properly and supported by a lifejacket. Markle (1991) came to precisely the same conclusion.

Stage 4 - Post-rescue collapse

Up to twenty percent of immersion deaths occur during extraction from the water, or within hours after rescue (Reference 57). This was first noticed in 1875, by Reinke, a police surgeon in Hamburg. He recorded cases of sailors who had fallen into the canals and harbour and died within 24 hours of being rescued (Reference 55). During the Second World War, the Germans and Allies noted that some of those who were rescued alive, died shortly afterwards. Matthes (Reference 109) noted how ditched German aircrew who had been conscious in the water and aided in their own rescue, became unconscious and died shortly afterwards. McCance et al, (1956) (Reference 108) found that seventeen percent of those shipwrecked survivors rescued from the water at 10° C or less died within 24 hours of rescue. None of the people rescued from water above 20° C died.

When the Wahine Ferry sank in 1969 in Wellington Harbour, Mercer (Reference 113) reported that, of the 51 lives lost, twelve were alive on rescue, but died shortly afterward. In the 1994 Estonia accident, at least one person who was noticed to be alive in the water, lost consciousness when in a helicopter hoist, fell back into the sea and died. An extensive list of post rescue collapse incidents is reported in Golden’s articles on shipwreck and survival (Reference 55) and Golden and Hervey’s article on the after-drop and death after rescue from immersion in cold water (Reference 53).

The Initial Responses to Immersion (Stage 1 and Stage 2) – New Scientific Information Since 1975

It has now become clear that over half of the immersion-related deaths occur during the first two stages of immersion, i.e. cold shock and swimming failure. However, as stated previously, investigators still concentrate on the cause of the marine accident and not the precise cause of an individual’s death. It is still hard to accurately document at what stage of the immersion death occurred. This is because little history has been gathered from survivors or by investigators. It is only possible, to a limited degree, to estimate the cause of death from a newspaper report or the scant information in the accident investigation. The problem is further compounded by the fact that such a good job has been done educating people on the dangers of cold water, immersion and hypothermia, that even the pathologists now list the cause of death as hypothermia, even though the cold, wet body on their autopsy table actually died from cold shock or swimming failure and drowning.

Although cold shock or an increased respiratory response to cold water has been known for many years (Falk, 1884) (Reference 45), the practical significance of this response has only really been evaluated in terms of its practical importance in the last 20 years. When considering at what water temperature protection should be provided against the initial responses to cold water immersion, it is now known that the cold shock response begins at water temperatures below 25° C (Reference 90) and peak at a temperature between 10-15° C (References 154 and 155). This is in part, the explanation for deaths that occur in water as high as 15° C long before standard survival curves would predict. It is now thought by many that the pressing threat to otherwise healthy individuals is the respiratory distress evoked by immersion and the consequent inability to control breathing and breath hold.

Swimming has a massive impact on the rate of body cooling and can increase the rate between 30-40% (Reference 92). Tipton et al (1999) (Reference 160) studied the deterioration of swimming performance after the subjects had adapted to the stage 1 cold shock respiratory responses. All ten competent swimmers completed a 90-minute swim in 25° C water; eight completed the swim in 18° C water. In 10° C water, five swimmers completed 90 minute swims, four were withdrawn between 22 and 50 minutes close to swim failure and one was withdrawn at 61 minutes close to swim failure. Stroke rate and length were similar in 25° C and 18° C water throughout the swims, but in 10° C water the stroke rate was increased and the stroke length decreased. These changes were most pronounced in those close to swim fatigue. Stroke length decreased by 50% during the last 30 minutes for the swimmer who reached swim failure in 61 minutes.

Coincident to this, the average swimming angle increased from an average of 18º at the start of the swim to 24º at the end of the swim. The swimmer who reached swim failure finished with a swim angle of 35º. After 15-30 minutes in 10° C water, swimmers’ fingers were splayed and started to flex. At the end of the swims, swimmers reported that it became increasingly difficult to straighten their limbs and coordinate swimming movements. Grip strength was not altered by swimming in water at 25° C , but in water at 18° C and 10° C , it was significantly decreased by 11% and 26% respectively.

Wallingford et al (2000) (Reference 170) investigated the factors which limit cold water swimming distance while wearing a personal flotation device. Five female and twelve male subjects took part in a swim in 14° C water. The subjects swam an average of 889 metres before swim failure. There was no correlation between distance swum and percentage body fat, aerobic fitness and abdominal skinfold thickness. However, those who swum the greatest distance had a significantly larger tricep skinfold thickness.

Wallingford et al. agreed with the conclusion made by Giesbreicht (1995) (Reference 49) that the majority of the decrement in arm performance is due to the local cooling of arm tissue and not due to hypothermia. Wallingford’s study did not support the assumption made by Hayward et al (1975) (Reference 70) that hypothermia could be responsible for the inability to swim in cold water while wearing a personal flotation device. If Hayward’s prediction was correct, the swimmers would have covered a distance of 2058 metres before incapacitation. This was more than double the distance of 889 metres covered by the subjects long before incapacitation from hypothermia (end average core temperature of 35.8° C ).

Markle (1991) (Reference 106) correctly noted that persons in the water with and without lifesaving equipment died at a much higher rate than predicted by the estimated survival graph. This supports Golden’s theory that many victims drown during the cold shock and swimming failure stage of immersion, not from hypothermia per se. Even if they survive long enough to cool, cold-induced muscle incapacitation can prevent their keeping their backs to the waves, and thus their oro-nasal cavities clear of water, sometime after their body core temperature is reduced 2-3° C . This is why it is essential to wear a lifejacket with good sea keeping properties, i.e. self-righting, good freeboard and a face shield to protect from hypothermia.

Markle further concluded that "The present requirements for lifejackets, life floats and buoyant apparatus have proven adequate in all studied casualties where water temperature was 15° C or less". This might have been the case in this study, but it is still possible to die from hypothermia and post rescue collapse as in the case of the Lakonia in 1965 that sank in 17.9° C water off Madeira (Reference 91).

The provision of a buoyant apparatus in which the survivor is basically floating with head only out of the water clinging to a becketed line in water below 15° C is only a last ditch measure if everything else has failed. Drowning is very likely from cold shock and swimming failure, in the short term, and hypothermia and post rescue collapse in the long term. The colder the water, the greater the chance of death. Again, as Markle clearly pointed out, in the case of the Cougar accident, the two people who managed to get themselves on top of a buoyant apparatus were the two not to be hospitalized. The remainder had to remain clinging to it in water at 13° C , three died. Similarly, in another case referred to by Markle (Zephyr ll accident), if the device had been a liferaft instead of a buoyant apparatus, the person without the lifejacket would have been able to board it and would have survived the few minutes in the water. In this accident, eight of the survivors got separated from the boat. They decided to swim to an island, only one was alive six hours later when he called for help when almost ashore.

A Typical Case Where Death was Incorrectly Attributed to Hypothermia

Paradoxically, as previously stated, we have done a very good job of educating the public about hypothermia. As a result, local rescuers, police, the Red Cross, coroners and pathologists always assume that someone who has been pulled out of cold water drowned form hypothermia, yet this often is not the case. Because this assumption has been made, little further questioning has been conducted to find out precisely how, when and where the victim met his/her demise. The Ocean Ranger sank in near freezing water on the Grand Banks off Newfoundland in February 1982 with the loss of all 84 men. No one was outfitted with a survival suit, although some wore lifejackets. The cause of death was attributed to drowning from hypothermia, yet from the testimony available, many died after only a matter of a few minutes in the water.

Below is the testimony from the Master of the Seaforth Highlander (Reference 118).

It was at that time that the lifeboat began to capsize to port in a very slow manner, like watching a slow motion picture. The men standing on top of the boat were thrown into the sea. The boat remained capsized. I believed during the capsize of the lifeboat the line we had made fast to it parted. After it had capsized it was approximately 12 feet maybe off the Seaforth Highlander, and I could see what I estimate to be eight or nine men clinging to the boat in the water. I could see all these men. They had lifejackets on, and there was a light on each lifejacket.…We were still along the lifeboat, and after maybe a minute and a half or two minutes – it is very difficult to estimate – the men clinging to the boat began to let go, and they drifted down my port side. At that point I shouted down to the mate on the deck via the loud hailer system to throw over a liferaft. I saw the men running up forward on my deck to go for the liferaft, and they threw a liferaft over the side which inflated right beside the men in the water. No effort was made by any man in the water to grab hold of the liferaft. No effort was made by any of the men in the water. No apparent effort was made by any of the men in the water to reach the lines which my men had been throwing to them after the boat capsized. I saw a life ring with line attached landing close to the men clinging to the boat, and they didn’t make any effort to reach the life ring. At this time there were some men drifting down my port side, but the lifeboat was still off the port quarter of the ship with two or three men clinging to it. It was close to my port propeller at this time, so I had to stop my port propeller in case the men got caught in it….I maneuvered the ship back around to an upwind position from the lifeboat and steamed down close to the lifeboat, the men and the lifejackets in the water. There was no sign of life at all. We could see all the men floating with their heads under the water, some of them with their arms outstretched, no sign of life, and the men on the deck were trying to pick up bodies

Death obviously in this case was caused by cold shock and possibly swimming failure, but certainly not hypothermia.

Breath Holding Ability and Ability to Control Breathing Rate

This is very critical for all who abandon ship into cold water. If they abandon dry shod into a liferaft, there is no problem. However, if they abandon ship into cold water, unless they are mentally and physically prepared for the cold shock, are protected with a survival suit, a lifejacket and a spray hood, they may drown in the immediate abandonment due to the inability to control breathing in the first three minutes of immersion. It is not just a problem of not being able to breath hold; if you are in choppy water, there is an inability to coordinate and control breathing with wave splash. This is a typical scenario for passengers on tourist vessels in Canada’s lakes and rivers in spring and early summer.

Sterba et al (1979) (Reference 142) investigated breath holding capability of humans in water ranging from 15° C -35° C . They concluded that breath holding ability at 15° C was approximately 30% of the nonimmersed values.

Hayward et al (1984) (Reference 74) showed clearly that there is an inverse relationship between water temperature and breath hold ability. Thus, for abandonment in 25° C water, average breath holding is 38 seconds, whereas for 15° C , 10° C and 5° C water it is 28, 24, and 19 seconds respectively. They concluded that breath holding time in water below 15° C was 25-50% of the presubmersion level. Their predictive curve was recently validated at the higher end of the scale by Cheung et al (2001) (Reference 35) in 25° C water following a breath holding experiment. Two hundred and twenty eight subjects participated and the average breath hold time was a mean of 39.8 ± 21.1 seconds.

Potential for Cardiac Arrhythmias

Tipton (1989) (Reference 153) had already documented the initial cardio-respiratory responses to immersion in cold water, i.e. the massive increase in heart rate and blood pressure within the first three minutes of immersion. Then in 1994, Tipton et al investigated the cardiac responses to submersion in water of 5° C and 10° C (Reference 157). Ectopic arrhythmias (irregular heartbeats) were observed in 11 of the 12 subjects in 29 of the 36 submersions. These occurred immediately after breaking of breath hold, i.e. just at the time after jumping into the water and having to take a breath. They were benign in most cases, (i.e. they were of short duration, supraventricular in origin and producing no symptoms). However, this may not be the case for an aging population of tourists that may have to abandon a vessel in cold water, such as the St. Lawrence River or one of the Great Lakes. For those with a potential heart conduction defect, the heart is likely to be very susceptible to sudden immersion in water of 10° C , resulting in a cardiac arrest or death. Sudden immersion in cold water to the neck makes the heart much more susceptible to arrythmias, due to an increase in output of the stress hormones (i.e. Adrenaline, Noradrenaline). The frequency of these arrhythmias is higher when the face is immersed.

Manual Dexterity

There has now been more research done on loss of tactility in cold water during the first 10-15 minutes of immersion (Reference 78). During this time, the cold water renders the limbs useless, and particularly the hands. It can become impossible to carry out any self-rescue procedures. This only enhances the possibility of perishing before hypothermia is established.

The ability to do such tasks as activate the life jacket inflation device (if fitted), climb into a life raft, cling to a becketted line or activate a flare depends on manual dexterity and grip strength. The ability of muscle to produce force is reduced when its temperature falls below 27° C . This can occur in as little as 20 minutes in water at 12° C (Reference 16). Vincent and Tipton (1988) (Reference 151) showed that the maximum voluntary grip strength ( MVGS ) of subjects who immersed their unprotected hands or forearms in 5° C water was reduced by 16% and 13% respectively, and that wearing a glove significantly reduced the MVGS by 16% in air and with the hand glove and water immersion combination, the reduction was 31%. Research has also shown that hand grip strength was reduced by up to 60% (References 36, 37, 60 and 81), manual dexterity was reduced by 30% (References 48, 95 and 148) and speed of finger flexion was decreased by 15- 25%. A recent study by Heuss et al (1995) (Reference 78) identified minimum hand temperature criteria for safety and performance – local skin temperature 15° C , nerve temperature 20° C and muscle temperature 28° C .

The sinking of the Hudson Transport on Christmas Day 1981 in the freezing water off the Gulf of St. Lawrence is a classic example where cold extremities contributed to the death of five seamen (Reference 80).

The raft was overcrowded. The night was pitch black. The deck lights had gone out a short time before. They could hear air escaping. They could feel freezing water coming up around them. A spirit of sauve qui peut seized them all. Six men made it back to the deck. They were helped by the captain and Kennedy to scramble up the ship’s side. Their desperate plight may be imagined from the fact that some of them were so chilled by wind and water that they climbed the ladder using knees and elbows rather than hands and feet. Five others fell into the sea and were lost. Perhaps some of them were simply too cold to be able to climb up the ladder

Should Passengers Wear Lifejackets Prior To Abandonment?

This question was raised after several rapid sinkings occurred. Particular accidents cited have been the loss of the MV George Prince (1976) (Reference 163) in the Mississippi River where 76 people died, the loss of the USCG Cuyahoga (1978) (Reference 164) in Chesapeake Bay where 11 people died; the loss of the Marchioness (1989) (Reference 105) in the River Thames, UK , where 51 people died; and the loss of the MV Miss Majestic (1999) (Reference 165) on Lake Hamilton, Arkansas where 13 people died. The problem in each of these accidents was that many of the people were trapped between decks. The wearing of an inherently buoyant lifejacket would have further hampered their escape if it was possible. Nevertheless, for those who found themselves in the water and in the dark in two of the accidents, a lifejacket was critical to their survival.

If one is therefore going to regulate that passengers must wear a lifejacket on a passenger-carrying vessel that does not have the ability to carry a liferaft, then the lifejacket must be an inflatable one. The modern inflatable lifejacket is an excellent piece of life-saving equipment; it is comfortable, unobtrusive and very reliable. The Europeans have been using them for recreation and commercial boating operations on their lakes, rivers and canals for years. Canada has simply been slow in effecting new legislation for approval and it is only in the last five years that they have started to come into general use.

The argument from ship’s operators that they are expensive to purchase and maintain is only partially true. The fact is that once operators start to use them and passengers become familiar with them, then the confidence in their merit will go up, the price (due to a higher demand) will go down, and maintenance costs will correspondingly go down due to the general public starting to respect a very good piece of equipment that will potentially save their life. The two children in the True North II accident would have likely been alive and well today if they had worn a good inflatable lifejacket as they stepped on board the boat.

Summary of Chapter 1

This chapter discusses essentials to know about the applied physiology of a sudden cold water immersion accident.

- Up until fifty years ago, no one really understood the reason why people suddenly immersed in cold water died. It was attributed to an inability to stay afloat and vague terms such as "exposure". Nor was anyone particularly concerned about the steady cost of life. It was simply accepted as an occupational hazard and fate.

- Any early attempt at saving ship wrecked mariners was to provide them with flotation in rather than out of the water.

- Death may occur from one of the four stages of immersion:

- Stage 1: Cold shock (3 – 5 minutes)

- Stage 2: Swimming failure (3-30 minutes)

- Stage 3: Hypothermia (after 30 minutes)

- Stage 4: Post rescue collapse (during or hours after rescue)

- Although the four stages have been known since World War ll, stages 1 and 2 were considered only of academic interest. As a result, regulators, teaching establishments and survival suit manufacturers all concentrated their efforts on protecting the human from hypothermia. Indeed, in this regard they have done a very good job.

- Even though there are well established teaching programs, good regulations and much improved life saving equipment, there are still in the order of 140 000 open water deaths each year. What has been overlooked is the significance of the first two stages - cold shock and swimming failure as a cause of death. The severity of the effects of cold shock is directly proportional to the water temperature peaking between 10-15° C .

- The layperson and accident investigators are often surprised that some people do not survive a lengthy immersion. Theoretically they are within the "safe" boundaries of one or more of the survival curves that have been developed to predict death from hypothermia. These people do not die of hypothermia per se. They die from a variety of problems in which moderate hypothermia is enough for them to lose their physical ability and mental determination to keep their backs to the waves. Thus, they inhale the next wave and die from drowning in spite of wearing a life jacket.

- From all the combined research on cold water accidents and scientific research, it has become clear that sudden immersion in cold water, i.e. below 15° C is very dangerous, it should be avoided if at all possible. It has now been shown that a person’s swimming ability in warm water bears no relationship to that in cold water. A conscious decision to swim (and rescue oneself) or stay floating still in the water (and be rescued) should not be taken lightly without assessing the pros and cons. In water below 15° C , crew and passengers must abandon ship dry shod. If it is not practical to stow a liferaft on small vessels, then passengers must wear a modern inflatable lifejacket at all times.

Chapter 2: How can we protect from the four physilogical stages of cold water immersion

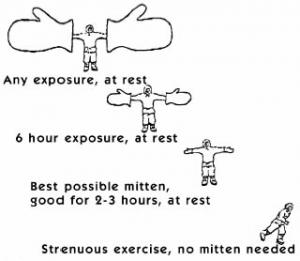

For the reader who has skipped Chapter 1 and moved straight into this chapter, the four physiological stages are: cold shock, swimming failure, hypothermia and post rescue collapse. The basic principle of protection is to prevent contact of the cold water with the skin. The areas of the body that are particularly important with regard to cooling on immersion in water are, for different reasons, the head, back of torso and limbs. The head has only a weak vasoconstrictor response, thus blood continues to perfuse this area even in the cold. Consequently, a lot of heat can be lost from the head and when unprotected it can be a major route of heat loss. Head immersion can significantly accelerate the rate of fall of deep body temperature and the onset of hypothermia (Froese and Burton (1957), (Reference 46). The combination of reduced blood flow to the extremities and the horizontal flotation angle adopted in the water when most immersion suits are worn, results in the greatest percentage of heat loss occurring through the back of the torso by conduction. One reason for this is that the hydrostatic compression of the suit can reduce insulation in this area (Tipton and Balmi, 1996) (Reference 159). Due to peripheral vasoconstriction, relatively little heat is lost from the core of the body via the limbs when the body is cooled. However, one consequence of the reduction in blood flow to the extremities is that local tissue temperature in these areas falls and neuromuscular function can be quickly impaired. Survival can then be compromised by the inability to use the hands for essential survival actions such as boarding life rafts, deploying life jackets or firing flares (Tipton and Vincent, 1988) (Reference 151).

For the layman who may not appreciate the severity of being immersed in icy water, the sinking of the Empress of Ireland in 1914 in under 14 minutes off Rimouski in the Gulf of St. Laurence paints a dreadful picture.

The ship sank, as she did so, a great and terrible cry arose from 700 throats. Where the ship had been was a struggling mass of men, women and children "as thick as bees" Those who had lifejackets found themselves dragged down by those who had not…

The scenes below decks (of the Storstad that had collided with the Empress of Ireland, but remained afloat to conduct the rescue), defied description, 1012 perished.

Drawn by a desperate search for warmth, hundreds of survivors crowded into the engine and boiler rooms. Some of them leaned against the cylinders until their flesh blistered. Women, shuddering with cold, tried to dry their scraps of nightdresses. Many of them were so frozen that they could not even remove what little clothing they were wearing. Mrs Andersen had to undress them and put on their numbed bodies whatever garments she could find. Then the women were packed into the Norwegian seamen’s narrow bunks two by two, head to toe like herrings in a can, to warm each other back to life. (Croall, 1978) (Reference 38)

The immediate solution that springs to mind is that practically speaking, it should be possible to enclose the body of a person up to the neck in some form of water tight or semi water tight garment or enclosure to prevent the cold responses. This is precisely the approach that has been taken to date. Indeed, the British Merchant Advisory Committee had known this since 1922, yet had done little about it (Reference 112).

The personal garment has under gone a whole series of name changes over the years: anti-exposure suit, immersion suit, marine abandonment suit, poopy suit, and survival suit. In this report it will always be referred to as an immersion suit, except where it has been used by authors to describe either a specific physiological experiment or marine accident report in their own literature.

At opposite ends of the world, two accidents occurred within a day of each other only recently. They emphasize that a personal immersion suit is just as necessary today in the 21st century as when humans took to the water thousands of years ago. As in Chapter 1, other accidents that occurred more recently will be discussed later to emphasize specific problems.

10 Reported Dead in Ferry Sinking (Oslo) (Halifax Chronicle Herald, November 27, 1999)

Ten people died and another 11 were missing and feared drowned after an ultra-modern Norwegian ferry sank in chilly, rough seas off western Norway on Friday.

Hopes of finding any of the missing alive were fading hours after the sleek Sleipner catamaran, with 88 people aboard, went down in the North Sea after hitting rocks near Haugesund in stormy weather after nightfall.

Ferry Founders off China (Halifax Chronicle Herald, November 26, 1999)

On Thursday, more than 24 hours after the ship’s first distress call, just 36 people had been rescued from the cold seas after sinking of the 9000 tonne Dashun ferry which carried 312 passengers and crew.

A similar catastrophe to either of these could easily occur to Canadian ferries, for instance on the run between Sydney, Nova Scotia and Newfoundland, or, Yarmouth, Nova Scotia and Bar Harbor, Maine. Currently with no protection, similar death rates can be predicted. The crew and passengers in the William Carson had a very close call in June 1977. The ferry en route to Goose Bay was holed by ice and sank very rapidly off St. Anthony’s, Newfoundland. Miraculously, all 128 ship’s company and passengers made an orderly and safe escape into the lifeboats in the dark (Reference 145).

Physiological Studies Conducted in Europe and North America 1939 - 1945

During the Second World War, none of the Navies on the Allied or Axis side wore immersion suits. Therefore, it is not surprising that the Talbot Report (1946) (Reference 147) and McCance et al’s report (1956) (Reference 108) showed that between 30- 40,000 sailors had simply drowned while escaping from the ship, i.e. during the survival phase. During the War, T.E. Metcalfe had invented a simple exposure suit for merchant sailors. By 1944, over 300,000 had been produced (Reference 22). Too often the suits went missing when required because there were often used for purposes for which they were never intended, i.e. painting ship. They were too flimsy for prolonged wear and were only meant to be used once in the liferaft and not during the abandonment into the water. Practically speaking, they probably made very little difference to the overall gloomy survival statistics. Macintosh and Pask (1957) (Reference 107) conducted their then secret pioneering work on the performance of lifejackets, but the fruits of their efforts were not realized in lifejacket improvements until well after hostilities ceased in the 1948 SOLAS standard and the 1963 BSI standard.

As mentioned in Chapter 1 under the post rescue collapse section, the Germans noted the terrible loss of critical personnel in sudden cold water immersion accidents. The sinking of the Bismarck and loss of airmen who bailed out alive and well into the cold North Sea during the Battle of Britain caused their physiologists and aviation medicine physicians to examine the problem. They commenced a large Research and Development program, which in part was the cause for the infamous Dachau experiments (Matthes, 1946) (Reference 109) and (Alexander, 1946) (Reference 4). They were the first to observe the "after drop" or continuation in reduction of body core temperature after being withdrawn from the cold water. They also experimented with survival suits and the Deutsches Textilforschunginstitut in München-Gladbach, ingeniously produced one that provided the insulation using soap bubbles (Alexander, 1946) (Reference 4), which appears to have gone into limited service (Reference 147).

Across the Atlantic during the Second World War, Canada, under the initial leadership of Professor Banting at the RCAF Institute of Aviation Medicine in Toronto was active in the research and development of an immersion suit for the Navy and Airforce. In 1941, Gagge, Burton and Bazett were having trouble explaining to the soldiers, sailors and airmen how much insulation to add or subtract to their clothing depending on the outside air temperature, their level of exercise / work and whether they were resting or not. They conceived the unit of Clo as a measure of clothing insulation, which could be used by heating engineers, physicians and physiologists (Gagge, et al, 1941) (Reference 47). It is defined as 0.155° C .m2.W-1, and is the insulation required to maintain comfort when a resting human is in an environment of 21° C , 50% relative humidity and with an air movement of 0.1 metres second-1. The European equivalent to a Clo used for sleeping bags and duvets insulation is the tog, which is 0.645 Clo . Clo value and its measurement will be discussed later in the report.

- 1 Clo = 0.155° C .m2.W-1

- 1 Tog = 0.645 Clo

- 0.1° C .m2.W-1.

Probably the largest equipment trial ever to be conducted was carried out on behalf of the Royal Navy in 1943 by the Royal Canadian Navy in Halifax, Nova Scotia. Surgeon Captain Best from the RCN Medical Research Unit (who in collaboration with Banting had discovered insulin in 1921) managed the huge project and the US Navy provided additional ships and American personnel as subjects (Reference 24). All of the often conflicting requirements that face designers of immersion suits today, and difficulties in providing them, were identified, including lightness, simplicity, wrist and neck seals, zips, closure and drawstrings, ease of donning, addition of gloves or not and flammability were noted (Hiscock, 1980) (Reference 79).

In 1942, Frankenstein’s in the UK had developed a leather immersion suit for the Hurricane pilots protecting the Murmansk convoys who were forced to ditch in near freezing water after launching because there were no aircraft recovery systems. Count Morner in Sweden (Reference 116) also invented a survival suit for merchant seamen during the war, but generally the principle throughout the world was to float survivors in rather than on the water, hence the grim survival statistics. By the end of the War, the Royal Canadian Air Force had developed an immersion suit for their ferry pilots (Figure 15) that went into limited service.

The US Navy was much slower in evaluating the requirement for immersion suits, because they did not join the war until later, and their operations, particularly against the Japanese were in relatively warm water, whereas the British, Canadian, and German operations were in sea water that rarely rose above 15-16° C , and for many months of the year was below 10° C . Another reason, was that their operational staff was still not convinced of the lethal effect of suddenly immersing humans in cold water. Therefore, funds and staff for R&D were slow in coming; so, they made only slow progress during the war. Important, however was the realization by Spealman (1944) (References 138) and Newburgh (1968) (Reference 119) of the dangers of hypothermia caused by cold water immersion.

All the initial, practical work in the US was done by LCdr. Hiscock in the Emergency Rescue Equipment Section ( ERE ). All the scientific work was done under the leadership of Dr. Newburgh at the NMRI in Bethesda. At the ERE liaison meeting in June 1943, the minutes reflected the fact that "lifesaving suits" had proved to be dangerous. The committee recommended that they be replaced by the "protective exposure suit" developed for the US Coast Guard by the B.F. Goodrich Company. This, according to Hiscock was the first reference by the committee to exposure suits for naval and merchant seamen. At the ERE conference in August 1943, the recommendations were that the immediate requirements of the suit were:

- As light as possible, for the least amount of bulk

- As simple as possible, without watertight zippers

- The hands must be free, with adequate wrist closures

- Could be used with a separate flotation jacket underneath; and could be stowed on the back of a lifevest or jacket (Reference 79)

Yet, typically after the war, all this research was shelved and no further work was done to protect the sailor or merchant seamen.

The ERE section was transferred to the Air Sea Rescue organization in 1944. Although an improved kapok life jacket was introduced into the Coastguard as a result of their work (Reference 3), it would appear in the US that immersion suits were commercially produced in very few numbers for the remainder of the war.

Physiological Studies Conducted in Europe and North America 1945 – 1970

The massive loss of life at sea during the War triggered several countries into investigating the problem. This section describes many of the different experiments that were conducted to explore the problems. It will illustrate:

- the range of investigations

- different concepts and design of suits

- subjects tended to be of white European or North American stock

- divers were often used as subjects, and they tended to already be cold acclimatized

- that experiments were done in calm or calm stirred water

- the lack of women as experimental subjects

- the lack of very large numbers of male subjects in each experiment

- that all the subjects were basically young, fit and healthy

- the wide range of water temperatures examined

- initial difficulty with procuring reliable, waterproof zips

- recurrent difficulty with keeping the suits waterproof

- quality control when prototype suits were massed produced

- little standardized experimental protocols, thus making it very difficult to make direct comparisons from one investigator’s experiment to another one.