Safety Promotion & Education

Carburetor icing is a common cause of general aviation accidents. Fuel injected engines have very few induction system icing accidents, but otherwise no airplane and engine combination stands out. Most carburetor icing related engine failure happens during normal cruise. Possibly, this is a result of decreased pilot awareness that carburetor icing will occur at high power settings as well as during descents with reduced power.

In most accidents involving carburetor icing, the pilot has not fully understood the carburetor heat system of the aircraft and what occurs when it is selected. Moreover, it is difficult to understand the countermeasures unless the process of ice formation in the carburetor is understood. Detailed descriptions of this process are available in most good aviation reference publications and any AME employed on type can readily explain the carburetor heat system. The latter is especially important because of differences in systems. The pilot must learn to accept a rough-running engine for a minute or so as the heat melts and loosens the ice which is then ingested into the engine.

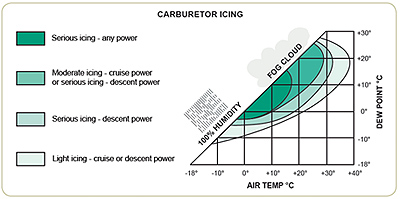

The following chart provides the range of temperature and relative humidity which could induce carburetor icing.

NOTE: This chart is not valid when operating on automotive gasoline (MOGAS). Due to its higher volatility, MOGAS is more susceptible to the formation of carburetor icing. In severe cases, ice may form at outside air temperatures up to 20°C higher than with aviation gasoline (AVGAS).

(Source: Transport Canada Aeronautical Information Manual (TC AIM) Section AIR 2.3.)

To view the complete updated Take Five list, please click here.

Carburetor Icing - TP 2228-38

(PDF, 1.53 MB)