Service Difficulty Reports about hanger noise that either show a trend or should be known by the airworthiness community.

On this page

BOMBARDIER

CL600 2D24 (RJ900) – RJ900 – Fuel Leak Due to Slat Canister Crack

SDR #: 20191203018

Subject:

Fuel leakage was noted on the underside of the left wing. Through visual examination, it was determined that the source was the leading edge slat canister assembly for the retraction and stowage of the driven slat track located on the left wing at station 163.00. Fuel seepage did not present itself until approximately 4000 pounds of total fuel was added to the tank due to the location of the crack. The canister assembly damage was found on the aft side, interior radius of the plate flange, where the flange plate joins to the canister tube and is adjacent to the weld (approximately 0.125 inches forward of the weld running parallel to the weld).

Transport Canada Comments:

The slat canisters provide a space for the slat tracks to retract into the fuel tank area and must also provide a seal against fuel leaks. These are welded and formed parts that are subjected to wing bending moments and flex stress during both flight and ground operations. The stresses on these formed parts will sometimes lead to cracking and fuel leakage as in this case.

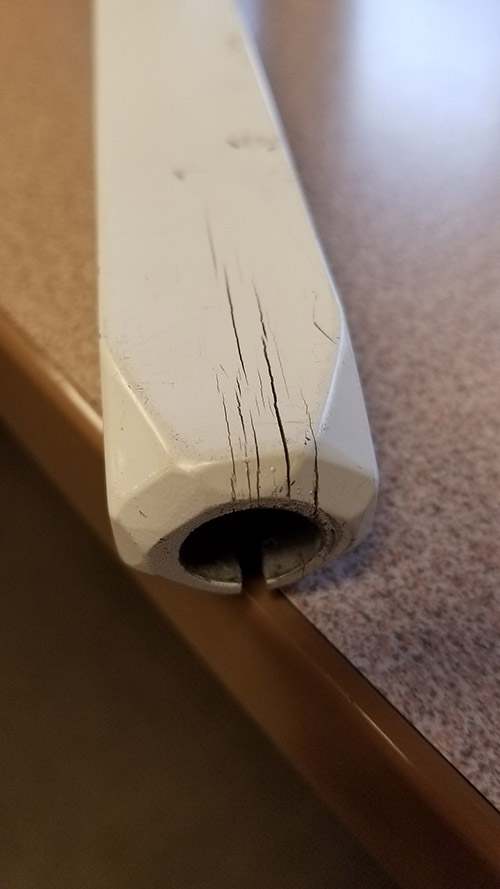

Figure 1: Cracked area of flange radius shown in circled area

Figure 2: Close-up of cracked area

CL600 2D24 (RJ900) - RJ 900 Slat Damage Found During Maintenance

SDR #: 20190924002

Subject:

During unrelated scheduled maintenance, a deep gouge was observed in the upper portion of the left-hand #2 slat assembly. The damage was caused by a leading edge screw that had backed out and interfered with the trailing edge of the slat during retraction. A check of the maintenance records indicated that there have been several incidents resulting in similar damage to the slats on this aircraft type.

Transport Canada Comments:

The screw that backed out and damaged the slat is located under the slat and is out of view when the slats are retracted. These screws thread into anchor nuts, so whenever they are removed and replaced, the condition of the anchor nut should be confirmed. Upon reinstallation, the proper torque should be applied to ensure these screws do not come loose.

As seen by the damage to the screw head, the loose screw went through many slat up and down cycles before damaging the trailing edge. As the screw loosened, it would likely have marked the bottom of the slat before gouging the trailing edge.

More frequent and/or detailed inspections may be required to find these loose fasteners before they cause slat damage.

Figure 1: Slat showing location of damage in trailing edge

Figure 2: Close-up of slat damage

Figure 3: Underside showing anchor nuts

Figure 4: Damaged screw head missing

CL600 2D24 (RJ900) - RJ900 – Passenger Door Inner Handle Cracking

SDR #: 20181114006

Subject:

While conducting a routine check, the passenger door inner handle lever was discovered with multiple cracks at the knob location and also at the inner handle shaft pivot point taper pin hole. Maintenance personnel replaced the door inner handle lever and the function check was carried out with no further fault noted.

Transport Canada Comments:

The passenger door mechanism and lever is a high use item on the aircraft and the areas where the cracks were found are reasonably accessible and visible. Regular and routine inspections are a good method to ensure the integrity of the mechanism.

Fig 1: Lever cracking on both sides

Fig 2: Lever crack through taper pin hole

Fig 3: Cracking and stress at pivot point

Fig 4: Parts information and location shown

CL-600-2D24 - Nose Landing Gear Damaged on Push-Back

SDR #: 20170505007

Subject:

During the aircraft push-back from the gate the tow bar shear pin sheared and the aircraft moved approximately 1 to 2 feet from its original position. The flight crew later reported the aircraft brakes were not released prior to initiating the push-back. Following the shear pin event, the tow bar was examined, the axle interface pins were bent and the tow bar head "yoke" was bent. Due to the over load caused by this event, the nose landing gear assembly and drag brace were replaced. The right nose wheel assembly was also replaced due to the damaged rim caused by the tow bar.

Transport Canada Comments:

This report serves as a reminder that these types of incidents can and do occur, even to highly trained and professional personnel.

It is easy to fall into the trap of examining only the events immediately leading to such an incident. Asking whether or not there was communication between the flight deck and ground crew prior to the aircraft being pushed back is natural and important, but there is also a lot of value in examining the organizational and human factors that likely contributed. Were there time pressures? Was fatigue a factor? Was this a routine push-back, or was something different? Etc.

A properly implemented Safety Management System (SMS) can help an organization learn from and avoid such incidents by helping them identify organizational and human factors during the investigation process. An SMS can also help identify hazards that are inherent, but not always obvious, in day to day operations. With that type of knowledge organizations can build policies and procedures to defend against these types of incidents and work to strengthen their own internal safety culture.

Right-hand nose wheel damage

Right-hand outboard towing spool showing tow bar pin damage

Bent tow bar yoke and bent pin

Pilatus

PC12 47E - Deteriorated Clamp Found before Failure

SDR #: 20210303003

Subject:

The issue was found during a function check of the stick pusher system. It was noticed that the torque transducer pipe assembly (oil line) Pilatus Illustrated Parts Catalogue (IPC) 12-B-77-10-00-010-941A-A item 15 pre-Service Bulletin SB-77-005 attaching upper Adel clamp rubber, appeared in poor condition but was still attached. It was pulled at the rubber portion slightly, and the rubber had worn through from the metal of the clamp and showed signs of chafing in the line. The clamp was removed to inspect further, and it was found chafed beyond limits. The oil line and both adjoining Adel clamps were replaced. The leak checks were completed. Note. If the line had failed, there would have been a potential for loss of propeller control.

Transport Canada Comments:

This Service Difficulty Report (SDR) is an excellent example of reinforcing the importance of being vigilant while performing maintenance tasks and inspections. This maintainer was able to identify the deteriorated clamp and replace it along with the oil tube before a failure occurred.

Remember that clamps and similar hardware are on-condition. It may only take a few minutes to prevent a failure.

Picture 1 – Damaged clamp attached to tube on the engine

Picture 2 – Clear damage caused to oil tube by clamp

Picture 3 – Deteriorated clamp