2012 Tire Technology Expo, Cologne, Germany

February 14, 2012

Overview

- ecoTECHNOLOGY for Vehicles II Program (eTV II)

- Background – Tire Labelling

- Part 1 – eTV Light Duty Vehicle (LDV) Tire Investigation

- Part 2 – eTV II Heavy Duty Vehicle (HDV) Tire Investigation

- Moving Forward

1. ecoTECHNOLOGY for Vehicles II Program

- The ecoTECHNOLOGY for Vehicles II (eTV II) Program supports Transport Canada (TC)'s strategic objective to develop a safe and environmentally responsible transportation system. Supports a proactive and integrated approach to address environmental benefits and potential safety risks of advanced transportation technologies.

- The initiative tests, evaluates and provides expert technical information on the environmental and safety performance of advanced light-duty vehicle (LDV) and heavy-duty vehicle (HDV) technologies.

- The program builds upon the program delivery experience and technical capacity established under the predecessor ecoTECHNOLOGY for Vehicles Program (2007-2011).

- Technical findings from the program:

- guide the proactive development of new or revised safety regulations, standards, codes and guidelines;

- support the development of non-regulatory industry codes and standards that anchor the market and industry efforts to integrate new vehicle technologies; and,

- help inform the development of future vehicle emissions regulations.

2. Background – Tire Labelling Programs

- The European Union (EU) regulation 661/2009 will set mandatory rolling resistance of 12 kg/t for all passenger car tires and EU regulation 1222/2009 will have mandatory consumer information for tires produced after July 2012.

- The U.S. National Highway Traffic Safety Administration (NHTSA) issued a proposed regulation in June 2009 that included rating systems for rolling resistance, wet traction and treadwear.

- Canada is also considering implementing a tire program to promote the use of fuel efficient tires.

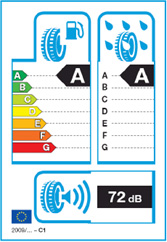

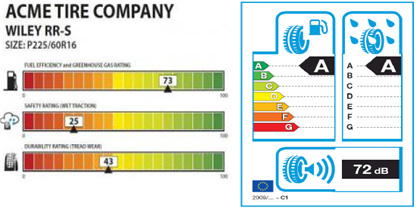

EU Tire Label 2012

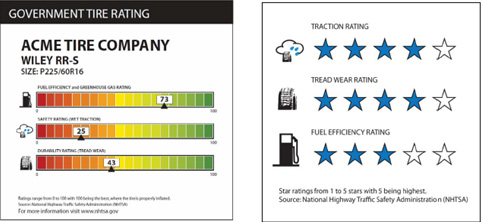

NHTSA Proposed Rating System and Rubber Manufacturers Association Alternative

3. Part 1 –Light Duty Vehicle (LDV) Low Rolling Resistance (LRR) Tire Investigation

Objectives

- In 2009-2010, as part of the program's mandate to test and evaluate emerging advanced vehicle technologies, eTV conducted a preliminary investigation of 25 light-duty vehicle tire models (including 4 winter tire models) to:

- evaluate whether rolling resistance coefficients can be used to compare the environmental benefits of tires;

- estimate the extent to which rolling resistance can affect fuel consumption;

- investigate whether rolling resistance has an impact on dry braking distances;

- compare coast down data to rolling resistance values; and, assess whether there is a relationship between Uniform Tire Quality Gradient (UTQG) ratings for traction and treadwear and rolling resistance coefficients.

3. Part 1 – Light-Duty Vehicle (LDV) LRR Tire Project

Test Methodology

- Testing was divided into two phases:

- Phase #1 – Laboratory testing (rolling resistance coefficients).

- Steady speed (standard reference conditions & special conditions).

- Coast down (standard reference conditions & special conditions).

- Standard mean equivalent rolling force (over driving cycle at standard reference conditions).

- Phase #2 – Dynamic testing.

- Braking distance (100 - 5 km/h).

- SAE J1263 coast downs.

- Phase #1 – Laboratory testing (rolling resistance coefficients).

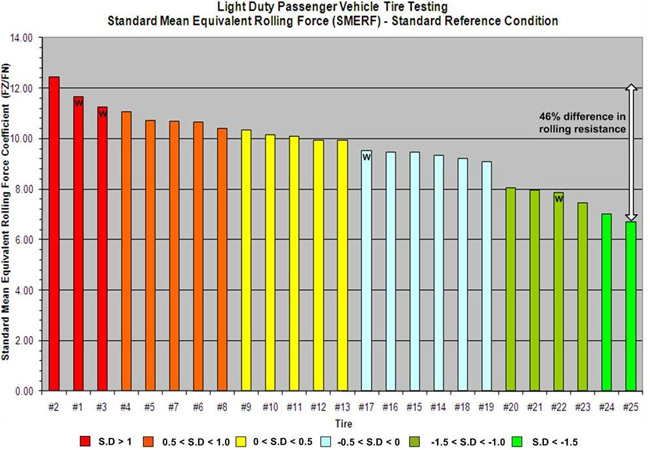

3. Part 1 – Rolling Resistance Coefficients Results

Findings

- Within the sample of 25 tires tested, there was a 46% variance in rolling coefficients.

- Rolling resistance also appeared to be independent of tire classification (all season vs. winter).

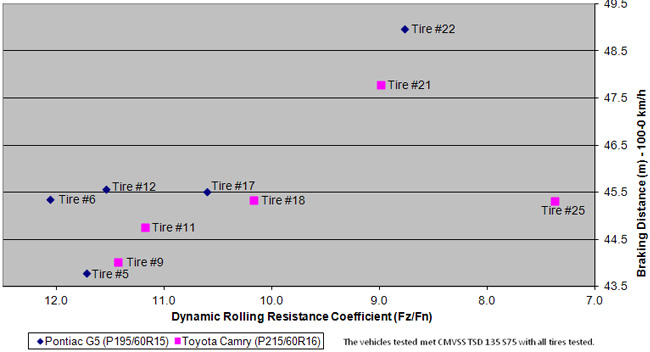

3. Part 1 – Braking Distance Results

Does rolling resistance affect braking distance?

Findings

- Preliminary findings suggest there is no correlation between rolling resistance and braking distance.

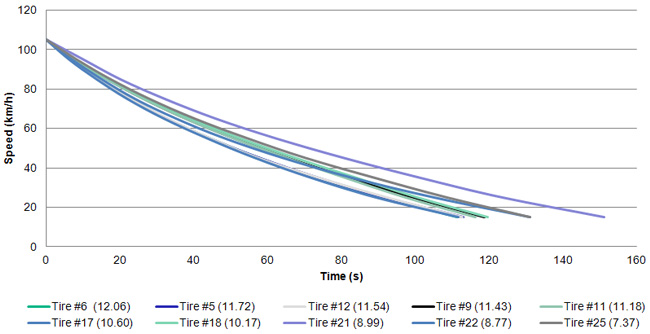

3. Part 1 – Coast Down Results

Does rolling resistance affect coast down times?

Findings

- On-road tests results indicate a correlation between tire rolling resistance values and coast down times – supporting the fuel savings potential of LRR tires.

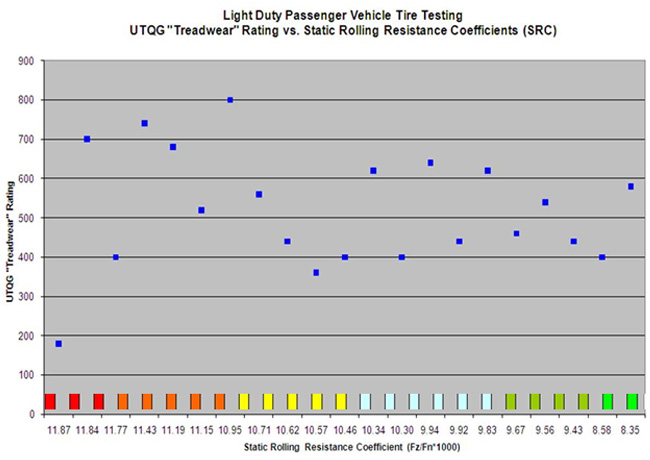

3. Part 1 – Treadwear vs. Rolling Resistance

Do tires with a lower rolling resistance coefficient wear faster?

Findings

- Preliminary tests suggest that there is no obvious relationship between tread wear and rolling resistance.

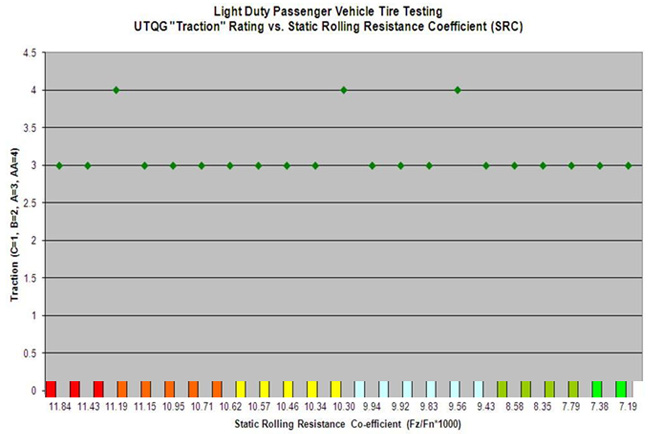

3. Part 1 – Wet Traction vs. Rolling Resistance

Does a lower rolling resistance value compromise traction?

Findings

- Tests did not demonstrate any apparent relationship between UTQG traction and rolling resistance.

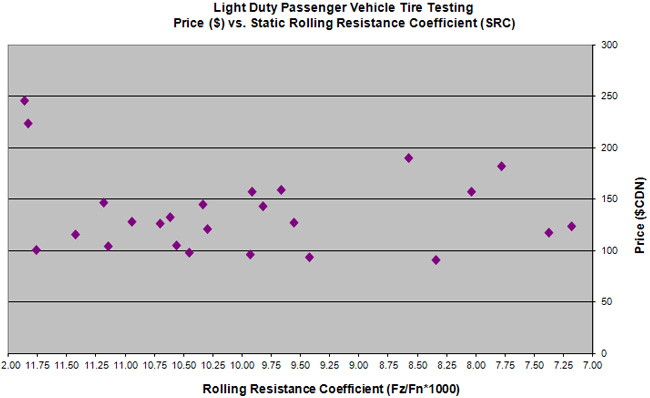

3. Part 1 – Cost vs. Rolling Resistance

Do tires with a lower rolling resistance coefficient cost more?

Findings

- Tests did not demonstrate any correlation between price and rolling resistance.

3. Part 1: Summary

- Based on a preliminary investigation of 25 tires, results suggest that LRR tire technologies can help reduce fuel consumption of light-duty vehicles without negatively affecting traction, braking performance or tire life (tread wear).

- However, what about heavy-duty (e.g. Class VIII Long-Haul) vehicles?

4. PART 2 – Investigations into Class 8 Heavy Duty Vehicles (HDVs) Low Rolling Resistance (LRR) and Single Wide Based (SWB) Tires

Rationale

- North American GHG programs for heavy-duty vehicles will accelerate the market uptake of LRR and SWB tires;

- Canadian industry has cited concerns about traction capabilities of LRR tires under certain cold weather (winter) conditions;

- and, Transport Canada is studying correlations between rolling resistance and durability, and winter traction.

Objectives

- Study correlations between rolling resistance, durability, and traction;

- Provide Transport Canada with data to better understand tire performance;

- and, Share results with other Federal departments (Environment Canada, Natural Resources Canada) who share aspects of tire regulation and reporting.

4. PART 2: Testing Methodology

Testing comprised of 2 main approaches:

-

1. Laboratory Testing Smithers Rapra (Ravenna, OH)

Rolling resistance and durability testing machine -

2. Dynamic (Track) Testing Smithers Rapra Winter Tire Testing Facility (Brimley, Michigan) GMs Cold Weather Testing Facility (Kapuskasing, ON)

Class VIII heavy duty vehicle (18 wheel)

4. Part 2: Laboratory Testing

A minimum of 10 distinct LRR EPA SmartWay-verified tires, and approximately 8 non-LRR tires (295/75R22.5 or equivalent), and up to 10 distinct SWB tires (445/50/R22.5).

Testing objectives are to evaluate:

- Rolling Resistance (ISO 28580)

- Endurance (CMVSS 119)

- Snow traction performance (modified ASTM F1805)

Data captured or calculated

- Rolling resistance coefficients

- Change in tire pressure, time to failure, type of failure

- Traction coefficients, acceleration (m/s2 or G)

5. Moving Forward

- Laboratory testing will evaluate relationships between rolling resistance, durability, and winter traction of tires under controlled conditions.

- Results are expected by March 31, 2012.

- Winter performance track testing will evaluate relationships between rolling resistance and straight line braking, acceleration and low speed turning on snow covered pavement.

- Results are expected by April 30, 2012.

- Summer performance testing will evaluate relationships between rolling resistance and straight line braking, acceleration, and low speed turning on wet pavement.

- Results are expected by June 30, 2012.

The need for additional testing will be assessed in mid-2012 and if work is needed, it will be completed in the winter of 2012/2013.