AV 2009-05

30 September 2009

Purpose: The purpose of this Advisory is to inform the aviation community of the importance of properly inspecting and maintaining aircraft flush-mounted fuel caps.

Background: The Canadian Transportation Safety Board (TSB) Aviation Safety Information Letter A08W0197-D1-L1, identifies a lack of specific original equipment manufacturer (OEM) inspection and maintenance guidelines for flush-mounted fuel caps.

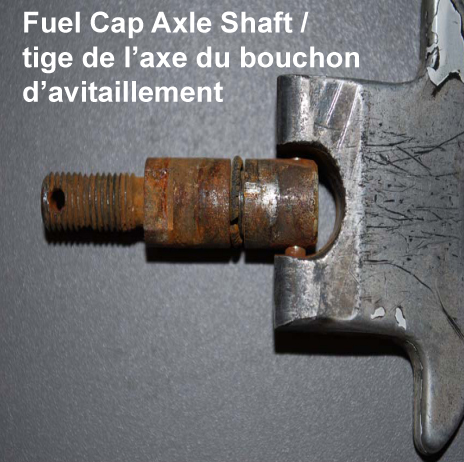

Fuel caps from an accident aircraft were tested to simulate the fuel pressure within an aircraft fuel tank. No leakage is considered permissible. The fuel caps leaked by the axle and handle assembly with a minimum pressure of 0.5 psi. Following disassembly and inspection, O-rings on the axle shaft were found cracked and broken. The corrosion on the axle shafts indicated long-term exposure to moisture. (see attached photo).

An important part of the aircraft preflight inspection is to drain fuel tank sumps, reservoirs, gascolators, filters, and other fuel system drains to assure the fuel supply is free of water. If water were to be detected, a deteriorated fuel cap would be a prime suspect. It is also important to verify that the fuel cap is properly seated, that it is properly sealed, and that any deteriorated parts are replaced. Excessive water should be brought to the attention of the maintainer, who in turn will investigate the source.

Some aircraft manufacturers, such as Cessna, have developed detailed guidelines for inspection and maintenance of flush mounted fuel caps (Service Information Letters SE80-59 and SE82-34). Some fuel cap OEMs consider the fuel caps to be a return item if repair, including O-ring replacement, or overhaul is required.

The Federal Aviation Administration’s (FAA) Advisory Circular AC 43.13-1B, titled Acceptable Methods, Techniques and Practices – Aircraft Inspection and Repair, is a primary maintenance reference to be used when the OEM does not supply repair or maintenance instructions. The AC simply states that fuel cap O-rings are to be inspected to determine that they are in good condition.

FAA Advisory Circular AC 20-125 (AC) is also a good source of information regarding water contamination in aviation gasoline and jet fuel. The AC references 114 aircraft accidents due to the infiltration of water in the fuel supply. The probable cause in 85 of those accidents was due to inadequate preflight checks.

Comments: Transport Canada Civil Aviation (TCCA) has researched the Service Difficulty Report (SDR) data to validate fuel cap reported discrepancies. The 275 SDRs that were retrieved indicated lack of inspection and maintenance as a theme.

Owners, operators, maintainers and other responsible persons should review maintenance related information provided by the respective aircraft manufacturer and OEM. Where maintenance instructions are lacking or not provided:

- inspect the condition of the fuel cap gaskets, seals and O-rings to ensure they are in place and not damaged;

- inspect seal surfaces to ensure they are smooth; and

- inspect locking mechanism to ensure it is properly adjusted.

Any discrepancies which may compromise the fuel cap sealing and locking functions should be resolved before returning the aircraft to service.

Defects, malfunctions and failures occurring on aeronautical products are to be reported to Transport Canada, Continuing Airworthiness in accordance with CAR 591 mandatory Service Difficulty Reporting requirements.

For further information, contact a Transport Canada Center, or Mr. Marcel Gauthier, Continuing Airworthiness, Ottawa at 613-952-4357, facsimile 613-996-9178, or email cawwebfeedback@tc.gc.ca

For Director, National Aircraft Certification

Derek Ferguson

Chief, Continuing Airworthiness