30 September 2005

Table of contents

- Foreword

- Approval

- Members

- 1. Purpose

- 2. Objective

- 3. Applicability

- 4. Related Regulatory Material

- 5. Related Reading Material

- 6. Definitions

- 7. Background

- 8. Wire degradation

- 9. Inspection of electrical wiring interconnection systems

- 10. Enhanced Zonal Analysis

- 11. Maintenance Practices: Protection and Caution Recommendations

- 12. Alteration

- Appendix A. Enhanced Zonal Analysis Procedure Diagram

- Appendix B. Examples of Typical EZAP Worksheets

- Appendix C. Determination If Service Bulletin Modification of STC Requires EZAP

- Appendix D. Electrical Wirin Interconnection System

- Appendix E. Causes of Wire Degradation

Foreword

This manual has been prepared for Transport Canada Civil Aviation and civil aviation industry, personnel to use when developing applicable and effective maintenance tasks for electrical wiring interconnection systems (EWIS). It contains guidance information that was derived through the efforts of the Aging Transport Systems Rulemaking Advisory Committee (ATSRAC). Transport Canada was invited to participate on the Committee initiated by the Clinton Administration of the United States who chartered ATSRAC to review the effects of aging on transport systems and to develop and make recommendations for the mitigation of those aging effects. This document was presented to the ATSRAC committee as a draft document suitable for the regulatory authorities to publish as an acceptable means to develop maintenance tasks and the associated maintenance intervals necessary to mitigate the effects of aging on Electrical Wire Interconnection Systems (EWIS). Transport Canada has accepted this document for the purposes of developing a program to enhance electrical wiring interconnection system maintenance.

This document may be obtained by downloading it from the Transport Canada Civil Aviation web site at the following address. [Link Unavailable]

Approval

This document is approved by Transport Canada for utilization by the aviation industry when performing the analytical logic "Enhanced Zonal Analysis Procedures" (EZAP) to develop applicable and effective tasks for the maintenance of electrical wire interconnection systems.

This document also presents accepted recommendations to industry for more robust protection and cautious procedures to be applied by those involved in installing aircraft design changes and those involved in maintenance in and around electrical wiring interconnect systems. It is recommended that industry review these recommendations for inclusion in the Instructions for Continued Airworthiness that they are responsible for.

Original signed by

D.B Sherritt

Director,

Aircraft Maintenance and Manufacturing

ATSRAC Working Group Members

The following listed members and organizations provided information, guidance and insight into the development of this publication. Particular recognition is made to the significant efforts of the ATSRAC Working Groups for Task 3 "Improvement of Maintenance Criteria", and Task 9 "Program to Enhance Aircraft Electrical Wiring Interconnection System Maintenance".

| Members | Organization |

|---|---|

| Tony Harbottle | Airbus Industrie |

| Norm Hennings | Boeing |

| Gil Palafox | Boeing |

| Frank Jaehn | Airbus Industrie |

| Martin Knegt | Fokker Services (representing AECMA |

| Ric Anderson | Air Transport Association |

| Randy Boren | Northwest |

| Tim Herndon | Delta |

| Martin Cheshire | Virgin Atlantic |

| Fred Sobeck | FAA |

| George Sedlack | FAA |

| Tony Heather | UK-CAA/JAA |

| Henry Dyck | Transport Canada |

| Armin Bruning | Electromec |

| Dave Allen | SAE |

| Members | Organization |

|---|---|

| Les Blades | Goodrich |

| Randy Boren | Northwest Airlines (US Co-Chair) |

| Armin Bruning | Electromec |

| Alex Brytak | Bombardier Aerospace |

| Martin Cheshire | Virgin Atlantic Airlines (European Co-Chair |

| Nick Drivas | Airtran Airways |

| Tony Harbottle | Airbus |

| Tony Heather | UK-CAA/JAA |

| Tim Hendron | Delta Airlines |

| Stefan Heutmann | Lufthansa Technik |

| Thomas Lexar | Austrian Airlines |

| Cliff Neudorf | Transport Canada |

| Gil Palafox | Boeing |

| Roy Patzke | FAA |

| Fred Sobeck | FAA |

| Hank Zuberer | United AirLines |

1. Purpose

This Transport Publication (TP) provides guidance for developing enhanced electrical wiring interconnection system (EWIS) maintenance for air carriers, air operators, holders of type certificates, holders of supplemental type certificates (STCs), maintenance providers, repair stations, and persons performing modifications or repairs. The guidance in this TP is based on recommendations submitted from the Aging Transport Systems Rulemaking Advisory Committee (ATSRAC). The information in this TP is derived from the maintenance, inspection, and alteration best practices identified through extensive research by ATSRAC working groups and federal government working groups. This TP provides a means for TCCA to officially endorse these best practices and to dispense this information industry wide so that the safety benefits of this information can be realized. Adoption of the recommendations in this TP will improve the awareness throughout the aviation industry of the importance of visual inspections of aircraft systems, particularly aircraft EWIS. This TP promotes a housekeeping philosophy of "protect, clean as you go" when performing maintenance, repair, or alterations on or around aircraft EWIS. This guidance is equally applicable to non-wiring related maintenance and modification activities where those activities could cause inadvertent contamination or damage to wiring.

2. Objective

The objective of this TP is to enhance the maintenance of aircraft EWIS through adoption by the aviation industry of the following:

- Enhanced Zonal Analysis Procedure (EZAP). This TP presents an "enhanced zonal analysis procedure" and logic that will benefit all aircraft regardless of whether they currently have a structured zonal inspection program (see Appendix A. Enhanced Zonal Analysis Logic Diagram and Steps and Appendix B. EZAP Worksheets). Application of this procedure will ensure that appropriate attention is given to wiring installations. Using EZAP it will be possible to select stand-alone inspections (either General or Detailed) and tasks to minimize the presence of combustible material. The procedure and logic in this TP complement existing zonal analysis procedures and will also allow the identification of new wiring tasks for those aircraft that do not have a structured zonal inspection program.

- Guidance for General Visual Inspection (GVI). This TP clarifies the definition for a General Visual Inspection and describes what is expected from a stand-alone GVI or zonal inspection task.

- Protections and Cautions. This TP identifies information for the protection of aircraft EWIS and cautions to be added to maintenance instructions, that will lead to minimization of contamination and accidental damage while working on the aircraft.

The information concerning enhanced aircraft wiring maintenance that has been described in this TP applies to maintenance and inspection programs for all aircraft systems. When these new practices are used appropriately, it will improve the likelihood that EWIS degradation, including age related problems, will be identified and corrected. Therefore, the goal of enhanced wiring maintenance information is to ensure that maintenance actions, such as inspection, repair, overhaul, replacement of parts, and preservation, do not cause a loss of EWIS function, do not cause an increase in the potential for smoke and fire in the aircraft, and do not inhibit the safe operation of the aircraft.

To fully realize the objectives of this TP, air carriers, air operators, type certificate holders, STC holders, maintenance providers, repair stations and persons performing modifications or repairs, will need to rethink their current approach to maintaining and modifying aircraft wiring and systems. This may require more than simply updating maintenance manuals and work cards and enhancing training. Maintenance personnel need to be aware that aircraft EWIS should be maintained with the same level of intensity as any other system in the aircraft. They also need to recognize that visual inspection of wiring has inherent limitations. Small defects such as breached or cracked insulations, especially in small gage wire may not always be apparent. Therefore effective wiring maintenance combines visual inspection techniques with improved wiring maintenance practices and training.

Good wiring maintenance practices should contain a "protect, clean as you go" housekeeping philosophy. In other words, care should be taken to protect wire bundles and connectors during work, and to ensure that all shavings, debris and contamination are cleaned up after work is completed. This philosophy is a proactive approach to EWIS health. Wiring needs to be given special attention when maintenance is being performed on it, or around it. This is especially true when performing structural repairs, work under STCs or modifications.

To fully achieve the objectives of this TP it is imperative that all personnel performing maintenance on or around EWIS receive appropriate training. In addition to technical content regarding maintenance and inspection of EWISs, the training should also include sections on good maintenance practices, including the "protect, clean as you go" housekeeping philosophy. Advisory Circular AC-120-YY Aircraft Wiring Systems Training Program contains guidance on recommended content and lesson plans for this training.

3. Applicability

- The guidance provided in this document is directed to air carriers, air operators, type certificate holders, STC holders, maintenance providers, repair stations and persons performing modifications or repairs.

- The guidance provided in this TP document can be applied to all aircraft maintenance or Inspection programs. The Enhanced Zonal Analysis Procedure in Appendix A of this TP is specifically directed towards enhancing the maintenance programs for aircraft whose current program does not include tasks derived from a process that specifically considers wiring in all zones as the potential source of ignition of a fire.

- This TP is not mandatory and does not constitute a regulation. This TP describes acceptable means, but not the only means, of developing; implementing and evaluating enhanced aircraft EWIS maintenance and inspection methods, practices and techniques.

4. Related Regulatory Material

- CAR Parts 511 and 513, Certification Procedures for Products and Parts.

- CAR Part 525, Airworthiness standards: Transport category aircrafts.

- CAR Standard 625 - Aircraft Equipment and Maintenance Standard

- CAR Part 6, General Operating and Flight Rules.

- CAR Part 7, Certification: Air Carriers and Commercial Operators.

- CAR Part 702, 703, 704, 705, Operating Requirements: Domestic, Flag, and Supplemental Operations.

- CAR Part 604, Certification and Operations: Aircrafts Having a Seating Capacity of 20 or More Passengers or a Maximum Payload Capacity of 6,000 pounds or More.

- CAR Part 701, Operations: Foreign Air Carriers and Foreign Operators of U.S.-Registered Aircraft Engaged in Common Carriage.

- CAR Part 573, Approved Maintenance Organization

5. Related Reading Material

a. Transport Canada Publications.

- TP 13850 Scheduled Maintenance Instruction Development Processes

- MSI–53, Supplemental Instructions for Continued Airworthiness

- MSI-42, Maintenance Schedule Amendment Instructions for the Inspection of Thermal/Acoustic Insulation

b. US Federal Aviation Administration Publications

- AC 25-16 Electrical Fault and Fire Protection and Prevention

- AC 25.981-1B Fuel Tank Ignition Source Prevention Guidelines

- AC 43-12A Preventive Maintenance

- AC 43.13-1B Acceptable Methods, Techniques and Practices for Repairs and Alterations to Aircraft

- AC 43-204 Visual Inspection For Aircraft

- AC 43-206 Avionics Cleaning and Corrosion Prevention/Control

- AC 65-15A Airframe & Powerplant Mechanics Airframe Handbook, Chapter 11, Aircraft Electrical Systems

- AC 120-XX Program to Enhance Aircraft Electrical Wiring Interconnection System Maintenance

- AC 120-YY Aircraft Wiring Systems Training Program

- AC 121-22 Maintenance Review Board (MRB) Procedures

c. EASA/JAA Publications.

- JAA Administration and Guidance Material (AGM)/Maintenance Procedure Chapter 16

d. Reports.

- Transport Aircraft Intrusive Inspection Project, (An Analysis Of The Wire Installations Of Six Decommissioned Aircraft), Final Report, The Intrusive Inspection Working Group, December 29, 2000.

http://www.mitrecaasd.org/atsrac/intrusive_inspection.html - FAA Aging Transport Non-Structural Systems Plan, July 1998.

[Link Unavailable] - National Transportation Safety Board, Safety Recommendation, September 19, 2000, A-00-105 through -108.

[Link Unavailable] - Wire System Safety Interagency Working Group, National Science and Technology Council, Review of Federal Programs for Wire System Safety 46 (2000).

http://www.ostp.gov/html/wire_rpt.pdf - Aging Transport Systems Rulemaking Advisory Committee, Aging Systems, Final Report. Task 1, Sampling Inspection of the Fleet & 2, Review of Fleet Service History

[Link Unavailable] - Aging Transport Systems Rulemaking Advisory Committee, Task 3, Review of Fleet Service History, Final Report.

[Link Unavailable] - Aging Transport Systems Rulemaking Advisory Committee, Task 4, Final Report, Standard Wiring Practices.

http://www.mitrecaasd.org/atsrac/final_reports/Task_4_Final_Report_Sept_2000.pdf - Aging Transport Systems Rulemaking Advisory Committee, Task 5, Final Report, Aircraft Wiring Systems Training Curriculum and Lesson Plans.

[Link Unavailable] - Aging Transport Systems Rulemaking Advisory Committee, Task 6, Final Report, Wire Systems Certification Requirements Harmonization Working Group

- Aging Transport Systems Rulemaking Advisory Committee, Task 7, Final Report, Electrical Standard Wire Practices Manual (ESWPM)

- Aging Transport Systems Rulemaking Advisory Committee, Task 8, Final Report, Enhanced Training Program for Wiring Systems.

- Aging Transport Systems Rulemaking Advisory Committee, Task 9, Final Report, Enhanced Maintenance Criteria for Systems

e. Other Documents.

- Operator/Manufacturer Scheduled Maintenance Development, Revision 2001, ATA Maintenance Steering Group (MSG-3). May be obtained from the Air Transport Association of America; Suite 1100, 1301 Pennsylvania Ave, NW, Washington, DC 20004-1707.

- ATA Specification 117 (Wiring Maintenance Practices/Guidelines).

[Link Unavailable] - FAA Inspector's Handbook Bulletin 8300.10 titled "Origin and Propagation of Inaccessible Aircraft Fire under In-flight Airflow Conditions."

6. Definitions

Arc tracking. A phenomenon in which a conductive carbon path is formed across an insulating surface. This carbon path provides a short circuit path through which current can flow. Normally a result of electrical arcing. Also referred to as "Carbon Arc Tracking," "Wet Arc Tracking," or "Dry Arc Tracking."

Combustible. For the purposes of this TP the term combustible refers to the ability of any solid, liquid or gaseous material to cause a fire to be sustained after removal of the ignition source. The term is used in place of inflammable/flammable. It should not be interpreted as identifying material that will burn when subjected to a continuous source of heat as occurs when a fire develops.

Contamination. For the purposes of this TP, wiring contamination refers to either of the following:

- The presence of a foreign material that is likely to cause degradation of wiring.

- The presence of a foreign material that is capable of sustaining combustion after removal of ignition source.

Detailed Inspection (DET). An intensive examination of a specific item, installation, or assembly to detect damage, failure or irregularity. Available lighting is normally supplemented with a direct source of good lighting at an intensity deemed appropriate. Inspection aids such as mirrors, magnifying lenses or other means may be necessary. Surface cleaning and elaborate access procedures may be required.

Electrical Wire Interconnection System (EWIS). An electrical connection between two or more points including the associated termination devices (e.g., connectors, terminal blocks, splices) and the necessary means for its installation and identification. (See Appendix D, Electrical Wire Interconnection System.)

Functional Failure. Failure of an item to perform its intended function within specified limits.

General Visual Inspection (GVI). A visual examination of an interior or exterior area, installation, or assembly to detect obvious damage, failure or irregularity. This level of inspection is made from within touching distance unless otherwise specified. A mirror may be necessary to enhance visual access to all exposed surfaces in the inspection area. This level of inspection is made under normally available lighting conditions such as daylight, hangar lighting, flashlight or droplight and may require removal or opening of access panels or doors. Stands, ladders or platforms may be required to gain proximity to the area being checked.

Lightning/High Intensity Radiated Field (L/HIRF) protection. The protection of aircraft electrical systems and structure from induced voltages or currents by means of shielded wires, raceways, bonding jumpers, connectors, composite fairings with conductive mesh, static dischargers, and the inherent conductivity of the structure; may include aircraft specific devices, e.g., RF Gaskets.

Maintenance. As defined in CAR 101 means the overhaul, repair, required inspection or modification of an aeronautical product, or the removal of a component from or its installation on an aeronautical product, but does not include:

- elementary work,

- servicing; or

- any work performed on an aircraft by the manufacturer prior to the issuance of the first certificate of airworthiness or the export airworthiness certificate;

Note: However, due to collateral wiring damage that frequently occurs when work is performed on aircraft, TCCA for the purposes of this TP document, interprets "Maintenance" to include those activities that are defined as (a) elementary work, (b) servicing, and (c) any work performed on an aircraft by the manufacturer prior to the issuance of the first certificate of airworthiness or the export airworthiness certificate.

Maintenance Significant Item (MSI). Items identified by the manufacturer whose failure could result in one or more of the following:

- A. could affect safety (on ground or in flight).

- B. is undetectable during operations.

- C. could have significant operational impact.

- D. could have significant economic impact.

Needling. The puncturing of a wire's insulation to make contact with the core to test the continuity and presence of voltage in the wire segment.

Stand-alone GVI. A General Visual Inspection which is not performed as part of a zonal inspection. Even in cases where the interval coincides with the zonal inspection, the Stand-alone GVI shall remain an independent step within the work card.

Structural Significant Item (SSI). Any detail, element or assembly that contributes significantly to carrying flight, ground, pressure, or control loads and whose failure could affect the structural integrity necessary for the safety of the aircraft.

Swarf. A term used to describe the metal particles, generated from drilling and machining operations. Such particles may accumulate on and between wires within a wire bundle.

Zonal Inspection. A collective term comprising selected General Visual Inspections and visual checks that are applied to each zone, defined by access and area, to check system and power plant installations and structure for security and general condition.

7. Background

Over the years there have been a number of in-flight smoke and fire events where contamination sustained and caused the fire to spread. TCCA and TSB together with the FAA, NTSB and the JAA have conducted aircraft inspections and found wiring contaminated with items such as dust, dirt, metal shavings, lavatory waste water, coffee, soft drinks, and napkins. In some cases dust has been found completely covering wire bundles and the surrounding area.

Research has also demonstrated that wiring can be harmed by collateral damage when maintenance is being performed on other aircraft systems. For example a person performing an inspection of an electrical power center or avionics compartment may inadvertently cause damage to wiring in an adjacent area.

In recent years the regulatory authorities and industry groups have come to the realization that current maintenance practices may not be adequate to address aging non-structural systems. While age is not the sole cause of wire degradation, the probability that inadequate maintenance, contamination, improper repair, or mechanical damage has caused degradation to a particular EWIS increases over time. Studies by industry and government agency working groups have found that although EWIS management is an important safety issue, there has been a tendency to be complacent about EWIS. These working groups have concluded that there is a need to manage EWIS so that they continue to function safely.

8. Wire Degradation

Normal maintenance actions, even using acceptable methods, techniques and practices, can over time be a contributing factor to wire degradation. Zones that are subject to a high level of maintenance activity display more deterioration of the wiring insulation than those areas not subject to frequent maintenance. Degradation of wiring is further accelerated when inappropriate maintenance practices are used. Examples include the practice of needling wires to test the continuity or voltage, and using a metal wire or rod as a guide to feed new wires into an existing bundle. These practices could cause a breach in the wiring insulation that can contribute to arcing.

Over time, insulation can crack or breach, thereby exposing the conductor. This breakdown, coupled with maintenance actions, can exacerbate EWIS malfunction. Wiring that is undisturbed will have less degradation than wiring that is disturbed during maintenance.

For additional information on the principle causes of wire degradation see Appendix E.

9. Inspection of Electrical Wiring Interconnection Systems

Typical analytical methods used for the development of maintenance programs have not provided a focus on wiring. As a result most operators have not adequately addressed deterioration of EWIS in their programs. The regulatory authorities reviewed the current inspection philosophies with the objectives of identifying improvements that could lead to a more consistent application of the inspection requirements, whether they are Zonal, Stand-alone GVI, or DET inspections.

TCCA believes that it would be beneficial to provide guidance on the type of deterioration that a person performing a GVI, DET, or Zonal Inspection would be expected to discover. Though it may be realistically assumed that all operators provide such guidance to their inspectors, it is evident that significant variations exist and, in certain areas of the world, a significant enhancement of the inspection could be obtained if internationally agreed guidance material could be produced. The guidance provided by this TP assumes each operator will adopt recent improvements made to the definitions of GVI and DET Inspections. This information should be incorporated in operators' training material and in the introductory section of maintenance planning documentation.

This section is divided into three parts. The first part addresses the levels of inspection applicable to EWIS, the second part provides guidance for performing zonal inspections, and the third part provides lists of installations and areas of concern.

a. Levels of inspection applicable to EWIS.

1. Detailed Inspection (DET).

An intensive examination of a specific item, installation or assembly to detect damage, failure or irregularity. Available lighting is normally supplemented with a direct source of good lighting at an intensity deemed appropriate. Inspection aids such as mirrors, magnifying lenses or other means may be necessary. Surface cleaning and elaborate access procedures may be required.

A DET can be more than just a visual inspection since it may include tactile assessment in which a component or assembly is checked for tightness/security. This is of particular significance when identifying applicable and effective tasks to ensure the continued integrity of installations such as bonding jumpers, terminal connectors, etc.

Note: Though the term Detailed Visual Inspection remains valid for DETs using only eyesight, it should be recognized that this may represent only part of the inspection called for in the source documents used to establish an operator's Maintenance Program. For this reason it is recommend that the acronym "DVI" not be used since it excludes tactile examination from this level of inspection.

2. General Visual Inspection (GVI).

A visual examination of an interior or exterior area, installation or assembly to detect obvious damage, failure or irregularity. This level of inspection is made from within touching distance unless otherwise specified. A mirror may be necessary to enhance visual access to all exposed surfaces in the inspection area. This level of inspection is made under normally available lighting conditions such as daylight, hangar lighting, flashlight or droplight and may require removal or opening of access panels or doors. Stands, ladders or platforms may be required to gain proximity to the area being checked.

Recent changes to this definition have added proximity guidance (within touching distance) and the allowance to use a mirror to enhance visual access to exposed surfaces when performing a GVI. These changes should result in more consistent application of GVI and support the expectations of what types of EWIS discrepancies should be detected by a GVI.

Though flashlights and mirrors may be required to provide an adequate view of all exposed surfaces, there is no requirement for equipment removal or displacement unless this is specifically called for in the access instructions. Paint and/or sealant removal is not necessary and should be avoided unless the observed condition is suspect. Should unsatisfactory conditions be suspected, items may need to be removed or displaced in order to permit proper assessment.

It is expected that the area to be inspected is clean enough to minimize the possibility that accumulated dirt or grease might hide unsatisfactory conditions that would otherwise be obvious. Any cleaning that is considered necessary should be performed in accordance with accepted procedures in order to minimize the possibility of the cleaning process itself introducing anomalies.

In general, the person performing a GVI is expected to identify degradation due to wear, vibration, moisture, contamination, excessive heat, aging, etc., and make an assessment as to what actions are appropriate to address a noted discrepancy. In making this assessment, any potential effect on adjacent system installations should be considered, particularly if these include wiring. Observations of discrepancies, such as chafing, broken clamps, sagging, interference, contamination, etc., need to be addressed.

3. Zonal Inspection.

A collective term comprising selected General Visual Inspections and visual checks that are applied to each zone, defined by access and area, to check system and power plant installations and structure for security and general condition.

A Zonal Inspection is essentially a GVI of an area or zone to detect obvious unsatisfactory conditions and discrepancies. Unlike a stand-alone GVI, it is not directed to any specified component or assembly.

b. Guidance for Zonal Inspections.

The following EWIS degradation items are typical of what should be detectable and subsequently addressed as a result of a zonal inspection (as well as a result of a stand-alone GVI). It is also recommended that these items be included in maintenance and training documentation. This list is not intended to be exhaustive and may be expanded as considered appropriate.

1. Wire/Wire Harnesses

- Wire bundle/wire bundle or wire bundle/structure contact/chafing

- Wire bundle sagging or improperly secured

- Wires damaged (obvious damage due to mechanical impact, overheat, localized chafing, etc.)

- Lacing tape and/or ties missing/incorrectly installed

- Wiring protection sheath/conduit deformity or incorrectly installed

- End of sheath rubbing on end attachment device

- Grommet missing or damaged

- Dust and lint accumulation

- Surface contamination by metal shavings/swarf

- Contamination by liquids

- Deterioration of previous repairs (e.g., splices)

- Deterioration of production splices

- Inappropriate repairs (e.g., incorrect splice)

- Inappropriate attachments to or separation from fluid lines

2. Connectors

- External corrosion on receptacles

- Backshell tail broken

- Rubber pad or packing on backshell missing

- No backshell wire securing device

- Fool proofing chain broken

- Missing or broken safety wire

- Discoloration/evidence of overheat on terminal lugs/blocks

- Torque stripe misalignment

3. Switches

- Rear protection cap damaged

4. Ground points

- Corrosion

5. Bonding braid/bonding jumper

- Braid broken or disconnected

- Multiple strands corroded

- Multiple strands broken

6. Wiring clamps or brackets

- Corroded

- Broken/missing

- Bent or twisted

- Faulty attachment (bad attachment or fastener missing)

- Unstuck/detached

- Protection/cushion damaged

7. Supports (rails or tubes/conduit)

- Broken

- Deformed

- Fastener missing

- Missing edge protection on rims of feed through holes

- Racetrack cushion damaged

- Obstructed drainage holes (in conduits)

8. Circuit breakers, contactors or relays

- Signs of overheating

- Signs of arcing

c. Wiring installations and areas of concern.

Research has shown that the following installations and areas need to be addressed in existing maintenance material.

- 1. Wiring installations.

Clamping points – Wire chafing is aggravated by damaged clamps, clamp cushion migration, or improper clamp installations. Aircraft manufacturers specify clamp type and part number for EWIS throughout the aircraft. When replacing clamps use those specified by the aircraft manufacturer. Tie wraps provide a rapid method of clamping especially during line maintenance operations. Improperly installed tie wraps can have a detrimental effect on wire insulation. When new wiring is installed as part of a STC, or modification the drawings will provide wiring routing, clamp type and size, and proper location. Examples of significant wiring modifications are the installation of new avionics systems, new galley installations and new instrumentation. Wire routing, type of clamp and clamping location should conform to the approved drawings. Adding new wire to existing wire bundles may overload the clamps causing wire bundle to sag and wires to chafe. Raceway clamp foam cushions may deteriorate with age, fall apart, and consequently would not provide proper clamping.

Connectors – Worn environmental seals, loose connectors, missing seal plugs, missing dummy contacts, or lack of strain relief on connector grommets can compromise connector integrity and allow contamination to enter the connector, leading to corrosion or grommet degradation. Connector pin corrosion can cause overheating, arcing and pin-to-pin shorting. Drip loops should be maintained when connectors are below the level of the harness and tight bends at connectors should be avoided or corrected.

Terminations – Terminations, such as terminal lugs and terminal blocks, are susceptible to mechanical damage, corrosion, heat damage and contamination from chemicals, dust and dirt. High current-carrying feeder cable terminal lugs can over time lose their original torque value due to vibration. One sign of this is heat discoloration at the terminal end. Proper build-up and nut torque is especially critical on high current carrying feeder cable lugs. Corrosion on terminal lugs and blocks can cause high resistance and overheating. Dust, dirt and other debris are combustible and therefore could sustain a fire if ignited from an overheated or arcing terminal lug. Terminal blocks and terminal strips located in equipment power centers (EPC), avionics compartments and throughout the aircraft need to be kept clean and free of any combustibles.

Backshells – Wires may break at backshells, due to excessive flexing, lack of strain relief, or improper build-up. Loss of backshell bonding may also occur due to these and other factors.

Sleeving and Conduits – Damage to sleeving and conduits, if not corrected, may lead to wire damage. Therefore, damage such as cuts, dents and creases on conduits may require further investigation for condition of wiring within.

Grounding Points – Grounding points should be checked for security (i.e., finger tightness), condition of the termination, cleanliness, and corrosion. Any grounding points that are corroded or have lost their protective coating should be repaired.

Splices – Both sealed and non-sealed splices are susceptible to vibration, mechanical damage, corrosion, heat damage, chemical contamination, and environmental deterioration. Power feeder cables normally carry high current levels and are very susceptible to installation error and splice degradation. All splices should conform to the TC or STC holder's published recommendations. In the absence of published recommendations, environmental splices are recommended to be used.

- 2. Areas of concern.

Wire Raceways and Bundles – Adding wires to existing wire raceways may cause undue wear and chafing of the wire installation and inability to maintain the wire in the raceway. Adding wire to existing bundles may cause wire to sag against the structure, which can cause chafing.

Wings – The wing leading and trailing edges are areas that experience difficult environments for wiring installations. The wing leading and trailing edge wiring is exposed on some aircraft models whenever the flaps or slats are extended. Other potential damage sources include slat torque shafts and bleed air ducts.

Engine, Pylon, and Nacelle Area – These areas experience high vibration, heat, frequent maintenance, and are susceptible to chemical contamination.

Accessory compartment and equipment bays – These areas typically contain items such as electrical components, pneumatic components and ducting, hydraulic components and plumbing, and may be susceptible to vibration, heat, and liquid contamination.

Auxiliary Power Unit (APU) – Like the engine/nacelle area, the APU is susceptible to high vibration, heat, frequent maintenance, and chemical contamination.

Landing Gear and Wheel Wells – This area is exposed to severe external environmental conditions in addition to vibration and chemical contamination.

Electrical Panels and Line Replaceable Units (LRUs) – Panel wiring is particularly prone to broken wires and damaged insulation when these high density areas are disturbed during troubleshooting activities, major modifications, and refurbishments. Wire damage may be minimized by tying wiring to wooden dowels to reduce wire disturbance during modification. There may be some configurations where connector support brackets would be more desirable and cause less disturbance of the wiring than removal of individual connectors from the supports.

Batteries – Wires in the vicinity of all aircraft batteries are susceptible to corrosion and discoloration. These wires should be inspected for corrosion and discoloration. Discolored wires should be inspected for serviceability.

Power Feeders – High current wiring and associated connections have the potential to generate intense heat. Power feeder cables, terminals, and splices may be subject to degradation or loosening due to vibration. If any signs of overheating are seen, splices or termination should be replaced. Depending on design, service experience may highlight a need to periodically check for proper torque of power feeder cable terminal ends, especially in high vibration areas. This applies to galley and engine/APU generator power feeders.

Under Galleys, Lavatories, and Cockpit – Areas under the galleys, lavatories, and cockpit, are particularly susceptible to contamination from coffee, food, water, soft drinks, lavatory fluids, dust, lint, etc. This contamination can be minimized by adherence to proper floor panel sealing procedures in these areas.

Fluid Drain plumbing – Leaks from fluid drain plumbing may lead to liquid contamination of wiring. In addition to routine visual inspections, service experience may highlight a need for periodic leak checks or cleaning.

Fuselage Drain provisions – Some installations include features designed to catch leakage that is plumbed to an appropriate exit. Blockage of the drain path can result in liquid contamination of wiring. In addition to routine visual inspections, service experience may highlight that these installations and associated plumbing should be periodically checked to ensure the drain path is free of obstructions.

Cargo Bay/Under floor – Damage to wiring in the cargo bay under floor can occur due to maintenance activities in the area.

Wiring subject to movement – Wiring that is subject to movement or bending during normal operation or maintenance access should be inspected at locations such as doors, actuators, landing gear mechanisms, and electrical access panels.

Access Panels – Wiring near access panels may receive accidental damage as a result of repetitive maintenance access and thus may warrant special attention.

Under Doors – Areas under cargo, passenger and service entry doors are susceptible to fluid ingress from rain, snow and liquid spills. Fluid drain provisions and floor panel sealing should be periodically inspected and repaired as necessary.

Under Cockpit Sliding Windows – Areas under cockpit sliding windows are susceptible to water ingress from rain and snow. Fluid drain provisions should be periodically inspected and repaired as necessary.

Areas where wiring is difficult to access – Areas where wiring is difficult to access (e.g., flight deck instrument panels, cockpit pedestal area) may accumulate excessive dust and other contaminants as a result of infrequent cleaning. In these areas it may be necessary to remove components and disassemble other systems to facilitate access to the area.

10. Enhanced Zonal Analysis Procedure

The Enhanced Zonal Analysis Procedure (EZAP) identified in Appendix A of this AC is designed to permit appropriate attention to be given to electrical wiring installations. This is achieved by providing a means to identify applicable and effective tasks to minimize accumulation of combustible materials and address wiring installation discrepancies that may not otherwise be reliably detected by inspections contained in existing maintenance programs.

For aircraft models operating on maintenance programs that already include a dedicated Zonal Inspection Program (ZIP), the logic described in this TP will result in enhancements to those programs, and the zonal inspection requirements may not differ greatly from the existing ZIPs.

In analysis conducted under the EZAP, items such as plumbing, ducting, systems installations, etc., should be evaluated for possible contribution to wiring failures. In cases where a General Visual Inspection is required to assess degradation of these items, a Zonal GVI within a ZIP may be considered as appropriate.

For those operators that do not have a dedicated ZIP, application of the logic is likely to result in identification of a large number of wiring related tasks that will need to be consolidated within the existing Systems/Powerplant Program.

In either case, any new tasks identified by the logic may be compared with existing tasks and credit given for equivalent tasks already contained in the maintenance program. For operators with ZIPs that already contain Zonal GVIs, the number of new tasks that must be added to the program may be significantly fewer than for an operator without a dedicated ZIP. Therefore, operators without a ZIP may find it beneficial to develop a ZIP in accordance with an industry-accepted methodology in conjunction with application of the EZAP.

The logic and procedures identified in this TP apply to TCs, STCs, and Service Bulletins. It is expected that the TC and STC holders would use the logic and procedures to identify any need for additional instructions for continued airworthiness. Operators may be required to use the logic to identify additional instructions for STCs where the STC has been "orphaned" (i.e., no longer supported by the STC holder).

While TC Holders are required to conduct the EZAP for all zones in an aircraft, it may be determined that EZAP for a Service Bulletin or STC is not necessary where the modification does not appreciably affect the zones where it is installed. Appendix C, "Determination if Service Bulletin Modification or STC Requires EZAP", was developed to identify modifications that sufficiently affect zone attributes to warrant re-application of EZAP to the entire zone.

11. Maintenance Practices: Protection and Caution Recommendations

TCCA together with the other participating regulatory authorities identified some specific maintenance and servicing tasks for which more robust practices are recommended to be adopted by air carriers, air operators, maintenance providers, repair stations. These recommendations apply to all tasks, including those performed on an unscheduled basis without an accompanying routine job instruction card. Performance of these maintenance practices will help prevent contamination of EWIS that result from contact with harmful solids (such as metal shavings) or fluids during maintenance, modifications, and repairs of aircraft structures, and components. In addition the training of maintenance and servicing personnel should address the potential consequences of their actions on the wiring in the work vicinity.

Item 1: Installation, Repair, or Modification to Wiring.

Wiring and its associated components (protective coverings, connectors, clamping provisions, conduits, etc.) often comprise the most delicate and maintenance sensitive portions of an installation or system. Extreme care should be exercised and proper procedures used during installation, repair, or modification of wiring to ensure safe and reliable performance of the function supplied by the wiring.

Proper wire selection, routing/separation, clamping configurations, use of splices, repair or replacement of protective coverings, pinning/de-pinning of connections, etc., should be performed in accordance with the applicable sections of the Aircraft Maintenance Manual (AMM), Wiring Practices Manual (WPM), or other documents authorized for maintenance use. In addition, special care should be taken to minimize disturbance of existing adjacent wiring during all maintenance activities. When wiring is displaced during a maintenance activity, special attention should be given to returning it to its normal configuration in accordance with the applicable maintenance instructions.

Item 2: Structural Repairs, STCs, Modifications

Structural repair, STC or modification activity inherently introduces tooling and residual debris that is harmful to aircraft wiring. Structural repairs or modifications often require displacement (or removal) of wiring to provide access to the work area. Even minor displacement of wiring, especially while clamped, can damage wire insulation, which can result in degraded performance, arcing, or circuit failure.

Extreme care should be exercised to protect wiring from mechanical damage by tools or other equipment used during structural repairs, STCs or modifications. Drilling blindly into the aircraft structure should be avoided. Damage to wire installation could cause wire arcing, fire and smoke. Wiring located adjacent to drilling or riveting operations should be carefully displaced or covered to reduce the possibility of mechanical damage.

Debris such as drill shavings, liberated fastener pieces, broken drill bits, etc., should not be allowed to contaminate or penetrate wiring or electrical components. This can cause severe damage to insulation and potential arcing by providing a conductive path to ground or between two (2) or more wires of different loads. Once contaminated, removal of this type of debris from wire bundles is extremely difficult. Therefore, precautions should be taken to prevent contamination of any kind from entering the wire bundle.

Before initiating structural repair, STC or modification activity, the work area should be carefully surveyed to identify all wiring and electrical components that may be subject to contamination. All wiring and electrical components in the debris field should be covered or removed to prevent contamination or damage. Consideration should be given to using drills equipped with vacuum aspiration to further minimize risk of metallic debris contaminating wire bundles. Clean electrical components and wiring after completion of work per applicable maintenance instructions.

Item 3: Aircraft De-Icing or Anti-Icing.

To prevent damage to exposed electrical components and wiring in areas such as wing leading and trailing edges, wheel wells, and landing gear, care should be exercised when spraying de/anti-icing fluids. Direct pressure spray onto electrical components and wiring can lead to contamination or degradation and thus should be avoided.

Item 4: Inclement Weather.

Electrical wiring interconnection systems in areas below doorways, floors, access panels, and servicing bays are prone to corrosion or contamination due to their exposure to the elements. Snow, slush, or excessive moisture should be removed from these areas before closing doors or panels. Remove deposits of snow/slush from any items (e.g., cargo containers) before loading in the aircraft. During inclement weather, keep doors/panels closed as much as possible to prevent ingress of snow, slush, or excessive moisture that could increase potential for EWIS degradation.

Item 5: Component Removal/Installation (Relating to Attached Wiring).

Excessive handling and movement during removal and installation of components may be harmful to aircraft wiring. Use appropriate connector pliers (e.g., soft jawed) to loosen coupling rings that are too tight to be loosened by hand. Alternately pull on the plug body and unscrew the coupling ring until the connector is separated. Do not use excessive force, and do not pull on attached wires. When reconnecting, special care should be taken to ensure the connector body is fully seated, the jam nut is fully secured, and no tension is on the wires.

When equipment is disconnected use protective caps on all connectors (plug or receptacle) to prevent contamination or damage of the contacts. Sleeves or plastic bags may be used if protective caps are not available. Use of sleeves or plastic bags should be temporary because of the risk of condensation. It is recommended to use a humidity absorber with sleeves or plastic bags.

Item 6: Pressure Washing.

To prevent damage to exposed electrical components and wiring in areas such as wing leading and trailing edges, wheel wells, and landing gear, care should be exercised when spraying water or cleaning fluids. Direct high-pressure spray onto electrical components and wiring can lead to contamination or degradation and should be avoided. When practical, wiring and connectors should be protected before pressure washing. Water rinse should be used to remove cleaning solution residue after washing. Breakdown of wire insulation may occur with long-term exposure of wiring to cleaning solutions. Although these recommendations are good practice and technique, the aircraft maintenance manual or STC holder's instructions for continued airworthiness should be consulted for additional detailed instructions regarding pressure washing.

Item 7: Cleaning of Electrical Wiring Interconnection Systems (In-situ).

Extreme care should be exercised and proper procedures used during cleaning to ensure safe and reliable performance of the function supplied by the wiring.

Care should be taken to avoid displacement or disturbance of wiring during cleaning of non-aggressive contamination. However, in the event of contamination by aggressive contaminants (e.g., livestock waste, salt water, battery electrolyte, etc.) such displacement may be necessary. In these cases wiring should be released from its installation so as to avoid undue stress being induced in wiring or connectors. Similarly, if liquid contamination enters the bundle then ties should be removed before separating the wires. Although these recommendations for cleaning of EWIS are considered good practice and technique, the aircraft maintenance manual or STC holder's instructions for continued airworthiness should be consulted for additional detailed instructions.

Clean only the area and items that have contamination. Before cleaning, make sure that the cleaning materials and methods will not cause more contamination. If a cloth is used, make sure that it is clean, dry, and lint-free. A connector should be completely dry before mating. Any fluids remaining on a connector can have a deteriorating affect on the connector or the system or both.

Item 8: Servicing, Modifying, or Repairing Waste Water Systems.

Electrical wiring interconnection systems in areas adjacent to waste/water systems are prone to contamination from those systems. Care should be exercised to prevent any fluids from reaching electrical components and wiring while servicing, modifying, or repairing waste/water systems. Cover exposed electrical components and wiring during waste/water system modification or repair. Operator practice may call for a weak acid solution to be periodically flushed through lavatory systems to enhance reliability and efficiency of operation. In view of the effect of acid contamination on systems and structure, the system should be confirmed to be free of leaks before using such solutions.

Item 9: Servicing, Modifying, or Repairing Oil Systems.

Electrical wiring interconnections in areas adjacent to oil systems are prone to contamination from those systems. To minimize the attraction and adhesion of foreign material, care should be exercised to avoid any fluids from reaching electrical components and wiring while servicing, modifying, or repairing oil systems. Oil and debris in combination with damaged wiring can present a fire hazard.

Item 10: Servicing, Modifying, or Repairing Hydraulic Systems.

Electrical wiring interconnection system in areas adjacent to hydraulic systems are prone to contamination from those systems. To minimize the attraction and adhesion of foreign material, care should be exercised to avoid any fluids from reaching electrical components and wiring while servicing, modifying, or repairing hydraulic systems.

Item 11: Gaining Access (Entering Zones).

When entering or working on the aircraft, care should be exercised to prevent damage to adjacent or hidden electrical components and wiring, including wiring that may be hidden from view (e.g., covered by insulation blankets). Use protective boards or platforms for adequate support and protection. Avoid using wire bundles as handholds, steps and supports. Work lights should not be hung or supported by wiring. If wiring must be displaced (or removed) for work area access, it should be adequately released from its clamping (or other restraining provisions) to allow movement without damage and returned after work is completed.

Item 12: Application of Corrosion Preventions Compounds (CPC).

When applying CPC in aircraft zones containing wire and associated components (i.e., clamps, connectors and ties), care should be taken to prevent CPC from coming in contact with the wire and components. Dust and lint is more likely to collect on wire that has CPC on it. Application of CPC should be done in accordance with the aircraft manufacturer's recommendations.

12. Alteration

The program to enhance EWIS maintenance also applies to EWIS installed, modified, or affected by operator alterations or STCs. Alterations that could affect EWIS include, but are not limited to, those that install new equipment in close proximity to wiring, introduce a heat source in the zone, or introduce potential sources of combustible material or harmful contamination into the zone.

The operator is responsible for determining if the EWIS has been altered (or affected by alteration) and enhancing the maintenance program as appropriate.

Appendix A. Enhanced Zonal Analysis Procedure Diagram

Figure 1. Enhanced Zonal Analysis Procedure

Figure 2. Step 8 - Wiring Inspection Level and Interval Selection

Text Description

Explanation for Steps in Enhanced Zonal Analysis Procedure Logic Diagram.

The following paragraphs provide further explanation of each step in the Enhanced Zonal Analyses Procedure logic, (Figures 1 and 2). It is recommended that, where possible, the analysts utilize the availability of actual aircraft to ensure they fully understand the zones being analyzed. This will aid in determination of density, size, environmental issues, and accidental damage issues.

Step 1. "Identify aircraft zones, including boundaries"

The system consists of Major Zones, Major Sub Zones and Zones.

The zones, wherever possible, shall be defined by actual physical boundaries such as wing spars, major bulkheads, cabin floor, control surface boundaries, skin, etc., and include access provisions for each zone.

If the type design holder or operator has not already established aircraft zones it is recommended that it do so. Whenever possible zones should be defined using a consistent method such as ATA iSpec 2200 (formerlyATA Spec 100), varied only to accommodate particular design constructional differences.

Step 2. "List of details of zone"

An evaluation will be carried out to identify system installations, significant components, L/HIRF protection features, typical power levels in any installed wiring bundles, combustible materials (present or possible accumulation), etc.

With respect to power levels the analyst should be aware whether the bundle consists primarily of main generator feeder cables, low voltage instrumentation wiring or standard bus wiring. This information will later be used in determining the potential effects of deterioration.

The reference to combustible materials highlights the need to assess whether the zone might contain material/vapor that could cause a fire to be sustained in the event of an ignition source arising in adjacent wiring. Examples include the possible presence of fuel vapors, dust/lint accumulation and contaminated insulation blankets. See also under Step 4 for further information.

For aircraft types whose design directives may not have excluded the possibility of inadequate segregation between systems, the analyst should identify locations where both primary and back-up flight controls are routed within 2 inches/50 mm of a wiring harness. This information is required to answer the question in Step 7.

Step 3. "Zone contains wiring?"

This question serves as a means to eliminate from the enhanced zonal analysis procedure those zones that do not contain any wiring.

Step 4. "Combustible materials in zone?"

This question requires an evaluation of whether the zone might contain combustible material that could cause a fire to be sustained in the event of an ignition source arising in adjacent wiring. Examples include the possible presence of fuel vapors, dust/lint accumulation, and contaminated insulation blankets.

With respect to commonly used liquids (e.g., oils, hydraulic fluids, corrosion prevention compounds) the analyst should refer to the product specification in order to assess the potential for combustibility. The product may be readily combustible only in vapor/mist form and thus an assessment is required to determine if conditions might exist in the zone for the product to be in this state.

Although liquid contamination of wiring by most synthetic oil and hydraulic fluids (e.g., Skydrol) may not be considered combustible, it is a cause for concern if it occurs in a zone where it causes significant adherence of dust and lint.

The analyst should assess what sources of combustible products may contaminate the zone following any single failure considered likely from in-service experience. Unshrouded pipes having connections within the zone should be considered as potential contamination sources. Inherent ventilation in the zone should be taken into account when determining the potential for subsequent combustion. This influences the response to the question of how near to the harness the source should be for there to be a concern.

Avionics and instruments located in the flight compartment and equipment bays tend to attract dust, etc. In view of the heat generated by these components and the relatively tightly packed installations, the analyst should consider these zones as having potential for combustible material. Thus the enhanced logic should always be used for these zones.

Note: Although moisture (whether clean water or otherwise) is not combustible, it's presence on wiring is a cause for concern because it may increase the probability of arcing from small breaches in the insulation which could cause a localized fire in the wire bundle. The risk of a sustained fire caused by moisture induced arcing is mitigated in Step 5 by identification of a task to reduce the likelihood of accumulation of combustible material on or adjacent to the wiring.

Step 5. "Is there an effective task to significantly reduce the likelihood of accumulation of combustible materials?"

Most operator maintenance programs have not included tasks directed towards removal or prevention of significant accumulations of combustible materials on or adjacent to wiring.

This question requires an evaluation of whether the accumulation on or adjacent to wiring can be significantly reduced. Task effectiveness criteria should include consideration of the potential for damaging the wiring.

Though restoration tasks (e.g., cleaning) are the most likely applicable tasks, the possibility to identify other tasks is not eliminated. A detailed inspection of a hydraulic pipe might be assessed as appropriate if high-pressure mist from pinhole corrosion could impinge a wire bundle and the inherent zone ventilation is low.

Step 6. "Define task and interval"

This step will define an applicable task and an effective interval. It should be included as a dedicated task in the Systems & Powerplant section. Within MRB Reports, this may be introduced under ATA 20 with no Failure Effect Category quoted.

It is not the intent that restoration tasks should be so aggressive as to damage the wiring, but should be applied to a level that significantly reduces the likelihood of combustion.

Step 7. "Is wiring close to primary and back-up hydraulic, mechanical, or electrical flight controls?"

Where wiring is close (i.e., within 2 inches/50 mm) to both primary and back-up hydraulic, mechanical, or electrical flight controls, this question is asked to ensure that Step 8 logic is applied even in the absence of combustible materials in the zone.

For zones where combustible materials are present (as determined in Step 4), proximity is addressed in the inspection level definition portion of Step 8 and this question need not be asked.

It addresses the concern that segregation between primary and back-up flight controls may not have been consistently achieved. Even in the absence of combustible material, a localized wire arcing could impact continued safe flight and landing if hydraulic pipes, mechanical cables, or wiring for fly-by-wire controls are routed in close proximity (i.e., within 2 inches/50 mm) to a wiring harness. In consideration of the redundancy in flight control systems, the question need be answered ‘Yes' only if both the primary and back-up system might be affected by wire arcing. Note that in zones where a fire might be sustained by combustible material the enhanced logic will automatically be followed.

On all aircraft type designs, irrespective of TC date, modifications performed by an STC holder may not have taken into account the TC holder's design criteria. It is thus recommended that STC holders assess their design changes with this question included in the logic unless they can demonstrate that they followed equivalent installation criteria. Similarly, air carriers and air operators will have to assess any modifications that have been accomplished on their aircraft.

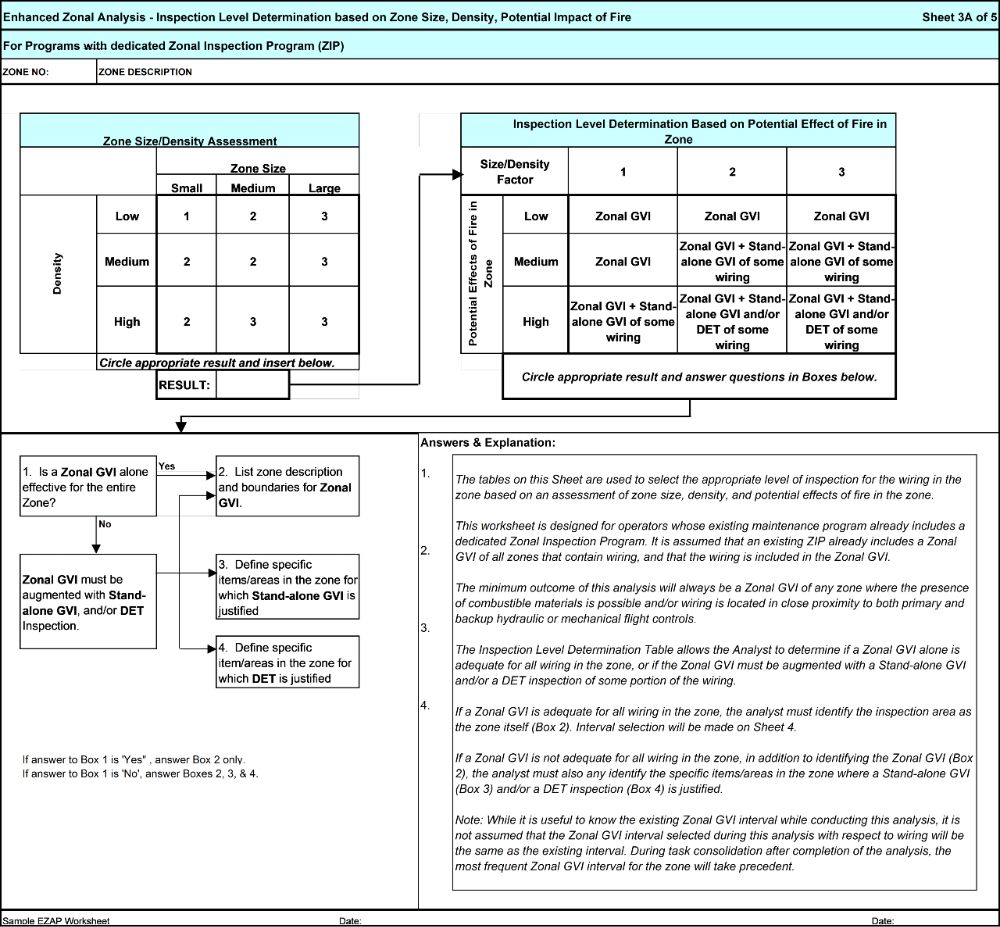

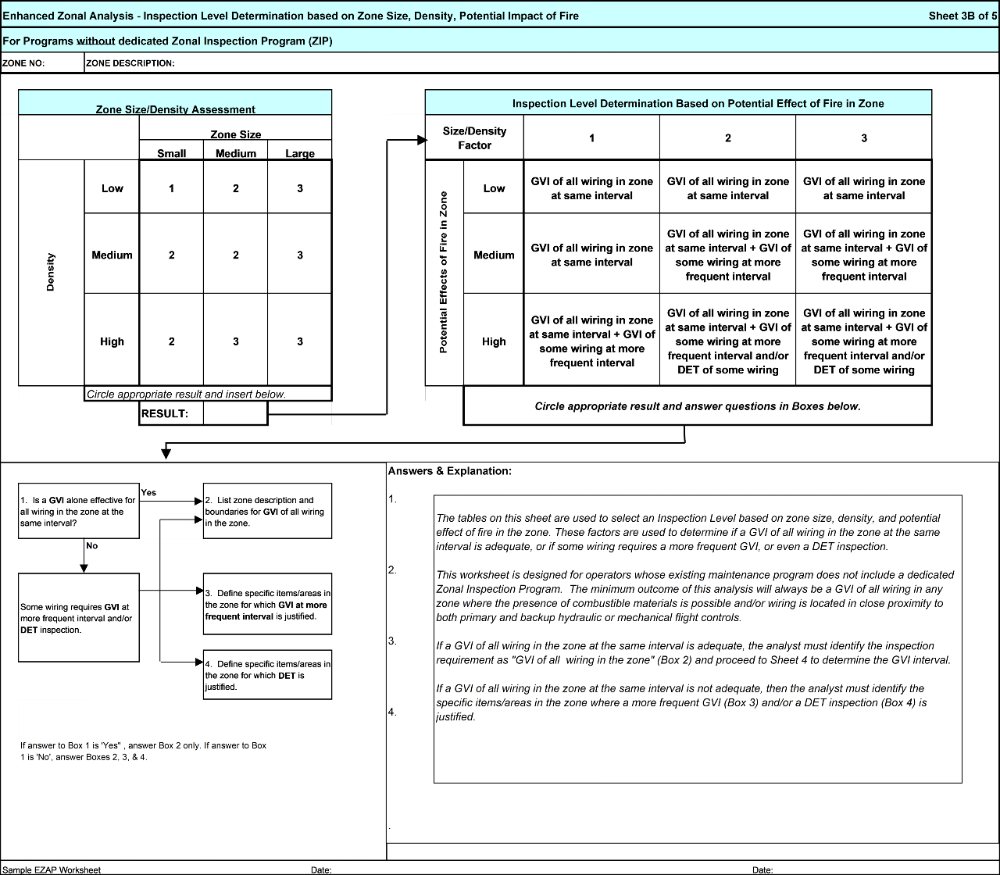

Step 8. "Selection of Wiring Inspection Level and Interval"

- a) Inspection Level

At this point in the analysis, it is already confirmed that wiring is installed in a zone where the presence of combustible materials is possible and/or the wiring is in close proximity to primary and backup hydraulic or mechanical flight controls. Therefore, some level of inspection of the wiring in the zone is required, and this step details how the proper level of inspection and interval can be selected.

One method of selecting the proper inspection level and interval is through the use of ratings tables which rate attributes of the zone and how the wiring is affected by, or can affect those attributes. The precise format of this will be determined by the analyst, but example rating tables appear in Appendix B and may be referred to for clarity.

The Inspection Level characteristics that may be included in the rating system are:

- Zone size (volume).

- Density of installed equipment within the zone.

- Potential effects of fire on adjacent wiring & systems.

Zone size will be assessed relative to the size of the aircraft, typically identified as small, medium or large. The smaller the zone and the less congested it is, the more likely it is that wiring degradation will be identified by GVI.

Density of installed equipment, including wiring, within the zone will be assessed relative to the size of the zone. The density of the zone is typically identified as low, medium or high.

Potential effects of fire on adjacent wiring and systems requires the analyst to assess the potential effect of a localized fire on adjacent wiring and systems by considering the potential for loss of multiple functions to the extent that continued safe operation may not be possible.

Consideration of potential effect must also include whether wiring is in close proximity (i.e., within 2 inches/50 mm) to both primary and back-up flight controls. A GVI alone may not be adequate if a fire caused by failure of the wiring poses a risk to aircraft controllability.

At minimum, all wiring in the zone will require a GVI at a common interval. For operators with a Zonal Inspection Program, this may be defined as a Zonal GVI. For operators without ZIP, it shall be defined as a GVI of all wiring in the zone.

The question is asked, "Is a GVI (or Zonal GVI) of all wiring in the zone at the same interval effective for all wiring in the zone?" This is to consider if there are specific items/areas in the zone that are more vulnerable to damage or contamination and thus may warrant a closer or more frequent inspection.

This determination could result in the selection of a more frequent GVI, a Stand-alone GVI (for operators with a ZIP), or even a DET inspection. The intention is to select a DET of wiring only when justified by consideration of all three characteristics of the zone (size, density, and potential effect of fire). The analyst should be cautious to avoid unnecessary selection of DET where GVI is adequate. Over-use of DET dilutes the effectiveness of the inspection.

Note: The level of inspection required may be influenced by tasks identified in Steps 5 and 6. For example, if a cleaning task was selected in Step 5 and 6 that will minimize the accumulation of combustible materials in the zone, this may justify selection of a GVI in lieu of a DET for the wiring in the zone.

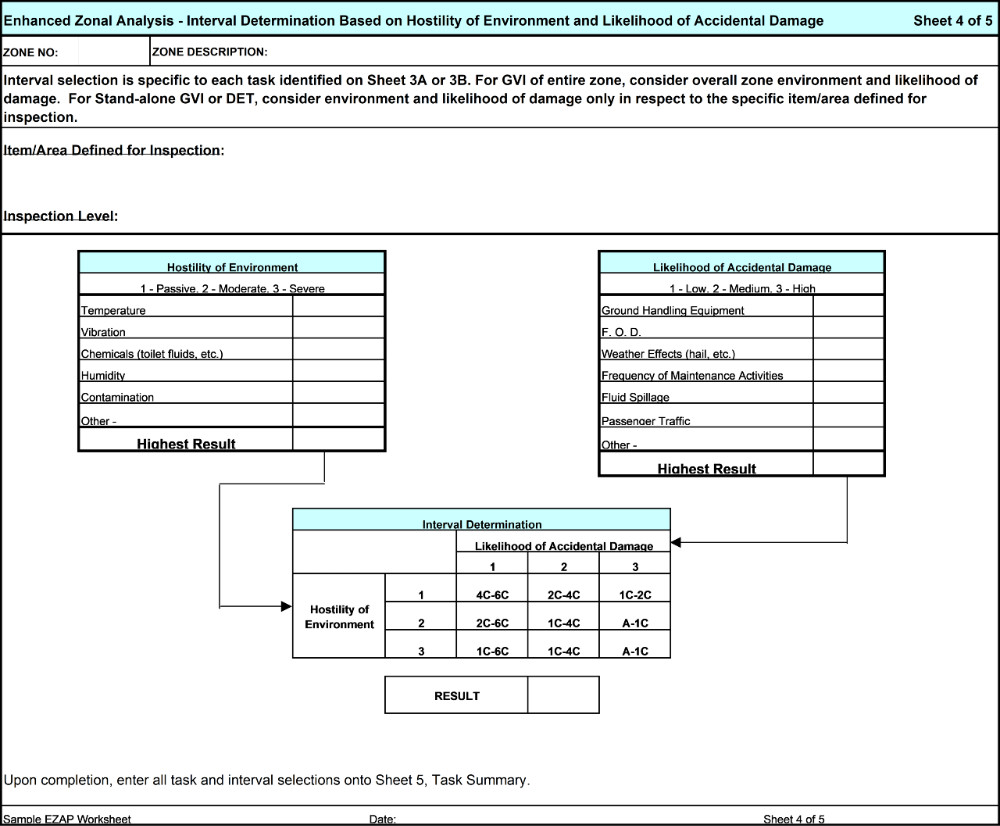

- b) Inspection Interval

The selection of an effective interval can also be accomplished using a rating system. The characteristics for wiring to be rated should include the following:

Possibility of Accidental Damage.

Environmental factors.

The rating tables should be designed to define increasing inspection frequency with increasing risk of accidental damage and increasing severity of the local environment within the zone. Examples are provided in Appendix E.

For ZIP programs, the possible inspection tasks are:

- Zonal GVI

- Stand-alone GVI

- DET

For non-ZIP programs, the possible inspection tasks are:

- GVI

- DET

Note: At this point the analyst will have determined the required inspection level and interval for wiring in the zone. Task consolidation in Step 9 allows consideration as to whether an inspection selected as a result of this analysis can be considered accomplished as part of the existing maintenance program.

Step 9. "Task Consolidation"

This step in the procedure examines the potential for consolidation between the tasks derived from the Enhanced Zonal Analysis Procedure and inspections that already exist in the Maintenance Program. Consolidation requires that the inspections in the existing maintenance program are performed in accordance with the inspection definitions provided in this TP.

For programs that include a Zonal Inspection Program (ZIP):

The consolidation of GVI tasks has to take into account the access requirements and the interval of each task. The Working Group may conclude that a stand-alone GVI of the wiring may be justified if the Zonal GVI of the other systems within the same zone does not need to have such a frequent inspection.

Stand-alone GVIs and DETs identified by application of EZAP cannot be consolidated into the Zonal Inspection Program and must be introduced and retained as dedicated tasks in the scheduled maintenance program under ATA 20. These tasks, along with tasks identified to reduce the accumulation of combustible materials, shall be uniquely identified to ensure they are not consolidated in the zonal program nor deleted during future program development. Within MSG-3 based MRB Reports, these may be introduced under ATA 20 with no Failure Effect Category quoted.

For programs without a Zonal Inspection Program (ZIP):

Although non-ZIP programs may already include some dedicated inspections of wiring that may be reviewed for equivalency to new tasks identified by application of the Enhanced Zonal Analysis Procedure, it is expected that a significant number of new wiring inspections will be identified for introduction as dedicated tasks in the System & Powerplant program. All new tasks identified by application of EZAP shall be uniquely identified to ensure they are not deleted during future program development.

The following guide can be used to determine proper consolidation between EZAP derived inspections and existing inspections of the same item or area with the caveat that EZAP Stand-alone GVIs and DETs cannot be consolidated into a Zonal GVI. Where a task is selected to be consolidated, the program documentation must include a record identifying the task which has been consolidated for traceability purposes. Where the EZAP inspection interval and existing inspection interval are equal, but the inspection levels are different, the more intense inspection will take precedent (i.e., a 1C DET takes precedent over a 1C GVI).

Where the EZAP inspection interval and existing inspection interval are different, but the inspection levels are equal, the more frequent inspection will take precedent (i.e, a 1C GVI takes precedent over a 2C GVI).

Where the EZAP inspection interval and level are different than the existing inspection interval and level, these tasks may be consolidated only when the more frequent inspection is also the more intense (i.e., a 1C DET takes precedent over a 2C GVI). When the more frequent inspection is less intense, the tasks should not be consolidated.

For all programs, EZAP stand-alone tasks shall be uniquely identified in the program documentation for traceability during future changes to the program. This is intended to prevent the inadvertent deletion or escalation of EZAP stand-alone tasks without proper consideration of the basis for the task and its interval.

For EZAP derived STC tasks, it may not be possible for the STC holder to determine whether a ZIP exists on specific aircraft that will utilize the STC. Therefore, where a ZIP exists, consolidation of EZAP derived STC tasks into a specific operator's ZIP will be the responsibility of the operator and subject to approval by the cognizant Civil Aviation Authorities PMI.

In cases where the STC holder determines a requirement for a GVI that should not be consolidated into a ZIP, this Stand-alone GVI should be specifically identified as such in the EZAP derived ICAW for the STC.

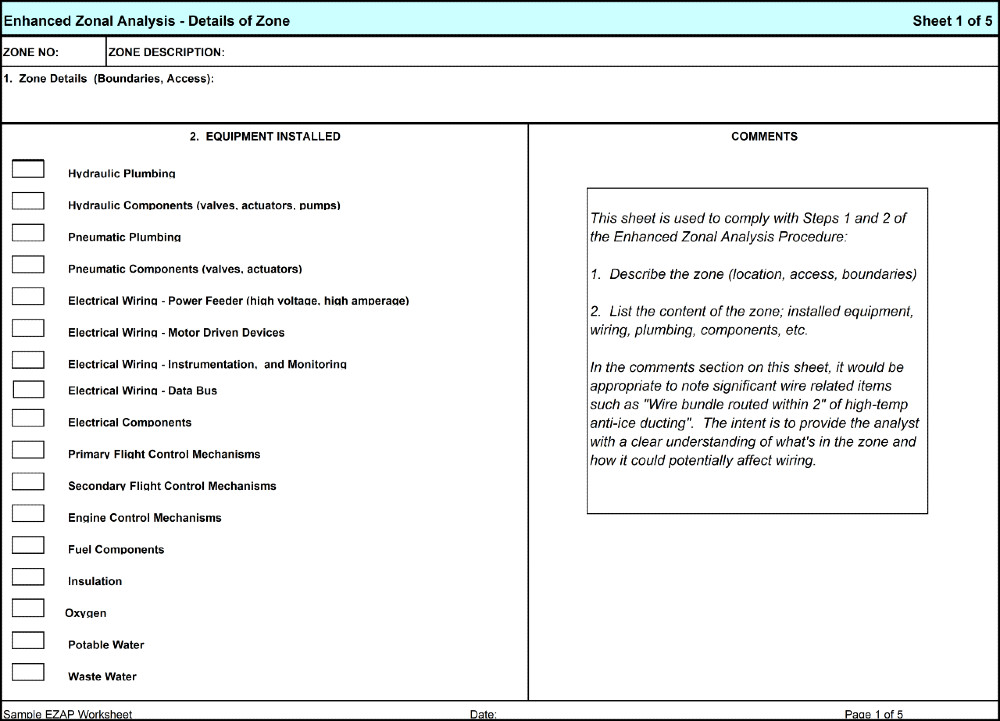

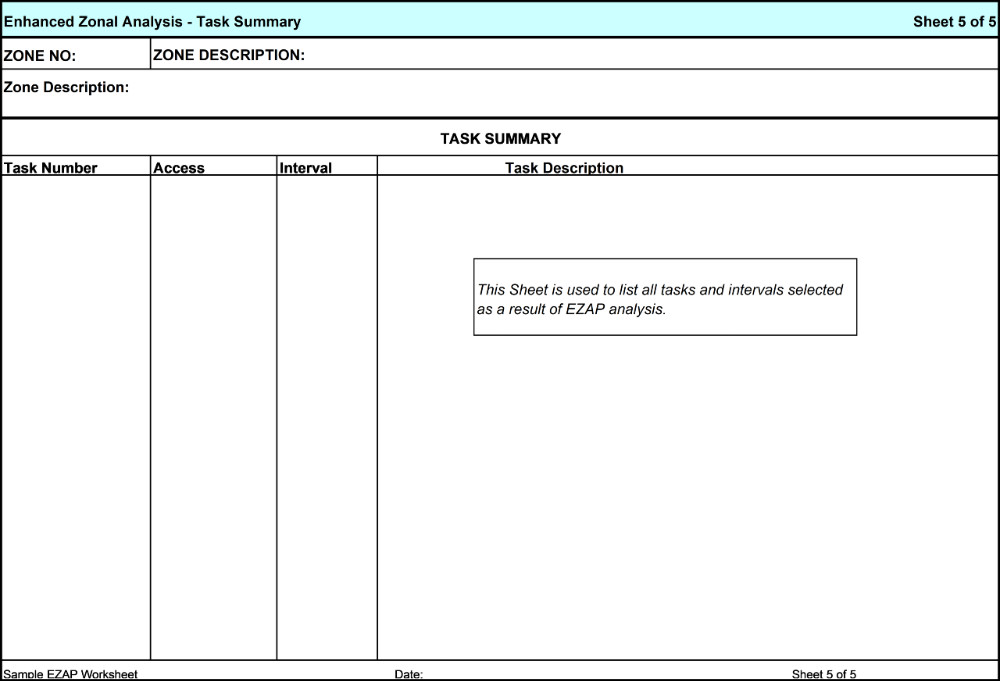

Appendix B. Examples of Typical EZAP Worksheets

The following worksheets are provided as an example to assist in application of the EZAP logic. The worksheets may be adjusted by the analyst to suit specific applications.

Sheet 1 Details of Zone

Sheet 2 Assessment of Zone Attributes

Sheet 3A Inspection Level Determination based on Rating Tables (for use where a dedicated Zonal Inspection Program exists)

Sheet 3B Inspection Level Determination based on Rating Tables (for use where no dedicated Zonal Inspection Program exists)

Sheet 4 Interval Determination based on Rating Tables

Sheet 5 Task Summary

Note: The interval ranges quoted in the rating table on Sheet 4 are solely to explain a typical arrangement of values. For a particular application, these must be compatible with the interval framework used in the existing maintenance or inspection program. They may be expressed in terms of usage parameter (e.g., flight hours or calendar time) or in terms of letter check (as in the example).

For this report, the worksheets have been electronically pasted into this section. TCCA is in possession of the source files that can be reformatted as necessary to achieve the level of quality required for distribution to industry review for review.

Appendix C. Determination If Service Bulletin Modification of STC Requires EZAP

The EZAP provides a means for TC and STC Holders to develop improvements to EWIS maintenance programs. These improvements will be in the form of new inspections and other tasks designed to prevent significant accumulation of combustible materials on or adjacent to EWIS components that would be added to the Instructions for Continued Airworthiness or Service Bulletins (SBs) for the aircraft and STC's.

While TC Holders are required to conduct the EZAP for all zones in an aircraft, it may be determined that EZAP for an SB or STC is not necessary where the modification does not appreciably affect the zones where it is installed. The "Determination if Service Bulletin Modification or STC Requires EZAP" procedure was developed to identify modifications that sufficiently affect zone attributes to warrant re-application of EZAP to the entire zone.

This logic assumes that the aircraft TC holder has accomplished the EZAP on each zone of the aircraft without consideration of the SB modification or STC installation. The objective of this analysis is to assess whether the modification itself has affected wiring or certain zone attributes that could change the outcome of the EZAP performed by the aircraft type certificate holder.

The determination if the SB or STC requires EZAP, and re-application of the EZAP to SB or STC affected zones, is the responsibility of the respective Holder of the SB or STC. It is expected that the TC and STC Holders will collaborate with each other and Operators as necessary to obtain information required to conduct the analysis. The TC or STC Holder should communicate the results of the procedure, including when no new tasks are identified. The method of communication may be via Service Bulletin or Service Letter and ICAW Revision, or other means acceptable to the TCAA.

In situations where a previously installed STC is no longer supported by a viable STC Holder (e.g., STC Holder defunct), the responsibility for determining if the STC requires EZAP, and re-application of EZAP to any affected zones, is assigned to the individual operators who utilize the STC on their aircraft. In cases where the operator does not have experience in application of analytical logic processes, it will be necessary for the operator to gain competence in, or seek external assistance in conducting the analysis.

A record of the outcome of Operator accomplished analysis for STC's (even if no tasks are identified) should be permanently retained by the Operator. A copy of the record should be included in the aircraft records normally transferred upon change of aircraft operator.

The attached logic chart provides a means to assess whether an SB modification or STC has sufficiently affected wiring or certain other zone attributes as to require reapplication of the EZAP to the entire zone with consideration of the modification present. The section following the chart provides detailed explanations of each step in the Determination If Service Bulletin Modification or STC Requires EZAP with appropriate examples.

It is recommended that where possible, the analyst should utilize the availability of actual aircraft to ensure they fully understand the zones being analyzed. Specifically, it must be determined how installation of the modification could affect zone attributes such as density, environment, proximity of wiring to primary and backup flight controls, presence of combustible materials, and potential for accidental damage to wiring.

Figure 1. Determination if Service Bulletin Modification or STC Requires EZAP

Text Description

Determination If Service Bulletin Modification or STC Requires EZAP

Explanation of Steps

Step 1. "For each zone containing any portion of the modification installation - answer the following."

Using the aircraft manufacturer's zone identification system (typically, zone numbers), identify all zones where any portion of the modification is installed, including non-wiring portions such as plumbing, ducting, cables, etc.

For each zone containing any portion of the modification, perform the following Steps:

Step 2. "Does the modification install or route wire(s) within 2 in (50 mm) of both primary & backup hydraulic, mechanical, or electrical flight controls?"

This questions addresses the concern that segregation between primary and back-up flight controls may not have been consistently achieved in the aircraft design. Even in the absence of combustible material, a localized arc emanating from wiring could impact continued safe flight and landing if the wiring is within 2-inches/50 mm of hydraulic, mechanical, or electrical flight controls. In consideration of the redundancy in flight control systems, the question need be answered ‘Yes' only if both the primary and back-up system might be affected by an arc from the wiring installed or routed by the modification.

If the answer to Step 2 is 'NO', bypass Steps 3 and 4 and proceed to Step 5.

If the answer is 'YES', proceed to Step 3.

Step 3. "Identify DET for wiring installed or routed by the modification in area of close proximity to flight controls. Assign interval based on Appendix C, Figure 2."

Wiring installed or routed within 2 inches/50 mm of both primary and backup flight controls will require a DET. The TC or STC Holder must identify the specific wiring for DET and use the worksheet in Figure 2 to determine the required interval. The DET and interval must be added to the SB instructions or the STC Instructions for Continued Airworthiness in accordance with CAR 525, Appendix H.

Step 4. "Include DET and Interval in Service Bulletin or STC Instructions for Continued Airworthiness."

The DET and interval identified in Step 3 must be added to the SB instructions or the STC Instructions for Continued Airworthiness.

After completion of Step 3 (and 4, if applicable), continue the analysis and proceed to Step 5.

Step 5. "Does the SB or STC modification affect key zone attributes?"

This step consists of multiple questions to determine if the modification has affected certain zone attributes that could change the outcome of the EZAP applied to the zone without the modification installed. A ‘YES' answer to any of the questions will require reapplication of EZAP to the entire zone.

Does it introduce the potential for presence of combustible materials in the zone for the first time?

This question assesses whether the modification could, by design, or failure of a single item, introduce combustible materials onto or adjacent to wiring in the zone for the first time. If yes, the full EZAP must be accomplished on the zone.

Example 1: