Last amendment to standard: 2021/11/02

Table of contents

- Chapter 1 - Introduction

- Chapter 2 - General

- Chapter 3 - Marking and Markers, General (effective 2016/03/01)

- Chapter 4 - Lighting, General

- Chapter 5 - Red Obstruction Lighting System, Configuration "A"

- Chapter 6 - Medium Intensity White System, Configuration "D" (effective 2016/03/01)

- Chapter 7 - High Intensity White System, Configuration "B" and "C" (effective 2016/03/01)

- Chapter 8 - Dual Red/White Medium Intensity System, Configuration "E" (effective 2016/03/01)

- Chapter 9 - Dual Red/White High Intensity System, Configuration "F" (effective 2016/03/01)

- Chapter 10 - Marking and Lighting of Catenaries

- Chapter 11 - Marking and Lighting of Tethered Objects (effective 2016/03/01)

- Chapter 12 - Marking and Lighting of Wind turbines and Wind farms (effective 2016/03/01)

- Chapter 13 - Obstruction Lighting Characteristics

- Chapter 14 - Maintenance

- Chapter 15 - Aircraft Detection System (ADS)

- Chapter 16 - Light Intensity Reduction (LIR) System (effective 2021/08/06)

- Appendix A - Contact Information

- Appendix B - Specification for Obstruction Lighting Equipment

- Appendix C - Aeronautical Assessment Form for Obstruction Marking and Lighting

Amendment Foreword

- 1. Purpose. The purpose of this publication is to provide standards for marking and lighting of objects that present a hazard to the safe operation of aircraft.

- 2. Effective date. The requirements of this edition are effective 30 days after the date of publication.

- 3. Cancellation. Standard 621, Obstruction Marking and Lighting, 1st Edition, dated 31 December 2011 is cancelled by this publication.

- 4. Standards changes and existing facilities. Unless otherwise directed by the Minister, existing installations of marking and/or lighting do not need to be upgraded if installed prior to the effective date of this 2nd edition, with the exception of installations as indicated in section 601.26 of the Canadian Aviation Regulations (CARs) for which there is an external change [e.g. removal of a shielding object or air traffic pattern].

- 5. Application. In accordance with section 601.24 of the CARs, persons having responsibility for or control over a building or object that constitutes an obstacle to air navigation shall either mark and light the building, structure or object in accordance with the requirements of Standard 621, or use equivalent marking and lighting approved by the Minister.

List of figures

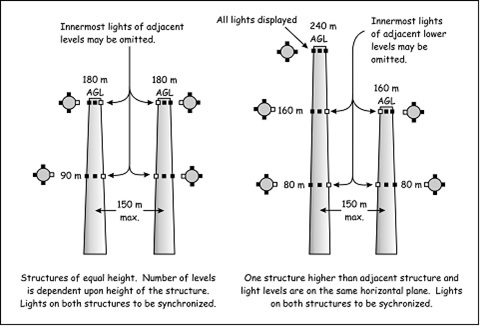

- Figure 2-1: Adjacent Structures

- Figure 2-2: Shielding of Cable Spans

- Figure 3-1: Day Marking - Checkerboard Pattern

- Figure 3-2: Day Marking - Banded Pattern

- Figure 3-3: Storage Tank Marking

- Figure 4-1: Configurations of Lighting on Skeletal Structures

- Figure 4-2: Methods of Monitoring

- Figure 5-1: Configuration A: Red Lighting Installation

- Figure 5-2: CL-810 and CL-864 Lights on Towers

- Figure 5-3: Alternative Configuration A' - Lighting Reduction to Reduce Bird Fatalities

- Figure 5-4: Prominent Buildings Lighting

- Figure 5-5: Bridge Lighting

- Figure 5-6: Groups of Objects

- Figure 6-1: Configuration "D": Medium Intensity White Flashing Lighting System

- Figure 7-1: Adjacent Building

- Figure 7-2: Lighting Adjacent Structures

- Figure 7-3: Lighting Adjacent Structures

- Figure 7-4: Configuration "B" and "C": High Intensity White Flashing System

- Figure 7-5: Hyperbolic Cooling Tower

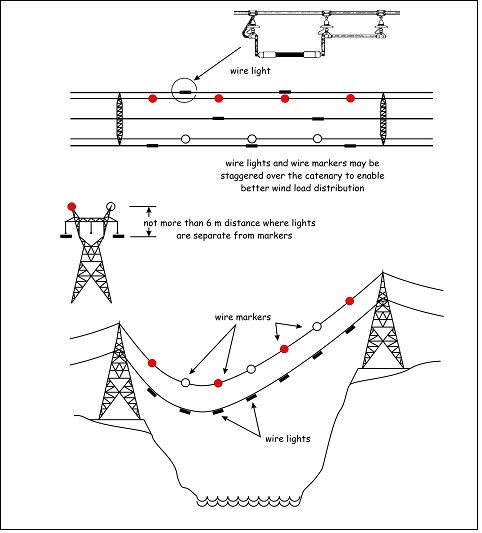

- Figure 10-1: Catenary Markers

- Figure 10-2: Catenary Wire Lights

- Figure 10-3: Catenary Flashing Lights

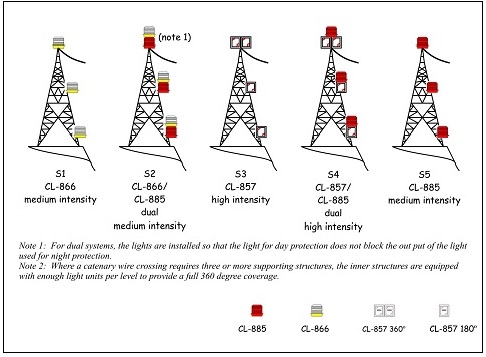

- Figure 10-4: Catenary Configurations

- Figure 10-5: Catenary Flashing Lights with ADS

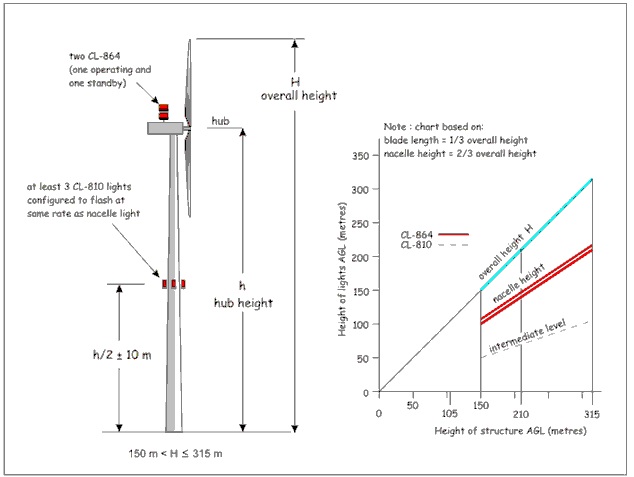

- Figure 12-1: Lighting Wind turbines; Heights up to 150 m AGL

- Figure 12-2: Lighting Wind turbines; Heights 150 m to 315 m

- Figure 12-3: MET Tower Marking

- Figure 13-1: Photocell Settings

- Figure 13-2: Low Intensity Photometric Requirement

- Figure 13-3: High and Medium Intensity Flashing Photometric Requirement

- Figure 14-1: In-service Aviation Orange Colour Tolerance Chart

- Figure 15-1: Catenary Crossing - Plan View

- Figure 15-2: Catenary Crossing - Profile View

- Figure 15-3: Potential Turning/Descent Manoeuvres

Chapter 1 Introduction

1.1 Definitions

In this Standard:

"appurtenance" - (Note: this term is defined as "projection" in the CARs) means that part of any vertical mast, pole or other appendage added to a building, structure or object that protrudes above the top of the building, structure or object; (accessoire)

"aviation colours" - for lighting, the colours as defined in the ICAO Annex 14; (couleurs)

"beam spread" - means the angle between the two directions in the vertical or horizontal plane in which the intensity is equal to 50 percent of the minimum specified peak beam effective intensity; (angle d'ouverture du faisceau)

"catenary" - means the curved span of overhead wires hung freely between two supporting structures, normally with regard to exceptionally long elevated spans over canyons, rivers and deep valleys; (caténaire)

"effective intensity" - means the effective intensity of a flashing light is equal to the intensity of a steady-burning (fixed) light of the same colour which produces the same visual range under identical conditions of observation; (intensité efficace).

"fixed light" - means a light having constant luminous intensity when observed from a fixed point; (feu fixe)

"lighting" - means any light displayed on an obstruction as a means of indicating the presence of the obstruction to pilots; (éclairage)

"lighting terms" - (unités photométriques)

- (a) Lumen - International System unit of luminous flux equal to the amount of light given out through a solid angle of 1 steradian by a point source of 1 candela intensity radiating uniformly in all directions. The unit expresses the quantity of light output per second. (lumen)

- (b) Candela - International System unit of luminous intensity of light emitted from a light source; equal to 1/60 of the luminous intensity per square centimetre of a blackbody radiating at the temperature of solidification of platinum (2,046° degrees Kelvin). A luminous intensity of one candela is one lumen per steradian (solid angle). The unit expresses the intensity of light within an incremental segment of the beam. (candela)

(effective 2016/03/01) - (c) Lux - International System unit of illumination, equal to one lumen per square metre (lm/m2). The unit expresses the amount of light falling on the surface area. (lux)

"marker" - means an object displayed on an obstruction during daytime as a means of indicating the presence of relatively invisible obstructions such as power lines; (balise)

"marking" - means a symbol, group of symbols, or markers that are displayed on the surface of an obstruction and intended to reduce hazards to aircraft by indicating the presence of the obstruction by day; (balisage)

"meteorological visibility" - means the greatest distance, expressed in statute miles, that selected objects (visibility markers) or lights of moderate intensity at night (25 candela) can be seen and identified under specific conditions of observation; (visibilité météorologique)

"painting" - means a marking applied to the surface of an obstruction and intended to identify the presence of the obstruction by day; (marque de peinture)

"vertical aiming angle" - means the angle formed between the horizontal and a line through the centre of the vertical beam spread. (calage en site)

"wind turbine" means a structure intended for the production of electrical power; comprising a support mast on which is installed a nacelle containing a generator unit and which supports rotor blades that are caused to rotate by the wind. The total height of the obstruction is the height of the nacelle, above ground level (AGL), plus the length of one of the blades held in a vertical position.(éolienne)

"wind farm" means a grouping of 3 or more wind turbines. (parc d'éoliennes)

"wind farm indicators" means light units installed with specified spacing on selected wind turbines and serving to indicate the location of a wind farm to pilots. (indicateurs de parc d'éoliennes)

1.2 Abbreviations and Symbols Used in this Standard

(effective 2016/03/01)

- AGL

- Above Ground Level

- cd

- candela (light intensity)

- km/h

- kilometres per hour

- m

- metre

- kt

- knot

- FAA

- Federal Aviation Administration

- cm

- centimetre

- ft

- foot

- ICAO

- International Civil Aviation Organization

- max

- maximum

- min

- minimum

- ADS

- Aircraft Detection System

- FIC

- Flight Information Centre

- < x

- less than x

- > x

- more than x

- ≥ x

- equal to or more than x

- ≤ x

- equal to or less than x

Chapter 2 - General

2.1 Purpose of Marking and Lighting Requirements

Information note 1:

The application of the marking and lighting requirements specified in this Standard and the approval of equivalent requirements is to ensure that an obstruction to air navigation remains visible at a range sufficient to permit a pilot in VMC conditions to take appropriate action in order to avoid the obstruction, by not less than 300 m vertically within a horizontal radius of 600 m from the obstruction. The purpose of obstruction marking and lighting standards is to provide an effective means of indicating the presence of objects likely to present a hazard to aviation safety. Equivalent lighting and marking requirements may be approved depending on terrain features, weather patterns, geographic location, and in the case of wind turbines, depending on the number of structures and overall layout of design.

(effective 2016/03/01)

Information note 2:

Guyed Structures. The guys of a 610 m [2000 foot] skeletal tower are anchored from 490 m (1600 feet) to 610 m (2000 feet) from the base of the structure. This places a portion of the guys 460 m (1500 feet) from the tower at a height of between 38 m (125 feet) to 150 m (500 feet) AGL. It is expected that pilots, when operating over other than congested areas, remain at least 150 m (500 feet) from manmade structures. Therefore, the tower must be cleared by 150 + 460 = 610 m (2000 feet) horizontally to avoid all guy wires. Properly maintained marking and lighting are important for increased conspicuity since the guys of a structure are difficult to see until aircraft are dangerously close.

(effective 2016/03/01)

Information note 3:

Intensity Requirements. An aircraft travelling at 250 knots (463 km/hr) requires 1.48 statute miles (2.4 km) to avoid an object horizontally by 610 m (2000 feet) once the pilot sees the obstruction light, recognizes the light as marking an obstruction, initiates evasive action and allowing for aircraft lag. An aircraft travelling at 165 knots (306 km/hr) requires 1.18 statute miles (1.9 km) to avoid an obstruction by 610 m horizontally.

(effective 2016/03/01)

Information note 4:

Conclusion. Aircraft travelling at 165 knots (306 km/hr) or less should be able to see the obstruction lighting in sufficient time to avoid the structure by at least 610 m horizontally under all conditions of operation, provided the pilot is operating in accordance with the Canadian Aviation Regulations (CARs). Aircraft travelling between 165 knots (306 km/hr) and 250 knots (463 km/hr) should be able to see the obstruction lighting unless the weather deteriorates to 1 statute mile (1.6 km) visibility at night during which time period 20,000 cd would be required to see the lights at 1.5 statute miles (2.4 km). This intensity of 20,000 cd if operated in 3 statute mile (4.8 km) visibility could generate a residential annoyance factor. In addition, aircraft in these speed ranges can normally be expected to operate under instrument flight rules (IFR) at night when the visibility is 1 statute mile (1.6 km).

(effective 2016/03/01)

2.2 Shielding

- (1) The principle of shielding is applied in a way that a dominant permanent building, structure or object which is marked or lighted, or both, obviates the need for marking or lighting other buildings, structures or objects in the immediate surrounding area, which might otherwise be treated as individual obstructions.

- (2) More specifically, the principle of shielding is applied if the marking or lighting, or both, of a dominant permanent building, structure or object is assessed by the Transport Canada regional office as providing sufficient warning to aircraft that, in avoiding the dominant obstruction, they will also avoid the unmarked or unlighted obstructions in the immediate surrounding area without risk of collision.

- (3) Where two similar objects of equal height are situated adjacent to each other, as shown in Figure 2-1, one of the two objects may be considered as shielded, provided the separations listed in Table 2-1 are not exceeded.

(effective 2016/03/01)Table 2-1: Separation between Shielded Objects

(effective 2016/03/01)Height of Objects AGL (metres) Maximum Separation (metres) 30 < x ≤ 75

15

75 < x ≤ 120

23

120 < x ≤ 200

30

200 < x ≤ 290

45

290 < x

60

- (4) A narrow obstruction may be considered as shielded when it is situated with respect to a large obstruction so that an aircraft, whose flight path would avoid the large obstruction would, as a result, also avoid the narrow one.

Figure 2-1: Adjacent Structures

(effective 2016/03/01)Text version – Figure 2-1: Adjacent Structures

Figure 2-1 has two schematics illustrating how an unmarked object can be shielded by an adjacent marked object.

The first schematic, on the left side, shows dis-similar objects of is a chimney next to a water tower. The second schematic, on the right side, shows similar objects of a chimney next to another chimney.

In each schematic, the objects are essentially of the same height and one of the objects is marked and this shields the adjacent object which does not thereby need marking.

The application of shielding is shown as limited to a maximum distance as given in Table 2-2. If the objects are separated by more than this distance, shielding is not possible and both objects would need to be marked.

- (5) Adjacent Catenaries

- (a) A catenary across a recognized VFR route does not require marking or lighting where it is shielded by a higher catenary.

(effective 2016/03/01) - (b) A catenary segment may be considered as shielded when it is situated within 300 m of the marked catenary of the dominant obstruction so that it remains below a sloping down surface at a gradient of 5% projected from the marked catenary as shown in Figure 2-2.

(effective 2016/03/01) - (c) If the second catenary is above the gradient, this span may not be considered as shielded and is marked or lighted, or both, in accordance with this Standard.

Figure 2-2: Shielding of Cable Spans

(effective 2016/03/01)Text version – Figure 2-2: Shielding of Cable Spans

The Figure 2-2 has two schematics illustrating how shielding can be applied to cable spans, as for example, adjacent spans which cross a river.

The top schematic shows a three dimensional view of two spans crossing a river, one of which has marker balls on the counterpoise wires. The shielded span does not have marker balls, because it is shielded by the marked span.

The bottom schematic has dimensions and shows an end view of the transmission line support towers and indicates that shielding is possible when the unmarked span is within a horizontal distance of 300 m from the nearest counterpoise of the marked span and of a height less than an inclined surface of 5 percent which originates from the height of the nearest counterpoise wire of the marked span [the marked span is shown with two counterpoise wires].

The bottom schematic also shows a third span, as a transmission tower in light grey, which may be located between the marked span and the shielded span. As long as this third span is within the 300 m distance and below the 5 percent incline, it also is shielded and does not need marking.

- (a) A catenary across a recognized VFR route does not require marking or lighting where it is shielded by a higher catenary.

- (6) Complex Objects

- (a) Where it is not possible to apply a uniform standard to a cluster of objects such as industrial plants, oil refineries, thermal generating stations, and similar structures, they shall be assessed by the Transport Canada regional office on an individual basis to determine whether or not to treat them as hazards to aviation safety or as an extended obstruction, taking into account the objects' location and height.

- (b) When treated as an extended obstruction, sufficient marking or lighting, or both, are provided to ensure that the extent of the cluster is defined and visual warning is provided from any angle of aircraft approach.

2.3 Lighting Equipment

-

(1) Conformance

Information note:

As a basis of ensuring procurement of equipment meets the requirements of this Standard, the person having responsibility or control over the obstruction should obtain an attestation of conformance through an established 3rd Party testing laboratory meeting ISO/ IEC Guide 17025, "General Requirements for the Competence of Testing and Testing Laboratories."

(effective 2016/03/01). - (2) Combined Light Units

Information note:

The requirements specified in this Standard are written with respect to the performance of obstruction lighting, without consideration of how they are actually designed. Manufacturers may supply light sources contained within a single fitting. For example, a combined CL-864 red flashing beacon with a CL-865 white flashing light, as may be used for a dual medium intensity, configuration "E" installation.

2.4 Environmental Evaluation

Information note:

The person having responsibility or control over an obstruction may be required to file an environmental evaluation with the appropriate authority having jurisdiction when seeking authorization for the use of the high intensity flashing white lighting system on structures located in residential neighbourhoods.

(effective 2016/03/01)

2.5 Notification Responsibilities

(effective 2016/03/01)

- (1) A person planning to erect or modify an obstruction, namely a building, structure or object, including a moored balloon or kite, either permanently or temporarily, contacts the appropriate regional Transport Canada Civil Aviation office, as specified in Appendix A , at least 90 days prior to erection and provide the information on the planned obstruction, using the Aeronautical assessment form for obstruction marking and lighting as shown in Appendix C.

- (2) If it appears that planned construction might create an obstruction to air navigation in the vicinity of a Department of National Defence (DND) aerodrome, the person having responsibility or control over the construction advises the appropriate DND authorities.

Information note:

Aerial cables over navigable waters: Persons planning to construct and/or place a work, including an aerial cable and any structures supporting the cable, should consider the requirements under the Navigation Protection Act (NPA). Under the NPA, all proposed works (including aerial cables) in, on, over, through, across, or under navigable waters listed in the NPA Schedule, may be subject to review and authorization by Transport Canada (TC) Navigation Protection Program (NPP) officials. Therefore, proponents of proposed works over scheduled waters need to contact their local TC NPP office for more information on the process for the review and authorization. It should be noted that the NPA also includes a Minor Works Order. Should the proposed work in a scheduled waterway meet the criteria listed in the Order, the work may proceed without authorization under the Act.

-

(3) Any person planning to erect an object also provides information to NAVCANADA, using the "Land Use Proposal Submission Form" (« Projet d'utilisation particulière d'un terrain ») which is available from the appropriate Transport Canada regional office. (See Appendix A)

Information note:

Where possible, for objects such as broadcast antennae and wind farms, a sign identifying the owner of the object and providing contact information should be installed at the entrance gate or any other place as appropriate.

2.6 Correction of Lighting Failure

(effective 2016/03/01)

Conspicuity of the obstacle is achieved only when all required marking and lighting is working. Partial equipment failures decrease the margin of safety. Any outage is corrected as soon as possible. Failure of a steady burning side or intermediate light is corrected as soon as possible, but notification is not required.

2.7 Light Failure Notification

(effective 2016/03/01)

Failure or malfunction of lighting is reported immediately to the appropriate Flight Information Centre (FIC) so that a NOTAM can be issued. Failure of a steady burning CL-810 light is corrected as soon as possible, but notification is not required. Toll-free numbers for FICs are listed in Appendix A. The report should contain the following information:

- (a) name of persons or organizations reporting the light failure including any title, address, and telephone number;

- (b) the type of structure;

- (c) location of structure (including latitude and longitude, if known, prominent structures, landmarks, etc.);

- (d) height of structure above ground level (AGL)/above mean sea level (AMSL), if known;

- (e) an estimated return to service date.

Information note 1:

When the primary lamp in a double CL-810 obstruction light fails, and the secondary lamp comes on, no report is required. However, when one of the lamps in the incandescent CL-864 flashing red beacon fails, it should be reported, as both lamps must be operating to provide the required photometrics.

Information note 2:

The sponsor is responsible for calling the nearest FIC to extend the outage date duration or to report a return to service date.

2.8 Object Height Tolerance

(effective 2016/03/01)

Object height values contained in this Standard have a tolerance of [0, + 2%].

Information note:

The purpose of the tolerance is to enable a transition from FAA height criteria.

Chapter 3 Marking and Markers, General

(effective 2016/03/01)

3.1 Scope

Chapter 3 governs marking requirements for obstructions to air navigation in order to make them conspicuous to pilots during daylight.

3.2 Paint Standards

Where alternate sections of aviation orange and white, referred herein as "orange" and "white" paint markings, are required under this Standard to be displayed on a building, structure or object, the colours of paint markings shall be in accordance with United States Federal Standard FED- STD-595B, for colours identified as:

- (a) orange, 12197; and

- (b) white, 17875.

3.3 Surfaces Not Requiring Paint

- (1) Except as otherwise provided for in Chapter 3, ladders, decks, and walkways of steel towers and similar structures are not to be painted, if a painted surface presents a potential hazard to maintenance personnel.

- (2) Subject to subsection (3), paint may be omitted from precision or critical surfaces, if it would have an adverse effect on the transmission or radiation characteristics of a signal.

- (3) Where markings are omitted under subsection (1) or (2), the overall marking effect of the structure shall not be reduced to the point of compromising the visibility criteria of section 2.1.

3.4 Use of Plastic Wrapping

In the case of poles, where the use of paint is impractical, a wrapping of plastic or other weather resistant material, in the required colours and dimensions, may be applied instead of painting provided that the colour of the wrapping corresponds as close as possible to that required for a painted marking.

3.5 Paint Patterns

Information note:

The following patterns of painting are dependent upon the size and shape of the structure.

- (1) Solid Pattern

A structure is coloured solid orange, if the structure has both horizontal and vertical dimensions not exceeding 3.2 m.

- (2) Checkerboard Pattern

- (a) Subject to paragraph (c), alternating rectangles of aviation orange and white are displayed on the following types of structure

- (i) storage tanks for water, gas, grain, and similar tanks,

- (ii) buildings,

- (iii) structures that both:

- (A) appear broad from a side view, that are 3.2 m or more across horizontally, and

- (B) have a horizontal dimension that is equal to or greater than the vertical dimension.

- (b) Checkerboard patterns have the following characteristics [refer to Figure 3-1]:

- (i) for structures having horizontal and vertical dimensions, both greater than 3.2 m, the sides of the checkerboard pattern measure not less than 1.5 m nor more than 6 m,

- (ii) for structures having horizontal or vertical dimensions, both less than 4.5 m, the sides of the checkerboard pattern may be less than 1.5 m, but not less than 1 m,

- (iii) the rectangles of the pattern are as nearly square as possible, and

- (iv) corners are coloured orange.

- (c) The following exceptions apply to the marking requirements set out in this subsection:

- (i) storage tanks not suitable for a checkerboard pattern are coloured with alternating bands of aviation orange and white or a limited checkerboard pattern applied to the upper one-third of the structure, and

- (ii) the skeletal framework of certain water, gas, and grain storage tanks may be excluded, as a result of a risk evaluation, from the checkerboard pattern, where the main structure of the storage tank is large enough that its checkerboard pattern adequately suits the purpose of day marking.

Figure 3-1: Day Marking - Checkerboard Pattern

(effective 2016/03/01)Text version – Figure 3-1: Day Marking - Checkerboard Pattern

Figure 3-1 shows a page which is a lined grid whose elements [squares] having a page dimension of one quarter inch representing a world distance of 1 m by 1 m. On this grid is drawn a main sequence of checkerboard paint patterns along the diagonal and which increase in size from a solid pattern to patterns of orange and white squares, in two sets of 3 by 3 and three sets of 5 by 5 for a total of 6 patterns. The normal minimum size of the squares is 1.5 m such that a 3 by 3 pattern would cover 4.5 grid elements on each side. A pattern of 5 by 5 with 1.5 m squares would cover 7.5 m on a side.

The purpose of Figure 3-1 is to illustrate how the number of pattern squares would change with increase of horizontal and vertical dimension. The patterns along the diagonal are symmetrical for horizontal and vertical dimensions. Additional patterns are shown to the left and right of the diagonal to show the effect of changing the horizontal dimension. As one moves away from the diagonal the horizontal dimension is increased for movement to the right or decreased for movement to the left. Movement up the diagonal is for increase in vertical dimension.

A series of six patterns are arranged on the diagonal and increase in size from ...

- (1) less than 3.2 m,

- (2) equal to or greater than 3.2 m,

- (3) less than 4.5 m,

- (4) equal to or greater than 4.5 m,

- (5) less than 7.5 m, and

- (6) equal to 7.5 m.

The figure does not show patterns of more than 7.5 m, because (1) there isn't enough space, and (2) the dimensioning becomes obvious from the treatment of lesser size patterns. A note is made that patterns of more than 7.5 m would can have colour square sizes from 1.5 m to 6 m.

The colour squares of each pattern should not be less than 1.5 m, but where this is not practical because of size of the object itself, the squares are not less than 1 m.

Note that for Figure 3-1, the case of equal to or greater than 4.5 m is actually shown as 5.0 m such that there are 5 colour squares for this dimension and each colour square is the minimum of 1 m on a side. Thus covering 5 grid elements. If the dimension were between 4.5 m and 5.0 m there would be only a pattern of 3 by 3 squares. The figure was done in this fashion to save space but it is also a weakness and should be corrected in future revision.

The first pattern on the diagonal, at the lower left of the grid, is an object which is less than 3.2 m on each side. The minimum number of orange and white squares on a side is three, with orange at the corners. The squares of a pattern provided for this size of object would be marginally 1 m and, therefore, it is painted a solid orange rather than a checkerboard. This is also related to the criteria of banding for which objects of less than 3.2 m height are painted a solid orange. Refer Figure 3-2. The first "pattern" is, therefore, not actually a pattern as it is an object painted a solid orange and provided in the figure for purpose of completeness.

The second pattern on the diagonal is a 3 by 3 pattern which is equal to or greater than 3.2 m on each side. This pattern is shown as covering 4.5 grid elements, with each colour square being 1.5 m on a side.

The third pattern on the diagonal is again a 3 by 3 pattern which is less than 4.5 m on each side. This pattern is shown as covering 4 grid elements such that the colour squares are 1.33 m. The third pattern is replicated 3 times horizontally to the right to show the effect of increasing the horizontal dimension for (1) equal to or greater than 4.5 m, (2) less than 7.5 m, and (3) equal to 7.5 m. The additional patterns have 3 squares vertically and 5 squares horizontally.

The fourth pattern on the diagonal is a 5 by 5 pattern. The horizontal and vertical dimensions are increased such that each square can now be at least 1.0 m. Again, the figure takes the "equal to or greater than 4.5 m" as being 5.0 m. The pattern is shown as covering 5 grid elements on each side. The fourth pattern is replicated, twice horizontally to the right to show the effect of increasing the horizontal dimension to (1) less than 7.5 m, and (2) equal to 7.5 m. These additional patterns to the right continue to have 5 colour squares horizontally and 5 colour squares vertically. A further replication is shown to the left of the diagonal, but in this case the horizontal dimension is now less than 4.5 m and the pattern is shown as having 3 squares horizontally and 5 squares vertically.

The fifth pattern on the diagonal is again a 5 by 5 pattern. The size of the orange and white squares is such that the pattern covers 7 grid elements on a side. Each colour square is 1.4 m. As in the case of the fourth pattern, this pattern is replicated once horizontally to the right for a horizontal dimension of equal to 7.5 m. The pattern is also replicated once horizontally to the left for a horizontal dimension of equal to or greater than 4.5 m. In this case, the horizontal dimension is taken as greater than 5.0 m and the pattern remains as 5 by 5 with colour squares measuring 1.0 m.

The sixth pattern on the diagonal is also a 5 by 5 pattern. The horizontal and vertical dimensions are 7.5 m such that it is shown as covering 7.5 grid elements with squares measuring 1.5 m. This sixth pattern is replicated twice horizontally to the left for (1) less than 7.5 m and (2) equal to or greater than 4.5 m. In each case, the 5 by 5 format is retained. Again, the dimension of equal to or greater than 4.5 m is taken as 5.0 m.

- (a) Subject to paragraph (c), alternating rectangles of aviation orange and white are displayed on the following types of structure

- (3) Colour Bands

- (a) Subject to subsection (4), alternate bands of orange and white are displayed on the following types of structure:

- (i) communications towers and supporting structures of overhead transmission lines,

- (ii) poles,

- (iii) chimneys,

- (iv) skeletal framework of storage tanks and similar structures,

- (v) wind turbine towers and rotor blades, including the nacelle or generator housing,

- (vi) cables, conduits, and materials attached to the face of a tower, whether at time of construction or when later added to the structure, and

- (vii) structures that appear narrow from a side view, that are 3.2 m or more across horizontally, and the horizontal dimension is less than the vertical dimension.

- (b) Bands applied to structures of any height in excess of 3.2 m [Refer to Figure 3-2]:

(effective 2016/03/01)- (i) are approximately equal in width and to a tolerance of ± 10 percent,

- (ii) are not more than 30 m wide,

- (iii) are coloured orange for the top and bottom bands,

- (iv) have an odd number of bands on the structure, and

- (v) are in accordance with Table 3-1, except that for each additional 60 m or fraction thereof, one (1) additional orange and one (1) additional white band are added.

Table 3-1: Structure Height to Number of Bands Requirement

Structure height (AGL) blank space

Greater than

(metres)Not exceeding

(metres)Number of Bands 0

3.2

solid

3.2

210

7

210

270

9

270

330

11

330

390

13

390

450

15

450

510

17

510

570

19

570

630

21

Figure 3-2: Day Marking - Banded Pattern

(effective 2016/03/01)Text version – Figure 3-2: Day Marking - Banded Pattern

Figure 3-2 is an orthogonal chart showing how the width of the paint bands changes with the height of the structure. The x coordinate is the height of the structure. The y-coordinate is the height of the paint band. The diagonal is x y = 0. The diagonal is the top of the structure including any appurtenance.

The number of bands changes according to height ranges as indicated in Table 3-1. The number of bands are 7, 9, 11, 13, 15, 17, 19 and 21. The numbers are odd valued because the banding is to start and end in an orange colour.

The presentation is fan shaped with orange and white bands displayed with increasing width for increased height. From 3.2 m to 210 m there are 7 bands. From 570 m to 630 m there are 21 bands. For the range of 3.2 m to 210 m the maximum width of the band is at the highest height of 210 m and is found from dividing the height by 7 with a result of 30 m. The 30 m maximum occurs for all the ranges. For example, for the range 570 m to 630 m there are 21 bands and the maximum band width is 630 m divided by 21 or 30 m.

From 0 m to 3.2 m there is no banding and object is painted a solid orange.

- (a) Subject to subsection (4), alternate bands of orange and white are displayed on the following types of structure:

- (4) Structures With a Cover or Roof

If a structure referred to in subsection (3) has a cover or roof whose profile in the line of sight of approaching aircraft is less than 1.5 m, the highest orange band is continued to cover the entire top of the structure. It is acceptable to have the roof made of a solid orange provided that the structure below has a checkerboard pattern.

- (5) Skeletal Structures Atop Buildings

Where a flagpole, skeletal structure, or similar object is erected on top of a building:

- (a) the combined height of the object and the building determines whether marking is required; however, only the height of the object determines the width of the colour bands; and

- (b) if the building is required to have a checkerboard pattern of marking, the object and its height are considered separately for banding determination.

- (6) Appurtenances

If a tower or similar skeletal structure is required to have banded marking and it also has an appurtenance of more than 12 m, then the combined height of the appurtenance plus that of the main structure determine the width of the banding.

- (7) Partial Marking

If marking is required for only a portion of a structure because of shielding by other objects or terrain:

- (a) the width of the bands is determined by the overall height of the structure;

- (b) a minimum of three bands are displayed on the upper portion of the structure; and

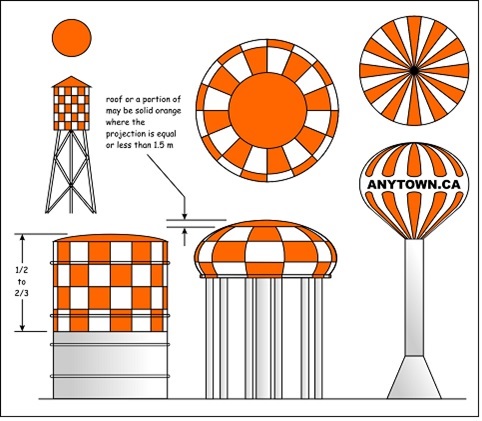

- (c) in the case of cylindrical storage tanks as shown in Figure 3-3, the checkerboard marking may be applied to the top ½ to 2/3 of the tank.

- (8) Teardrop Pattern

Spherical water storage tanks with a single circular standpipe support may be marked in a teardrop-striped pattern having the following characteristics:

- (a) alternate stripes of aviation orange and white are displayed on the tank, as shown in Figure 3-3;

(effective 2016/03/01) - (b) the stripes extend from the top centre of the tank to its supporting standpipe; and

- (c) the width of the stripes is nearly as equal as possible and the width at the greatest girth of the tank is not to be less than 1.5 m nor more than 6 m.

(effective 2016/03/01)Figure 3-3: Storage Tank Marking

(effective 2016/03/01)Text version – Figure 3-3: Storage Tank Marking

Figure 3-3 illustrates the marking of storage tanks such as water towers. The tanks may be marked with a checkerboard pattern or with tear-drop shapes for spherical tanks on a stem-like support structure. Room is left in the marking to enable placement of the town name.

What is important in Figure 3-3 is that it shows that the legs or support structures beneath the tank do not need marking since the marked tank itself is more than sufficient for aircraft daytime warning. In the case of cylindrical water tank without legs, the top 1/2 to 2/3rds of the tank height is painted, leaving the lower portion unpainted.

- (a) alternate stripes of aviation orange and white are displayed on the tank, as shown in Figure 3-3;

- (9) Community Names

If it is desirable to paint the name of the community on the side of a tank, the marking pattern may be broken for a height of not more than 1.0 m to serve this purpose.

3.6 Flag Markers

- (1) Application

One or several flags may be used as markers instead of paint to indicate the presence of certain structures or objects when it is technically impractical to use spherical markers or painting.

Information note:

Some examples of structures or objects where flags may be used are temporary construction equipment, cranes, derricks, oil and other drilling rigs.

- (2) Characteristics

Flags used as markers under subsection (1) have the following characteristics:

- (a) Minimum Size - each side of a flag is at least 0.6 m in length;

- (b) Colour Patterns - they are coloured as follows:

- (i) if solid, the colour is orange,

- (ii) if orange and white colours are used, two triangular sections, one aviation orange and the other white, are arranged to form a rectangle, or

- (iii) a checkerboard pattern of aviation orange and white squares of 0.3 m to a side, is used if the flags are 0.9 m or larger;

- (c) Shape - they are rectangular in shape and have stiffeners to keep it from drooping in calm wind; and

- (d) Manner of Display - they are displayed as follows:

- (i) around, on top, or along the highest edge of the obstruction,

- (ii) when used to mark extensive or closely grouped obstructions, the flags are displayed approximately 15 m apart, and

- (iii) the flag stakes are to be of such strength and height that they are able to support the flags above all surrounding ground, structures, or objects of natural growth, as the case may be.

3.7 Omission of Marking with Use of Lighting

A high or medium intensity white flashing lighting system may be used in place of marking if the following conditions are met:

- (a) the lighting system is operated 24 hours a day; and

- (b) in the case of a medium intensity lighting system, the system:

- (i) is operated 24 hours per day, and

- (ii) the structure on which it is used is 150 m AGL or less.

Chapter 4 Lighting, General

4.1 Scope

Chapter 4 governs lighting requirements for obstructions to air navigation in order to make them conspicuous to pilots during night time, except as otherwise provided for in this Standard.

(effective 2016/03/01)

Information note:

Lighting is used to warn pilots of a potential collision during night time operations. If the lighting is of sufficient intensity, it may also serve to give warning during daytime operations and may be approved, by way of a risk evaluation, in lieu of other means of day marking. Criteria for lighting structures, as a result of a risk evaluation, can vary depending on terrain features, weather patterns, and geographic location.

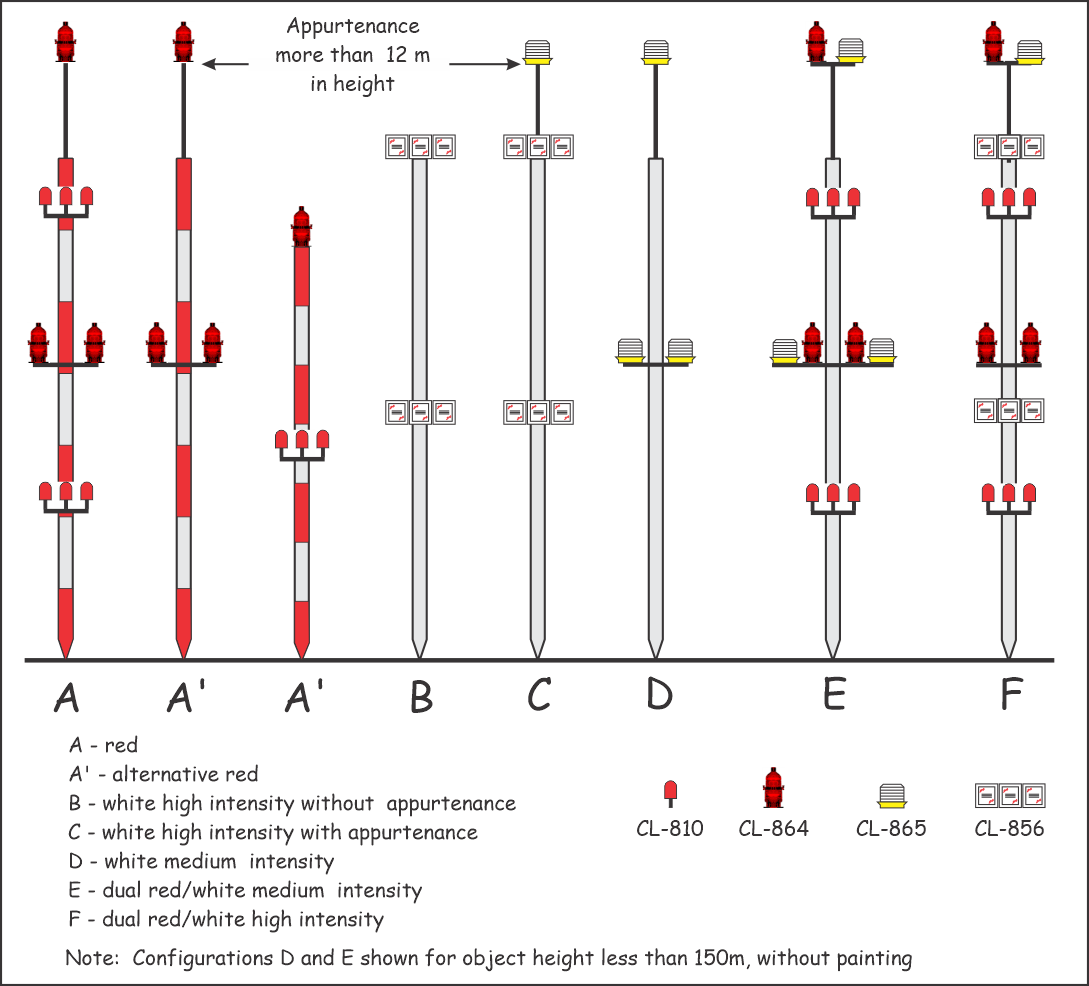

4.2 Lighting Systems

- (1) Configurations

Obstruction lighting is displayed on a building, structure or object in one of six configurations, as shown in Figure 4-1 and listed in Table 4-2.

Information note:

The following is a listing of light units required under this Standard. Chapter 13 provides detailed characteristics of these light units. Appendix B contains the governing electrotechnical requirements and quality assurance testing.

Table 4-1: Light Units

Type Intensity Colour Signal Flash Rate (fpm) CL-810

Low

red

fixed

n/a

CL-864

Medium

red

flashing

20-40

CL-865

Medium

white

flashing

40

CL-866, Catenary

Medium

white

flashing

60

CL-885, Catenary

Medium

red

flashing

60

CL-856

High

white

flashing

40

CL-857, Catenary

High

white

flashing

60

Note 1: In certain cases, some of these lights are supplied as a combined unit (e.g. CL-864/CL-865)

Note 2: fpm = flashes per minute

Information note:

The listing above for "catenary" applies to lighting of the support structures. Catenary wire lights meet the photometric requirements for CL-810.

(effective 2016/03/01)Table 4-2: Lighting Configurations

(effective 2016/03/01)Configuration Lighting A

CL-810 low and CL-864 medium intensity red lighting system

A'

Alternative red, light reduction to reduce bird fatalities

B

CL-856 white high intensity (without appurtenance lighting)

C

CL-856 white high intensity (with CL-865 appurtenance lighting)

D

CL-865 white medium intensity

E

Dual CL-810/CL-864 red with CL-865 white medium intensity lighting

F

Dual CL-810/CL-864 red with CL-856 white high intensity lighting

Figure 4-1: Configurations of Lighting on Skeletal Structures

(effective 2016/03/01)Text version – Figure 4-1: Configurations of Lighting on Skeletal Structures

Figure 4-1 illustrates a series of 8 towers for the various configurations of lighting as listed in Table 4-2. The configurations are A to F, illustrated as towers from left to right. The configuration A' is included to show the alternate to configuration A that is used for reducing bird fatalities.

Towers 1 to 3 are for configurations A and A' which are red lighting systems. Two versions of A' are shown; one with and a second without appurtenance.

Tower 4 is for configuration B which is high intensity lighting.

Tower 5 is for configuration C which is high intensity lighting with a single medium intensity light for an appurtenance of more than 12 m height.

Tower 6 is for configuration D which is medium intensity lighting.

Towers 7 and 8 are for configurations E and F are dual lighting systems. Configuration E is for medium intensity white lighting combined with a red lighting system. Configuration F is for high intensity white lighting combined with a red lighting system. The white systems are operated during twilight and day and the red system is operated during the night. Where medium intensity is installed on a tower of less than 150 m in height and operated during the daytime, painting can be omitted.

For configurations A, A', C, D, E and F [excluding configuration B] a medium intensity light is provided for appurtenances of more than 12 m is shown. Note that if the appurtenance is less than 12 m, such light would not be provided.

For configurations A, A' and D, the height of the light for the appurtenance determines the overall height of the lighting and subsequently the location of the intermediate levels of lighting. For configuration C, the top medium intensity light is an addition and the intermediate levels of high intensity lighting is base on the height of the main structure without appurtenance.

- (2) Red Lighting Systems

A red obstruction lighting system consists of CL-810 low intensity steady burning aviation red lights and CL-864 medium intensity red flashing aviation beacons.

-

(3) CL-865 Medium Intensity White Flashing Lighting Systems

- (a) A medium intensity white flashing lighting system consists of CL-865 medium intensity flashing white lights used during day/twilight with automatically selected reduced intensity for night time operation.

- (b) When the system is used on a building, structure or object 150 m AGL or less in height, the marking requirements may be omitted.

Information note 1:

No exemption applies from the requirement to display markings on a building, structure or object exceeding 150 m AGL that has a CL-865 medium intensity white flashing lighting system.

Information note 2:

This lighting system, except for the rotating type CL-865, is not normally recommended on buildings, structures or objects 60 m AGL or less.

(effective 2016/03/01)

- (4) High Intensity White Flashing Lighting Systems

- (a) A high intensity white flashing lighting system consists of CL-856 and CL-857 high intensity flashing white lights used during daytime with automatically selected reduced intensities for twilight and night time operations.

- (b) When the system is in use, the markings and the other lights required to be displayed on the building, structure or object may be omitted.

Information note:

This lighting system should not be used on buildings, structures or objects 150 m AGL or less, unless a risk evaluation shows otherwise.

-

(5) Dual Lighting Installation

- (a) A dual lighting system consists of red lights for night time use and high or medium intensity flashing white lights for daytime and twilight use.

- (b) When a dual lighting system incorporates medium flashing intensity lights on a building, structure or object 150 m or less in height, or high intensity flashing white lights on a building, structure or object of any height, the marking and the other lighting requirements may be omitted.

4.3 Obstruction Lights During Construction

- (1) As the height of a building, structure or object under construction progressively exceeds each level at which permanent obstruction lights would be required, two or more temporary medium intensity white flashing lights are installed at that level.

- (2) Temporary lighting required under subsection (1) is operated 24 hours a day until all permanent lights required under this Standard are in operation.

- (3) If practical, permanent obstruction lighting required under this Standard shall be installed and operated at each level as construction progresses.

- (4) The lights shall be positioned to ensure that a pilot has an unobstructed view from any angle of approach of at least one light at each level.

4.4 Temporary Construction Equipment Lighting

Information note:

Since there is such a variance in construction cranes, derricks, oil and other drilling rigs, each case should be assessed individually. However, in principle, lights should be installed according to the standards given herein, as they would apply to permanent structures.

4.5 Groups of Obstructions

- (1) When individual buildings, structures or objects within a group of obstructions are not the same height and are spaced more than 45 m apart, the prominent building, structure or object within the group is lighted in accordance with the standards for individual obstructions of a corresponding height.

- (2) If an outer building or structure is shorter than the prominent one, it is lighted in accordance with the requirements for individual obstructions of a corresponding height.

- (3) Light units required under this section are placed to ensure that the light is visible to a pilot approaching from any direction.

- (4) In addition to the requirement set out in subsection (3), at least one flashing beacon is installed at the top of a prominent centre obstruction or on a special tower located near the centre of the group.

- (5) If there is no prominent centre obstruction, a risk evaluation shall be performed to assess the location of the applicable beacons.

4.6 Glare from Flashing Obstruction Lights

- (1) Where obstruction lighting is likely to distract operators of aircraft, railway trains, surface vessels, and other vehicles, or if the lighting is in a congested residential area, a suitable shield is installed on the appropriate lights to minimize the glare effects of the light.

- (2) The application of such shielding shall not diminish the required performance of the light as specified in Chapter 13 of this Standard for obstruction identification to pilots.

- (3) Shielding applied to the exterior of the light unit is suitable for environmental conditions such as snow, ice and frost cover, so that the light output is not degraded from that required by this Standard.

- (4) In the proximity of navigable waterways or along coastal regions, the installation of an obstruction lighting system is coordinated with marine authorities by the owner or operator of the obstruction in order to avoid interference with marine navigation.

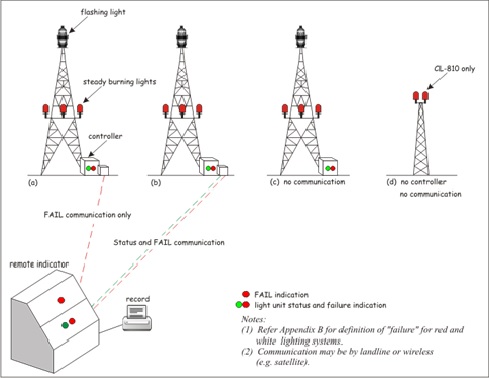

4.7 Monitoring of Obstruction Lights

The objective of monitoring is to enable the owner to maintain the lighting system in operation without failure. The occurrence of light failure is detected so that a NOTAM can be issued and repair action undertaken in a timely fashion.

(effective 2016/03/01)

- (1) The owner of a structure with a flashing obstruction light system is responsible:

(effective 2016/03/01)- (a) to know there is occurrence of any failure, by observation once every 24 hours, either visually or through observation of a remote indicator designed to show failure of such lighting regardless of position or colour. For medium and high intensity lighting and dual lighting systems, observation is made for at least the day and night modes of operation; and

- (b) to have a documented program of at least annual inspection of all automatic or mechanical control devices, indicators, and alarm systems associated with the structure lighting to ensure that the such apparatus is functioning properly.

- (2) The owner is exempt from paragraph 4.7(1)(b) where the alarm system has self-diagnostic features to confirm the communication link and operational status of the monitoring system itself at least once every 24 hours.

(effective 2016/03/01) - (3) Where it is not possible to observe either visually or through means of a remote indicator, the objective of monitoring is accomplished through provision of lamps having a rated life of more than one year of operation and establishment of a documented program of at least annual inspection.

(effective 2016/03/01) - (4) For each structure, a log is maintained showing the history of observations, inspections, failures, repairs, and relamping, as applicable for the method of monitoring used.

(effective 2016/03/01) - (5) The owner of the structure advises NAV CANADA, as soon as possible, of any obstruction light failure so that a NOTAM can be initiated in accordance with paragraph 2.7(1).

(effective 2016/03/01)Information note:

Each flashing light system, in accordance with Appendix B, is to have a controller which gives indication of the status of both the flashing lights and any associated steady burning lights. The controller has provision to permit connection to a remote alarm indicator (supplied by others or as an option)

(effective 2016/03/01)Figure 4-2 illustrates a variety of methods for monitoring. Method (a) is the use of an alarm system for failure indication only. Method (b) determines the status of all the lights in a 24 hour period, which may be considered as a form of self-diagnosis.

Since it is the responsibility of the owner to know of a failure, Method (b) may be chosen over Method (a) in consideration of reliability. If the failure alarm is given only at the time of occurrence, will the communication link and overall monitoring system be functioning properly to transmit the alarm to the owner?

Method (c) is an instance for which it is not possible to provide a communications link. For this method the objective of monitoring is accomplished through the use of lamps having a rated life of more than one year of operation combined with at least annual inspection and relamping. In the case of LED sources the owner may choose to not re-lamp based on experience; annual inspection, however, should still take place.

In the case of Method (d), monitoring would not normally be required as it is not a flashing light system. However, inspection and relamping should be undertaken as in Method (c).

Figure 4-2: Methods of Monitoring

(effective 2016/03/01)Text version – Figure 4-2: Methods of Monitoring

Figure 4-2 illustrates four methods of monitoring obstacle lights, shown left to right. The variation is with respect to the means of communication to a remote indicator which is shown in the bottom left of the figure. It is of importance to note that the primary consideration of variation is for communication and not for the controller. Provision of a controller at the tower location is a requirement for all flashing systems in accordance with Appendix B of Standard 621.

Method (a) is where there is communication from the controller for only a failure alarm. That is, the alarm is provided only when failure occurs. Use of long life lamps having an operational life of more than a year and annual inspection are required as mitigation.

Method (b) is where there is capability for 24 hour status indication. This enables not only a knowledge of a failure, but also to know whether the communication means is functioning properly. As mentioned in the Standard 621 text, where this method is used, the provision of long life lamps and annual inspection can be omitted.

Method (c) is where provision of a communication link is not possible. The Standard 621 text states mitigation is through use of long life lamps having an operational life of more than a year and annual inspection.

Method (d) is included for completeness and is for where a controller is not provided at the tower. This is typically where the lights are only the steady burning CL-810. This method, however, is similarly mitigated through use of long life lamps and annual inspection.

4.8 Placement Factors

- (1) The height of a building, structure or object above ground (AGL) is used to determine the number of light levels required to be installed as part of a lighting system.

- (2) The height of light levels required to be installed may be adjusted slightly, but not to exceed 3 m, when necessary to accommodate guy wires and personnel who replace or repair light fixtures.

- (3) Except for catenary support structures, the following factors are considered when determining the placement of obstruction lights on a building, structure or object:

- (a) for a red obstruction lighting system or a medium intensity white flashing lighting system, the overall height of the structure including all appurtenances such as rods, antennae, obstruction lights and similar objects, determine the number of light levels;

- (b) for a high intensity white flashing lighting system,

- (i) the overall height of the main structure excluding all appurtenances is used to determine the number of light levels, and

- (ii) if required, a CL-865 medium intensity flashing light is displayed on the highest portion of any antenna or other appurtenance supported by the main structure; and

- (c) for a dual obstruction lighting system, the determination of the number of light levels is in conformity with the pertinent requirements for white and red lighting systems.

- (4) The elevation of the tops of adjacent buildings or structures in congested areas is used as the equivalent of ground level to determine the proper number of light levels required.

- (5) If an adjacent building, structure or object shields any light, horizontal placement of the lights is adjusted or additional lights are mounted on that object to retain or contribute to the definition of the obstruction.

4.9 Ice Protectors

- (1) Where icing is likely to occur, metal grates or similar protective means are installed directly over each light unit required under this Standard to be installed on a building structure or object to prevent falling ice or accumulations from damaging the light units.

- (2) The protective means are of a design and manner of placement such that the required photometric output of the fixtures is not affected.

Chapter 5 Red Obstruction Lighting System, Configuration "A"

5.1 Scope

Chapter 5 governs obstruction lighting that uses a configuration "A" lighting system.

Information note:

Red Obstruction lights are used to increase conspicuity during nighttime. Daytime and twilight marking is required. Recommendations on lighting structures can vary depending on terrain features, weather patterns, geographic location, and in the case of wind turbines, number of structures and overall layout of design.

(effective 2016/03/01)

5.2 System Requirements

- (1) General

- (a) A configuration "A" red obstruction lighting system, as shown in Figure 5-1, consists of one or several CL-864 red flashing beacons or CL-810 steady burning red lights, or a combination thereof.

(effective 2016/03/01) - (b) When red lighting alone is used for night protection, no exemption to markings for day protection required under this Standard is allowed.

(effective 2016/03/01) - (c) Refer to Chapter 13 for control of red lighting systems.

(effective 2016/03/01)Information note:

The CL-810 comes in two forms; a single unit [one lamp and one globe] and a double unit [two lamps and two globes].

- (a) A configuration "A" red obstruction lighting system, as shown in Figure 5-1, consists of one or several CL-864 red flashing beacons or CL-810 steady burning red lights, or a combination thereof.

-

(2) Single CL-810 Obstruction Light Units

Where more than one obstruction light is required either vertically or horizontally, or where maintenance can be accomplished within a reasonable period of time, single unit CL-810 lights may be used as follows:

- (a) Top Level atop structures such as airport ILS buildings and long horizontal structures such as perimeter fences and building roof outlines; or

- (b) Intermediate Level at intermediate levels on skeletal or solid structures when more than one level of lights is required to be installed and there are two or more single units per level.

- (3) Double Obstruction Light Units

Subject to subsection (2), when used as a top light or in areas or locations where the failure of a single unit could cause an obstruction to be totally unlighted, double unit CL-810 lights are installed at each end of a row of single unit obstruction lights, and more specifically as follows:

(effective 2016/03/01)- (a) Top Level on a structure, building or object 45 m AGL or less, one or more double unit lights operating simultaneously are installed at the highest point;

- (b) Intermediate levels,

- (i) double unit lights are installed when a malfunction of a single unit light could create an unsafe condition and in remote areas where maintenance cannot be performed within a reasonable time, and

- (ii) both lamps of the double unit operate simultaneously or a transfer relay is used to switch to the inactive lamp should the active lamp fail; and

- (c) Lowest Level at the lowest level of a building, structure or object,

- (i) light units may be installed at a higher elevation than standard if the surrounding terrain, trees or any adjacent buildings would obscure the lights, or

- (ii) in certain exceptional instances, as determined by a risk evaluation, the lighting otherwise required for the lowest level may be omitted.

- (4) Flashing Display

When one or more levels of lights are comprised of CL-864 flashing beacons, the lights flash simultaneously.

(effective 2016/03/01) - (5) Equivalent Method of Displaying Obstruction Lights

Provided that approval is obtained following the result of a risk evaluation, lights may be placed on poles equal to the height of the building, structure or object required to be lighted, and may be installed on or adjacent to such building, structure or object.

5.3 Poles, Radio and Television Towers and Similar Skeletal Structures

(effective 2016/03/01)

The following requirements apply to radio and television towers, supporting structures for overhead transmission lines, and similar structures. Refer to Figures 5-1 and 5-2.

- (1) On the topmost part of a structure:

- (a) 45 m AGL or less, two or more CL-810 steady burning lights are installed in a manner to ensure an unobstructed view of one or more lights by a pilot; or

(effective 2016/03/01) - (b) exceeding 45 m AGL, at least one CL-864 red flashing beacon is installed in a manner to ensure an unobstructed view of one or more lights by a pilot.

(effective 2016/03/01)

- (a) 45 m AGL or less, two or more CL-810 steady burning lights are installed in a manner to ensure an unobstructed view of one or more lights by a pilot; or

- (2) On the intermediate levels of a structure:

- (a) the number of levels of lights is in accordance with Figure 5-1;

- (b) the number of lights at each level is determined by the shape and height of the structure;

- (c) the lights are installed so as to provide an unobstructed view of at least one light by a pilot from any angle of approach;

- (d) where CL-810 steady burning red lights are installed on:

- (i) a structure 105 m AGL or less, two or more steady burning red lights are installed on diagonally or diametrically opposite positions, and

- (ii) a triangular shaped structure 105 m AGL or less:

- (A) two red light units, single or double, are installed, provided that at least one can be viewed unobstructed by a pilot from any angle of approach, or

- (B) where the requirement specified in clause (A) is impractical, three red light units are installed, one on each apex of the triangular cross-section, or

- (iii) a structure exceeding 105 m AGL, a CL-810 steady burning red light is installed on each outside corner at each level; and

(effective 2016/03/01)

-

(e) where CL-864 flashing red beacons are used on a structure exceeding 105 m AGL, the CL-864 lights at intermediate levels are installed on the outside of the tower structure on diagonally or diametrically opposite positions at each level.

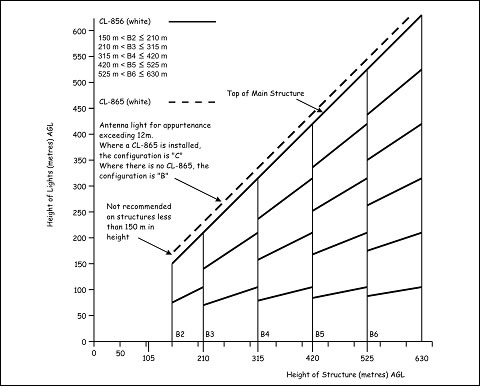

(effective 2016/03/01)Figure 5-1: Configuration A: Red Lighting Installation

(effective 2016/03/01)Text version – Figure 5-1: Configuration A: Red Lighting Installation

Figure 5-1 is an orthogonal chart for location of red lights on a tower. The x-coordinate is the height of the tower and the y-coordinate is the height of the lights. The location of the top light is on the diagonal ... x - y = 0. The chart has inclined lines representing the location of the lights. The number of levels and type of light whether CL-810 or CL-864 are indicated by dashed lines and solid heavy lines respectively.

The number of levels of lighting changes according to seven height ranges and these are titled using the FAA designations of A0, A1, A2 to A6. The number of levels is double the designation number, except for A0. For example, in the case of the height range A2 from 105 m to 210 m, there are four levels of lighting and the type of lighting alternates so that there is a top CL-864, then downwards after an interval a set of CL-810 lights, then a mid level of a set of CL 864 lights, followed by a the lower level of a set of CL-810 lights. For other height ranges the same principle of alternation CL-864 and CL-810 lights is followed. The top light is always a flashing CL-864 for ranges A1 to A6.

In the case of the A0 range from 0 m to 45 m there is only one level and this is normally a dual CL-810 top light.

Within the A2 range there are four levels of lighting including the top light. The inclined lines on the chart represent level heights of 1/4, 1/2, 3/4 and 1. For say an overall height of 150 m, this represents 37.5 m, 75 m, 112.5 m and the top light at 150 m. The chart is only for illustration and does not have sufficient resolution to permit reading precise values from the chart itself. Instead the designer obtains the values mathematically. Where there are 4 levels and the overall vertical height is say 150 m, this is divided by 4 to give a 37.5 m interval or spacing. A3 has six levels and the interval is found by dividing the overall height by 6. The A4 height is divided by 8, and so forth.

Figure 5-2: CL-810 and CL-864 Lights on Towers

(effective 2016/03/01)Text version – Figure 5-2: CL-810 and CL-864 Lights on Towers

Figure 5-2 shows the manner of installation for lighting as applied to a tower. The Figure 5-1 addressed the vertical spacing of the lights. Figure 5-2 addresses the number and placement of lights for particular levels. For lattice-work towers, the lights are installed external to the structure, since, if installed inside the structure, the light emission would be blocked by structural members.

The top light is normally a single CL-864 medium intensity light. Except that for towers less than 45 m, in which case the top light is a dual unit CL-810 for purpose of redundancy.

For intermediate levels the light units are installed at the ends of the diagonals so as to be viewable from 360 degrees. This includes lower levels of CL-864 lights. In the case of an intermediate level of CL-810 lights, single units are normally used but dual units may be used to facilitate planned repair action.

- (3) Appurtenances

Where a building, structure or object required to be lighted includes an appurtenance such as a rod, antenna, or similar extension, a topmost light is installed above the main part of the building, structure or object in accordance with the provisions of this subsection.

- (a) Where the appurtenance is 12 m or less in height and:

- (i) is incapable of supporting a red flashing beacon, the beacon may be placed at the base of the appurtenance, or

- (ii) if the mounting location does not allow unobstructed viewing of the beacon by a pilot from any angle of approach, additional beacons are added.

- (b) Where the appurtenance exceeds 12 m in height and:

- (i) is incapable of supporting a red flashing beacon, a supporting mast with one or more beacons is installed adjacent to the appurtenance, and

- (ii) the adjacent installation of (i) does not exceed the height of the appurtenance and is within 12 m of the tip of the appurtenance to allow the pilot an unobstructed view of at least one beacon, from any angle of approach.

Information note:

The primary focus of "appurtenance" is to enable installation of a short rod, antenna or similar extension of less than 12 m in height without lighting. It is not intended that the feature of "appurtenance" would involve extensions that are significantly in excess of 12 m. In such an instance, the extension is to be considered as adding to the height of the main object.

(effective 2016/03/01)

- (a) Where the appurtenance is 12 m or less in height and:

5.4 Alternative Configuration A' to Reduce Bird Fatalities

(effective 2016/03/01)

- (1) An alternative Configuration A' is applied for the purpose of reducing bird fatalities and consists of only CL-864 lights, as shown in Figure 5-3, for object heights of more than 105 m.

(effective 2016/03/01) - (2) For A1 heights of more than 45 m to 105 m, the CL-810 lights are made to flash at the same rate as the top mounted CL-864 light.

(effective 2016/03/01)Information note:

The alternate Configuration A' is only applicable to towers and similar skeletal structures.

(effective 2016/03/01)Figure 5-3: Alternative Configuration A' - Lighting Reduction to Reduce Bird Fatalities

(effective 2016/03/01)Text version – Figure 5-3: Alternative Configuration A' - Lighting Reduction to Reduce Bird Fatalities

Figure 5-3 is an orthogonal chart for the alternative Configuration A' to reduce bird fatalities. The chart is the same as that of Figure 5-1 for configuration A, with omission of steady burning CL-810 lights, except for height ranges A0 [0 m to 45 m] and A1 [45 m to 105 m]. The steady burning CL-810 lights are considered to be attractive to birds which subsequently fly around the tower and are killed by collision with the guy wires. Thus the alternative for omission of CL-810 steady burning lights.

For the range A1, from 45 m to 105 m, there is the one CL 864 top light and one intermediate level of CL-810 lights. Since there is only the one CL-864 top light, it is desirable to retain the lower CL-810 lights in case of failure of the top light. Otherwise, with failure, the total length of the tower would be left unlighted. The CL-810 lights, however, are made to flash at the same rate as the CL-864 top light.

For the A0 range the single top light of steady burning CL-810 is retained because towers of this height are typically without guy wires.

5.5 Chimneys, Flare Stacks and Similar Solid Structures

- (1) Number of Light Units per Level

Subject to subsection (3), the number of lights to be installed at the top and at each level of a chimney, flare stack or similar solid structure depends on the diameter of the structure and is in accordance with Table 5-1.

Table 5-1: Number of lights

(effective 2016/03/01)Diameter Minimum Number of Lights at top and per level ≤ 6 m

3

6 m < x ≤ 30 m

4

30 m < x ≤ 60 m

6

x > 60 m

8

- (2) Top Mounted Obstruction Lights

(effective 2016/03/01)- (a) For structures 45 m AGL or less, CL-810 lights are installed horizontally at regular intervals at or near the top.

- (b) For Structures Exceeding 45 m AGL, at least three CL-864 beacons are installed.

- (c) For chimneys, cooling towers, and flare stacks, lights may be displayed as low as 6 m below the top to avoid the obscuring effect of deposits and heat generally emitted by this type of structure.

- (d) For flare stacks, as well as other structures associated with the petrol-chemical industry, depending upon assessment, normal lighting requirements may not be necessary. This could be due to the location of the flare stack/structure within a large well-lighted petrol-chemical plant or the fact that the flare, or working lights surrounding the flare stack/structure, is as conspicuous as obstruction lights.

Information note:

It is important that the lights be readily accessible for cleaning and lamp replacement.

(effective 2016/03/01)

- (3) Mounting Intermediate Levels

(effective 2016/03/01)- (a) Steady Burning (CL-810) Lights. The number of light levels is obtained from Figure 5-1. At least three lights are installed on each level.

- (b) Flashing (CL-864) Beacons. The number of beacon levels may be obtained from Figure 5-1. At least three lights are installed on each level, and

- (i) for structures 105 m AGL or less, intermediate levels of flashing lights are not required, and

- (ii) for structures exceeding 350 feet (107 m) AGL at least three flashing (CL-864) beacons should be installed on each level in a manner to allow an unobstructed view of at least one beacon.

- (4) Hyperbolic Cooling Towers

Where any cooling tower:

(effective 2016/03/01)- (a) is 180 m in height or less AGL, intermediate light levels may be omitted; or

- (b) exceeds 180 m AGL in height, a second level of light units is installed approximately at the midpoint of the structure and in a vertical line with the top level of lights.

5.6 Prominent Buildings and Similar Extensive Obstructions

- (1) Subject to subsection (4), individual obstructions having a similar height above ground and located not more than 45 m apart within a group of obstructions may be considered as an extensive obstruction for lighting purposes, in which case the group displays steady burning red lights to indicate the extent of the obstruction as specified in this section.

- (2) On a structure 45 m or less in both horizontal dimensions:

(effective 2016/03/01)- (a) a CL-810 light is displayed on the highest point at each end of the major axis of the obstruction; or

(effective 2016/03/01) - (b) a dual CL-810 light is displayed in the centre of the highest point.

(effective 2016/03/01)

- (a) a CL-810 light is displayed on the highest point at each end of the major axis of the obstruction; or

- (3) On a structure exceeding 45 m in at least one horizontal dimension:

(effective 2016/03/01)- (a) CL-810 lights are displayed on:

(effective 2016/03/01)- (i) the highest point at each end of the obstruction, and

- (ii) the highest points for each 45 m, or fraction thereof, for the overall length of the major axis.

- (b) If the minor axis of a structure exceeding 45 m in one of its horizontal dimensions is 45 m or less in length, the lights referred to in paragraph (a) may be installed as a row along the middle or along either side, as shown in Figure 5-4.

(effective 2016/03/01) - (c) If a structure exceeding 45 m in any horizontal dimension is located near a landing area and two or more edges of the structure are of the same height, the edge nearest the landing area is lighted with CL-810 lights.

- (a) CL-810 lights are displayed on:

- (4) Structures Exceeding 45 m AGL

- (a) Top Lights - CL-810 steady burning red lights are installed on the highest point at each end.

(effective 2016/03/01) - (b) At intermediate levels of the structure,

- (i) CL-810 steady burning red lights are displayed for each 45 m or fraction thereof,

(effective 2016/03/01) - (ii) the vertical position of the intermediate lights is equidistant between the top lights and the ground level as the shape and type of obstruction will permit, and

- (iii) one CL-810 steady burning red light is displayed at each outside corner on each level with the remaining lights evenly spaced between the corner lights.

- (i) CL-810 steady burning red lights are displayed for each 45 m or fraction thereof,

- (a) Top Lights - CL-810 steady burning red lights are installed on the highest point at each end.

- (5) Exceptions

Flashing red CL-864 beacons may be used instead of CL-810 steady burning lights if early or special warning to pilots is necessary, provided that, in the case of an extensive obstruction:

(effective 2016/03/01)- (a) they are displayed on the highest points of the obstruction, at intervals not exceeding 900 m; and

- (b) at least three beacons are displayed on one side of the obstruction to indicate a line of lights.

Figure 5-4: Prominent Buildings Lighting

(effective 2016/03/01)Text version – Figure 5-4: Prominent Buildings Lighting

Figure 5-4 has a number of schematics illustrating the location and spacing of CL-810 lights on prominent buildings.

The spacing on the top of the building and vertically along the sides is in increments of 45 m or less depending on the horizontal, depth or vertical dimensions of the building.

Horizontal is across the page. Vertical is up the page. Depth is into the page.

If both the horizontal and depth dimensions [a roof top] are less than 45 m, two CL-810 lights are placed at the ends of the major axis or a dual light is installed at the centre.

In the case of a building having a depth of less than 45 m and a horizontal dimension of more than 45 m, the lights can be installed along a major horizontal axis at the top or on one side of the top closest to the aerodrome [referred to as the "landing area side"].

5.7 Bridges

- (1) A bridge assessed through a risk evaluation as a likely hazard to aviation safety has CL-864 red flashing lighting, as shown in Figure 5-5.

(effective 2016/03/01) - (2) If the bridge referred to in subsection (1) is over navigable water, the obstruction lighting installer consults with the Coast Guard to avoid interference with signals to marine navigation.

Figure 5-5: Bridge Lighting

(effective 2016/03/01)Text version – Figure 5-5: Bridge Lighting

Figure 5-5 illustrates the installation of obstacle lighting on a bridge. The bridge as shown in Figure 5-5 is a cantilever bridge with two sets of uprights, one set near each end. Red flashing CL-864 lights are installed on the top of the uprights.

Note is made in the figure that it is illustrative of a typical application. An actual bridge may need additional lighting.

5.8 Groups of Objects

- (1) When objects within a group of obstructions are approximately the same overall height AGL and are located not more than 45 m apart, the group of obstructions may be considered an extensive obstruction and lighted in accordance with section 5.6.

(effective 2016/03/01)Information note:

Where the objects are not more than 45 m apart, the grouping effectively simulates a building for the pilot as shown in Figure 5-6. The lights are installed as shown in Figure 5-3 and some of the objects may be unlighted.