AV 2010-04

April 20 2010

Purpose:

The purpose of this advisory is to inform the aviation community of the importance for the correct stowage of engine core cowl stay support strut/rods for all Bombardier Regional Jet Series (CL-600-2B19) and Challenger 600 (CL-600-2A12/2B16) aircraft with CF34-1 & CF34-3 engines.

Background:

Transport Canada Civil Aviation (TCCA), has been made aware of several cases where the upper core cowl door stay support strut/rod was not in its correctly stowed position, resulting in in-flight engine shutdowns.

In one occurrence after the aircraft was parked with the left engine throttle jammed at high power, the flight crew lost control of the aircraft, travelling about 220 meters before striking a building.

Bombardier has determined that, for a CF34-1 & CF34-3 engine installed in the left position, an unstowed upper core cowl door stay support strut/rod can interfere with the throttle control mechanism.

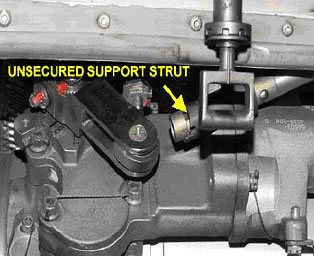

An important step prior to the closure of all engine core cowls is to ensure the correct stowage of the stay support strut/rod. If done incorrectly, the scenario as seen in figures 1 & 2 may occur, where the strut/rod can fall into the rotational path of the main fuel control unit (MFC) link lever:

Even though the following figures represent aircraft post Service Bulletin (SB) CF34-NAC-71-013C and pre SB CF34-NAC-71-045A / -054, the possibility for a core cowl support strut/rod jam exists for any configuration.

Figure 1. Fuel Control Link lever at 100% N1 Position

When the engine throttles are retarded towards the idle position, the MFC link lever can contact the support strut/rod and create a jam condition as seen below in figure 2.

Figure 2. Fuel Control Link lever at 93% N1 Position

In this condition the engine RPM cannot be controlled or reduced below 93% N1 and can only be shutdown by the operation of the applicable ENG FIRE PUSH switch.

Recommended Action:

It is essential that all defined procedures found in Aircraft Maintenance Manual (AMM) 71-12-01-410-802, Temporary Revision (TR) 71-137 are followed, ensuring that:

- The primary lock has properly engaged its clip pin on the core cowl door as seen in figure 3;

Figure 3. Primary Lock Correctly Engaged - The stay support strut/rod secondary lock pin is correctly oriented as seen in figure 4;

Figure 4. Secondary Lock Pin Correctly Installed as seen when the core cowl is in the open position

Note that the secondary lock pin will be inversed (pin pointing up) as seen in figure 4 when the core cowl is open, as normally seen during maintenance activities but will be positioned (pin pointing down), with the core cowl in the closed position. The AMM has been corrected, which was in error prior to TR 71-137, to stipulate this important pin configuration.

Defects, malfunctions and failures occurring on aeronautical products are to be reported to Transport Canada, Continuing Airworthiness in accordance with CAR 521 mandatory Service Difficulty Reporting requirements.

For further information, contact a Transport Canada Centre, or Gary Voght, Continuing Airworthiness, Ottawa at 613-952-4357, facsimile 613-996-9178, or email CAWWEBFeedback@tc.gc.ca

For Director, National Aircraft Certification

ORIGINAL SIGNED BY

Derek Ferguson

Chief, Continuing Airworthiness

Note: For the electronic version of this document, please consult the following Web address: https://tc.canada.ca/en/aviation/aircraft-airworthiness/aircraft-certification