EVS26 - International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium

Los Angeles, California, May 6-9, 2012

Norm Meyer1, Ian Whittal1, Martha Christenson2, Aaron Loiselle-Lapointe2

Abstract With the introduction of battery electric vehicles ( BEV s) to the Canadian market, it is contingent upon manufacturers and government regulators to consider the impact of cold winter temperatures on BEV performance. This paper assesses the effect of North American driving schedules, auxiliary electrical load and temperature on the performance of three BEV s from three separate original equipment manufacturers ( OEM s). The minimum temperature tested during this round of testing was -20 °C . Additionally, -7 °C testing was performed as this is currently the coldest temperature mandated by fuel/energy consumption and emissions testing in the United States and Canada. Significant portions of the testing were performed in support of the development of SAE International Committee SAE J1634: Electric Vehicle Energy Consumption and Range Test Procedures. These procedures describe the driving schedules, test procedures, data acquisition requirements and calculation methods required to assess BEV energy consumption and determine range. Results showed that abbreviated test procedures (part of SAE J1634) may offer a reasonable proxy for full range testing – potentially providing significant savings to both manufacturers and regulators on lab resources. Other significant cold performance results included; at -7 °C , the driving range of the BEV s was reduced by ~20% vs. 20 °C , at -7 °C , the use of maximum cabin heating reduced the driving range by an additional ~25% (versus no cabin heating at -7 °C ), at -18 °C /-20 °C , with the use of maximum cabin heating, the vehicle’s range was reduced by 55%-60% (vs. no auxiliary load at 20 °C ).

Keywords: electric vehicles, duty cycle, range, cold, SAE 1634

1 Introduction

The mandate of Transport Canada’s ecoTECHNOLOGY for Vehicles ( eTV ) program is to test and evaluate advanced technology vehicles for safety and environmental performance. Results are used to support the development of relevant codes and standards, and support the development of safety and environmental regulations. Results are disseminated in appropriate fora, such as EVS26.

As such, battery electric vehicles form an important area of eTV ’s testing and evaluation activities. Starting in 2009, Transport Canada identified the winter performance of BEV s as an area of potential concern and one that required further investigation. A work plan was developed in conjunction with Environment Canada’s Emissions Research and Measurement Section (ERMS) to undertake controlled dynamometer testing of several battery electric vehicles from different OEM s, considering portions of:

- SAE J1634: Electric Vehicle Energy Consumption and Range Test Procedures (DRAFT)

- ‘5-cycle’-type testing, additionally -7 °C and -18 °C /-20 °C

Both Transport Canada and Environment Canada have representation on the SAE J1634 committee. As part of Canada’s participation in the process of developing the SAE test procedures the program focussed on evaluating the effect of cold temperatures on BEV performance versus standard 20 °C testing. The normalized results have been submitted to the SAE J1634 committee (amongst numerous submissions from other groups) so that they may be considered for inclusion in development of the finalized test procedures.

Currently the dynamometer test procedures for evaluating the range and performance of BEV s in Canada are under development. Additionally, the labelling of the energy consumption and range performance of BEV s, which is under the purview of Natural Resources Canada, has not been finalized in Canada. Given the highly integrated nature of the North American auto sector, historically Canada has aligned with the Environmental Protection Agency’s (EPA) test procedures.

2 Testing Program

2.1 Laboratory Testing

Tests for energy consumption were performed by Environment Canada’s Emissions and Research Measurement Section located in Ottawa, Ontario. This facility contains Canada’s national vehicle emissions and fuel consumption testing laboratory.

The three BEV s were tested over the duty-cycles used for light-duty “5-mode” fuel and energy consumption testing by the United States Department of Transportation (DOT) and the EPA to determine conventional vehicle fuel consumption. In addition, the New York City Cycle ( NYCC ) was performed on the test vehicles due to its popularity as a dense urban duty-cycle and the fact that BEV s will likely see more urban operation than highway in everyday use.

The BEV s were tested over the above mentioned driving schedules in accordance with the latest available version of BEV test procedure from the Society of Automotive Engineers SAE J1634 – Recommended Practice for Measuring Electric Vehicle Energy Consumption and Range Test Procedure. This document sets out the recommended test procedures being developed specifically for battery electric vehicles. The procedure also requires the performance of a 55 mph steady state battery capacity test in order to determine the baseline battery capacity available for each BEV being tested. At the time of writing of this paper SAE J1634 was still in draft format but nearing finalization.

It is worth noting that all three BEV s were not tested over an identical number of full range and abbreviated driving schedules as SAE J1634 changed over the duration of the test program. Transport Canada modified its test program to provide results to validate and aid SAE J1634’s development, as well as address the effects of cold operation on BEV range.

2.1 Data collection

Data collected and calculated over the various full and abbreviated tests includes:

- Range and extrapolated range (capacity and kWh / km )

- DC discharge and AC charge energy consumption

During test cycles, total DC electricity consumption, rate of consumption and amount of regenerative braking were measured by direct measurement using non-invasive DC clamps. In this way, combined with AC charge data, vehicle energy consumption and actual home electricity energy consumption could be compared and charge efficiency calculated.

In order to compare partial-range (abbreviated) testing to full-range testing, some abbreviated testing was performed on two of the three BEV s. Full vs. abbreviated testing is described in greater detail in Section 2.2.

Additionally, several applicable Electric Drive Transportation Association test procedures were followed (when applicable), such as;

- ETA-TP003 Implementation of SAE J1634 Electric Vehicle Energy Consumption and Range Test Procedure

- ETA-TP008 Battery Charging

- ETA-TP010 Measurement and Evaluation of Electric Vehicle Battery Charger Performance

- ETA-TP012 Evaluation of Electric Vehicle On-Board Battery Energy Management Systems (BEMS)

2.1.1 Chassis Dynamometer

The vehicles were evaluated using a 122 cm diameter single roll electric dynamometer capable of simulating inertia weight and road loads that light duty vehicles are subjected to during on-road operation. The rotating speed of the dynamometer roll is measured by a pulse counter, which communicates this information to a microprocessor controller. The controller translates the pulses into the linear speed of the vehicle and it is displayed on a video screen as a cursor. The vehicle driver then uses the cursor to follow a selected speed versus time trace. In this way, the vehicle may be operated over a selected transient operation or driving schedule. Dynamometer parameters are recorded continuously, including distance, speed, acceleration, torque, simulated road load force, and simulated inertia force. On-road coast down data for the BEV ’s were target coefficients were derived by the ERMS using the SAE J1263 recommended practice. For cold temperature testing, the target coefficients were adjusted using a 10% decrease in the target coast down time as specified in 40 CFR § 86.229-94. SAE J1263, Road Load Measurement and Dynamometer Simulation using Coast Down Techniques. For all vehicles, the dynamometer set coefficients were derived by the ERMS according to SAE J2643, at both standard and cold temperature.[1]

Laboratory testing was conducted at four separate temperatures (20 °C , -7 °C , -18 °C and -20 °C ). The former two temperatures were chosen as they represent the test cell temperatures required under the current Code of Federal Regulations for fuel consumption and emissions measurement on a chassis dynamometer. Originally, -20 °C was the preferred cold test temperature; however an earlier test program on plug-in hybrid electric vehicles (See EVS24 paper by Martha Chistenson et al.) had been performed at -18 °C and it was considered desirable to be able to compare the data sets for relative performance. In addition, some manufacturers have instituted certain battery management protocols below the -20 °C that affect both vehicle (electric motor) performance and battery recharging. Thus both -18 °C and -20 °C tests were performed over the test program.

2.2 Full vs. Abbreviated Testing

Full range testing requires the test vehicle to complete the required test cycle repeatedly (stops may be necessary) until the main battery is unable to provide sufficient power for the vehicle to maintain the required speed and/or acceleration to remain at the dynamometer duty-cycle prescribed speed.

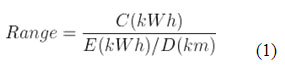

Abbreviated testing requires the test vehicle to complete the required test cycle a pre-determined number of times (typically 3-4). The energy used for those cycles is recorded and the full range the vehicle can travel is extrapolated based on the available capacity remaining in the main battery, or the energy used to recharge the main battery back to a full state of charge. The estimated range is calculated using equation (1) for both AC and DC energy consumption.

Where,

R = Estimated range vehicle should travel (

km

)

C = Main battery capacity as determined from 55mph steady state test at test temperature,

AC

or

DC

(

kWh

)

E = Energy consumption during abbreviated test,

AC

or

DC

(

kWh

)

D = Distance travelled during abbreviated test (

km

)

2.3 Data Acquisition & Analysis

The total energy consumed over the various driving schedules and during the recharging period was determined by measuring the DC current and system voltage during operation as well as the AC current and voltage from the recharge outlet/device. For the purposes of this report, AC and DC current are explained:

- Alternating Current ( AC ): The current supplied from a wall outlet to the BEV ’s onboard charger in amperes.

- AC recharge energy: Combining AC with outlet voltage, total AC recharge energy is reported in kilowatt-hours ( kWh ).

- Direct Current ( DC ): The current, in amperes, supplied from the BEV ’s main batteries to the electric motor(s).

- DC discharge energy: Combining DC with system voltage, total DC discharge energy is reported in kilowatt-hours ( kWh ).

All instrumentation was powered by external power sources, not from the vehicle. Power analyzers were used to measure both current and voltage to determine the total DC energy consumed while driving and the AC energy consumed during periods of recharging.

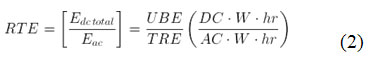

2.3.1 Round Trip Efficiency

The round trip efficiency is a full depletion efficiency measurement that relates the useable battery energy (UBE) (full depletion DC discharge energy) to the total recharge energy (TRE) (full depletion AC recharge energy). This factor enables the determination of cycle-specific AC energy consumption for multi-cycle tests.

2.4 LA4 Urban Dynamometer Driving Schedule

The U.S. LA4 cycle is also known as the FTP-72 or Urban Dynamometer Driving Schedule (UDDS). The cycle is a simulation of an urban driving route.

The cycle is separated into two phases. The first phase begins with a cold start and lasts 505 seconds (a little over 8 minutes), with a distance of 5.8 km (3.6 miles) and an average speed of 41.2 km/h (25.6 mph). The second phase lasts 864 seconds (about 14 minutes).

2.4.1 Deviated Electric Vehicle Procedure for LA4 Cycle

The LA4 cycle was driven repeatedly, beginning with a cold-start, with a 10 minute power off soak period between each cycle. The cycle was tested for both full range testing and abbreviated testing, in which the vehicle drove the cycle 4 times.[1]

2.5 Highway Fuel Economy Cycle Test ( HWFET )

The United States Highway Fuel Economy Test (U.S. HWFET ) cycle was developed by the Environmental Protection Agency to determine the highway fuel economy for light-duty vehicles. The cycle is a simulation of higher speed highway driving. It takes 765 seconds (nearly 13 minutes) to complete, with a total distance of 16.5 km (10.3 miles) travelled. The maximum speed of the cycle is 96.5 km/h (59.9 mph ) and a minimum speed of 45.7 km/h (28.4 mph ) is reached at the 296-second (about 5-minute) mark of the cycle.

2.5.1 Deviated Electric Vehicle Procedure for HWFET Cycle

Full range testing had the following test sequence:[1]

- Perform (2) HWFET cycles repeated without stops

- 10 minute key-off soak

- Repeat HWFET cycles continuously until vehicle is no longer able to maintain cycle speeds

- Recharge vehicle within three hours of test completion at test temperature

Abbreviated testing had the following sequence:[1]

- Two HWFET cycles repeated without stops

- 10 minute key-off soak

- Two HWFET cycles repeated without stops

- Recharge vehicle within three hours of test completion at test temperature

2.6 US06 Supplemental Federal Test Procedure

The US06 Supplemental Federal Test Procedure (SFTP) is used in addition to the above-mentioned LA4. The US06 simulates aggressive acceleration, higher speed driving behavior. Also included are rapid speed fluctuations and driving behavior following start-up. The cycle takes 596 seconds (nearly 10 minutes) to complete, with a total distance of 12.8 km (8.01 miles) travelled. The maximum speed of the cycle is 129.2 km/h (80.3 mph ). The average speed of the cycle is 77.4 km/h (48.4 mph ).

2.6.1 Deviated Electric Vehicle Procedure for US06 Cycle

Full range testing had the following test sequence:[1]

- Perform (1) US06 cycle, 90 second power-on pause, Repeat (1) US06 cycle

- 10 minute key-off soak

- Repeat US06 cycles continuously until vehicle is no longer able to maintain cycle speeds

- Recharge vehicle within three hours of test completion at test temperature

Abbreviated testing had the following sequence:[1]

- Perform (1) US06 cycle, 90 second power-on pause, Repeat (1) US06 cycle

- Recharge vehicle within three hours of test completion at test temperature

2.7 SC03 Speed Correction Driving Schedule

The US SC03 Speed Correction Driving Schedule is used in addition to the above-mentioned LA4. It simulates urban driving and engine load with the air-conditioning unit turned on for the entire duration of the test (A/C fan speed to be determined). The cycle takes 596 seconds (nearly 10 minutes) to complete, with a total distance of 5.8 km (3.6 miles) travelled. The maximum speed of the cycle is 88.2 km/h (54.8 mph ). The average speed of the cycle is 34.8 km/h (21.6 mph ).

2.7.1 Deviated Electric Vehicle Procedure for SCO3 Cycle

Abbreviated testing had the following sequence:[1]

- Perform (1) SC03 cycle

- 10 minute key-off soak

- Repeat SC03 cycle four times with no stops

- Recharge vehicle within three hours of test completion at test temperature

2.8 NYCC Driving Cycle

The Environmental Protection Agency’s New York City Cycle is an additional test cycle that is not included in the 5-cycle average used to calculate fuel economy ratings. The test cycle was chosen because it includes significant stop-and-go driving, with long idle periods, particularly favorable to BEV performance.

The cycle takes 598 seconds (nearly 10 minutes) to complete, with a total distance of 1.9 km (1.2 miles) travelled. The maximum speed of the cycle is 44.6 km/h (27.7 mph ), with an average speed of 11.4 km/h (7.1 mph ). As well, there are 14 individual stops throughout the cycle.

2.8.1 Deviated Electric Vehicle Procedure for EPA NYCC Cycle

Abbreviated testing had the following sequence:[1]

- Perform (4) NYCC cycles without stopping

- 10 minute key-off soak period

- Repeat Steps I and II until battery depleted.

2.9 55 mph Steady State Battery Capacity Test

The 55 mph steady state test sequence consisted of:[1]

- Acceleration to 55 mph (88.5 km/h ) within 30 seconds

- Maintain constant speed of 55 mph (88.5 km/h ) for 50 minutes

- 10 minute key-off soak period

- Repeat steps I to III continuously until vehicle is no longer able to maintain the required cycle speeds

3 Results and Discussion

Summary tables of the normalized range results appear in Tables 1-3 and Figures 1-4. Normalized results allow for the comparison of the relative performance of all BEV s, without reporting actual range. For all vehicles tested, the range achieved over the LA4 driving schedule at 20 °C equals 100%, as range is generally greatest on this cycle. Energy consumption, full range versus abbreviated range and charging efficiency are also reported for comparison.

Tables 1-3 show all of the tests that were performed on each BEV . It is worth noting that due to test cell availability and changes in the desired areas of investigation, each BEV has its own distinct test matrix.

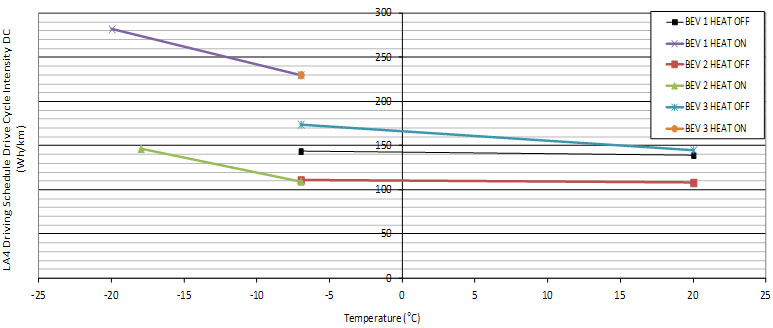

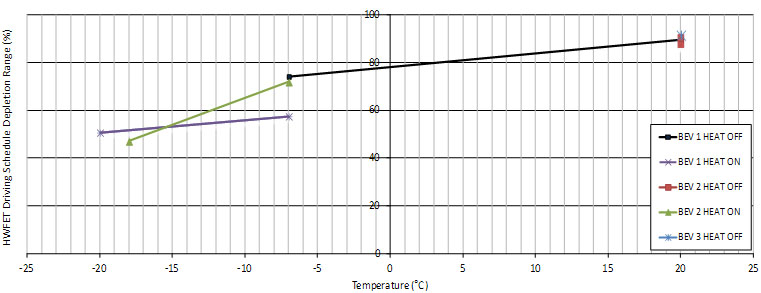

It is difficult to quickly discern specific trends from the tabulated data. Thus Figures 1-4 have been included to demonstrate the effects of temperature and heating load on range and rate of energy usage over the LA4 and highway driving schedules.

3.1 Testing Variations

The test vehicles were tested in accordance with all procedures currently published or in draft form at the time of testing. Each vehicle had separate test schedules and variations in testing that should be noted include:

No vehicle cabin pre-heating was performed on any of the three BEV s before the start of a test;

BEV 1 was tested in accordance to the most recent draft of SAE J1634. In addition climate control was available and used for cabin heating set to 22 °C .

BEV 2 was tested in accordance with a recent draft of SAE J1634. The DC energy discharge was measured only for the propulsion motor. However the AC energy recharge includes energy consumed by the on-board heater. Thus, trip efficiencies, with cabin heating on in Table 2 should not be compared to the trip efficiencies with heater on from Tables 1 and 3. Cabin heating was not programmable; therefore all testing with “Heat On” was set to maximum heat to ensure repeatability on separate cycles.

BEV 3 was tested in accordance with an earlier version of the draft SAE J1634 test procedures. Similar to BEV 2, cabin heating was not programmable; therefore all testing with “heat on” involved manually setting cabin heating to maximum throughout the tests. “Top-off” charging was performed on this vehicle at the manufacturer’s request to ensure that the battery was at full capacity before the start of each test.

3.2 Driving Schedule Results

Tables 1, 2 and 3 show the test results for all tests performed on the three BEV s. All abbreviated tests are denoted with “Abb” before the driving schedule name. The range for these tests is calculated according to Equation 1.

It can be seen for BEV 2 and BEV 3 that abbreviated testing correlated well with full range test results. For BEV 2, the abbreviated LA4 and HW results were calculated to within 3% of the full range LA4 and HW values respectively. For BEV 3, the abbreviated -7 °C LA4 (with heat on), HW and US06 results were calculated to within 2% of the full range values for each test respectively. Future BEV testing will investigate the accuracy of abbreviated testing, compared to full range testing, over additional driving schedules and test cell temperatures.

The LA4 and HW results shown in Tables 1-3 are represented in Figures 1-4 and are further discussed in the next section of this paper.

| Driving Schedule | Test Cell ( °C ) | Heat On/Off | Range (%) | DC Discharge (Wh/km) | AC Recharge (Wh/km) | Trip Eff. (%) |

|---|---|---|---|---|---|---|

| LA4 | 20 | Off | 100.0 | 139 | 151 | 91.8% |

| LA4 | -7 | On | 51.6 | 230 | 282 | 81.8% |

| LA4 | -7 | Off | 82.5 | 143 | 176 | 81.6% |

| LA4 | -20 | On | 40.2 | 282 | 363 | 77.8% |

| HW | 20 | Off | 89.6 | 146 | 169 | 86.5% |

| HW | -7 | On | 57.6 | 220 | 258 | 85.0% |

| HW | -7 | Off | 74.3 | 157 | 196 | 80.1% |

| HW | -20 | On | 50.8 | 218 | 304 | 71.8% |

| SCO3 | 20 | Off | 54.4 | 231 | 279 | 83.0% |

| SCO3 | -7 | On | 46.2 | 261 | 315 | 82.9% |

| SCO3 | -20 | On | 39.5 | 291 | 374 | 77.9% |

| NYCC | -7 | On | 25.5 | 455 | 576 | 79.0% |

| NYCC | -7 | Off | 63.8 | 181 | 231 | 78.3% |

| NYCC | -20 | On | 19.2 | 572 | 735 | 77.9% |

| ss55 mph | -7 | On | 59.4 | 185 | 238 | 77.6% |

| ss55 mph | -7 | On | 46.8 | 226 | 309 | 73.1% |

| ss55 mph | -20 | On | 55.5 | 208 | 257 | 80.7% |

| Driving Schedule | Test Cell ( °C ) | Heat On/Off | Range (%) | DC Discharge (Wh/km)* | AC Recharge (Wh/km) | Trip Eff. (%) |

|---|---|---|---|---|---|---|

| LA4 | 20 | Off | 100.0 | 108 | 131 | 82.8% |

| Abb LA4 | 20 | Off | 102.7 | 103 | 125 | 82.4% |

| LA4 | -7 | Off | 85.1 | 111 | 148 | 75.1% |

| LA4 | -7 | On | 59.0 | 110 | 217 | 50.5% |

| LA4 | -18 | On | 42.5 | 147 | 284 | 51.7% |

| HW | 20 | Off | 88.1 | 133 | 152 | 87.4% |

| Abb HW | 20 | Off | 90.9 | 121 | 141 | 85.9% |

| HW | -7 | On | 71.9 | 133 | 178 | 74.8% |

| HW | -18 | On | 47.1 | 155 | 259 | 60.1% |

| Abb US06 | 20 | Off | 61.9 | 190 | 215 | 88.6% |

| Abb SC03 | 20 | Off | 58.2 | 110 | 220 | 50.1% |

| Abb NYCC | 20 | Off | 62.2 | 127 | 206 | 61.6% |

*Note – DC discharge values and round trip efficiency calculations do not include the measurement of the on-board heater’s consumption.

3.2.1 Discussion of LA4 and HW Test Results

For comparative purposes Figures 1 & 3 display the results for each BEV for both the city and highway schedules as a normalized percentage of total driving schedule range. As illustrated, each BEV experiences a decrease in range as cell temperature drops. The rate of decrease in range appears to increase as the test cell temperature drops -7 °C to -18 °C /-20 °C . All -18 °C /-20 °C testing was performed with the cabin heating on, -7 °C was performed both with cabin heating on and off.

Figure 1 displays the comparative results of the LA4 driving schedules range relative to tests performed at several different temperatures and auxiliary load settings. There is a strong correlation between decreasing range and colder test temperatures, both with and without the use of cabin heating. The effect of the cold at -7 °C resulted in a reduced range of 15% to 21% across the three test vehicles. Additionally, the use of cabin heating resulted in a further decrease of 19% and 30% respectively compared to results at -7 °C with cabin heating off. Overall, a maximum decrease in the range of 60% was observed with BEV 1 & 2 as the test temperature was lowered from 20 °C to -18 °C /-20 °C .

| Driving Schedule | Test Cell ( °C ) | Heat On/Off | Range (%) | DC Discharge (Wh/km) | AC Recharge (Wh/km) | Trip Eff. (%) |

|---|---|---|---|---|---|---|

| LA4 | 20 | Off | 100.0 | 145 | 178 | 81.4% |

| LA4 | -7 | On | 59.8 | 230 | 274 | 83.9% |

| Abb LA4 | -7 | On | 58.6 | 233 | 277 | 84.1% |

| Abb LA4 | -7 | Off | 78.8 | 174 | 206 | 84.3% |

| HW | 20 | Off | 91.7 | 158 | 195 | 80.9% |

| Abb HW | 20 | Off | 91.2 | 164 | 205 | 80.0% |

| Abb SCO3 | 20 | Off | 57.2 | 252 | 314 | 80.4% |

| Abb NYCC | 20 | Off | 77.8 | 185 | 230 | 80.3% |

| USO6 | 20 | Off | 69.7 | 203 | 256 | 79.3% |

| Abb US06 | 20 | Off | 70.6 | 203 | 264 | 76.9% |

| ss 55 mph | 20 | Off | 90.0 | 160 | 199 | 80.3% |

| ss 55 mph | -7 | On | 80.0 | 171 | 203 | 84.1% |

Figure 2 shows the DC main battery discharge rate in watt-hours per kilometre (Wh/km) for the LA4 driving schedule. Electrical energy consumption was strongly correlated with decreasing test cell temperature from -7 °C to -18 °C /-20 °C but less so from 20 °C to -7 °C .

For BEV s 1 and 2 lower trip efficiency (see Tables 1-3) combined with lower battery capacity (See Table 4) account for the decrease in range from 20 °C to -7 °C . For BEV 3 the decreased range, from 20 °C to -7 °C , is the result of a combination of higher rate of energy discharge and decreased battery capacity.

In Figure 2 BEV 2’s energy discharge rate should be higher with the heater on than what is shown in the figure. However, it was not possible to instrument the cabin heating separately, as noted in Table 2. As a result, the trip efficiency calculations for BEV 2, with cabin heating on, do not include a significant component of the total energy expenditure and should not be compared to BEV s 1 and 3.

Figure 1: City schedule vehicle depletion - normalized to the LA4 schedule at 20

°C

Figure 2: City schedule drive cycle intensity

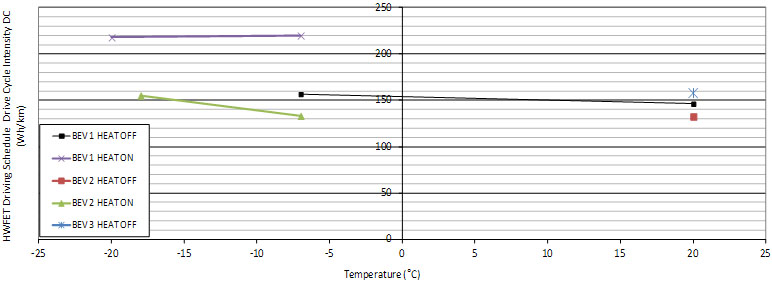

Figure 3 illustrates the comparative results for the highway driving schedules normalized to each vehicle’s LA4 range at 20 °C as reported in Figure 1. The relative effect of temperature and cabin heating on the range of all three BEV s tested was considerable, and similar in magnitude to the range reduction seen over the LA4 cycle. At 20 °C each vehicle travelled approximately 10% less than on the LA4 schedule. The effect of cold temperature testing at -7 °C on range resulted in a reduction in range of approximately 18% compared to 20 °C for BEV 1 without cabin heating, similar to the magnitude measured of the LA4 cycle. At -7 °C with cabin heating on, BEV 1’s range was reduced approximately by an additional 20% compared to no heat at -7 °C . At -18 °C and -20 °C , with cabin heating, the range is reduced by 46% and 43% respectively compared to 20 °C . BEV 2’s range decreased 35% at -18 °C relative to its range at -7 °C .

Figure 3: Highway schedule vehicle depletion - normalized to the LA4 schedule at 20

°C

Figure 4: Highway schedule drive cycle intensity

Figure 4 shows the DC main battery discharge rate in watt-hours per kilometre for the highway driving schedule. Based on the limited number of tests performed over the highway driving schedule, it is difficult to state the existence of a definite trend. However, inspection of Tables 1-3, over all the driving schedules shows a general trend towards higher battery discharge rates as test cell temperature decreases. For BEV 2 energy consumption is also under reported because it does not reflect the added energy used from the main batteries for cabin heating. It is interesting to note that the that DC energy consumption for BEV 1 remained approximately the same with cabin heating on at -7 °C and -20 °C . However, when looking at the AC energy recharged to the battery post-test, the overall trip efficiency decreased from 85% at -7 °C to 71% at -20 °C as the main batteries offered less available capacity, resulting in less range as reported in Figure 3.

As shown in Table 4 the battery capacity of all three BEV s was reduced at cold ambient temperatures (-7 °C , -18 °C /-20 °C ) relative to 20 °C by 4% to 9%. For BEV 2 AC charge energy was reduced by 4% at -7 °C and 8% at -18 °C on the LA4 cycle. From these results it can be seen that battery capacity, when defined as the total AC outlet energy required to recharge a battery to a full state of charge, is not a single static value. This should be taken into account when using abbreviated testing energy consumption rates from cold testing and overall battery capacity (from a 20 °C test) to estimate cold range performance. A notable exception was BEV 1 which at -18 °C /-20 °C was measured at 1.02.

| Driving Schedule | Test Cell ( °C ) | Heat On/Off | BEV 1 Capacity AC ( kWh ) | BEV 2 Capacity AC ( kWh ) | BEV 3 Capacity AC ( kWh ) |

|---|---|---|---|---|---|

| LA4 | 20 | Off | 1.00 | 1.00 | 1.00 |

| LA4 | -7 | On | 0.96 | 0.98 | 0.92 |

| LA4 | -7 | Off | 0.96 | 0.96 | 0.91 |

| LA4 | -18/-20 | On | 0.97 | 0.92 | |

| HW | 20 | Off | 1.00 | 1.02 | 1.00 |

| HW | -7 | On | 0.98 | 0.98 | |

| HW | -7 | Off | 0.96 | ||

| HW | -18/-20 | On | 1.02 | 0.93 |

4 Summary

Cold ambient temperature and associated cabin heating have a significant impact on overall driving range. This not only poses a performance issue to the operators of BEV s but may pose safety concerns under certain conditions, particularly if the vehicle loses power while in traffic. Government and industry should communicate this messaging to BEV adopters to avoid negative consumer experiences which could affect market uptake of BEV s in North America.

At -7 °C , the use of cabin heating reduced the driving range by ~25% (versus no cabin heating at -7 °C ). At -18 °C , with the use of maximum cabin heating, the vehicle range is reduced by more than 50% (vs. no heating or cooling at 20 °C ).

Abbreviated test procedures may offer a reasonable proxy for full range testing thereby providing significant savings on lab resources. Accurate cold temperature range estimates could possibly be determined using abbreviated cold LA4 energy consumption and cold battery capacity (from a steady state 55 mph cold test).

The repeatability of cold tests appears to be similar to the repeatability of 20 °C temperature tests. However, the repeatability of abbreviated tests can be affected by the intermittent intervention of the battery management systems. This effect is muted over full range tests.

Variations in battery management, charging procedures and driving modes across manufacturers may present regulatory challenges to measuring and publishing BEV range. Most manufacturers offer a “maximum range” mode and a “performance” mode. Manufacturers vary in the method in which these modes are offered. For some manufacturers range mode is achieved by reducing maximum acceleration. For other manufacturers it is achieved by increasing the available state of charge (SOC) operating range of the battery. Therefore regulators face the added task of fairly assessing the initial vehicle settings prior to performing BEV range testing.

Further testing is required to test with regulated climate control and/or heated seats instead of “maximum heat” tests and to study the effect of pre-conditioned cabin heating. (Pre-heated cabin while charging)

Acknowledgments

The authors would like to thank the staff of the Emissions Research and Measurement Section of Environment Canada for undertaking the dynamometer portion of the work described in this paper. Specifically, Greg Rideout, Peter Barton, Joseph Edgar, and Jill Hendren.

Furthermore, engineer Marc Belzile of Transport Canada’s eTV program for compiling the results for BEV 3, and allowing their use in this paper for dissemination.

The authors and more specifically Transport Canada thank each of the vehicle manufacturers that provided technical support during testing when required.

References

[1] M. Christensen, J. Edgar, ERMS Report # 10-21, Electric Vehicle 5-Cycle Testing and Test Procedure Investigation. 2010.

[2] California Air Resources Board; California Exhaust Emissions Standards and Test Procedures for 2009 and Subsequent Model Zero-Emission Vehicles and Hybrid Electric Vehicles, in Passenger Car, Light-Duty and Medium Duty Vehicle Classes; December 2007.

[3] Available from the Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402.

40CFR 86 - EPA; Control of Emissions from New and In-Use Highway Vehicles and Engines; Certification and Test Procedures

40CFR 600 - EPA; Fuel Economy of Motor Vehicles

[4] Available from Society of Automotive Engineers, 400 Commonwealth Drive, Warrendale, PA 15096-0001.

SAE J 1263: Road Load Measurement and Dynamometer Simulation Using Coastdown Techniques

SAE J 1634: Electric Vehicle Energy Consumption and Range Test Procedure

Authors

Norm Meyer is the Technical Head of the ecoTECHNOLOGY for Vehicles program of Transport Canada. His experience has included marine engine, hybrid and fuel cell bus and battery electrical vehicle testing. He received his M.A.Sc. in Environmental Engineering from Carleton University in Ottawa, Canada.

Ian Whittal is an Advanced Vehicles Engineer for Transport Canada since 2007. His experience is with testing of battery electric vehicles, hydrogen fuel cells and high efficiency internal combustion engines. He received his B.Eng in Mechanical Engineering from Carleton University in Ottawa, Canada.

Martha Christenson has been testing Hybrid/ BEV vehicles at the ERMS since 2007. She received her B.Sc. in Mechanical Engineering from Queen’s University in Kingston, Canada and M.A.Sc. in Environmental Engineering from Carleton University in Ottawa, Canada.

Aaron Loiselle-Lapointe is a Project Engineer at the Emissions Research and Measurement Section of Environment Canada where he oversees a variety of mobile source programs. Currently he is leading the electric mobility portfolio at the ERMS and is a member of the SAE J1634 committee. Aaron has a MASc. in Environmental Engineering and a Bachelors Degree in Aerospace Engineering.

1Environmental Initiatives, Transport Canada, Ottawa, Ontario, Canada

2Emissions Research and Measurement Section, Environment Canada, Ottawa, Ontario, Canada