Airport Pavement Bearing Strength Reporting

| Issuing Office: | Standards | Document No.: | AC 302-011 |

|---|---|---|---|

| File Classification No.: | Z 5000-34 | Issue No.: | 02 |

| RDIMS No.: | 11247436-V2 | Effective Date: | 2016-01-04 |

- 1.0 INTRODUCTION

- 2.0 REFERENCES AND REQUIREMENTS

- 3.0 BACKGROUND

- 4.0 DETERMINATION OF AIRPORT PAVEMENT BEARING STRENGTH

- 5.0 HISTORICAL AIRCRAFT/PAVEMENT LOAD RATING SYSTEM

- 6.0 AIRCRAFT/PAVEMENT CLASSIFICATION NUMBER SYSTEM

- 7.0 DETERMINATION OF TIRE PRESSURE LIMITATIONS

- 8.0 DETERMINATION OF PCN VALUES FROM PLR VALUES

- 9.0 PAVEMENT STRENGTH REPORTING

- 10.0 PAVEMENT OVERLOAD OPERATIONS

- 11.0 INFORMATION MANAGEMENT

- 12.0 DOCUMENT HISTORY

- 13.0 CONTACT OFFICE

- APPENDIX A - TABLES 1 TO 9

- APPENDIX B - FIGURES 1 TO 15

1.0 INTRODUCTION

- This Advisory Circular (AC) is provided for information and guidance purposes. It describes an example of an acceptable means, but not the only means, of demonstrating compliance with regulations and standards. This AC on its own does not change, create, amend or permit deviations from regulatory requirements, nor does it establish minimum standards.

1.1 Purpose

- The purpose of this document is to outline methodologies for determining and reporting airside pavement bearing strengths at Canadian airports. The document reviews Transport Canada's historical Aircraft/Pavement Load Rating (ALR/PLR) system and the International Civil Aviation Organization (ICAO) Aircraft/Pavement Classification Number (ACN-PCN) method. Correlations between the two systems are presented to enable determination of Pavement Classification Numbers from existing Pavement Load Ratings.

1.2 Applicability

- This document applies to Canadian airport operators and is also available to the aviation industry for information purposes.

1.3 Description of Changes

- Issue 02 of this AC includes the following principal revisions:

- With the publication of TP 312 5th Edition, the standard method for airport pavement bearing strength reporting will be the internationally recognized ACN- PCN method. The ALR/PLR system for pavement strength reporting will be phased out within the next 3 years.

- The maximum allowable tire pressure categories given in Table 5 were revised based on TP 312 5th Edition and ICAO Annex 14.

- Revision to Table 2: Tire Pressure Restrictions (MPa) for Asphalt Surfaced Pavements.

- New section 7.0 Determination of Tire Pressure Limitations was added.

- New section 8.0 Pavement Overload Operations was added.

- Other minor changes of an editorial nature.

2.0 REFERENCES AND REQUIREMENTS

2.1 Reference Documents

-

It is intended that the following reference materials be used in conjunction with this document:

- Part III, Subpart 2 of the Canadian Aviation Regulations (CARs)—Airports;

- Transport Canada Publication (TP) 312 5th Edition – Aerodrome Standards and Recommended Practices;

- Advisory Circular (AC) 300-004 – Unpaved Runway Surfaces;

- TP 14371 – Aeronautical Information Manual (TC-AIM);

- TP 1848, Historical Reference Document AK-68-31-000, Transport Canada, Airports Authority Group, Surface Structures Division, September 1987 – Airport Pavement Evaluation – Bearing Strengths;

- TP 714, Historical Reference Document AK-68-12-000 – Manual of Pavement Structural Design. (A newer version of this manual was published by Public Works and Government Services Canada (PWGSC), Architectural and Engineering Services, Airport Engineering, as ASG-19, July 1992 – Manual of Pavement Structural Design;

- Federal Aviation Administration (FAA) Advisory Circular (AC) 150/5335-5C, 2014-08-14 – Standardized Method of Reporting Airport Pavement Strength - PCN;

- International Civil Aviation Organization (ICAO) Annex 14 to the Convention on International Civil Aviation – International Standards and Recommended Practices: Aerodromes (Sixth Edition, July 2013);

- ICAO – Document 9157 – AN/901 – Aerodrome Design Manual – Part 3 – Pavements (Second Edition, 1983); and

- NAV CANADA – Canada Flight Supplement – Canada and North Atlantic Terminal and Enroute Data.

2.2 Cancelled Documents

- As of the effective date of this document, the following document is cancelled:

- ERD-133 (TP 6348E), 2002-07 — Transport Canada and ICAO Methods for Reporting Airport Pavement Bearing Strengths.

- By default, it is understood that the publication of a new issue of a document automatically renders any earlier issues of the same document null and void.

2.3 Definitions and Abbreviations

-

The following definitions are used in this document:

- Aircraft Classification Number (ACN): a number expressing the relative structural loading effect of an aircraft on a pavement for a specified standard subgrade category.

- Aircraft Load Rating (ALR): a number expressing the relative structural loading effect of an aircraft on a pavement (historical Transport Canada pavement strength reporting format).

- Bearing Modulus (k): a measure of the stiffness of supporting layers beneath a concrete slab. It is measured on the surface of the layer immediately beneath the concrete slab by applying a load through a 750 mm diameter plate to produce a deflection of 1.25 mm. The unit load on the plate (in Pa) is then divided by the deflection of 1.25 mm to give a bearing modulus in units of MPa/ m.

- Bearing Strength: the measure of the ability of a pavement to sustain the applied load.

- California Bearing Ratio (CBR): a measure of the load bearing capacity of a given sample of soil expressed as a ratio relative to the load bearing capacity of crushed limestone.

Note: The load bearing capacity of crushed limestone is expressed as a CBR of 100.

- Composite Pavement: a flexible asphalt pavement or a rigid concrete pavement that has received an overlay of flexible or rigid construction.

- Flexible Pavement: a pavement structure that is designed on the principle of distributing traffic loads to the subgrade, and depends on aggregate interlock, particle friction, and cohesion for stability.

- Pavement: the structural material layers above the subgrade that both comprises and underlay an airside movement area surface, including the subbase, base, and wearing courses.

- Pavement Classification Number (PCN): a number expressing the bearing strength of a pavement for unrestricted operations.

- Pavement Equivalent Granular Thickness (t): the thickness of a pavement constructed of granular materials alone that would have a capacity for the distribution of traffic loads to the subgrade equivalent to that of a flexible pavement constructed with layers of various materials having different load characteristics.

- Pavement Load Rating (PLR): a number expressing the bearing strength of a pavement for unrestricted operations (historical Transport Canada pavement strength reporting format).

- Rigid Pavement: a pavement structure that depends on the tensile beam strength of a Portland cement concrete slab for the support of traffic loads.

- Subgrade: the soil prepared and compacted to support a pavement structure.

- Subgrade Bearing Strength (S): the load kilonewtons (kN) that will produce a deflection of 12.5 mm after 10 repetitions of load when the load is applied through a 750 mm diameter rigid plate. The bearing strength is variable with location and time of year, and the value used to characterize subgrade bearing strength is the 25th percentile value exhibited during the spring thaw period (lower quartile, spring-reduced value).

-

The following abbreviations are used in this document:

- AC: Advisory Circular

- ACN: Aircraft Classification Number

- ALR: Aircraft Load Rating

- CBR: California Bearing Ratio

- FAA: Federal Aviation Administration

- ICAO: International Civil Aviation Organization

- PCN: Pavement Classification Number

- PLR: Pavement Load Rating

3.0 BACKGROUND

- TP 312 5th Edition states as a standard:

"2.4.1.1 The bearing strength of a pavement in the movement area is determined and reported as follows:

- For movement areas intended for aircraft of an apron gross weight greater than 5,700 kg, the bearing strength of a pavement is made available using the aircraft classification number – pavement classification number (ACN- PCN) method by reporting all of the following:

- the pavement classification number (PCN);

- pavement type for ACN- PCN determination;

- subgrade strength category;

- maximum allowable tire pressure category or maximum allowable tire pressure value; and

- evaluation method.

- For movement areas intended for aircraft of an apron gross weight equal to or less than 5 700 kg, the bearing strength of a pavement is made available by reporting the following information:

- maximum allowable aircraft gross weight; and

- maximum tire pressure (e.g. 4,000 kg / 0.50 MPa).

- For movement areas intended for aircraft of an apron gross weight greater than 5,700 kg, the bearing strength of a pavement is made available using the aircraft classification number – pavement classification number (ACN- PCN) method by reporting all of the following:

- The operating authority for every certified airport in Canada is required to determine the bearing strength of all airside pavement operational surfaces at the airport. The resulting strength information is to be made available (reported) so as to enable determination of the structural suitability of the pavements to support intended aircraft operations.

- The historical Canadian ALR/ PLR strength reporting system was originally introduced in the late 1970's at Transport Canada owned and operated airports. One of the advantages of the ALR/ PLR system was the direct link it provided to Transport Canada pavement design and evaluation methodologies which are still used in Canada today.

- To facilitate the reporting of airport pavement bearing strength information on an international basis, ICAO developed the ACN- PCN method which came into use world-wide in the mid-1980's. To comply with ICAO standards, only international airports in Canada were required to report pavement strengths using the standard ICAO PCN reporting code format. However, most airports in Canada made strength information available using both the Canadian PLR and the ICAO PCN formats. With the publication of TP312 5th edition, it is the intent that the standard method for pavement strength reporting will be the internationally recognized ACN- PCN method. The ALR/ PLR system will be phased out within the next three (3) years.

- This Advisory Circular AC gives guidelines on the determination of airport pavement bearing strength, reviews the historical ALR/ PLR system and the ACN- PCN method for reporting airside pavement bearing strengths, and outlines a correlation between the two systems. A methodology is given to derive PCN strength codes from existing PLR data, for Canadian airport operators who have their strength data only available in PLR format.

- An alternative method for determining PCN strength codes is given in the Federal Aviation Administration (FAA) Advisory Circular AC 150/5335-5C Standardized Method of Reporting Airport Pavement Strength – PCN.

- Information on the determination and reporting of surface shear strength for unpaved runways is given in AC 300-004 – Unpaved Runway Surfaces.

4.0 DETERMINATION OF AIRPORT PAVEMENT BEARING STRENGTH

- The bearing strength of airside pavement operational surfaces should be determined on behalf of the airport operating authority by a professional engineer or engineering consulting firm experienced in the measurement and analysis of the bearing strength of airport pavements, in determining their ability to support aircraft loads, and in assessing the effect that aircraft loads are likely to have on the future structural performance and condition of the pavement.

- The determination of airport pavement bearing strength should be made based on the results of in-situ pavement strength tests combined with a knowledge of the thicknesses and strength properties of the various material layers comprising the pavement structure.

- An established and industry recognized engineering methodology consistent with the pavement design model and construction type should be used to determine the structural capability of the pavement to support proposed aircraft loads and traffic levels. Selection of an appropriate methodology should also take into account any strength and/or other pavement material test results that may already be available for the pavement.

- The bearing strength of a pavement should be reviewed and re-determined when the structural composition and/or properties of the pavement change as a result of new or restorative construction or when a significant change in the structural condition of the pavement has occurred.

- As a minimum, the bearing strength of a pavement should be reviewed, re-affirmed or re-determined as appropriate at least once every 10 years. As part of the review process, consideration should be given to retesting the strength of all or selected pavements at the airport.

5.0 HISTORICAL AIRCRAFT/PAVEMENT LOAD RATING SYSTEM

5.1 Aircraft/Pavement Load Rating System

- The Aircraft/Pavement Load Rating (ALR/ PLR) system is presented in this AC for historical reference purposes and to provide a method for determination of PCN values from PLR values using the figures/equations given subsequently. The Aircraft/Pavement Load Rating (ALR/ PLR) system for reporting airside pavement bearing strengths is based on historical Transport Canada design and evaluation procedures for airport pavements which are contained in document ASG-19.

5.2 Aircraft Standard Gear Loadings

-

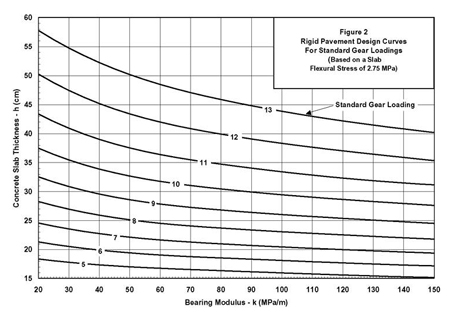

The ALR/ PLR system is based on 13 standard aircraft gear loadings which span the range of aircraft loadings. The loading characteristics of the standard aircraft gear are given in Table 1. Pavement thickness design requirements for these standard gear loadings, as determined by historical Transport Canada (and Public Works Government Services Canada - PWGSC) design methods (document ASG-19) are shown in Figures 1 and 2. Figure 1 for flexible pavement structures gives the pavement equivalent granular thickness required as a function of subgrade bearing strength. Figure 2 for rigid pavement structures gives the concrete slab thickness required as a function of the supporting bearing modulus beneath the slab.

5.3 Aircraft Load Ratings

- An Aircraft Load Rating (ALR) is a number expressing the relative structural loading effect of an aircraft on a pavement. The ALR is determined by superimposing the aircraft pavement design requirements on Figures 1 and 2 and comparing the requirements to those for the standard gear loadings. The load rating of the aircraft is defined as the standard gear loading which has the same pavement thickness requirement as the aircraft.

- Due to variations in the landing gear loading characteristics of actual aircraft, their design thickness curves usually do not fall exactly on or parallel to the standard gear curves (Figures 1 and 2) over the entire range of subgrade support values. As a result, aircraft load ratings vary depending on the subgrade bearing strength in the case of flexible pavements and on the bearing modulus in the case of rigid pavements. For this reason, aircraft load ratings for flexible pavements are determined and reported at four standard subgrade bearing strengths (50, 90, 130 and 180 kN). Similarly, aircraft load ratings for rigid pavements are determined and reported at four standard bearing modulus values (20, 40, 80 and 150 MPa/ m). A maximum (nominal) ALR is also reported at each aircraft weight so that pavement strength suitability can be assessed quickly without the need for detailed subgrade strength or bearing modulus values.

- In order to facilitate the determination of aircraft load ratings, the standard gear load design curves of Figures 1 and 2 have been redrawn in Figures 3 and 4 respectively for the standard subgrade/bearing modulus strength values; equations are also given for the curves. Aircraft load ratings are determined by first calculating the aircraft's design pavement thickness requirements at the four standard subgrade/bearing modulus strengths and then using the appropriate curve or equation to compute the ALR at each subgrade support strength.

5.4 Pavement Load Ratings

- A Pavement Load Rating PLR is a number expressing the bearing strength of a pavement for unrestricted aircraft operations. PLRs are expressed on a scale of 1 (weakest pavements) to 13 (strongest pavements). Pavement bearing strengths are determined from field measured data on pavement thicknesses and subgrade bearing strengths. Using this data in conjunction with Figures 1 and 2, the bearing strength of a pavement can be expressed in terms of the standard gear loading for which the pavement provides sufficient design thickness. For example, referring to Figure 1, a flexible pavement with a subgrade bearing strength "S" of 110 kN and an equivalent granular thickness "t" of 60 cm would have a PLR value of "9". If the pavement thickness "t" is increased to 70 cm, then the PLR would be "10" (i.e. the value of the standard gear loading curve immediately above the plotted point). Similarly, referring to Figure 2, a rigid pavement with a bearing modulus "k" of 50 MPa/ m and a concrete slab thickness of 25 cm would have a PLR value of "8". If the slab thickness is increased to 27 cm, then the PLR would be "9" (i.e. the value of the standard gear loading curve immediately above the plotted point).

- Pavement Load Ratings for an airport are reported as PLR xx. In some cases, an aircraft tire pressure restriction (in megapascals) may be added in brackets following the load rating as in PLR xx (yy). For example, the coding PLR 10 (1.0 MPa) designates a pavement with a load rating of 10, and a tire pressure restriction of 1.0 MPa. The coding PLR 8 designates a pavement with a load rating of 8 and no tire pressure restriction.

- For flexible pavements, a knowledge of the subgrade bearing strength "S" is required to determine the pavement load rating. This information should normally be available from airport technical data inventories. If not available, procedures for measuring and determining pavement bearing strength are given in TP 1848 document AK-68-31-000. The subgrade bearing strength may also be estimated from subgrade soil characteristics as given in Table 3. The spring reduced subgrade bearing strength should be used for determining pavement load ratings.

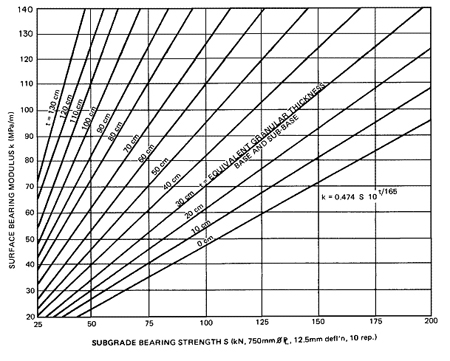

- For rigid pavements, a knowledge of the bearing modulus "k" is required to determine the pavement load rating. This information should normally be available from airport technical data inventories. If not available, procedures for measuring and determining pavement bearing strength are given in TP 1848 document AK-68-31-000. The bearing modulus may also be estimated from Figure 5, based on the subgrade bearing strength and the thickness of the base and sub-base placed between the subgrade and concrete slab. In the equation given in the chart, "t" is the equivalent granular thickness in cm of the base and subbase as determined using the granular equivalency factors given in Table 4.

- For flexible pavements, a knowledge of the equivalent granular thickness "t" is required to determine the pavement load rating. This information should normally be available from airport technical data inventories. If the equivalent granular thickness is not available, it can be calculated using the granular equivalency factors given in Table 4. The depth of each layer in the pavement as obtained from construction records, is multiplied by the granular equivalency factor for the material in that layer, and the sum of these converted layer thicknesses is the pavement equivalent granular thickness.

- For rigid pavements with a single concrete slab, a knowledge of the concrete slab thickness "h" is required to determine the pavement load rating. This information should normally be available from airport technical data inventories.

- For composite pavements, it is required to determine whether the pavement structure behaves as a flexible pavement or rigid pavement. The following are the various combinations that may be encountered:

- Asphalt pavement overlaid with asphalt (with or without a granular base sandwich course). The pavement structure is flexible and the appropriate granular equivalency factors are used to convert the various layers to an equivalent granular thickness "t".

- Asphalt pavement overlaid with a concrete slab. The pavement structure is rigid and the concrete slab thickness "h" is determined from construction records. The original asphalt is considered to be part of the base and granular equivalency factors are used when calculating the thickness of the base and subbase to estimate the bearing modulus "k".

- Concrete overlaid with asphalt. The pavement structure may be considered as flexible or rigid depending on the thickness of the overlay:

- If the asphalt overlay is greater than 25 cm in thickness or greater than the thickness of the concrete slab, the pavement is considered to be flexible and the pavement equivalent granular thickness "t" is determined using the appropriate granular equivalency factors for the various layers.

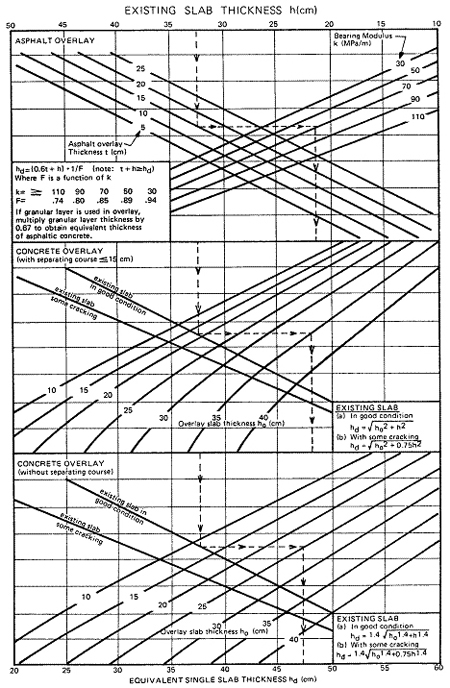

- If the asphalt overlay is less than 25 cm in thickness and less than the thickness of the concrete slab, the pavement is considered to be rigid. The thickness of slab and asphalt overlay is converted to an equivalent slab thickness "hd" using Figure 6 (top chart). In the equation given in the top chart of Figure 6, "t" is the thickness of the asphalt overlay in cm and the equivalent slab thickness "hd" must be less than or equal to the slab thickness plus the overlay thickness (hd = t + h).

- Concrete pavement overlaid with a concrete slab. The pavement structure is rigid but is analysed in one of three ways depending on the thickness of the base course placed between the two slabs:

- If there is no separation course between the two slabs, the equivalent slab thickness "hd" is determined from Figure 6 (bottom chart).

- If the separation course is less than or equal to 15 cm in thickness, the thickness of the two slabs is converted to an equivalent single slab thickness "hd" using Figure 6 (middle chart).

- If the separation course is greater than 15 cm in thickness, the upper overlay is considered to act independently as a single slab, with the lower slab forming part of the base course. The concrete slab thickness "h" is the thickness of the upper overlay slab. An appropriate granular equivalency factor is applied to the lower concrete layer when computing the bearing modulus "k".

5.5 Aircraft Operations Under the HistoricalAircraft/Pavement Load Rating System

- Using the aircraft ALR and the reported pavement PLR, the status of a proposed aircraft operation could be determined. The airport operator first referred to a published ALR table to find the aircraft ALR for the pavement type (flexible or rigid) and at the known subgrade strength. If detailed pavement strength information was not available, then the maximum published ALR value could be used. ALR values at other than the aircraft maximum and minimum weights found in published tables could be estimated with sufficient accuracy by linear interpolation between the maximum and minimum ALR values. From a structural viewpoint, an aircraft could operate on an airport pavement provided that:

- the ALR was equal to or less than the PLR assigned to the pavement; and

- the tire pressure of the aircraft did not exceed the tire pressure restriction (if any) assigned to the pavement.

- The PLR strength values reported for pavements were valid on a year-round basis and took into account seasonal variations and reductions in strength which may occur as a result of the springtime weakening of subgrade soils.

- Aircraft operators planning flight(s) into a particular airport notified and obtained prior permission from the airport operating authority. Application for approval of aircraft operations that marginally exceeded the reported pavement strength limit could also be made to the airport operating authority but usually required an engineering evaluation prior to approval.

6.0 AIRCRAFT/PAVEMENT CLASSIFICATION NUMBER METHOD

6.1 Aircraft/Pavement Classification Number Method

-

In order that pavement strengths could be reported and understood internationally, ICAO developed the Aircraft Classification Number-Pavement Classification Number (ACN-PCN) method, which in some respects resembles the historical Canadian ALR/ PLR system. The ICAO ACN- PCN reporting method is fully detailed in TP 312 5th Edition, ICAO Annex 14 and ICAO Document 9157. With the publication of TP 312 5th edition, it is the intent that the standard method for reporting pavement strength will be the ACN- PCN method.

6.2 Aircraft Classification Numbers

- The Aircraft Classification Number (ACN) expresses the relative structural loading effect of an aircraft on different pavement types (flexible or rigid) for specified standard subgrade/bearing modulus values. The ACN of an aircraft is defined as being the load (kg) divided by 500 which acting on a standard single wheel (at 1.25 MPa tire pressure) will have the same pavement thickness design requirements as the aircraft gear load being classified. The equivalency of pavement thickness design requirements is determined using the design methods of the Portland Cement Association for rigid pavements, and with some minor modifications, the historical CBR design methods of the Federal Aviation Administration (FAA) for flexible pavements. Full details on these methods and computer programs for determining ACN's are contained in ICAO Document 9157.

- Using this approach, ACN's for flexible pavements are reported at four standard subgrade California Bearing Ratio (CBR) values of 3, 6, 10, and 15 which correspond to Canadian subgrade bearing strengths of 50, 90, 130 and 180 kN respectively. Similarly, ACN's for rigid pavements are reported at four standard bearing modulus values (20, 40, 80 and 150 MPa/ m). The classification number of an aircraft varies substantially, depending on the subgrade bearing strength in the case of flexible pavements and on the bearing modulus in the case of rigid pavements.

- ACNs are computed only for aircraft having an apron (ramp) mass greater than 5,700 kg (56 kN or 12,600 lbs). Under the ACN system, the loading effect of aircraft having a mass equal to or less than 5,700 kg is reported in terms of the aircraft maximum mass and tire pressure.

- Official ACN values are provided by the aircraft manufacturer.

- The U.S. FAA has developed software for calculating ACN values in accordance with the ICAO ACN- PCN method. The software is called ICAO ACN and may be downloaded from the FAA web site. The software is useful for calculating ACN values under various conditions but as stated above, the official ACN values are obtained from the aircraft manufacturer.

6.3 Pavement Classification Numbers

- The method of determining pavement bearing strength is not specified under the ACN- PCN method, but is left open to the choice of each individual state. Pavement strength determinations may be made on the basis of field measured data or simply on the basis of past experience with aircraft that have used the facility without causing pavement structural damage. Regardless of how it is determined, bearing strength is to be reported in terms of a PCN. The PCN reported is to indicate that an aircraft having an ACN equal to or less than the reported PCN can operate on the pavement without restriction subject to any limitation on tire pressure.

- In addition to the actual PCN value, the PCN reporting code contains other information such as pavement type (flexible or rigid), subgrade strength category, maximum allowable tire pressure and the evaluation method used to determine the pavement strength. Full details of the PCN reporting code are given in TP 312 5th Edition and in ICAO Annex 14 and are summarized with examples in Table 5.

- The PCN is the first part of a five-part strength code (eg. 40/F/B/1.0 MPa/T) that includes the following information.

- The PCN

- The PCN is a number that expresses the bearing strength of a pavement (the higher the number, the stronger the pavement) for unrestricted aircraft operations.

- Pavement Type for ACN/ PCN Determination

- Rigid Pavement - indicated by the Code Letter "R"

- Flexible Pavement - indicated by the Code Letter "F"

- Subgrade Strength Category

- High Strength - indicated by the Code Letter "A"

- Medium Strength - indicated by the Code Letter "B"

- Low Strength - indicated by the Code Letter "C"

- Ultra Low Strength - indicated by the Code Letter "D"

- Maximum Allowable Tire Pressure Category or Value

- Unlimited - indicated by the Code Letter "W"

- High - indicated by the Code Letter "X"

- Medium - indicated by the Code Letter "Y"

- Low - indicated by the Code Letter "Z"

It is preferable to state the maximum allowable tire pressure in MPa rather than the tire pressure category. Tire pressure limitations are generally only applied to flexible pavements. If a tire pressure limit does not apply to a pavement, the Code Letter "W" is used.

- Strength Evaluation Method

- Technical Evaluation - indicated by the Code Letter "T"

- Using Aircraft Experience - indicated by the Code Letter "U"

- The PCN

- The bearing strength of pavements intended for use by aircraft of apron (ramp) mass equal to or less than 5,700 kg (56 kN or 12,600 lbs) is made available by reporting:

- the maximum allowable aircraft mass, and

- the maximum allowable tire pressure.

Example: 4000 kg/0.50 MPa

6.4 Aircraft Operations Under the Aircraft/Pavement Classification Number System

- Determining the structural suitability of a pavement for aircraft operations using the ACN- PCN method follows the same general process as that used under the ALR- PLR system but with some technical differences.

- The airport operator must first have available the five part PCN reporting code for the pavement. Reference is then made to published Aircraft Classification Number tables to determine the aircraft ACN for the pavement type (flexible or rigid) and the subgrade strength level reported in the 2nd and 3rd parts of the PCN code. ACN values at other than the aircraft maximum/minimum weights can be calculated with acceptable accuracy by linear interpolation between the ACN values given in the tables or by using the FAA software referenced in Section 6.2 (5). From a structural viewpoint, an aircraft can operate on a pavement provided that:

- the ACN of the aircraft is equal to or less than the PCN assigned to the pavement (for the given pavement type and subgrade strength code), and

- the tire pressure of the aircraft does not exceed the tire pressure restriction (if any) assigned to the pavement, and

- subject to any limitation on the maximum allowable aircraft mass (primarily applicable to light aircraft of mass equal to or less than 5,700 kg).

- The PCN strength codes reported for pavements are valid on a year-round basis and take into account seasonal variations and reductions in strength which may occur as a result of the springtime weakening of subgrade soils.

- Aircraft operators planning flight(s) into a particular airport should notify and obtain prior permission from the airport operating authority. Application for approval of aircraft operations that marginally exceed the reported pavement strength limit may also be made to the airport operating authority but usually require a detailed engineering evaluation prior to approval.Further information on pavement overload operations is given in section 10.0.

7.0 DETERMINATION OF TIRE PRESSURE LIMITATIONS

- For rigid pavement systems (Portland cement concrete), aircraft tire pressures will have little effect on the pavement surface. Rigid pavements inherently possess adequate surface stability and normally do not require tire pressure limitations. Rigid pavements can usually be rated as code W.

- For flexible asphaltic concrete pavement systems, suggested tire pressure restrictions are given in Table 2 based on the thicknesses of asphalt surface and granular base course layers. However, tire pressure restrictions should also take into account the quality of the asphalt mixture (stability of the asphalt mix in resisting shearing) and climatic conditions. Tire pressure limitations for flexible pavement systems having gravel surfaces are determined as specified in AC 300-004.

8.0 DETERMINATION OF PCN VALUES FROM PLR VALUES

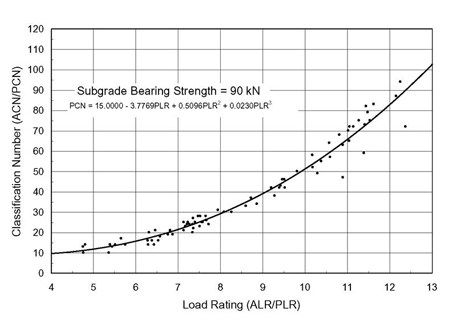

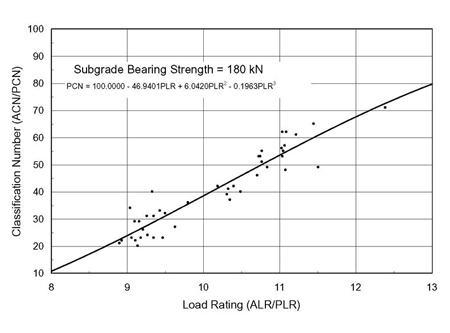

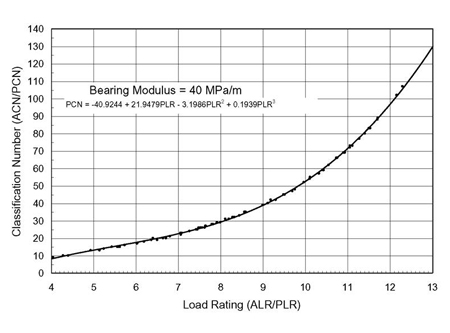

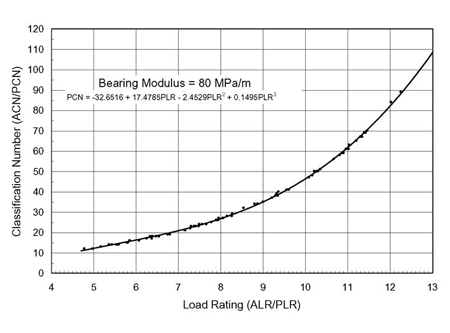

- The relationship between classification numbers and load ratings is shown in Figures 7 to 14. Figures 7 to 10 plot flexible pavement ACN values against corresponding ALR values for the 46 aircraft listed in Table 6 at each of the four standard subgrade bearing strengths. Figures 11 to 14 are similar ACN/ ALR plots for rigid pavements for the 46 aircraft listed in Table 7 at each of the four standard bearing modulus levels.

- Aircraft classification numbers and load ratings may be viewed as a relative ranking or indexing of the severity of aircraft loadings, and there is not a one-to-one relationship between these rankings because of the different methods used for their determination. For rigid pavements, the correlation is quite good because there are only minor differences between Transport Canada's pavement design methods (basis of the ALR determination) and the Portland Cement Association's design methods (basis of ACN determination). Greater variation exists for flexible pavements because of the differences between Transport Canada design methods (basis of the ALR determination) and those of the FAA historical CBR method (basis of ACN determination).

- Despite the variations present, Figures 7 to 14 suggest that PCN numbers correlate with PLR ratings with sufficient accuracy to determine the former from the latter when reporting pavement bearing strengths.

- Table 8 gives PLR to PCN conversion tables and equations for flexible and rigid pavements based on the various regression curves plotted in Figures 7 to 14.

- To make the conversion, a knowledge is required of subgrade bearing strength in the case of flexible pavements, and bearing modulus in the case of rigid pavements. This information is not reported under the Pavement Load Rating system, but should be available from airport pavement technical data inventories. Using this information in conjunction with Tables 8 and 5, the PCN value and the entire PCN code can be determined.

- Table 9 provides examples of PLR to PCN conversions for flexible (asphalt), rigid and gravel surfaced pavements.

- In order to promote consistency of results, it is recommended that when both PLR and PCN codes are to be reported, rounded-up PLR values be used to convert PLR to PCN as illustrated in the example of Table 9. By reporting rounded-up strength values, the PLR system inherently accommodates a limited degree of pavement overloading whereas the PCN method permits 5-10% overloads based on the reported PCN number (reference Section 10.0) However, diligence must be exercised to ensure that 5 -10% overloads are not "automatically" applied to PCN values that have been derived by conversion of rounded up PLR values.

- If only PCN codes are reported, then the more precise PLR value and the regression equations may be used to convert PLR to PCN, to determine a more conservative (precise) PCN value. In the example of Table 9 for flexible pavements, the rounded-up PLR value of 9 is derived from "S" and "t" values using Figure 1. The more precise PLR value would be approximately 8.6 (interpolated between the curves for PLR 8 and PLR 9). Using the equation for subgrade category D (S = 50 kN), would give a PCN of 44 as compared to a PCN of 50 derived from the rounded-up PLR value. Similarly, in the example of Table 9 for rigid pavements, the rounded up PLR value of 11 is derived from "k" and "h" values using Figure 2. The more precise PLR value would be approximately 10.2 (interpolated between the curves for PLR 10 and PLR 11). Using the equation for subgrade category B (k = 100 MPa/ m), would give a PCN of 49 as compared to a PCN of 60 derived from the rounded up PLR value.

9.0 PAVEMENT STRENGTH REPORTING

- The operating authority for every certified airport in Canada is required to determine the bearing strength of all airside pavement operational surfaces at the airport and the resulting strength information is to be made available (reported) using the standard ICAO PCN reporting code format which is understood world-wide.

- In some cases, airport authorities may publish airside pavement strength information (PCN reporting codes) in the form of a computerized chart similar to the one shown in Figure 15. Other airport authorities may publish the data in a tabular format. Regardless of the publishing format, it is imperative that pavement strength information be made available (ICAO- PCN code) in a format that can easily be interpreted and applied by operational personnel. The reported airside pavement strengths can then be compared to corresponding aircraft ACN values to determine those aircraft which can operate on the pavements.

- For the purpose of reporting pavement strength(s), runway operational surfaces should be assigned only one pavement strength rating (i.e. one PCN value) which should be representative of the overall strength of the runway and which should apply to the entire length of the runway. For runway pavements of varying strengths, engineering judgement may be required to determine a representative overall pavement strength rating. Factors that may be considered include the location and extent of weaker pavement sections and the pavement condition.

- Taxiway and apron areas should be sectioned for pavement strength reporting surfaces as deemed appropriate by the airport authority to account for traffic flow and usage patterns.

- The pavement strength values reported should apply on a year-round basis and should take into account any seasonal variations which may result in a temporary reduction in pavement strength.

- Pavement strength information is available from the airport operating authority. A listing of all Canadian airport operating authorities and contact phone numbers can be obtained by consulting the latest version of the NAV CANADA – Canada Flight Supplement.

10.0 PAVEMENT OVERLOAD OPERATIONS

- Aircraft with ACN's greater than the PCN reported for a pavement may still be allowed to use the pavement subject to the approval of the airport operating authority. However, the airport authority should fully understand the implications of allowing overload operations in terms of the accelerated structural deterioration and the reduction in pavement service life which may occur.

- The overloading of pavements can result either from loads that are too large or from a substantially increased load application rate, or both. Loads larger than the original design or as-built evaluated load may shorten the pavement service life, while smaller loads will usually have a minimal effect on pavement deterioration.

- With the exception of massive overloading, pavements in their structural behaviour are not subject to a particular limiting load above which they will suddenly or catastrophically fail. Behaviour is such that a pavement can sustain a definable load for an expected number of repetitions during its service life. As a result, occasional minor overloading is acceptable, when expedient, with only limited loss in pavement life expectancy and relatively small acceleration of pavement deterioration.

- ICAO Annex 14, Attachment A, Section 20 gives the following suggested criteria for determining the acceptability of aircraft operations which overload the pavement. (Refer to Section 6.0 part (7) for cautionary note regarding overload operations.)

- For flexible pavements, occasional movements by aircraft with ACN not exceeding 10 per cent above the reported PCN should not adversely affect the pavement.

- For rigid or rigid composite pavements, in which a rigid pavement layer provides a primary element of the structure, occasional movements by aircraft with ACN not exceeding 5 per cent above the reported PCN should not adversely affect the pavement.

- If the pavement structure is unknown, a 5 per cent limitation should apply.

- The annual number of overload movements should not exceed approximately 5 per cent of the total annual aircraft movements.

- Overload movements defined by the criteria above should not normally be permitted on pavements exhibiting signs of distress or failure. Furthermore, overloading should also be avoided during any periods of thaw following frost penetration, or when the strength of the pavement or its subgrade could be weakened by water.

- Where overload operations are conducted, the airport authority should inspect and review the structural condition of the pavement regularly to ensure that the pavement is not being damaged and that the criteria being used to allow the overload operations is appropriate for the particular pavement. Excessive repetition of overloads can cause severe shortening of pavement life or require premature major rehabilitation of the pavement

- For those aircraft operations where the magnitude of overload and/or the frequency of use exceed the limits of the criteria given above, it is recommended that the advisability of the allowing the operation be determined on the basis of a detailed engineering analysis comparing the individual aircraft load to the structural capability of the pavement.

- The airport authority may also wish to have a detailed engineering analysis of the airside pavements carried out to determine the maximum overloads which could safely be allowed in the event that an "emergency only" type of aircraft operation is required on short notice. The determination of "emergency only" overload limits should be based on ensuring the safety of the aircraft from pavement surface "break-through" during the "emergency" operation.

11.0 INFORMATION MANAGEMENT

- Not applicable.

12.0 DOCUMENT HISTORY

-

Advisory Circular AC 302-011 Issue 01, RDIMS 6697505 (E), 6817992 (F), dated 2012-03-16 – Airport Pavement Bearing Strength Reporting.

13.0 CONTACT OFFICE

For more information, please contact the appropriate Transport Canada Regional Civil Aviation Office at the following address:

https://tc.canada.ca/en/corporate-services/regions

Suggestions for amendment to this document are invited, and should be submitted via:

TC.FlightStandards-Normsvol.TC@tc.gc.ca

[Original signed by]

David White

A/Director, Standards

Civil Aviation

APPENDIX A Tables 1 to 9

Table 1: Aircraft Standard Gear Loadings

Standard Gear Load Rating

| Standard Gear Load Rating | Characteristics of Standard Gear Loadings | |||||||

|---|---|---|---|---|---|---|---|---|

| Single Wheel Gear | Dual Wheel Gear | Dual Tandem Gear | ||||||

| Gear Load (kN) | Tire Pressure (MPa) | Gear Load (kN) | Tire Pressure (MPa) | Dual Tire Spacing (cm) | Gear Load (kN) | Tire Pressure (MPa) | Dual Tandem Spacing (cm) | |

| 1 | 20 | 0.30 | ||||||

| 2 | 30 | 0.35 | ||||||

| 3 | 45 | 0.40 | ||||||

| 4 | 60 | 0.45 | 80 | 0.50 | 50 | |||

| 5 | 80 | 0.50 | 110 | 0.60 | 55 | |||

| 6 | 110 | 0.55 | 130 | 0.65 | 60 | |||

| 7 | 140 | 0.60 | 170 | 0.70 | 65 | |||

| 8 | 220 | 0.85 | 70 | |||||

| 9 | 290 | 1.05 | 75 | 440 | 1.10 | 65 x 115 | ||

| 10 | 400 | 1.15 | 90 | 660 | 1.20 | 90 x 150 | ||

| 11 | 900 | 1.55 | 110 x 165 | |||||

| 12 | 1120 | 1.80 | 115 x 165 | |||||

| 13 | 1380 | 1.80 | 115 x 165 | |||||

Table 2: Tire Pressure Restrictions (MPa) for Asphalt Surfaced Pavements

| Asphalt Thickness (cm) | Base Course Thickness (cm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | >=23 | |

| 5.0 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| 5.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| 6.0 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| 6.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | 1.0 |

| 7.0 | 0.5 | 0.5 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| 7.5 | 0.5 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| 8.0 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| 8.5 | 0.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | |

| 9.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | ||

| 9.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | |||

| 10.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | ||||

| 10.5 | 1.0 | 1.0 | 1.0 | 1.0 | |||||

| 11.0 | 1.0 | 1.0 | 1.0 | ||||||

| 11.5 | 1.0 | 1.0 | |||||||

| 12.0 | 1.0 | ||||||||

| >=12.5 | |||||||||

1.75 MPa or

No Restriction

Notes:

1) Tire pressure restrictions are "0.5 MPa", "1.0 MPa", "1.75 MPa" or "No Restriction". It is at the discretion of the airport operating authority to select either "1.75 MPa" or "No Restriction" depending on site specific conditions for pavements falling into this category.

2) "Asphalt thickness" refers to the actual thickness of the asphalt surface layer(s).

Table 3: Typical Subgrade Bearing Strengths

| Subgrade Soil Type | Usual Spring Reduction % * |

Subgrade Bearing Strength (kN) | ||

|---|---|---|---|---|

| Fall Range |

Design Value | |||

| Fall | Spring | |||

| GW – well graded gravel | 0 | 290 – 400 | 290 | 290 |

| GP – poorly graded gravel | 10 | 180 - 335 | 220 | 200 |

| GM – gravel with silty fines | 25 | 135 - 335 | 180 | 135 |

| GC – gravel with clay fines | 25 | 110 - 245 | 145 | 110 |

| SW – well graded sand | 10 | 135 - 335 | 180 | 160 |

| SP – poorly graded sand | 20 | 110 - 200 | 135 | 110 |

| SM – sand with silty fines | 45 | 95 - 190 | 120 | 65 |

| SC – sand with clay fines | 25 | 65 - 155 | 85 | 65 |

| ML – silt with low liquid limit | 50 | 90 - 180 | 110 | 55 |

| CL – clay with low liquid limit | 25 | 65 - 135 | 85 | 65 |

| MH – silt with high liquid limit | 50 | 25 - 90 | 40 | 20 |

| CH – clay with high liquid limit | 45 | 25 - 90 | 55 | 30 |

| * Note: When the water table is within 1 metre of the pavement surface, the % spring reduction factor should be increased by 10 for each soil type except GW and GP. | ||||

Table 4: Granular Equivalency Factors for Pavement Materials

| Pavement Material |

Granular Equivalency Factor |

|---|---|

| Selected granular sub-base Crushed gravel or stone base Waterbound macadam base Bituminous stabilized base Cement stabilized base Asphaltic concrete (good condition) Asphaltic concrete (poor condition) Portland cement concrete (good condition) Portland cement concrete (fair condition) Portland cement concrete (poor condition) |

1 |

| NOTE: The equivalent granular thickness of a layer is calculated by multiplying the layer thickness by the granular equivalency factor for the material in the layer. |

|

|

EXAMPLE Given: A pavement structure of 8 cm Asphaltic Concrete (A.C.) + 25 cm base + 20 cm sub-base Solution: |

|

Table 5: Pavement Classification Number PCN Reporting Codes

| Pavement Type for ACN- PCN Determination | Codes |

|---|---|

| Rigid Pavement Flexible Pavement Note: If the actual pavement construction is composite or non-standard, include a note to that effect (see Example 2 below). |

R |

| Subgrade Strength Category |

|

|

High Strength: Characterized by k=150 Mn/m3 and representing all k values above 120 Mn/m3 for rigid |

A B C D |

| Maximum Allowable Tire Pressure Category or Value |

|

|

The maximum reported tire pressure is reported by either: i) Using the code letters listed below: or by: |

W |

| Evaluation Method |

|

|

Technical Evaluation: Representing the results of a specific engineering study of the structural characteristics of the pavement and application of the pavement structural behaviour technology. Using Aircraft Experience: Representing a knowledge of the specific type and weight of aircraft satisfactorily being supported by the pavement under regular use. |

T

U |

|

Note 1: The following examples illustrate how pavement strength data are to be reported using the ACN- PCN method. Example 1: If the bearing strength of a rigid pavement, resting on a medium strength subgrade, has been assessed by technical evaluation to be PCN 80 and there is no tire pressure limitation, then the reported information would be: PCN 80/ R/ B/ W/ T Example 2: If the bearing strength of a composite pavement, behaving like a flexible pavement and resting on a high strength subgrade has been assessed by using aircraft experience to be PCN 50 and the maximum allowable tire pressure is 1.25 MPa, then the reported information would be: PCN 50/ F/ A/ 1.25 MPa/ U (Preferred method) (or PCN 50/ F/ A/ Y/ U) Note: Composite construction. Example 3: If the bearing strength of a flexible pavement, resting on a medium strength subgrade, has been assessed by technical evaluation to be PCN 40 and the maximum allowable tire pressure is 0.80 MPa, then the reported information would be: PCN 40/ F/ B/ 0.80 MPa/ T Example 4: If a pavement is subject to a B747-400 all-up mass limitation of 390,000 kg, then the reported information would include the following note: Note: the reported PCN is subject to a B747-400 all-up mass limitation of 390,000 kg. |

|

Table 6: ACN/ ALR Comparison for Flexible Pavements

| Aircraft Model |

Wt. (kN) Max/ Min |

% Load on Gear |

Tire Press. (MPa) |

Wheel Spacing (cm) |

ACN/ ALR for Flexible Pavements for Subgrade Bearing Strength – S (kN) |

||||

|---|---|---|---|---|---|---|---|---|---|

| Dual | Tandem | 50 | 90 | 130 | 180 | ||||

| Airbus A300-B4-200 |

1627 | 46.97 | 1.28 | 90.2 | 139.7 | 80/10.98 | 63/10.88 | 52/10.89 | 46/10.70 |

| 1236 | 55/9.63 | 42/9.51 | 35/9.39 | 32/9.49 | |||||

| Airbus A310-200 |

1509 | 46.6 | 1.46 | 92.7 | 139.7 | 72/10.41 | 55/10.37 | 46/10.39 | 41/10.32 |

| 800 | 29/7.15 | 22/7.35 | 20/7.66 | 19/---- | |||||

| Airbus A321-200 |

877 | 47.46 | 1.46 | 92.7 | ---- | 63/9.83 | 58/10.16 | 52/10.52 | 49/10.83 |

| 461 | 30/7.10 | 26/7.66 | 24/8.13 | 23/9.05 | |||||

| Airbus A330-200 |

2264 | 47.5 | 1.42 | 139.7 | 198.1 | 97/11.27 | 72/11.13 | 62/11.13 | 57/11.06 |

| 1650 | 61/9.62 | 46/9.45 | 41/9.35 | 39/10.30 | |||||

| Airbus A340-600 |

3590 | 33.0 | 1.42 | 140 | 198 | 112/11.76 | 83/11.61 | 70/11.61 | 65/11.44 |

| 1750 | 39/7.92 | 31/7.93 | 28/8.65 | 27/9.62 | |||||

| A380-800 | 5514 | 28.5 | 1.47 | 153 | 170 | 106/12.21 | 75/11.52 | 62/10.97 | 56/11.02 |

| 2758 | Six Wheel Gear | 36/7.55 | 28/7.64 | 25/8.51 | 23/9.46 | ||||

| Antonov AN-124-100 |

3844 | 47.5 | 1.03 | 99.5 | 165 | 83/12.02 | 59/11.38 | 46/10.90 | 40/9.32 |

| 2000 | 10 Wheel Gear | 30/8.22 | 21/7.12 | 18/7.36 | 16/---- | ||||

| Antonov AN-225 |

5884 | 47.5 | 1.13 | 87 | 175 | 101/12.89 | 72/12.36 | 57/12.04 | 49/11.50 |

| 4500 | 14 Wheel Gear | 67/11.39 | 47/10.88 | 37/10.47 | 33/9.42 | ||||

| B1-B Bomber |

2123 | 47.5 | 1.65 | 85 | 145 | 113/12.18 | 94/12.24 | 80/12.34 | 71/12.38 |

| 1400 | 66/10.09 | 52/10.17 | 44/10.34 | 40/10.48 | |||||

| BAC-111 Series 500 |

467 | 47.5 | 1.10 | 51.8 | ---- | 35/8.22 | 33/8.59 | 31/8.85 | 29/9.09 |

| 250 | 18/5.90 | 16/6.37 | 14/---- | 13/---- | |||||

| B707-120 | 1150 | 47.0 | 1.17 | 86 | 142 | 50/9.42 | 38/9.27 | 32/9.11 | 29/9.15 |

| 700 | 25/6.83 | 19/6.86 | 17/7.24 | 16/---- | |||||

| B707-320 | 1484 | 47.5 | 1.24 | 86.0 | 142.0 | 72/10.67 | 57/10.58 | 47/10.60 | 42/10.39 |

| 800 | 31/7.49 | 23/7.50 | 20/7.63 | 19/---- | |||||

| B720 | 1045 | 47.8 | 1.01 | 86.0 | 142.0 | 45/9.15 | 34/8.85 | 28/8.49 | 26/---- |

| 700 | 25/7.01 | 19/6.75 | 17/7.02 | 16/---- | |||||

| B727-200 Standard |

770 | 47.5 | 1.15 | 86.4 | ---- | 55/9.56 | 50/9.80 | 44/10.00 | 42/10.18 |

| 450 | 30/7.23 | 25/7.55 | 23/7.72 | 23/---- | |||||

| B727-200 Advanced |

934 | 47.5 | 1.19 | 86.4 | ---- | 69/10.35 | 64/10.56 | 57/10.83 | 53/11.03 |

| 450 | 30/7.21 | 25/7.57 | 23/7.79 | 23/---- | |||||

| B737-100 | 445 | 47.5 | 1.02 | 77.5 | ---- | 30/7.43 | 26/7.65 | 23/7.76 | 23/---- |

| 260 | 16/5.40 | 14/5.74 | 12/---- | 12/---- | |||||

| B737-200 | 572 | 47.5 | 1.26 | 77.5 | ---- | 41/8.40 | 37/8.71 | 32/9.04 | 31/9.34 |

| 300 | 19/5.97 | 16/6.52 | 15/7.04 | 15/---- | |||||

| B747-100 SR |

2690 | 23.8 | 1.04 | 111.8 | 147.3 | 58/9.74 | 42/9.38 | 35/8.92 | 33/9.42 |

| 1600 | 27/6.88 | 21/6.45 | 18/7.38 | 18/---- | |||||

| B747-200 | 3720 | 23.8 | 1.38 | 111.8 | 147.3 | 91/11.16 | 70/11.01 | 57/11.00 | 51/10.76 |

| 1750 | 31/7.17 | 24/7.26 | 21/7.92 | 20/---- | |||||

| B747-400 | 3905 | 23.8 | 1.38 | 111.8 | 147.3 | 97/11.41 | 75/11.26 | 61/11.23 | 55/11.04 |

| 1800 | 32/7.30 | 24/7.33 | 22/7.98 | 21/8.89 | |||||

| B757-200 | 1134 | 47.5 | 1.24 | 86.4 | 114.3 | 55/9.62 | 43/9.41 | 35/9.21 | 31/9.25 |

| 570 | 21/6.13 | 16/6.27 | 14/6.91 | 13/---- | |||||

| B767-200 | 1410 | 47.5 | 1.31 | 114.3 | 142.2 | 63/9.76 | 46/9.50 | 39/9.31 | 36/9.79 |

| 800 | 27/6.74 | 21/6.80 | 19/7.61 | 18/---- | |||||

| B777-200 LR |

3345 | 46.9 | 1.50 | 139.7 | 144.8 | 118/12.84 | 87/12.14 | 70/11.64 | 62/11.03 |

| 1424 | Six Wheel Gear | 32/7.15 | 24/7.20 | 22/8.18 | 20/9.13 | ||||

| B777-300 | 2945 | 47.4 | 1.48 | 139.7 | 144.8 | 101/12.11 | 73/11.40 | 59/10.77 | 53/10.72 |

| 1562 | Six Wheel Gear | 38/7.79 | 28/7.46 | 25/8.39 | 23/9.34 | ||||

| Convair 990 | 1135 | 48.5 | 1.28 | 61.0 | 118.0 | 59/10.23 | 49/10.28 | 42/10.37 | 37/10.34 |

| 600 | 25/7.11 |

20/7.33 |

17/7.45 | 16/---- | |||||

| Dassault Falcon 900 |

202 | 47.5 | 1.30 | 42.0 | ---- | 15/5.62 | 14/6.28 | 12/---- | 11/---- |

| 103 | 7/4.25 | 6/---- | 5/---- | 5/---- | |||||

| DC-3 | 147 | 46.8 | 0.31 | ---- | ---- | 12/3.97 | 10/---- | 7/---- | 5/---- |

| 80 | 7/2.26 | 5/---- | 4/---- | 3/---- | |||||

| DC-4 | 335 | 46.8 | 0.53 | 74.0 | ---- | 21/6.32 | 17/5.64 | 15/---- | 12/---- |

| 200 | 11/4.07 | 9/---- | 8/---- | 6/---- | |||||

| DC-6 | 480 | 44.0 | 0.73 | 78.0 | ---- | 30/7.57 | 25/7.39 | 23/7.05 | 20/---- |

| 300 | 17/5.50 | 14/5.38 | 13/---- | 11/---- | |||||

| DC-7 | 640 | 47.5 | 0.89 | 76.2 | ---- | 46/9.10 | 42/9.19 | 36/9.24 | 34/9.03 |

| 400 | 27/7.08 | 23/7.16 | 20/7.10 | 19/---- | |||||

| DC-8-62 | 1593 | 47.5 | 1.35 | 81.3 | 139.7 | 80/11.06 | 65/11.03 | 54/11.13 | 48/11.07 |

| 800 | 31/7.57 | 24/7.71 | 21/7.80 | 20/---- | |||||

| DC-9-21 | 445 | 47.5 | 1.02 | 61.0 | ---- | 32/7.87 | 30/8.07 | 26/8.27 | 25/---- |

| 300 | 21/6.26 | 18/6.56 | 16/6.78 | 15/---- | |||||

| DC-10-10 | 2037 | 47.5 | 1.34 | 137.2 | 162.6 | 93/11.03 | 68/10.80 | 57/10.68 | 53/10.74 |

| 1035 | 34/7.31 | 27/7.34 | 24/8.27 | 23/9.17 | |||||

| DC-10-30 | 2593 | 39 | 1.22 | 137.2 | 162.6 | 99/11.33 | 72/11.04 | 60/10.89 | 55/10.76 |

| 1220 | 32/7.21 | 25/7.12 | 23/8.08 | 22/8.92 | |||||

| DHC7 Dash 7 |

209 | 46.8 | 0.74 | 42.0 | ---- | 15/5.40 | 13/5.43 | 12/---- | 10/---- |

| 120 | 8/3.75 | 7/---- | 6/---- | 5/---- | |||||

| Dornier 328 Jet |

155 | 46.4 | 1.13 | 41.0 | ---- | 11/4.84 | 10/5.35 | 8/---- | 8/---- |

| 93 | 6/3.85 | 5/---- | 5/---- | 4/---- | |||||

| Fokker F27 Friendship |

205 | 47.5 | 0.57 | 45.0 | ---- | 14/5.16 | 13/4.74 | 11/---- | 9/---- |

| 120 | 8/3.31 | 6/---- | 5/---- | 5/---- | |||||

| Fokker F28 Fellowship |

325 | 47.5 | 0.53 | 55.0 | ---- | 23/6.78 | 20/6.30 | 17/---- | 14/---- |

| 175 | 11/4.18 | 9/---- | 8/---- | 6/---- | |||||

| Gulfstream G159 |

156 | 47.5 | 0.83 | 42.0 | ---- | 11/4.60 | 10/4.75 | 8/---- | 8/---- |

| 100 | 6/3.52 | 5/---- | 5/---- | 4/---- | |||||

| Gulfstream V |

405 | 47.5 | 1.37 | 46.0 | ---- | 31/7.65 | 30/8.25 | 28/8.70 | 26/9.20 |

| 215 | 15/5.73 | 14/6.42 | 13/6.88 | 12/---- | |||||

| HS/BAe 125-600 |

112 | 47.5 | 0.83 | 32.0 | ---- | 8/4.01 | 7/---- | 6/---- | 6/---- |

| 61 | 4/2.75 | 3/---- | 3/---- | 3/---- | |||||

| HS/BAe 748 |

227 | 47.5 | 0.51 | 48.0 | ---- | 16/5.44 | 14/4.79 | 11/---- | 9/---- |

| 120 | 7/3.07 | 6/---- | 5/---- | 4/---- | |||||

| L-1011-500 Tristar |

2295 | 47.6 | 1.35 | 132.1 | 177.8 | 107/11.64 | 79/11.47 | 67/11.43 | 61/11.21 |

| 1070 | 35/7.55 | 28/7.51 | 25/8.36 | 24/9.26 | |||||

| MD-11 | 2805 | 39.0 | 1.38 | 137.2 | 162.6 | 110/11.64 | 82/11.43 | 68/11.35 | 62/11.08 |

| 1200 | 31/7.05 | 25/7.22 | 23/8.19 | 22/9.10 | |||||

| Saab 2000 | 226 | 47.5 | 0.69 | 46.0 | ---- | 16/5.57 | 14/5.50 | 13/---- | 11/---- |

| 136 | 9/3.86 | 7/---- | 7/---- | 6/---- | |||||

| Shorts 360 | 121 | 47.5 | 0.54 | ---- | ---- | 11/4.03 | 10/---- | 9/---- | 7/---- |

| 77 | 7/2.99 | 7/---- | 6/---- | 5/---- | |||||

Table 7: ACN/ ALR Comparison for Rigid Pavements

| Aircraft Model |

Wt. (kN) Max/ Min |

% Load on Gear |

Tire Press. (MPa) |

Wheel Spacing (cm) |

ACN/ ALR for Rigid Pavements for Bearing Modulus – k (MPa/m) |

||||

|---|---|---|---|---|---|---|---|---|---|

| Dual | Tandem | 20 | 40 | 80 | 150 | ||||

| Airbus A300-B4-200 |

1627 | 46.97 | 1.28 | 90.2 | 139.7 | 75/10.73 | 66/10.74 | 56/10.66 | 46/10.44 |

| 1236 | 51/9.54 | 45/9.47 | 38/9.28 | 32/8.99 | |||||

| Airbus A310-200 |

1509 | 46.6 | 1.46 | 92.7 | 139.7 | 67/10.41 | 59/10.42 | 51/10.34 | 43/10.14 |

| 800 | 29/7.60 | 25/7.41 | 21/7.15 | 19/6.99 | |||||

| Airbus A321-200 |

877 | 47.46 | 1.46 | 92.7 | ---- | 64/10.24 | 62/10.54 | 59/10.85 | 56/11.13 |

| 461 | 31/7.81 | 29/7.98 | 28/8.14 | 26/8.25 | |||||

| Airbus A330-200 |

2264 | 47.5 | 1.42 | 139.7 | 198.1 | 85/11.16 | 73/11.10 | 61/11.01 | 53/10.98 |

| 1650 | 55/9.79 | 47/9.68 | 41/9.60 | 37/9.61 | |||||

| Airbus A340-600 |

3590 | 33.0 | 1.42 | 140 | 198 | 97/11.57 | 83/11.52 | 70/11.45 | 60/11.41 |

| 1750 | 37/8.44 | 32/8.31 | 28/8.25 | 29/8.34 | |||||

| A380-800 | 5514 | 28.5 | 1.47 | 153 | 170 | 110/11.96 | 88/11.69 | 67/11.33 | 55/11.05 |

| 2758 | Six Wheel Gear | 38/8.57 | 31/8.18 | 27/7.94 | 26/8.01 | ||||

| Antonov AN-124-100 |

3844 | 47.5 | 1.03 | 99.5 | 165 | 100/11.63 | 73/11.04 | 48/10.15 | 35/9.28 |

| 2000 | 10 Wheel Gear | 32/7.92 | 23/7.07 | 18/6.37 | 17/6.12 | ||||

| Antonov AN-225 |

5884 | 47.5 | 1.13 | 87 | 175 | 125/12.34 | 89/11.70 | 61/10.95 | 45/10.20 |

| 4500 | 14 Wheel Gear | 75/10.81 | 55/10.10 | 39/9.31 | 30/8.67 | ||||

| B1-B Bomber |

2123 | 47.5 | 1.65 | 85 | 145 | 113/12.03 | 102/12.14 | 89/12.24 | 77/12.28 |

| 1400 | 65/10.29 | 57/10.31 | 50/10.26 | 43/10.12 | |||||

| BAC-111 Series 500 |

467 | 47.5 | 1.10 | 51.8 | ---- | 36/8.31 | 35/8.55 | 34/8.79 | 33/8.97 |

| 250 | 18/5.96 | 17/6.02 | 16/6.06 | 15/6.12 | |||||

| B707-120 | 1150 | 47.0 | 1.17 | 86 | 142 | 47/9.20 | 40/9.10 | 34/8.86 | 28/8.54 |

| 700 | 24/6.96 | 20/6.70 | 17/6.36 | 16/6.16 | |||||

| B707-320 | 1484 | 47.5 | 1.24 | 86.0 | 142.0 | 67/10.40 | 59/10.40 | 50/10.29 | 42/10.03 |

| 800 | 29/7.65 | 25/7.44 | 21/7.14 | 18/6.91 | |||||

| B720 | 1045 | 47.8 | 1.01 | 86.0 | 142.0 | 41/8.76 | 35/8.58 | 29/8.26 | 24/7.88 |

| 700 | 24/6.93 | 20/6.63 | 17/6.24 | 15/6.00 | |||||

| B727-200 Standard |

770 | 47.5 | 1.15 | 86.4 | ---- | 54/9.69 | 52/9.95 | 50/10.20 | 47/10.39 |

| 450 | 29/7.64 | 28/7.78 | 26/7.89 | 24/7.95 | |||||

| B727-200 Advanced |

934 | 47.5 | 1.19 | 86.4 | ---- | 69/10.42 | 66/10.72 | 63/11.02 | 59/11.28 |

| 450 | 29/7.66 | 28/7.81 | 26/7.93 | 25/8.00 | |||||

| B737-100 | 445 | 47.5 | 1.02 | 77.5 | ---- | 29/7.64 | 28/7.78 | 26/7.88 | 25/7.93 |

| 260 | 16/5.62 | 15/5.61 | 14/5.53 | 13/5.53 | |||||

| B737-200 | 572 | 47.5 | 1.26 | 77.5 | ---- | 41/8.74 | 39/8.98 | 37/9.20 | 35/9.35 |

| 300 | 19/6.29 | 19/6.35 | 18/6.38 | 16/6.42 | |||||

| B747-100 SR |

2690 | 23.8 | 1.04 | 111.8 | 147.3 | 50/9.46 | 42/9.29 | 35/8.99 | 29/8.67 |

| 1600 | 25/7.09 | 21/6.79 | 18/6.46 | 16/6.33 | |||||

| B747-200 | 3720 | 23.8 | 1.38 | 111.8 | 147.3 | 82/11.05 | 72/11.04 | 61/10.96 | 51/10.78 |

| 1750 | 30/7.71 | 26/7.51 | 22/7.27 | 20/7.17 | |||||

| B747-400 | 3905 | 23.8 | 1.38 | 111.8 | 147.3 | 88/11.25 | 77/11.26 | 65/11.19 | 54/11.03 |

| 1800 | 31/7.84 | 27/7.64 | 23/7.40 | 20/7.29 | |||||

| B757-200 | 1134 | 47.5 | 1.24 | 86.4 | 114.3 | 52/9.54 | 45/9.50 | 38/9.34 | 32/9.03 |

| 570 | 20/6.46 | 18/6.18 | 15/5.80 | 13/5.57 | |||||

| B767-200 | 1410 | 47.5 | 1.31 | 114.3 | 142.2 | 56/9.83 | 48/9.74 | 41/9.55 | 34/9.32 |

| 800 | 26/7.28 | 22/7.05 | 19/6.79 | 18/6.71 | |||||

| B777-200 LR |

3345 | 46.9 | 1.50 | 139.7 | 144.8 | 129/12.47 | 107/12.28 | 84/12.01 | 64/11.66 |

| 1424 | Six Wheel Gear | 36/8.33 | 29/7.91 | 24/7.55 | 24/7.50 | ||||

| B777-300 | 2945 | 47.4 | 1.48 | 139.7 | 144.8 | 108/11.90 | 89/11.70 | 69/11.38 | 54/11.00 |

| 1562 | Six Wheel Gear | 42/8.84 | 33/8.43 | 27/8.04 | 20/7.92 | ||||

| Convair 990 | 1135 | 48.5 | 1.28 | 61.0 | 118.0 | 60/10.02 | 54/10.09 | 47/10.07 | 40/9.89 |

| 600 | 26/7.21 | 23/7.04 | 19/6.74 | 17/6.44 | |||||

| Dassault Falcon 900 |

202 | 47.5 | 1.30 | 42.0 | ---- | 15/5.48 | 15/5.55 | 14/5.58 | 14/5.69 |

| 103 | 7/---- | 7/---- | 7/---- | 6/---- | |||||

| DC-3 | 147 | 46.8 | 0.31 | ---- | ---- | 9/4.05 | 9/---- | 8/---- | 8/---- |

| 80 | 5/---- | 5/---- | 5/---- | 4/---- | |||||

| DC-4 | 335 | 46.8 | 0.53 | 74.0 | ---- | 19/6.08 | 17/6.01 | 16/5.84 | 14/5.65 |

| 200 | 10/4.24 | 9/4.03 | 8/---- | 7/---- | |||||

| DC-6 | 480 | 44.0 | 0.73 | 78.0 | ---- | 27/7.39 | 26/7.47 | 24/7.48 | 22/7.42 |

| 300 | 16/5.62 | 15/5.57 | 14/5.42 | 12/5.33 | |||||

| DC-7 | 640 | 47.5 | 0.89 | 76.2 | ---- | 44/8.96 | 42/9.17 | 40/9.35 | 37/9.44 |

| 400 | 26/7.16 | 24/7.25 | 23/7.29 | 21/7.28 | |||||

| DC-8-62 | 1593 | 47.5 | 1.35 | 81.3 | 139.7 | 77/10.84 | 69/10.89 | 59/10.86 | 50/10.69 |

| 800 | 31/7.81 | 27/7.63 | 23/7.36 | 20/7.14 | |||||

| DC-9-21 | 445 | 47.5 | 1.02 | 61.0 | ---- | 32/7.91 | 31/8.10 | 29/8.27 | 28/8.37 |

| 300 | 20/6.41 | 19/6.49 | 18/6.53 | 17/6.56 | |||||

| DC-10-10 | 2037 | 47.5 | 1.34 | 137.2 | 162.6 | 80/10.99 | 69/10.92 | 58/10.80 | 49/10.67 |

| 1035 | 32/7.99 | 28/7.80 | 24/7.65 | 23/7.67 | |||||

| DC-10-30 | 2593 | 39 | 1.22 | 137.2 | 162.6 | 84/11.12 | 72/11.04 | 59/10.89 | 50/10.71 |

| 1220 | 30/7.77 | 26/7.55 | 23/7.37 | 21/7.39 | |||||

| DHC7 Dash 7 |

209 | 46.8 | 0.74 | 42.0 | ---- | 14/5.23 | 14/5.23 | 13/5.16 | 12/5.17 |

| 120 | 8/---- | 7/---- | 7/---- | 6/---- | |||||

| Dornier 328 Jet |

155 | 46.4 | 1.13 | 41.0 | ---- | 11/4.43 | 10/4.39 | 10/---- | 10/---- |

| 93 | 6/---- | 6/---- | 6/---- | 5/---- | |||||

| Fokker F27 Friendship |

205 | 47.5 | 0.57 | 45.0 | ---- | 13/4.98 | 13/4.92 | 12/4.77 | 11/---- |

| 120 | 7/---- | 7/---- | 6/---- | 6/---- | |||||

| Fokker F28 Fellowship |

325 | 47.5 | 0.53 | 55.0 | ---- | 21/6.38 | 20/6.39 | 18/6.32 | 16/6.21 |

| 175 | 10/4.18 | 9/---- | 9/---- | 8/---- | |||||

| Gulfstream G159 |

156 | 47.5 | 0.83 | 42.0 | ---- | 11/4.34 | 10/4.27 | 10/---- | 9/---- |

| 100 | 6/---- | 6/---- | 6/---- | 5/---- | |||||

| Gulfstream V |

405 | 47.5 | 1.37 | 46.0 | ---- | 33/8.01 | 32/8.27 | 32/8.53 | 31/8.75 |

| 215 | 16/5.64 | 16/5.72 | 15/5.77 | 14/5.88 | |||||

| HS/BAe 125-600 |

112 | 47.5 | 0.83 | 32.0 | ---- | 8/---- | 8/---- | 7/---- | 7/---- |

| 61 | 4/---- | 4/---- | 4/---- | 3/---- | |||||

| HS/BAe 748 |

227 | 47.5 | 0.51 | 48.0 | ---- | 14/5.20 | 13/5.13 | 12/4.97 | 11/---- |

| 120 | 7/---- | 6/---- | 6/---- | 5/---- | |||||

| L-1011-500 Tristar |

2295 | 47.6 | 1.35 | 132.1 | 177.8 | 93/11.44 | 80/11.39 | 67/11.29 | 56/11.18 |

| 1070 | 33/8.08 | 29/7.90 | 25/7.77 | 24/7.80 | |||||

| MD-11 | 2805 | 39.0 | 1.38 | 137.2 | 162.6 | 96/11.53 | 83/11.49 | 69/11.41 | 58/11.30 |

| 1200 | 30/7.80 | 26/7.61 | 23/7.47 | 22/7.51 | |||||

| Saab 2000 | 226 | 47.5 | 0.69 | 46.0 | ---- | 15/5.42 | 15/5.42 | 14/5.35 | 13/5.32 |

| 136 | 8/---- | 8/---- | 7/---- | 7/---- | |||||

| Shorts 360 | 121 | 47.5 | 0.54 | ---- | ---- | 9/4.06 | 9/4.03 | 9/---- | 9/---- |

| 77 | 6/---- | 6/---- | 6/---- | 6/---- | |||||

Table 8: PLR TO PCN Conversions for Flexible and Rigid Pavements

| Flexible Pavements | ||||

|---|---|---|---|---|

|

Canadian |

ICAOSubgrade Strength Category Code Letter Flexible Pavement Subgrade Strength – S (kN) – Range and Nominal Value |

|||

| A (High) >160 180 |

B (Medium) 160 - 110 130 |

C (Low) 110 - 70 90 |

D (Ultra Low) <70 50 |

|

| Equivalent ICAOPavement Classification Number PCN | ||||

| 2 3 4 5 6 7 8 9 10 11 12 13 |

---- ---- ---- ---- ---- ---- ---- 24 38 53 68 80 |

---- ---- ---- ---- ---- 16 23 32 43 57 72 88 |

---- ---- ---- 12 16 21 29 39 51 66 83 103 |

4 6 9 13 19 27 37 50 64 81 101 124 |

| For Category A: PCN = 100.000 - (46.9401 * PLR) + (6.0420 * PLR2) - (0.1963 * PLR3) For Category B: PCN = 75.0000 - (24.7528 * PLR) + (2.7623 * PLR2) - (0.0603 * PLR3) For Category C: PCN = 15.0000 - (3.7769 * PLR) + (0.5096 * PLR2) + (0.0230 * PLR3) For Category D: PCN = 5.0000 - (1.3799 * PLR) + (0.4657 * PLR2) + (0.0264 * PLR3) |

||||

| Rigid Pavements | ||||

|

Canadian |

ICAO Subgrade Strength Category Code Letter Rigid Pavement Bearing Modulus – k (MPa/m) – Range and Nominal Value |

|||

| A (High) >120 150 |

B (Medium) 120 - 60 80 |

C (Low) 60 - 25 40 |

D (Ultra Low) <25 20 |

|

| Equivalent ICAO Pavement Classification Number PCN | ||||

| 4 5 6 7 8 9 10 11 12 13 |

---- 11 15 19 25 32 42 54 70 91 |

---- 12 16 21 27 35 46 62 82 108 |

8 13 17 22 29 39 53 72 97 130 |

9 14 18 24 32 44 60 82 111 148 |

| For Category A: PCN = - 25.5382 + (13.3710 * PLR) - (1.7555 * PLR2) + (0.1090 * PLR3) For Category B: PCN = - 32.6516 + (17.4785 * PLR) - (2.4529 * PLR2) + (0.1495 * PLR3) For Category C: PCN = - 40.9244 + (21.9479 * PLR) - (3.1986 * PLR2) + (0.1939 * PLR3) For Category D: PCN = - 30.0000 + (17.9684 * PLR) - (2.7926 * PLR2) + (0.1894 * PLR3) |

||||

Table 9: Example PLR to PCN Conversions

Flexible Pavements

Given: A flexible pavement system having a subgrade strength "S" of 60 kN and a pavement equivalent granular thickness "t" of 100 cm (i.e. a strength code of S60t100). The asphalt thickness is 8.5 cm, the base course thickness is 20 cm, and the sub-base course thickness is 63 cm.

Solution: Plot the strength code parameters S = 60 kN and t = 100 cm on Figure 1. The PLR is taken as the value of the standard PLR curve lying immediately above the plotted point – in this case, the PLR is 9. Using Table 2 with an asphalt thickness of 8.5 cm and a base course thickness of 20 cm, the tire pressure restriction is 1.0 MPa. The PLR code is 9 (1.0 MPa).

Using Table 8, the PLR value can be converted to an equivalent PCN value of 50 for a Code D (Ultra Low) strength subgrade. The resulting ICAO PCN code is: 50/F/D/1.0 MPa/T where "F" indicates a flexible pavement system, "D" an Ultra Low strength subgrade and "T" indicates that the code has been derived based on a technical evaluation. It is preferable to state the actual tire pressure limitation in MPa rather than use the ICAO tire pressure code letters except that where there is no tire pressure limit, the code letter "W" should be used.

Rigid Pavements

Given: A rigid pavement system having a bearing modulus strength "k" of 100 MPa/m and a concrete slab thickness "h" of 30 cm (i.e. a strength code of k100h30).

Solution: Plot the strength code parameters k = 100 MPa/m and h = 30 cm on Figure 2. The PLR is taken as the value of the standard PLR curve lying immediately above the plotted point – in this case, the PLR is 11. Tire pressure restrictions need not be applied to rigid pavement systems. The PLR Code is 11.

Using Table 8, the PLR value can be converted to an equivalent PCN value of 62 for a Code B (Medium) strength bearing modulus. The resulting ICAO PCN Code is: 62/R/B/W/T where "R" indicates a rigid pavement system, "B" a Medium strength subgrade, "W" that there is no tire pressure limitation and "T" that the code has been derived based on a technical evaluation.

Gravel Surfaced Pavements

Given: A flexible pavement system having a subgrade strength of "S" = 60 kN and a pavement equivalent granular thickness "t" of 100 cm (i.e. a strength code of S60t100). The surface is of gravel construction and the tire pressure restriction has been assessed to be 0.69 MPa.

Solution: Plot the strength code parameters S = 60 kN and t = 100 cm on Figure 1. The PLR is taken as the value of the standard PLR curve lying immediately above the plotted point – in this case, the PLR is 9. The PLR Code is 9 (0.69 MPa).

The PCN code is determined as described for flexible pavements above except that the gravel surface tire pressure limitation is used. As illustrated in the examples of Table 5, a note should be appended to the PCN code to indicate that the surface is gravel. The ICAO PCN Code is: 50/F/D/0.69 MPa/T Note: Gravel Surface Construction.

APPENDIX B - FIGURES 1 TO 15

Figure 1: Flexible Pavement Design Curves for Standard Gear Loadings

Figure 1 gives the flexible pavement design curves (based on a subgrade overload ratio of 1.00 "S") for the standard gear loadings given in Table 1. The pavement equivalent granular thickness (cm) is plotted as a function of the subgrade bearing strength (kN), for each of the 13 standard gear loadings.

Figure 2: Rigid Pavement Design Curves for Standard Gear Loadings

Figure 2 gives the rigid pavement design curves (based on a slab flexural stress of 2.75 MPa) for the standard gear loadings given in Table 1. The concrete slab thickness required (cm) is plotted as a function of the supporting bearing modulus (MPa/m) beneath the slab, for the standard gear load ratings of 5 to 13.

Figure 3: Flexible Pavement PLR/ ALR

Figure 3 is a plot of the flexible pavement PLR/ ALR versus the pavement equivalent granular thickness (cm), for each of the four standard subgrade bearing strengths (50, 90, 130, and 180 kN). Equations are also given for the curves as follows:

- For S = 180 kN : PLR = 6.7528 + 0.1211t - 8.5861E-04t2 + 3.4311E-06t3

- For S = 130 kN : PLR = 4.6796 + 0.1147t - 5.4262E-04t2 + 1.4249E-06t3

- For S = 90 kN : PLR = 2.4532 + 0.1216t - 5.8324E-04t2 + 1.5627E-06t3

- For S = 50 kN : PLR = 0.0237 + 0.1072t - 3.6233E-04t2 + 6.9438E-07t3

Figure 4: Rigid Pavement PLR/ ALR

Figure 4 is a plot of the rigid pavement PLR/ ALR versus the concrete slab thickness (cm), for each of the four standard bearing modulus values (20, 40, 80 and 150 MPa/m). Equations are also given for the curves as follows:

- For k = 150 MPa/m : PLR = -5.8707 + 0.9452h – 0.0168h2 + 1.2378E-04h3

- For k = 80 MPa/m : PLR = -5.9650 + 0.8983h – 0.0156h2 + 1.0974E-04h3

- For k = 40 MPa/m : PLR = -4.8057 + 0.7460h – 0.0116h2 + 7.3659E-05h3

- For k = 20 MPa/m : PLR = -3.9694 + 0.6393h – 9.1769E-03h2 + 5.5358E-05h3

Figure 5: Rigid Pavement Bearing Modulus (k) on Top of Base

Figure 5 gives the rigid pavement bearing modulus (k) on top of the base. The surface bearing modulus (MPa/m) on top of the base is plotted versus the subgrade bearing strength (kN), as function of the equivalent granular thickness "t" (cm) of the base and subbase. Curves are given for "t" values ranging from 0 to 130 cm, in increments of 10 cm. The following equation for the curves is also given on the chart : k = 0.474 S 10t/165

Figure 6: Equivalent Single Slab Thickness of Overlaid Concrete Slab

Figure 6 gives the equivalent single slab thickness of an overlaid concrete slab. There are 3 charts given as follows: a) for an asphalt overlay, b) for a concrete overlay with a separating course of less than or equal to 15 cm, and c) for a concrete overlay without a separating course.

For chart a), the equivalent slab thickness is determined by starting with the existing slab thickness, proceeding down to the appropriate curve for the asphalt overlay thickness (curves given for 5, 10, 15, 20 and 25 cm), then proceeding across to the appropriate curve for the bearing modulus (curves given for 30, 50, 70 and 90 MPa/m), and finally proceeding down to the axis for equivalent single slab thickness.

For chart b), the equivalent single slab thickness is determined by starting with the existing slab thickness, proceeding down to the appropriate curve for existing slab condition (curves given for "existing slab in good condition" and "existing slab some cracking"), then proceeding across to the curve for overlay slab thickness (curves gives for 10, 15, 20, 25, 30, 35 and 40 cm), and finally proceeding down to the axis for equivalent single slab thickness.

For chart c), the equivalent single slab thickness is determined by starting with the existing slab thickness, proceeding down to the appropriate curve for existing slab condition (curves given for "existing slab in good condition" and "existing slab some cracking"), then proceeding across to the curve for overlay slab thickness (curves gives for 10, 15, 20, 25, 30, 35 and 40 cm), and finally proceeding down to the axis for equivalent single slab thickness.

Figure 7: ACN/ PCN vs ALR/ PLR for Flexible Pavements (S = 50 kN)

Figure 7 is a graph of the relationship between classification numbers and load ratings for flexible pavements with a subgrade bearing strength of 50 kN. ACN values are plotted against the corresponding ALR values for the 46 aircraft listed in Table 6. The following equation is given for the curve:

PCN = 5.000 - (1.3799 * PLR) + (0.4657 * PLR2) + (0.0264 * PLR3)

Figure 8: ACN/ PCN vs ALR/ PLR for Flexible Pavements (S = 90 kN)

Figure 8 is a graph of the relationship between classification numbers and load ratings for flexible pavements with a subgrade bearing strength of 90 kN. ACN values are plotted against the corresponding ALR values for the 46 aircraft listed in Table 6. The following equation is given for the curve:

PCN = 15.000 - (3.7769 * PLR) + (0.5096 * PLR2) + (0.0230 * PLR3)

Figure 9: ACN/ PCN for Flexible Pavements (S = 130 kN)

Figure 9 is a graph of the relationship between classification numbers and load ratings for flexible pavements with a subgrade bearing strength of 130 kN. ACN values are plotted against the corresponding ALR values for the 46 aircraft listed in Table 6. The following equation is given for the curve:

PCN = 75.000 - (24.7528 * PLR) + (2.7623 * PLR2) - (0.0603 * PLR3)

Figure 10: ACN/ PCN vs ALR/ PLR for Flexible Pavements (S = 180 kN)

Figure 10 is a graph of the relationship between classification numbers and load ratings for flexible pavements with a subgrade bearing strength of 180 kN. ACN values are plotted against the corresponding ALR values for the 46 aircraft listed in Table 6. The following equation is given for the curve:

PCN = 100.000 - (46.9401 * PLR) + (6.0420 * PLR2) - (0.1963 * PLR3)

Figure 11: ACN/ PCN vs ALR/ PLR for Rigid Pavements ( k = 20 MPa/m)

Figure 11 is a graph of the relationship between classification numbers and load ratings for rigid pavements with a bearing modulus of 20 MPa/m. ACN values are plotted against the corresponding ALR values for the 46 aircraft listed in Table 6. The following equation is given for the curve:

PCN = -30.000 + (17.9684 * PLR) - (2.7926 * PLR2) + (0.1894 * PLR3)

Figure 12: ACN/ PCN vs ALR/ PLR for Rigid Pavements (k = 40 MPa/m)

Figure 12 is a graph of the relationship between classification numbers and load ratings for rigid pavements with a bearing modulus of 40 MPa/m. ACN values are plotted against the corresponding ALR values for the 46 aircraft listed in Table 6. The following equation is given for the curve:

PCN = -40.9244 + (21.9479 * PLR) - (3.1986 * PLR2) + (0.1939 * PLR3)

Figure 13: ACN/ PCN vs ALR/ PLR for Rigid Pavements (k = 80 MPa/m)

Figure 13 is a graph of the relationship between classification numbers and load ratings for rigid pavements with a bearing modulus of 80 MPa/m. ACN values are plotted against the corresponding ALR values for the 46 aircraft listed in Table 6. The following equation is given for the curve:

PCN = -32.6516 + (17.4785 * PLR) – (2.4529 * PLR2) + (0.1495 * PLR3)

Figure 14: ACN/ PCN vs ALR/ PLR for Rigid Pavements (k = 150 MPa/m)

Figure 14 is a graph of the relationship between classification numbers and load ratings for rigid pavements with a bearing modulus of 150 MPa/m. ACN values are plotted against the corresponding ALR values for the 46 aircraft listed in Table 6. The following equation is given for the curve:

PCN = -25.5382 + (13.3710 * PLR) - (1.7555 * PLR2) + (0.1090 * PLR3)

Figure 15: Airport Pavement Load Rating Chart