This report includes a broad overview of the 180 research, development and deployment (RD&D) projects that Transport Canada (TC) advanced over the past year. It highlights 6 projects and demonstrates how the results directly impact TC's policies, regulations and decisions.

On this page

- Executive summary

- Research at a glance

- 2020-2021 Research highlights

- 1. Improving our knowledge on underwater vessel noise

- 2. Testing drones for inspections

- 3. Testing cooperative truck platooning systems

- 4. Developing clean rail technologies

- 5. Improving safety in the transportation of dangerous goods

- 6. Working with governments and industry to launch a low speed automated shuttle pilot

- The Experimentation Fund

- What's next?

- Annex A: RD&D governance at TC

- Annex B: List of TC's RD&D projects 2020-2021

Executive summary

This report includes a broad overview of the 180 research, development and deployment (RD&D) projects that Transport Canada (TC) advanced over the past year. It highlights 6 projects and demonstrates how the results directly impact TC's policies, regulations and decisions.

With an investment of $12.2M, these 6 projects have gone a long way towards improving our understanding of and ability to address emerging transportation technologies, and overseeing and modernizing regulations.

The results of these projects fed into core governmental and departmental priorities, including the Pan-Canadian Framework, Transportation 2030 and the Trade and Transportation Corridors Initiative.

TC's research priorities in 2020-2021 included:

- addressing and adapting to climate change

- promoting the use of zero-emissions vehicles

- protecting Canada's oceans and land, and

- investing in infrastructure, public transit, science and innovation

In the fall of 2020, we launched Canada's first low speed automated shuttle trial. We are incredibly proud of the team, who assisted more than 600 passengers and collected data that will help us decide how to approach low speed automated shuttle regulations in Canada. The trial took place over 2 weeks at Tunney's Pasture in Ottawa, while carefully following COVID-19 protocols.

We also launched an underwater acoustic glider to detect North Atlantic right whales in the St. Lawrence. This helped us implement mandatory slowdown measures and complemented TC's other work detecting whales, including the National Aerial Surveillance Program's use of remotely piloted aircraft systems (RPAS), also known as drones.

Innovation has been hardwired into TC through improved governance structures and collaborations. We created Assistant Deputy Minister and Director General-level innovation committees to make sure our scientific priorities align with the needs of the department and government.

We used new tools, like the Experimentation Fund, to spark innovation. We solved RD&D challenges from industry through the Innovative Solutions Canada Program. We also hired a Departmental Science Advisor to strengthen our links to academia.

TC continues to develop and improve processes to address emerging and disruptive technologies, and we are proud to present a high calibre selection of these projects.

Research at a glance

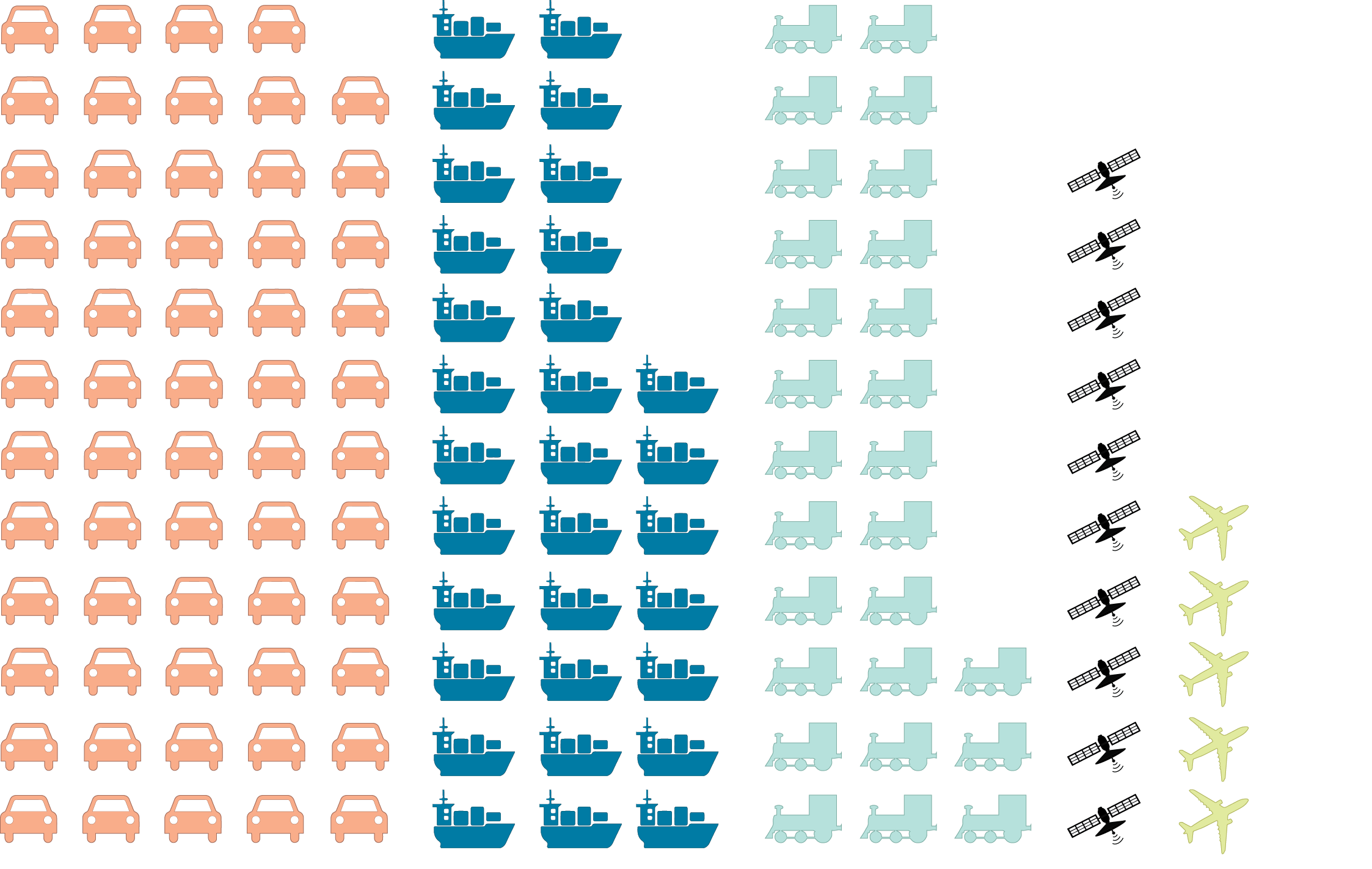

Over the past year, TC has invested approximately $24M in 180 RD&D projects across the 5 modes (air, marine, rail, road and multi-modal) of transportation. The Innovation Centre played a key role in leading over 70% of these projects. In 2020-21, the Innovation Centre worked with groups across the department, other government bodies and industry to fund 59 road projects, 31 marine projects, 27 rail projects, 10 multi-modal projects, and 5 air projects.

The most heavily studied mode at the Innovation Centre is road transportation, with 59 projects led by the ecoTECHNOLOGY for Vehicles program, the program to Advance Connectivity and Automation in the Transportation System and the Crash Avoidance program.

Figure 1: Pictorial representation of the Innovation Centre research projects by transportation mode. The image shows 59 road vehicles, 31 ships, 27 trains, 10 satellites representing multi-modal projects and 5 planes.

This report features 6 major projects that span all modes of transportation. Throughout, we highlight how the project results will help us update and develop important regulations and policies to support a safe, secure, clean and integrated transportation system. Each project includes a box with quick facts: the total project funding; the project partners; the regulations, policies and government initiatives that the project contributes to; and a key result of the project.

2020-2021 Research highlights

1. Improving our knowledge on underwater vessel noise

9.5 M

The world’s largest ship noise database

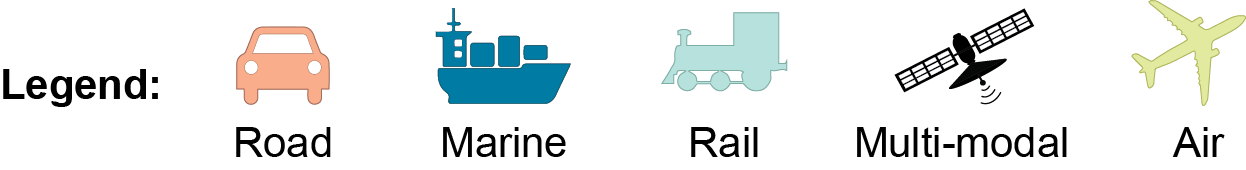

Figure 2: Underwater listening station before deployment, photo by JASCO Applied Sciences.

Underwater noise from vessels negatively impacts the marine environment and vulnerable marine mammals, but shipping is a key part of Canada’s economy. To address this challenge in an environmentally responsible way, TC partnered with JASCO Applied Sciences to deploy a state-of-the-art underwater listening station (ULS) in Boundary Pass (a strait along the border between British Columbia and Washington State) to collect real-time underwater noise readings from vessels, ambient noise and marine mammal calls. The ULS was officially commissioned in June 2020.

Underwater noise is collected through 2 observation frames installed 190 metres deep below the incoming and outgoing shipping lanes in Boundary Pass. The frames consist of underwater microphones (hydrophones) that can detect and locate calling marine mammals and nearby vessels, and are connected by fibreoptic cables to a shore station on Saturna Island. The ULS is also equipped with a video camera to capture live footage of marine life.

Since TC and JASCO began measuring underwater noise, ULSs in the area have been able to measure underwater noise emissions from over 11,000 commercial vessel transits from ships visiting BC’s southern ports, contributing to the world’s largest ship noise database. The Boundary Pass ULS measures 4,000 to 5,000 vessel transits every year. Every day the ULS sends over 1 terabyte of data to shore in real-time, so we can immediately analyse and report it. The station is a critical piece of scientific equipment that directly helps TC manage the impact of underwater vessel noise on the marine environment, and vulnerable marine mammals – including Southern Resident killer whales.

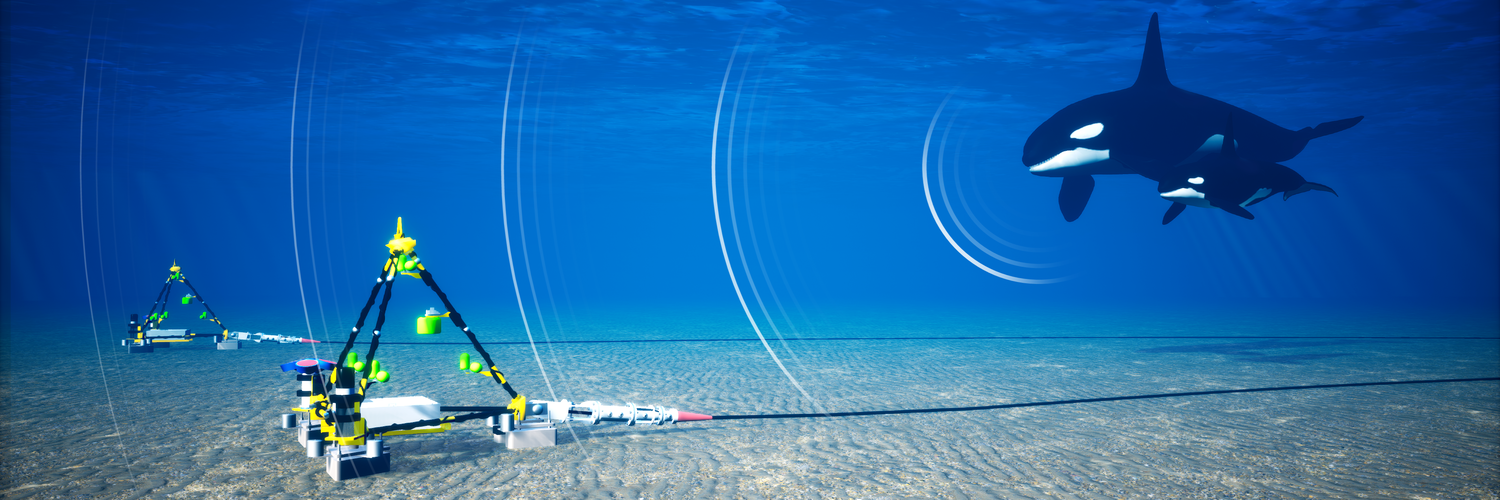

Figure 3: Visual representation of underwater listening station hydrophones, located 190 metres underwater, interaction with Southern Resident killer whales.

The data collected by the ULS will enable TC and other key stakeholders (e.g. Department of Fisheries and Oceans, Vancouver Fraser Port Authority – ECHO Program) to assess whether the measures (such as slowing down or redirecting vessels) we’ve put in place to improve underwater vessel noise are effective. It’s also helping us understand the different noise emissions from different sizes and types of vessels. The results of this project will also help us understand the relationship between underwater vessel noise emissions and operational and design factors, helping us test the effectiveness of “quiet ship” technologies.

2. Testing drones for inspection

88k

ARA Robotics, Innovative Solutions Canada

Demo drones meet oversight needs

Figure 4: Picture of drone from ARA

As part of the Transformation Agenda, TC is looking for ways to improve and modernize the way we do inspections. To meet this goal, the Innovation Centre is working with inspectors from the Navigation Protection Program to test remotely piloted aircraft systems, also known as drones, for inspections. The Navigation Protection Program helps to keep Canada’s navigable waters open by monitoring things like:

- work permits for bridges, causeways, dams and aquaculture

- human-made obstructions, such as wrecked and abandoned vessels, and

- the reduction of water content from mine tailings

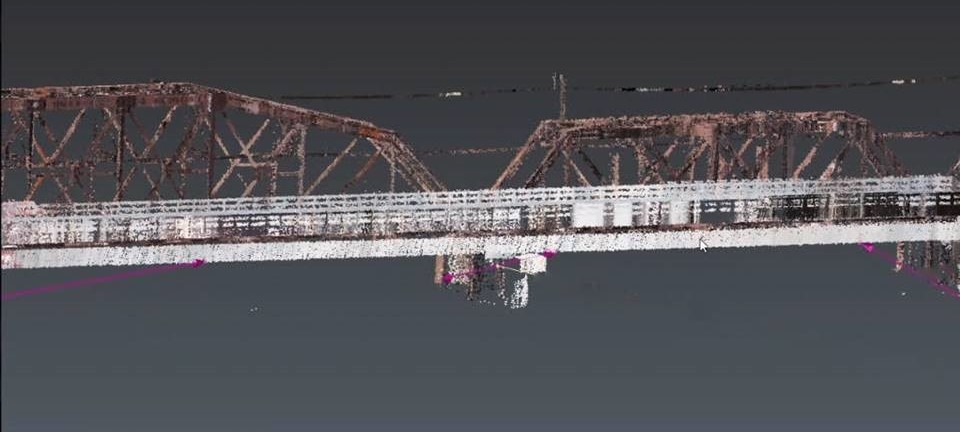

Figure 5: High resolution image of inspection site taken with ARA drone (top) and a recreation of the inspection site recreated using laser sensing technology (bottom)

Through Innovative Solutions Canada, TC launched a pilot project with ARA Robotics to evaluate whether drones could be used to monitor 5 locations in Quebec, Ontario and Nova Scotia.

The drones use high resolution cameras and lasers to measure and scan sites. To date, the drones have finished scanning the sites in Quebec and Ontario, and scans are being planned for sites in Nova Scotia.

Initial results have confirmed that the high resolution images gave inspectors the information they needed for most inspection activities. Using drones gives us a safer way to inspect dangerous areas or places where access is limited. We also found that this technology accurately measured inspection sites. During the trials, live images were securely streamed online, so offsite inspectors could watch the operation.

In the future, we will assess using drones in more challenging sites, assess the cost of in-person vs. drone inspections, evaluate training for drone operators, and explore the challenges of storing and managing data.

3. Testing cooperative truck platooning systems

2.3 M

Greenhouse gas reduction, retrofit and automated vehicle regulations

Report on the considerations for on-road trials

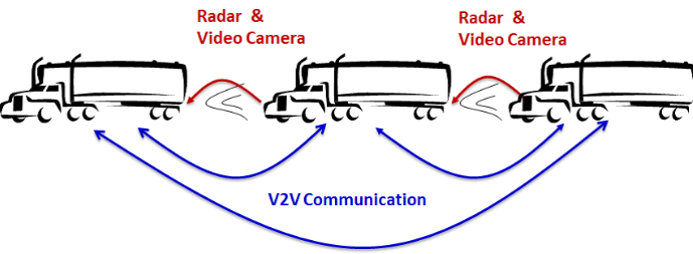

Figure 6: Illustration of how truck platoons use radar, video cameras and vehicle-to-vehicle communication

In 2019, TC began a 3-year Cooperative Truck Platooning System pilot as part of the government's regulatory review roadmap. A cooperative truck platoon uses wireless signals and automation to create a group of trucks that drive close together. This reduces aerodynamic drag and can improve fuel use, greenhouse gas emissions, road safety and road use. Results from this trial will help us develop industry guidance, guidelines, tools and regulations needed to support the use of cooperative truck platooning in Canada.

In summer 2019, we tested the fuel use, fuel consumption and behavior of platooning trucks at our Motor Vehicle Test Centre in Blainville, Quebec. This work was done in partnership with the Ontario Ministry of Transportation, the Quebec Ministry of Transportation, the National Research Council, the U.S. Department of Energy National Renewable Energy Laboratory, Auburn University, PMG Technologies and FPInnovations.

We found that platooning could save over 10% of fuel. The data we collected gives us valuable information on fuel use in curved roads, imperfectly aligned trucks within traffic lanes and the effects of nearby light-duty vehicles on traffic conditions. We developed tests to assess how platoons performed during hard braking and vehicle cut-ins. This testing can help us define the conditions that are safe for operating a platoon.

Figure 7: Areal picture of a 2-truck platoon track test with Auburn University

In September 2020, we published a report on key considerations for starting on-road trials of cooperative truck platooning systems in Canada. This includes considering operational concepts, safety, technical needs, legal requirements, regulatory requirements and infrastructure.

After publishing the report, we launched a request for proposals for a 6-month trial to combine a cooperative truck platooning system with an existing Canadian trucking fleet with professional drivers on a route used to transport passengers and revenue-earning freight or goods. The Alberta Motor Transport Association will be carrying out this on-road trial, and will monitor fuel use, traffic impacts, safety factors and driver fatigue.

4. Developing clean rail technologies

50k

Pan Canadian Framework on Clean Growth and Climate Change, Clean Fuel Standard

Analyzed Switcher locomotive design and cost model

Figure 8: Picture of a GP38-2 switcher locomotive

The rail sector is responsible for approximately 4% of Canada's greenhouse gas emissions. Due to the long lifecycle (30+ years) of rail equipment, we need to develop commercially ready, zero-emission propulsion systems in order to meet our zero emissions goal for the rail sector by 2050. Using hydrogen is one way that we could meet this goal that would capitalize on Canada's efforts to establish a robust hydrogen economy as set out in Canada's Hydrogen Strategy (PDF, 11.1 MB).

In June 2020, the Innovation Centre completed a feasibility study (PDF, 8.09 MB) to assess the technical and regulatory requirements and cost of converting a diesel switcher locomotive to use hydrogen fuel. Switcher locomotives are used to move railcars around a railyard, and take apart trains once they return. They are in constant operation and a steady source of air pollution and greenhouse gas emissions. They operate at a single location and only need one refueling spot, making them attractive tests for hydrogen propulsion technology.

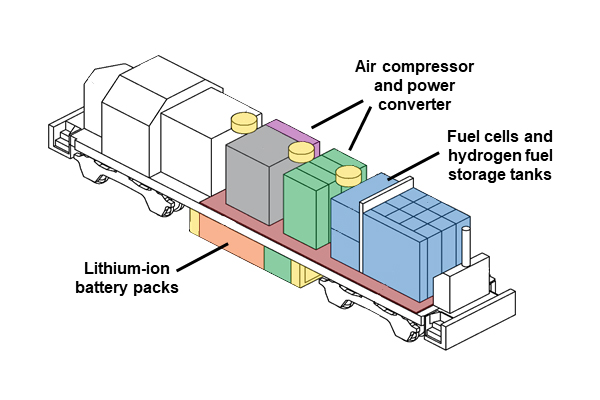

The study created a framework to demonstrate a hydrogen locomotive prototype. We analyzed a concept design for a retrofitted GP38-2 switcher locomotive using commercially available parts:

- fuel cell power modules

- onboard hydrogen storage and

- battery packs with enough power to match or exceed the power needed for the locomotive's daily work

Figure 9: Proposed design of retrofitted GP38-2 switcher locomotive illustrating the location of hydrogen fuel cells and storage tanks, air compressors, power converters, and lithium-ion battery packs.

We developed order of magnitude estimates of the costs for a conversion and demonstration project. The estimated cost to design and convert a locomotive may be in the order of magnitude of $7M. The simplest way to supply hydrogen is using a truck tank trailer, with a capital equipment cost of approximately $300k. However, this is more expensive than buying diesel. This system will help keep costs low for short-term testing, but having an electrolyzer on-site to produce hydrogen could help lower fuel costs over time for larger, long-term tests. This change could help generate savings in approximately ten years.

In the final report, a pilot project is proposed that would use a hydrogen switcher locomotive in more complex tests. This would help us understand the safety considerations, codes, standards and best practices needed for hydrogen switcher locomotives to be used commercially.

5. Improving safety in the transportation of dangerous goods

In-kind services

Means of containment safety standards, emergency response

Updated chlorine release computer models and ERG

Figure 10: Large scale chlorine release field trial with Utah Valley University Emergency Services showing the green toxic release cloud and testing environment

In North America, chlorine is the second most transported toxic inhalation hazard gas. It is difficult for computer models to simulate chlorine releases because chlorine is denser than air. In 2010, the U.S. Department of Homeland Security Chemical Security Analysis Centre and the U.S. Defense Threat Reduction Agency launched the Jack Rabbit Research Program to close this knowledge gap.

The program was originally created to study small releases of chlorine and ammonia. Since 2013, our Transportation of Dangerous Goods Directorate has participated in Jack Rabbit II to better understand how large-scale chlorine releases behave.

With funding from Defence Research and Development Canada, the directorate has participated in large-scale field trials and a chlorine reactivity chamber study. The results of field trials were used to update the computer models that evaluate impact areas and validate the initial isolation and protective distances in the 2020 edition of the Emergency Response Guidebook (ERG).

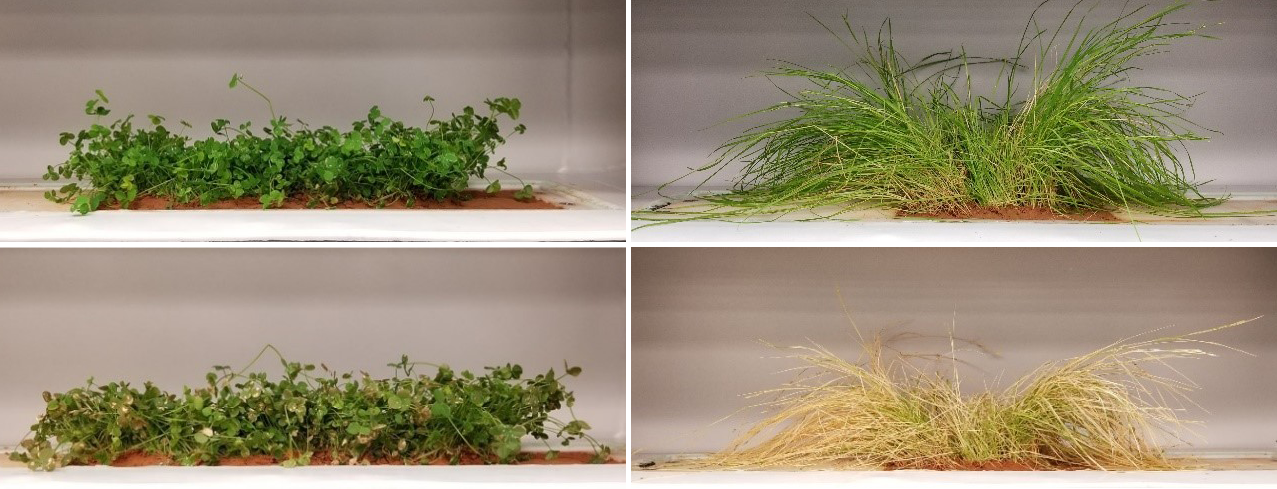

Figure 11: White clover (left) and rye grass (right) samples before and after chlorine reactivity testing. After testing the plants have both lost colour due to reaction with chlorine.

The guidebook was developed by TC (CANUTEC), the U.S. Department of Transportation, the Secretariat of Transport and Communications of Mexico, and the Centro de Informaciòn Quìmica para Emergencias of Argentina. The guidebook is updated every 4 years, and includes information on evacuation distances for a dangerous goods incident for firefighters, police, and other emergency responders.

A controlled environment reactivity test chamber study was done at the University of Arkansas. During the study, researchers designed and built a chamber to test chlorine’s reactivity with different types of soil and plants. Results showed that reactivity rates vary between plants, and that there’s a point where plants stop reducing the concentration of a chlorine cloud.

A final report was written by the University of Arkansas in March 2020. These findings will be used to update computer models, and could lead to changes in initial isolation and protective action distances in future versions of the guidebook.

6. Working with governments and industry to launch a low speed automated shuttle pilot

500k

Connected and Automated Vehicle Regulations

First on-road trial, operated in automated mode 95% of the time

Figure 12: Easymile EZ10 Shuttle

There’s interest, in Canada and around the world, in using low-speed automated shuttles as a solution for gaps in public transportation at the beginning or end of a trip, known as the first or last-mile transit.

In September 2020, the Innovation Centre launched a 3-stage low-speed automated shuttle pilot project to:

- learn about the planning and approval process for these kinds of tests in Canada

- understand the driving abilities of low-speed automated shuttles, and

- feed into TC, the Ontario Ministry of Transportation and the City of Ottawa's safety approaches for this technology

The project tested an EasyMile EZ10 all-electric 6-seat shuttle. The shuttle used laser technology to measure distances and detect objects and its environment. Combined with GPS information, this allowed the shuttle to carry passengers in automated mode on a pre-set route.

Figure 13: Low speed automated shuttle test to validate how sensors react to an artificial Canada goose

The project began with extensive planning and stakeholder engagement to develop a safety management plan and have the project approved. In Phase 2, we worked with Invest Ottawa and the National Research Council on closed-track testing at Area X.O test facilities.

Our tests evaluated how the shuttle interacted with vulnerable road users (cyclists, pedestrians), signal localization, human factors, and battery efficiency. These tests were followed by an on-road trial in Ottawa where the vehicle operated in automated mode at 15 km/h in on a 1,500 m loop. The shuttle was supervised by a driver, and the vehicle was exposed to environmental conditions, such as blowing snow and Canadian Geese.

During the 2-week trial, the shuttle carried 670 passengers and drove on its own (automated mode) 95% of the time. We collected data on how the shuttle dealt with vulnerable road users and weather, such as emergency stops for blowing leaves or snow.

The final results of the pilot project will give us valuable data on real-world use of a low-speed automated shuttle. This data will help us develop guidelines, best practices, and approaches so low-speed automated shuttles can be safely used in Canada.

The Experimentation Fund

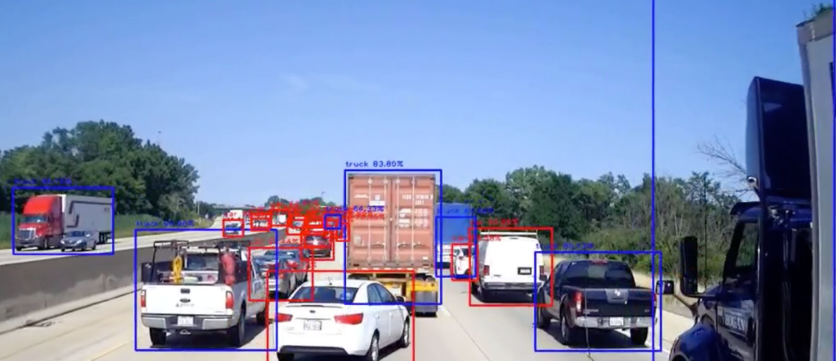

Figure 14: Advanced driver assistance systems testing in winter conditions. Images of cars with advanced driver assistance systems tested under snowy conditions, responding to pedestrians and other vehicles

The Experimentation Fund was created in 2020 to support the use of innovative practices at TC and a culture of experimentation and continuous improvement in the way we design and deliver programs and policies. Experimenting is key to the government's focus on evidence-based policy-making, results and discovery.

In 2021, the fund split $3M across 12 projects:

- Automating robotic processes (Corporate Services)

- Analysing and visualising financial data (Corporate Services)

- Creating a Centre of Excellence for automating robotic processes (Digital Services and Transformation Office)

- Emerging and Disruptive Tech Incubation Lab (Digital Services and Transformation Office)

- Improving federal service delivery in the North led by TC's Government of Canada Entrepreneur (Digital Services and Transformation Office)

- Advanced driver assistance systems (Programs Group)

- Demonstrating low speed electric and autonomous shuttles (Programs Group)

- Operationally testing, evaluating and reviewing drones (Programs Group)

- Improving corporate planning processes using Corporate Data Pathfinder (Management and Operations)

- Hiring more staff to monitor social media (Communications Group)

- Remotely piloted aircraft systems (Safety and Security Group, Aviation Security Branch)

- Approving automated inspection technology for rail safety transformation plan (Safety and Security Group)

Many of these projects have interesting initial results. For examples, the advanced driver assistance systems project was created to improve our understanding of how these systems perform in winter conditions and to find ways to improve safety.

Tests were developed based on European methods used to assess the effects of snow and ice build-up on vehicles and roads, and winter clothing worn by pedestrians. We tested the advanced driver assistance systems of 6 vehicles to get data that could be representative of Canada's fleet.

Initial results show that the advanced driver assistance systems performed poorer in winter conditions than summer, including delays in the detection of vehicles and pedestrians. This means that there may be fewer benefits to using these systems in the winter.

Future tests will capture how commercially available systems evolve to manage the risks of collisions year-round. Additionally, we will continue to develop winter testing methods.

What’s next?

Figure 15: Cooperative truck platooning system on-road trial. Picture of platoon trucks and surrounding traffic that affects platoon operation. Photo by Alberta Motor Transport Association

In the next year, TC will continue to research, develop and deploy projects that directly impact policies and regulations for a safe, secure, clean and integrated transportation system. We will focus on next generation technologies, like launching Canada’s first on-road cooperative truck platooning test-bed in Alberta.

The on-road test bed will operate for 6 months starting in summer 2021, allowing us to evaluate platooning in summer, fall, and winter. We will collect data from more than 60,000 km of real world use to assess how platooning affects fuel use, safety, reliability, and the experiences of drivers. Results will help us to decide how to develop the laws, policies and programs we need to use connected and automated vehicles in Canada.

The Innovation Centre's Rail Research Work Plan for 2022-2025 will tackle the following priorities:

- automating inspections

- cyber security

- developing drop-in diesel replacements

- reducing emissions from air pollution

- looking at codes and standards for hydrail development, and

- supporting demonstration projects for zero-emission, low-carbon fuels

With $3.69M, the Experimentation Fund will continue to fund 14 new projects in 2021-2022:

- Monitoring of transportation infrastructure networks by satellite (Programs Group, Innovation Centre)

- Developing and certifying electric propulsion systems for civil aviation (Safety and Security Group)

- Drone range estimator demonstration project (Programs Group, Innovation Centre)

- Using data analytics to optimize multimodal oversight planning (Safety and Security Group)

- Pre-load air cargo targeting with artificial intelligence (Safety and Security Group)

- Testing advanced driver assistance systems in complex intersections (Programs Group, Innovation Centre)

- Ice crystal icing in aircraft engines (Safety and Security Group)

- MASS sensor test bed platform (Programs Group, Innovation Centre)

- Automated Navigation Protection Program scanning tool, phase I (Programs Group, Innovation Centre)

- Web-based information for TC's delegation of HR authorities (Corporate Services)

- Broad deployment and testing of a common client relationship management platform (Safety and Security Group)

- Testing truck platoon dynamics (Programs Group, Innovation Centre)

- Aircraft ground icing (Safety and Security Group)

- Experimenting with artificial intelligence and PowerApps improve the public's awareness of TC's service pages (Digital Services and Transformation Office)

In 2021, TC's first Departmental Science Advisor, Dr. Gordon Lovegrove, will begin a 2-year, part-time tenure. Jointly appointed with Infrastructure Canada, Dr. Lovegrove will use his expertise and network to give scientific advice, help with early issue identification, and strengthen the department's core research and scientific capacity.

With improved governance, new programs, and renewed linkages with other government departments, academia and industry, TC continues to enable bold and innovative transportation solutions to support the safe and secure implementation of next generation clean, integrated transportation.

Annex A: RD&D governance at TC

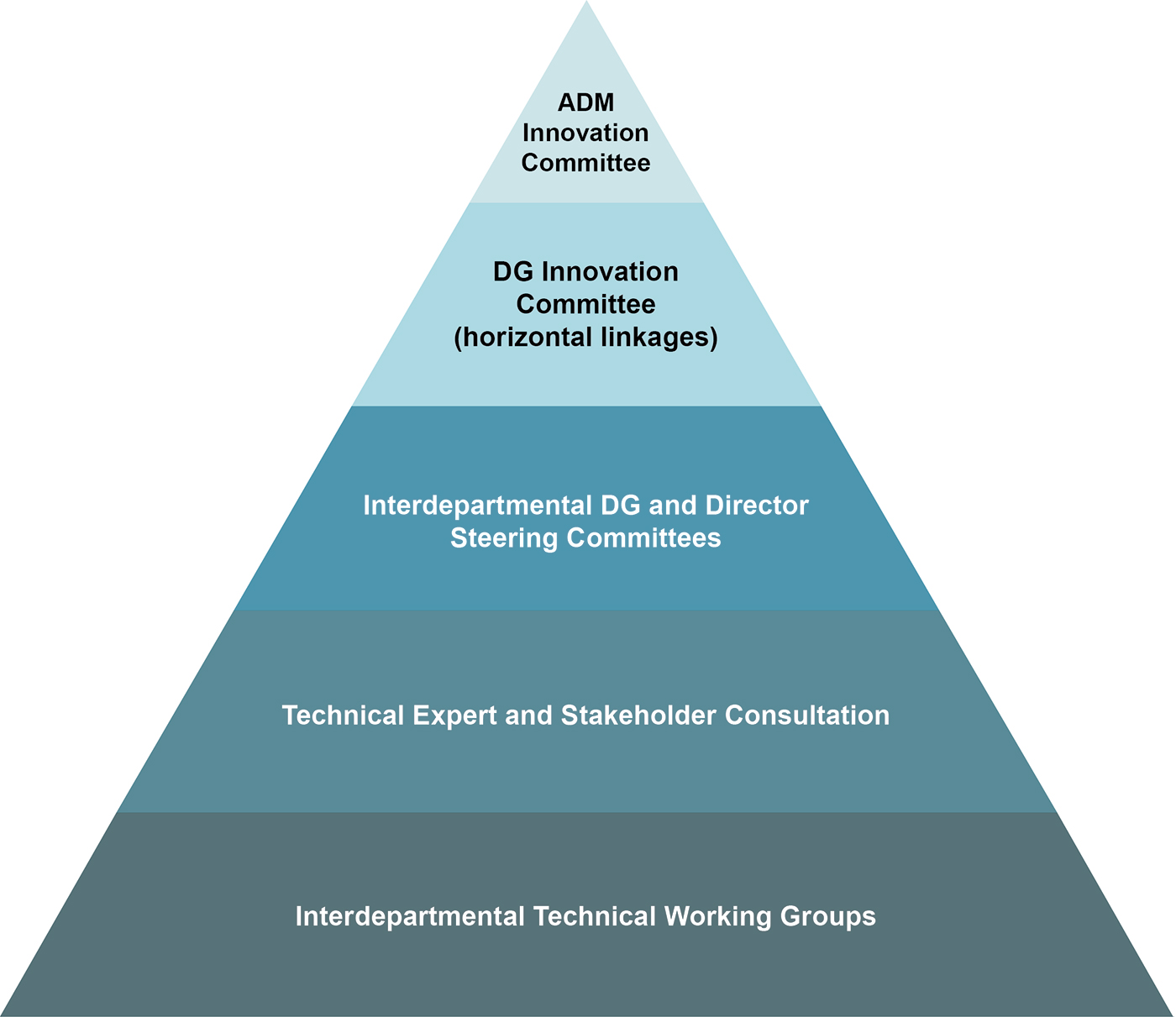

We have created a number of committees to strengthen the department's RD&D oversight and governance, enhance linkages with industry and government, and ensure research outcomes are aligned with departmental and transportation stakeholder needs. These committees provide high level oversight of innovation projects and engage with key external stakeholders in the project review process.

RD&D governance is overseen by the following structures:

- The Assistant Deputy Minister (ADM) Innovation Committee provides high level oversight of RD&D activities.

- The Director General (DG) Innovation Committee is a horizontal, multi-modal committee with DG membership from across TC. The committee engages in information sharing, strategic integration and alignment, and medium-term planning of innovative departmental initiatives. The committee also supports integrated business planning and corporate reporting activities where coordination is required.

- The DG and Director-level Committees establish priorities and approve annual work plans.

- Technical Expert and Stakeholder Consultations are held regularly to engage technical staff from federal departments, Provinces, Territories, and U.S. agencies to inform work plan development.

- Interdepartmental Technical Working Groups convene regularly to share information, peer review results and methodologies, problem solve, review project plans and propose new ideas.

Figure 16: Pyramid structure of RD&D governance at TC. From top to bottom, the governance structures include: ADM Innovation Committee, DG Innovation Committee, Interdepartmental DG and Director Committees, Technical Experts and Stakeholder Consultation, and Interdepartmental Technical Working Groups.

Annex B: List of TC’s RD&D projects 2020-2021

| Theme | Project Title | |

|---|---|---|

| Air (Innovation Centre) | ||

| De-icing Technology | 1 | Cold Climate Aviation Technologies – Ground icing research and development of products, processes and equipment involved in de/anti-icing aircrafts |

| 2 | Cold Climate Aviation Technologies with NRC Climate Engineering Facility, including cold chamber testing | |

| 3 | Testing new de/anti-icing fluids with freezing or frozen precipitation in order to further develop holdover and allowance time tables | |

| 4 | Airborne in-cloud icing and large drop experiment and instrumentation research and development with ECCC | |

| 5 | Preparation for the development of artificial snow machines for the evaluation of de/anti-icing fluid lifespan performance | |

| Air (Safety & Security) | ||

| Civil Aviation, Environmental Protection | 6 | Research on non-volatile particulate matter (nvPM) and black carbon emissions for civil aviation gas turbine engines |

| 7 | Effects of conventional jet fuel and biofuel blend use on aviation emissions and contrail formation | |

| RPAS | 8 | Drone impact assessment – air-to-air collisions |

| 9 | Traffic density model – air-to-air collisions | |

| 10 | Ground impact injury study to study effects of air-to-ground collisions on vulnerable populations and determine what level of injury is ‘acceptable’ from a brain response perspective | |

| 11 | RPAS Traffic Management (RTM) trial | |

| 12 | Detect and Avoid solutions | |

| 13 | Icing/severe weather conditions – effect of propeller size and wind | |

| 14 | Investigation of wind effects on RPAS in different environments | |

| 15 | Certification of autonomous flight systems | |

| 16 | Drone site selection tool | |

| Marine (Innovation Centre) | ||

| Clean Marine | 17 | Characterization of marine black carbon emissions and development of new measurement methodologies |

| 18 | Conversion of a Cape Islander fishing vessel from diesel propulsion to side by side hybrid electric systems and comparative analysis of emissions | |

| 19 | Quantify the benefit of new friction coatings and their effect on vessel fuel consumption and underwater radiated noise | |

| 20 | Study of liquefied natural gas as a marine fuel in the Canadian Arctic | |

| 21 | Marine zero fuel assessment tool to assess alternative fuels for a marine fleet and port operations in Canada | |

| 22 | Feasibility study to determine the potential adoption of a scrubber barge technology to reduce air emissions from vessels at Canadian ports | |

| 23 | Development of best practices/maintenance strategies to accomplish fuel savings, environmental benefits, and optimize maintenance costs associated with hull coating and propeller polishing on Laker vessels | |

| 24 | Project to support implementation of a vessel fuel optimization software to identify fuel efficient routes for vessels and develop a web tool to demonstrate greenhouse gas reductions for optimized routes | |

| 25 | Prototype design of an on-the-go robotic ship cleaning technology as a hull cleaning device to be used in transit | |

| Marine Mammal Protection – Reducing Underwater Noise and Vessel Strikes | 26 | Voluntary lateral displacement in the Strait of Juan de Fuca to mitigate underwater noise |

| 27 | Contract with Vancouver Fraser Port Authority (VFPA) Enhanced Cetacean Habitat and Observation (ECHO) program to analyze hydrophone data collected by various hydrophones, including from the Boundary Pass ULS, to measure and mitigate underwater vessel noise | |

| 28 | Modelling and analysis to evaluate the non-cavitational noise generated from the vessel propellers | |

| 29 | Deployment of an underwater listening station in Boundary Pass to collect vessel noise data and marine mammal calls | |

| 30 | Passive acoustic monitoring for North Atlantic Right Whale detection using a hydrophone-mounted glider in the Golf of St. Lawrence | |

| 31 | Study of how propeller defects can affect propeller performance and underwater radiative noise | |

| 32 | Establishment of noise baseline in the Salish Sea and modelling of noise reduction from ships in various scenarios | |

| 33 | Study of quiet ship certifications using the Vancouver Fraser Port Authority Enhanced Cetacean Habitat and Observation (ECHO) program ship noise database | |

| 34 | Technology scan of mature and near commercial technologies for reducing underwater noise | |

| 35 | Report on technical and operational means of mitigating underwater radiated noise from small vessels | |

| 36 | Study of underwater radiated noise from echolocation sources used on commercial and recreational vessels to develop recommendations for design and operational mitigation measures | |

| 37 | Creation of a technical bibliography on underwater radiated noise | |

| 38 | Study of off-board vessel noise prediction in ORCA-class training vessels | |

| 39 | Report to support the validation of predictive models for underwater radiated noise of ORCA-class vessels for the Netherlands Defense Material Organization workshop ‘Benchmark Underwater Radiated Noise Simulation (BURNSi)’ | |

| 40 | Design and evaluation of new propellers for ORCA-class vessels to reduce underwater radiated noise through simulation and model testing | |

| 41 | Optimization of commercial vessel propellers of two civilian ships to reduce underwater radiated noise and determine the transferability to other ship types | |

| 42 | Study to identify a suitable propeller design to mitigate underwater radiated noise in ferries | |

| 43 | Development of a real-time cavitation monitoring and feedback system for small vessels with KINETIX shock and vibration sensors | |

| 44 | Support the development of shallow water vessel noise measurements standard, through a contract with JASCO Applied Sciences | |

| 45 | Develop and test a prototype cavitation monitoring system based on pressure transducer(s) mounted on the hull above the propeller and determine its effectiveness to reduce underwater noise emissions | |

| 46 | Study of the impact of underwater radiated noise reduction on compliance with Energy Efficiency Design Index Criteria | |

| 47 | Study of the impact of graphene coatings on fish vessels on underwater vessel noise and greenhouse gas reductions and development of an educational program for fishing fleets | |

| Multi-modal | ||

| Innovation Centre | 48 | Satellite-based infrastructure monitoring |

| 49 | ARA Robotics Drone-based Infrastructure Health Monitoring | |

| 50 | Advancing Connected/Automated Vehicle Security Technology with Carleton University and Blackberry | |

| 51 | Self-Healing Automotive Cyber Security (SHACS) to enhance the cyber-resiliency of electronic automotive systems with AKIMBO Inc. | |

| 52 | Heavy Duty Vehicle Truck Trailer Cyber Security to investigate security vulnerabilities | |

| 53 | Assessing the performance of Canadian technology to monitor and track trucking operations at the Port of Trois-Rivières through Bluetooth tagging | |

| 54 | Research in Position-Navigation-Timing (PNT) requirements for next generation transportation systems through research and stakeholder engagement | |

| 55 | SmartWhales initiative to contribute to the protection and recovery of North Atlantic Right Whales (NARW) in Canadian coastal waters through detection and monitoring and predictive modelling of behavior and movement in their habitat | |

| 56 | Investigate automated tools to help locate, identify and scrutinize potentially unlawful structures in navigable waters under the Navigation Protection Program (NPP) | |

| 57 | Explore and address Canada’s involvement with Marine Autonomous Surface Ships (MASS) | |

| Rail (Innovation Centre) | ||

| Harsh and Changing Environments | 58 | Railway Ground Hazard Research Program to identify, assess and mitigate ground hazard risk and develop standards and solutions |

| 59 | Enhanced landslide monitoring and assessment tools and technologies | |

| 60 | Assist in the management and delivery of the Canadian Rail Research Laboratory Phase II research program to address railway stakeholder priorities to improve safety and efficiency of Canadian railways | |

| 61 | Assessment of new and existing technologies to help resolve cold weather track and equipment challenges | |

| Infrastructure and Rolling Stock | 62 | Emerging Technologies for monitoring and managing water levels around railway tracks |

| 63 | Modeling and analysis of derailment risk factors | |

| 64 | International Collaborative Research Initiative (ICRI) collaboration to develop solutions to wear of rails and wheels to reduce catastrophic failures | |

| 65 | Cold climate subgrade research to understand the viability of linear infrastructure under permafrost and winter conditions to extend access to northern communities | |

| 66 | Literature review on the railways constructed in Canadian permafrost regions | |

| 67 | Rail data collection analysis comparative analysis of Canadian rail data collection systems to other world regions | |

| Service Efficiency and Capacity | 68 | Risk tolerance strategy for rail transport of dangerous goods |

| 69 | Automated inspection technologies quantitative assessment of rolling stock inspection technologies | |

| 70 | Software assessment tool for short line rail risk to develop risk assessments for federally-regulated railways | |

| 71 | Rolling stock and equipment inspection technologies scan literature review | |

| Human Factors | 72 | Cognitive impacts of in-cab warning systems – assessment of locomotive operating practices and guidelines related to in-cab warning systems to assess impacts on cognitive workload |

| 73 | Assessment of wearable GPS and automated communications systems to improve safety of railway workers in the field | |

| 74 | Automation of rail (passenger and freight) operations – study of current automation in passenger and freight operations around the world and feasibility considerations in the Canadian context | |

| Clean Rail | 75 | Hyperloop exploratory study to understand the technical capabilities, maturity and costs of the Hyperloop technologies to inform regulatory policy and prototype funding |

| 76 | Quantitative assessment of the methane slip occurring from the transportation of LNG by rail | |

| 77 | Development of travel advisory tools and applications to provide traveler information and traffic management tools to mitigate congestion and delays caused by blocked grade crossings | |

| 78 | Review of the data, approaches and tools to measure the impact of transportation system improvements on trade corridor productivity and sustainability | |

| 79 | Assessment of impact higher-concentration-blend lignin-derived diesel fuels on diesel engine exhaust emissions | |

| 80 | Measurement of locomotive exhaust emissions during normal revenue operations in summer and winter conditions | |

| 81 | Two-in-one catalytic converter for removal of nitrous oxides and particulate matter from locomotives without reducing power output | |

| 82 | Hydrail switcher locomotive project assessment of the design and deployment characteristics and requirements | |

| 83 | Rail innovation in Canada Scan with the Canadian Urban Research and Innovation Consortium (CUTRIC) to support the department’s efforts to facilitate a more integrated and sustainable transportation system | |

| 84 | Hydrail Railway Transition in Canada: Technological, Operational, Economical, and Societal Barriers and Opportunities | |

| Road (Collaborative between the Innovation Centre and Motor Vehicle Safety) | ||

| 85 | Evaluating testing protocols and performance of commercially available automatic emergency braking (AEB) technologies under common collision scenarios | |

| 86 | Evaluating current and future testing procedures of commercially available lane support system (LSS) technologies including Lane Keeping Assistance System (LKAS), Automatic Emergency Steering Assist (AES) and Blind Spot Monitoring Assist (BSM) | |

| 87 | Evaluating and developing testing protocols using commercially available Vulnerable Road User (VRU) AEB technologies under various scenarios including adult pedestrian, child, cyclist and motorcyclist (Applies to school buses) | |

| 88 | Evaluating established protocols for heavy-duty advanced driver assistance systems (ADAS) | |

| 89 | Evaluating how advanced technologies on school buses could improve the safety of students | |

| 90 | Study of ADAS limitations, event data recorder (EDR) parameters and other on-board data during AEB activation | |

| 91 | Track Testing of School Bus Safety Equipment | |

| 92 | Automatic Emergency Braking for Heavy Duty Vehicles | |

| 93 | Automatic Emergency Braking (AEB) – Methods and vehicle performance assessment | |

| 94 | Lane Support System (LSS) and Blind Spot Monitoring | |

| 95 | Reconstructions of crashes involving potential ADAS technology malfunctions | |

| 96 | Low Speed Automated Driving Shuttle testing support | |

| 97 | Advanced Driver Assistance System (ADAS) testing to evaluate new testing protocols and performance of commercially available ADAS technologies under a range of collision scenarios | |

| Road (Innovation Centre) | ||

| ACATS | 98 | Canadian Automobile Association to educate consumers about new connected and automated safety technologies |

| 99 | Canadian National Institute for the Blind study on the impacts of connected and automated vehicles on pedestrians with sight loss | |

| 100 | Canadian Urban Transit Research and Innovation Consortium study on the integration of automated and electric transit shuttles in nine communities across Canada | |

| 101 | Carleton University study to evaluate how connected and automated vehicles will influence infrastructure design and planning | |

| 102 | City of Calgary project to establish a connected vehicle test-bed along 16th Avenue North | |

| 103 | City of Calgary project to test an automated shuttle connecting light transit with the Calgary Zoo and Telus Spark Science Centre | |

| 104 | City of Ottawa project to install smart traffic signals to reduce vehicle emissions and improve traffic flows | |

| 105 | City of Saskatoon project to support capacity building on connected and automated vehicles | |

| 106 | City of Toronto pilot deployment of an automated transit shuttle on public roads | |

| 107 | City of Vancouver study to prepare an urban CAV testing strategy for future trials and deployments, focusing on civic fleets and infrastructure | |

| 108 | CSA Group project to develop guidelines and a standardization roadmap for the safe deployment of connected and automated vehicle technologies in Canada | |

| 109 | Intelligent Transportation Systems Society of Canada project to update planning tools to help Canadian transportation professionals implement smart roadway infrastructure | |

| 110 | Ministry of Transportation of Ontario project to support planning and capacity building for connected and automated vehicles in the Greater Toronto and Hamilton Area and Waterloo corridor | |

| 111 | University of Alberta project to investigate new approaches to help ensure that connected vehicle communications are safe, secure and consistent with Canadian privacy requirements | |

| 112 | Unmanned Systems Canada competition to help students learn about automated vehicle technologies | |

| Crash Avoidance | 113 | AEB winter testing project |

| 114 | Developing and evaluating test methods for 2D motion of vehicles to understand ADAS technologies in more complex scenarios | |

| Road (Motor Vehicle Safety & Security) | ||

| School Bus Safety | 115 | Seat Belt in School Buses Pilot Project |

| Truck Safety | 116 | Vulnerable Road User (VRU) Safety Around Heavy Duty Vehicles – Field of View Study |

| Automated Vehicles and Driver Assistance | 117 | Technical review of AV sensors |

| 118 | Technical Review of Best Practices for the use of Simulations and Simulation-Based Testing for CAVs and Lessons Learned from Other Sectors | |

| 119 | Simulation-based Testing Framework and Qualification of Virtual Testing Tools for Automated Driving Systems | |

| 120 | Public Opinion Research on Consumer Awareness of and Confidence in AVs and ADAS technologies | |

| 121 | V2V testing | |

| 122 | Safety implications of cooperative truck platooning | |

| 123 | Technical review of connectivity technologies | |

| Human Factors | 124 | Rider Perceptions of Safety, Interaction and Acceptance of a Low Speed Automated Shuttle in Mixed Traffic: EasyMile Shuttle-Tunney’s Pasture |

| 125 | User Experience Assessments of Automated Driving Systems: Workshop Data Collection: Auto UI 2020 | |

| 126 | Non-Driving Related Task (NDRT) Interfaces for L3 Automated Driving Systems | |

| 127 | Human Machine Interface (HMI) & User Interaction Assessment of L2 Vehicles | |

| 128 | On-road performance of ADAS systems from a safety and human factors perspective | |

| 129 | Human Factors Challenges of Remote Support & Control: A position paper from HF-IRADS for the UNECE | |

| 130 | International Organization for Standardization (ISO) development of standards (ISO TC 22 SC 39 WG 8) for driver monitoring and system intervention, naturalistic driving studies, driver misbehaviour | |

| Road (Innovation Centre - eTV) | ||

| Emerging light duty vehicle technologies | 131 | Emissions and energy performance testing of advanced light-duty vehicles including zero emission vehicles, advanced engines, and fuels |

| 132 | Electric vehicle durability testing: Evaluating the long-term performance durability of EVs subjected to bi-directional charging and fast charging | |

| 133 | Testing the crashworthiness of electric vehicles and light-weight vehicles in comparison to conventional counterparts | |

| 134 | Assessing the performance of an electric taxi fleet through collection and analysis of battery usage data and operational parameters during charging and driving events | |

| 135 | Evaluating the safety performance of state-of-the-art fuel cell vehicles in terms of hydrogen leak detection and vehicle crashworthiness | |

| 136 | Electric vehicle component tear-down to evaluate the power-to-mass ratio of motors and power electronics in order to verify or update 2025 projections used by environmental regulators | |

| 137 | Light duty vehicle GHG reduction technology review: Potential benefits, costs and payback times | |

| 138 | Aerodynamic testing in real-world traffic conditions to assess the impact of traffic density on fuel savings and GHG reduction potential of emerging aerodynamic technologies | |

| 139 | Analysis of hydrogen metering approaches | |

| 140 | Tire safety and environmental testing: Evaluating the relationship between rolling resistance and wet-grip/snow-traction to inform the development of tire standards and test procedures | |

| 141 | Electric vehicle battery cell testing to assess the impacts of cell/pack design and operational conditions on battery durability | |

| 142 | Electric vehicle lifecycle analysis to assess the GHG and cost impacts of transitioning to electric and electrified vehicles | |

| Emerging heavy duty vehicle technologies | 143 | Aerodynamic and coast down testing: Supporting development of reliable road-load and aerodynamic track-based methods for regulatory performance and compliance testing of ground vehicles |

| 144 | On-board sensors (OBS) for assessing HDV emissions of criteria air contaminants | |

| 145 | Natural gas vehicle emission testing to assess and demonstrate emission reduction potential compared to conventional vehicles | |

| 146 | Tire Pressure Monitoring Systems (TPMS): testing to assess the durability and reliability of TPMS in the HDV segment | |

| 147 | Analyzing track test results and infrastructure impacts to inform provincial/territorial regulations on 6x2 drivetrains | |

| 148 | Testing the effect of aerodynamic trailer side skirts on underbody corrosion | |

| 149 | Literature review of zero emission vehicle technology usage in the heavy duty vehicle sector | |

| 150 | Evaluating the performance of NOx after-treatment systems for Heavy duty vehicles in cold climates | |

| 151 | Steerable axles: Study of dynamic performance on long combination semi-trailers | |

| Connected and Automated Vehicles | 152 | Cooperative Truck Platooning Systems (CTPS): Assessment of factors to be considered in operating CTPS on Canadian roads |

| 153 | Evaluating the performance and failure modes of CAV implementations including dedicated short range communication (DSRC) systems and automated driver assist systems (ADAS) | |

| 154 | Assess the environmental impacts of connected and automated vehicles | |

| 155 | Building internal technical capabilities, developing, and demonstrating ITS-based tools and applications for safety and environmental benefits | |

| 156 | Cybersecurity testing on vehicles to identify threats and mitigation strategies | |

| Off-road sector | 157 | Off-road GHG emissions review and testing of technologies for reducing GHG emissions from off-road machines used in agriculture, construction & mining, and logging applications |

| 158 | Motorcycle and off-road recreational vehicle drive cycle development and fuel testing to improve and align North American test methods | |

| Green transit | 159 | Heavy- and medium-duty electric and fuel cell vehicle testing and demonstration |

| Transportation of Dangerous Goods | ||

| 160 | Tank car Fire Risk Analysis model - Crude Oil Computational Fluid Dynamics (CFD) & Equation of State (EOS) Modelling | |

| 161 | Analysis of Crude Oil Pool Fire Testing Data | |

| 162 | Tank Car Fire Failure Assessment Using Combined Models | |

| 163 | Crude Oil Sampling and Analysis Campaign | |

| 164 | Tank Car Coupling Speed Analysis | |

| 165 | Jack Rabbit II Chlorine Reactivity Chamber Studies | |

| 166 | Extension of Life for Composite Cylinders | |

| 167 | Validation of recommended emergency actions for liquefied natural gas (LNG) in the Emergency Response Guidebook (ERG) | |

| 168 | Comprehensive review of the criteria and thresholds for emergency response assistance plans (ERAPs) in the TDG Regulations | |

| 169 | Hazard assessment of energy storage systems (ESS) being transported in enclosed vessels for marine transport | |

| 170 | Development of a smart package for lithium battery transportation that indicates a warning about an issue inside the package | |

| 171 | Evaluation of any increased risks resulting from greater amounts of hydrogen being transported to hydrogen-vehicle fuelling stations | |

| 172 | Development of a geographic-information-system (GIS) based risk assessment methodology for the transport of dangerous goods by road | |

| 173 | Lithium Battery Packaging Standard Validation Testing | |

| 174 | Evaluation of the Risks Posed by Sub-Standard Lithium Batteries in Transport | |

| 175 | Modelling of Liquefied Natural Gas (LNG) Tank Fire Test | |

| 176 | Numerical Modelling of Crude Oil Pool Fires | |

| 177 | Validation of Dangerous Goods Rail Car Placement Rules | |

| 178 | Assessment of Advanced Non-Destructive Testing of Highway and Rail Tank Car Steels | |

| 179 | Assessing Derailment Performance of TC-117R Tank Cars | |

| 180 | Extension of Life for Intermediate Bulk Containers | |