Table of contents

- Part A - Canadian modifications to the LSA Code

- Part B - Canadian life-saving appliance (Non-SOLAS)

- Part C - Testing and evaluation of Canadian life-saving appliances (Non-SOLAS)

Part A Canadian modifications to the LSA Code

Chapter 1 General

1.1 Definition

No modification.

1.2 General requirements for life-saving appliances

1.2.1 In addition to the requirements of paragraph 1.2 of the International Life-Saving Appliance (LSA) Code (LSA Code), all equipment installed on board a Canadian vessel that requires instructions on how to operate it, must have:

1.2.1.1 essential operating or donning instructions clearly marked/printed on the equipment in English and French or pictograms; or

1.2.1.2 independent essential operating or donning instruction signage in lieu of the marked/printed instructions on the equipment, if the signage is:

1.2.1.2.1 in both English and French or a pictogram;

1.2.1.2.2 highly visible;

1.2.1.2.3 water and weatherproof; and

1.2.1.2.4 posted at each muster station or where the life-saving equipment is stored.

1.2.2 In addition to the requirements of section 1.2.1 above, instructions must be provided on how to properly attach the equipment when it is integrated into a system (e.g., hydrostatic release unit, lifebuoy lights, smoke signal), including any limitations.

1.2.3 In addition to the requirements of paragraph 1.2.2.9 of the LSA Code, labelling on equipment must include:

1.2.3.1 the standard to which it was tested and approved;

1.2.3.2 the name of the manufacturer; and

1.2.3.3 information that can be traced, including the date of manufacture or lot number, model designation and approval, and file or certificate number.

Chapter 2 Personal life-saving appliances

2.1 Lifebuoys

No modification.

2.2 Lifejackets

No modification.

2.3 Immersion suits

2.3.1 In addition to the requirements of paragraph 2.3.1 of the LSA Code, immersion suits must:

2.3.1.1 have a label clearly showing the sizing; and

2.3.1.2 be stored in bags or containers that clearly show the sizing.

2.3.2 For the purpose of paragraph 2.3.1.2 of the LSA Code, immersion suits must be designed to be worn without a lifejacket.

2.3.3 Despite paragraph 2.3.2.1 of the LSA Code, immersion suits must be made of material that has inherent insulation in accordance with paragraph 2.3.2.2 of the LSA Code.

2.4 Anti-exposure suits

No modification.

2.5 Thermal protective aids

No modification.

Chapter 3 Visual signals

No modification.

Chapter 4 Survival craft

4.1 General requirements for liferafts

4.1.1 All instructions and documentation required in paragraph 4.1.5.1 of the LSA Code must be provided in English and French.

4.1.2 One first-aid outfit referred to in paragraph 4.1.5.1.8 of the LSA Code is required for every 75 people of the capacity of a liferaft.

4.2 Inflatable liferafts

No modification.

4.3 Rigid liferafts

No modification.

4.4 General requirements for lifeboats

No modification.

4.5 Partially enclosed lifeboats

No modification.

4.6 Totally enclosed lifeboats

No modification.

4.7 Free-fall lifeboats

No modification.

4.8 Lifeboats with a self-contained air support system

No modification.

4.9 Fire-protected lifeboats

No modification.

Chapter 5 Rescue boats

No modification.

Chapter 6 Launching and embarkation appliances

6.1 Launching and embarkation appliances

6.1.1 General requirements

6.1.1.1 In addition to the requirements of paragraph 6.1.5 of the LSA Code, liferaft launching appliances must:

6.1.1.1.1 not use gravity as a means of turning out the device; and

6.1.1.1.2 in the case of a free-fall launching appliance, be capable of launching one liferaft at a time and be capable of being operated by one person.

6.2 Marine evacuation systems

No modification.

Chapter 7 Other life-saving appliances

7.1 Line-throwing appliances

No modification.

7.2 General alarm and public address system

No modification.

Part B Canadian life-saving appliance (Non-SOLAS)

Chapter 1 General

1.1 General requirements for life-saving appliances

1.1.1 All appliances listed in this Part must meet the requirements set out in Chapter 1 of Part A of this Standard.

Chapter 2 Personal life-saving appliances

2.1 Lifebuoys

The following lifebuoys are not intended to be operated with the quick-release arrangement provided for self-activated smoke signals and self-igniting lights.

2.1.1 Lifebuoys required under the Small Vessel Regulations must meet the requirements of paragraph 2.1 of the LSA Code, other than 2.1.1.1, 2.1.1.3 and 2.1.1.4, and must:

2.1.1.1 have an outer diameter of not more than 610 mm, an inner diameter of not less than 356 mm, a major axis of 127 mm, and a minor axis of 95 mmFootnote 1; or

2.1.1.2 have an outer diameter of 610 mm, an inner diameter of 330 mm, a major axis of 140 mm, and a minor axis of 76 mm.

2.1.2 A lifebuoy must be capable of supporting a weight of 7.5 kg of iron in freshwater, for a period of 24 hours.

2.1.3 A lifebuoy must have a mass of not less than 1.1 kg and not more than 6 kg.

2.1.4 In addition to the colours set out in paragraph 1.2.2.6 of the LSA Code, lifebuoys can be yellow, orange, red and white quartered, or white.

2.1.5 When a buoyant lifeline is fitted on the lifebuoy, it must meet the requirements of paragraph 2.1.4 of the LSA Code and must have a length of at least 15 m.

2.2 Lifejackets

2.2.1 Class 1 lifejackets must meet the requirements of CAN/CGSB-65.7 – Lifejackets.

2.3 Immersion suits

2.3.1 Immersion suits must meet the requirements of ANSI/CAN/UL 15027-2 Standard for Immersion suits – Part 2: Abandonment suits, requirements including safety, and must:

2.3.1.1 have a label clearly showing the sizing;

2.3.1.2 be stored in bags or containers that clearly show the sizing; and

2.3.1.3 be designed to be worn without a lifejacket.

2.4 Anti-exposure suits

2.4.1 Anti-exposure suits must meet the requirements of ANSI/CAN/UL 15027-2 Standard for Immersion suits – Part 2: Abandonment suits, requirements including safety, and must:

2.4.1.1 have a label clearly showing the sizing;

2.4.1.2 be stored in bags or containers that clearly show the sizing; and

2.4.1.3 be designed to be worn without a lifejacket.

2.5 Personal flotation devices

2.5.1 Personal flotation devices (PFD) must meet the requirements of:

2.5.1.1 Underwriters Laboratories, Inc. UL 1180 Standard for Fully Inflatable Recreational Personal Flotation Devices; or

2.5.1.2 Level 70 performance devices from ANSI/CAN/UL 12402-5 Standard for Personal Flotation Devices – Part 5: Buoyancy Aids (Level 50) – Safety Requirements.

Chapter 3 Visual signals

3.1 Hand flares

3.1.1 Hand flares must meet the requirements of paragraphs 3.2.1, 3.2.2.1 and 3.2.2.4 of the LSA Code, and must have a luminosity of not less than 500 candelas for a period of at least two minutes.

3.2 Multi-star flares

3.2.1 Multi-star flares must be capable of producing, in rapid succession and at intervals not greater than 15 seconds, two or more red stars, each of which star must burn with a bright red colour with a luminosity of not less than:

3.2.1.1 10,000 candelas for a period of not less than 5.5 seconds, and be capable of being projected to an altitude of not less than 60 m and burn out before touching the sea; or

3.2.1.2 5,000 candelas for a period not less than 4 seconds and be capable of being projected to an altitude of not less than 90 m and burn out before touching the sea.

3.2.2 Where a visual signal only produces a single red star within a 15-second interval but meets the requirements of multi-star flares in all other respects, the visual signal or its package must be clearly marked to indicate that the two devices must be projected within 15 seconds of one another to meet the requirements of multi-star flares.

3.2.3 Multi-star flares must be provided with a firing device capable of throwing the stars automatically or a cartridge-firing device that requires loading for each signal.

Chapter 4 Survival craft

4.1 Reduced capacity liferafts

4.1.1 Reduced capacity liferafts must meet the requirements of paragraphs 4.1.1, 4.1.2.2, 4.2 and 4.3 of the LSA Code.

4.1.2 Instead of the marking requirements in paragraph 4.2.6.3.4 of the LSA Code, the “SOLAS” marking must be replaced with “REDUCED CAPACITY LIFERAFT” and “RADEAU DE SAUVETAGE À CAPACITÉ RÉDUITE”.

4.2 Inflatable rescue platforms

4.2.1 Inflatable rescue platforms must meet the requirements of paragraphs 4.1.1.2 to 4.1.1.4, 4.1.3.1, 4.1.6.1 to 4.1.6.3, and 4.2.6.1 of the LSA Code and the modifications provided in this section.

4.2.2 Inflatable rescue platforms must be fitted with an emergency pack meeting the requirements of paragraph 4.1.5 of the LSA Code and must be fitted in a location accessible from both sides of the platforms.

4.2.3 Construction

4.2.3.1 Inflatable rescue platforms must be constructed so that the appliance can perform its intended function in exactly the same manner either side up.

4.2.3.2 Inflatable rescue platforms must have a single-layer floor mounted between the buoyancy compartments.

4.2.3.3 Inflatable rescue platforms must inflate with non-toxic gas in no more than three minutes after the activation of the inflation mechanism at a core temperature of 0˚C. After inflation, the platform must maintain its form when loaded with its full complement of persons and equipment.

4.2.3.4 Each compartment of an inflatable rescue platform must be capable of withstanding a pressure exceeding three times the working pressure and must be prevented from reaching a pressure exceeding twice the working pressure, by means of pressure relief valves or limited gas supply.

4.2.3.5 Every inflatable rescue platform must be fitted with a painter of a length equal to at least the greater of 15 m and twice the distance from the stowed location to the waterline of the vessel in its lightest seagoing condition.

4.2.3.6 Every inflatable rescue platform must have an automatically activated light, meeting the requirements of paragraph 4.1.3.3 of the LSA Code, with the exception that the light will not be fixed to a canopy.

4.2.3.7 Every inflatable rescue platform must be provided with towing patches capable of withstanding a force required to tow the platform at a speed of at least 2 knots.

4.2.3.8 Water pockets are not required but if fitted, they must be provided on both sides of the platform and constructed in accordance with paragraph 4.2.5.4 of the LSA Code.

4.2.3.9 If the floor includes one or more drains, each drain must be arranged to completely drain the floor of water when the device is fully loaded and prevent water from flowing back onto the floor.

4.2.3.10 If the buoyancy tubes are not made of yellow, orange or red, panels of such colours must be secured to the buoyancy chambers so that a minimum of 1 m2 is visible from above the platform.

4.2.3.11 Every liferaft, irrespective of its colour, must be fitted with retro-reflective tape on the upper- and outer-most surfaces of each buoyancy compartment so as to be visible from above and from the water level.

4.2.3.12 The retro-reflective tape required in section 4.2.3.11 above must be of not less than 50 mm in width, not less than 300 mm in length and spaced so that the distance between the centres of adjacent sections is not more than 500 mm.

4.2.3.13 The maximum number of persons an inflatable rescue platform can accommodate cannot be greater than 150 persons and must be calculated as the lesser of:

4.2.3.13.1 the greatest whole number obtained by dividing the volume, measured in cubic metres, of the main buoyancy chamber when inflated by 0.064;

4.2.3.13.2 the greatest whole number obtained by dividing the inner horizontal cross-sectional area of the platform, measured in square metres (which for this purpose may include thwarts, if fitted), measured to the innermost edge of the buoyancy chamber by 0.248; or

4.2.3.13.3 the number of persons, each having an average mass of 75 kg, all wearing standard lifejackets that can be seated with sufficient comfort without interfering with the operation of any of the liferaft’s equipment.

4.2.4 Access to inflatable rescue platforms

4.2.4.1 Inflatable rescue platforms capable of accommodating 38 persons or less must have at least one semi-rigid boarding ramp allowing persons to board the platform from the sea, and if inflated, must be arranged to prevent deflation if the ramps are damaged.

4.2.4.2 Inflatable rescue platforms capable of accommodating more than 38 persons must be fitted with at least two diametrically opposed boarding ramps.

4.2.4.3 In addition to the boarding ramps, inflatable rescue platforms accommodating 38 persons or less must be fitted with one boarding ladder, and platforms accommodating more than 38 persons must be fitted with two boarding ladders.

4.2.4.4 The total number of boarding ramps and ladders required in sections 4.2.4.1 to 4.2.4.3 above refer to those which are capable of being used with either side up. The total number of boarding ramps and ladders must be doubled on inflatable rescue platforms when the correct function of the boarding ramp or ladder is dependent on which side of the platform is floating up.

4.2.5 Markings

4.2.5.1 Every inflatable rescue platform and its container must be marked in accordance with paragraphs 4.2.6.3 and 4.2.7.1 of the LSA Code except there must be no reference to SOLAS (4.2.6.3.4).

4.2.5.2 Every container must be marked with “INFLATABLE RESCUE PLATFORM” and “PLATE-FORME DE SAUVETAGE GONFLABLE”.

4.3 Coastal liferafts

4.3.1 General requirements

4.3.1.1 A coastal liferaft must be constructed with materials capable of withstanding exposure for 15 days afloat in any sea condition.

4.3.1.2 A coastal liferaft must be constructed so that it can fully inflate in an upright position following a drop from a height of 5 m.

4.3.1.3 Coastal liferafts must be fitted with an emergency pack meeting the requirements of paragraph 4.1.5 of the LSA Code.

4.3.2 Buoyancy chambers

4.3.2.1 Every inflatable coastal liferaft must be constructed of:

4.3.2.1.1 a main buoyancy chamber, which must be divided into not less than two separate compartments, or

4.3.2.1.2 a single buoyancy chamber divided longitudinally into two equal airtight compartments.

4.3.2.2 Each buoyancy chamber compartment must be inflated by an automatic gas inflation system through a non-return inflation valve.

4.3.2.3 The buoyancy chamber must be arranged in such a manner that if any one of the compartments is damaged or fails to inflate, the intact compartment can support, with positive freeboard over the entire periphery, the number of persons which the coastal liferaft can carry, as indicated in section 4.3.6.3 below.

4.3.2.4 Each compartment must contribute to the total buoyancy required, where the maximum designed volume of either compartment does not exceed 60% of the total volume of the buoyancy chamber.

4.3.3 Canopy and floor

4.3.3.1 The specifications for a coastal liferaft canopy are as follows:

4.3.3.1.1 every entrance must be clearly indicated and provided with an adjustable closing arrangement that can be easily and quickly opened from the inside and the outside to permit ventilation, but prevent seawater, wind and cold from entering;

4.3.3.1.2 it must always admit air for the occupants, even with the entrances closed;

4.3.3.1.3 it must provide sufficient headroom under all parts of the canopy for the complement to sit upright on the floor; and

4.3.3.1.4 it must erect automatically.

4.3.3.2 The floor of the inflatable coastal liferaft must be waterproof.

4.3.4 Canopy supports

4.3.4.1 Arches or other means for supporting the coastal liferaft canopy must be:

4.3.4.1.1 inflated automatically by a gas inflation system;

4.3.4.1.2 fitted with a non-return valve; and

4.3.4.1.3 provided with a means of being manually topped-up.

4.3.4.2 Inflation arrangements must be such that, should one of the buoyancy chambers of the coastal liferaft deflate, the canopy would remain erect.

4.3.5 Cordage, webbing and thread

4.3.5.1 All cordage, webbing and thread used in the construction of a coastal liferaft, or in the make-up of its fittings or equipment, must be inherently rot-proof.

4.3.5.2 All cordage must be attached to the coastal liferaft in such a manner that, if the cordage is accidentally detached, the buoyancy tubes would not be damaged.

4.3.6 Capacity

4.3.6.1 A coastal liferaft must have a carrying capacity of not less than four persons.

4.3.6.2 The total mass of a coastal liferaft, its container and its equipment must not be more than 185 kg.

4.3.6.3 The maximum number of persons that the coastal liferaft can carry must be the lesser of:

4.3.6.3.1 the greatest whole number obtained by dividing the volume, measured in cubic metres of the main buoyancy chamber (which for this purpose is to not include the canopy support arches nor any thwarts, if fitted) when inflated, by 0.096;

4.3.6.3.2 the greatest whole number obtained by dividing the inner horizontal cross-sectional area of the coastal liferaft, measured in square metres, (which for this purpose must include thwarts, if fitted) to the innermost edge of the buoyancy chamber, by 0.372; or

4.3.6.3.3 the number of persons, each having a mass of not less than 82.5 kg, all wearing an anti-exposure suit that meets the requirements of section 2.4.1 of Part B of this Standard, that can be seated without interfering with the operation of any of the coastal liferaft’s equipment.

4.3.7 Stability

4.3.7.1 Every coastal liferaft must be constructed in such a manner that when fully inflated and floating with the canopy fully erected it is stable in a seaway.

4.3.7.2 Every coastal liferaft must be fitted with water pockets on the underside meeting the requirements in paragraph 4.2.5.4 of the LSA Code.

4.3.7.3 The stability must be such that:

4.3.7.3.1 when in the inverted position, unless self-righting, it can be righted by one person in calm water; and

4.3.7.3.2 when loaded with the number of persons that the coastal liferaft can carry, determined according to section 4.3.6.3 above, or weights equivalent to persons and equipment, it can be towed at a speed of not less than 3 knots in calm water.

4.3.8 Entrance

4.3.8.1 Every inflatable coastal liferaft must have at least one entrance fitted with a semi-rigid boarding step to enable persons to board the liferaft from the sea and arranged to prevent deflation of the liferaft if the step is damaged.

4.3.8.2 Any entrance not fitted with a boarding step must have a boarding ladder, the lowest step of which is not less than 0.4 m below the light waterline of the coastal liferaft.

4.3.8.3 The inside of the coastal liferaft must be provided with means to assist persons to pull themselves into it from the ladder or boarding step.

4.3.9 Fittings

4.3.9.1 Every coastal liferaft must be fitted with arrangements for securing the entrance opened, closed to be weather tight, and in any intermediate position between opened and closed.

4.3.9.2 Every coastal liferaft must be provided with lifelines securely becketed around the inside and outside.

4.3.9.3 Every coastal liferaft must be fitted with a painter system of not less than 8 mm in diameter and of a length equal to but not less than twice the distance from the stowed position to the waterline in the lightest seagoing condition and must:

4.3.9.3.1 provide a connection between the vessel and the liferaft;

4.3.9.3.2 be arranged so that the released liferaft is not dragged under by the sinking vessel; and

4.3.9.3.3 provide a weak link that will break under a strain of 2.2 +/- 0.4 kN.

4.3.9.4 The painter required to be fitted to every coastal liferaft, including its means of attachment to the liferaft but excluding the weak link, must have a breaking strength of not less than 7.5 kN.

4.3.9.5 In the case of vessels normally operating in waters shallower than the length of the painter system required under section 4.3.9.3 above, the painter system must be capable of being shortened to a length that is equal to the depth of the deepest point of those waters.

4.3.9.6 The length of the painter system must be clearly marked on the coastal liferaft container.

4.3.10 Float-free arrangements

4.3.10.1 Coastal liferafts must be fitted with a weak link that must:

4.3.10.1.1 not be broken by the force required to pull the painter from the coastal liferaft container;

4.3.10.1.2 be of sufficient strength to permit the inflation of the coastal liferaft; and

4.3.10.1.3 break under a strain of 2.2 +/- 0.4 kN.

4.3.11 Light systems

4.3.11.1 Every coastal liferaft must have, fitted to the exterior top of its canopy, a lamp that:

4.3.11.1.1 is visible at a distance of at least 2 miles for a period of at least 12 hours, on a dark night with a clear atmosphere;

4.3.11.1.2 if it is a flashing light, flashes at a rate of not less than 50 flashes per minute during the first two hours and can flash for a period of at least 12 hours;

4.3.11.1.3 is powered by a dry chemical cell;

4.3.11.1.4 lights automatically when the liferaft canopy is set in place; and

4.3.11.1.5 is capable of being switched off and on conveniently.

4.3.11.2 The cell required by 4.3.11.1.3 above must be of a type that does not deteriorate due to dampness or humidity in the stowed coastal liferaft.

4.3.11.3 Every coastal liferaft must be fitted inside with a lamp that:

4.3.11.3.1 is capable of continuous operation for a period of at least 12 hours;

4.3.11.3.2 lights automatically when the canopy is set in place;

4.3.11.3.3 is of sufficient intensity to enable reading of survival and equipment instructions; and

4.3.11.3.4 is capable of being switched off and on conveniently.

4.3.12 Colour

4.3.12.1 The outer surface of the canopy must be yellow, orange or red.

4.3.12.2 The inner surface of the canopy must be of a colour that does not cause discomfort to the occupants.

4.3.13 Container, packing and marking

4.3.13.1 Every coastal liferaft, together with its equipment, must be packed in a container that:

4.3.13.1.1 is watertight except for drain holes in the bottom;

4.3.13.1.2 is free from sharp edges and abrasive areas on the inside;

4.3.13.1.3 provides a neat fit for the packed liferaft so as not to cause any damage to the liferaft fabric by chafing;

4.3.13.1.4 is constructed to permit the liferaft to break free on inflation;

4.3.13.1.5 is constructed so that the opening through which the painter runs is arranged in such a manner that the container will free itself from the painter on inflation of the liferaft;

4.3.13.1.6 is provided with a means to enable it to be carried from its place of stowage to a place of launching; and

4.3.13.1.7 is of sufficient inherent buoyancy when packed with the liferaft and its equipment to pull the painter from within and to operate the inflation mechanism should the vessel sink.

4.3.13.2 Ventilation openings and entrance closures must be open when the coastal liferaft inflates.

4.3.13.3 The coastal liferaft must be packed in its container in such a way that the waterborne liferaft inflates in an upright position on breaking free.

4.3.13.4 Every coastal liferaft and its container must be marked in accordance with paragraphs 4.2.6.3 and 4.2.7.1 of the LSA Code except there must be no reference to SOLAS and all references to “LIFERAFT” are to be replaced with “COASTAL LIFERAFT” and “RADEAU DE SAUVETAGE CÔTIER”.

4.3.14 Passive detection

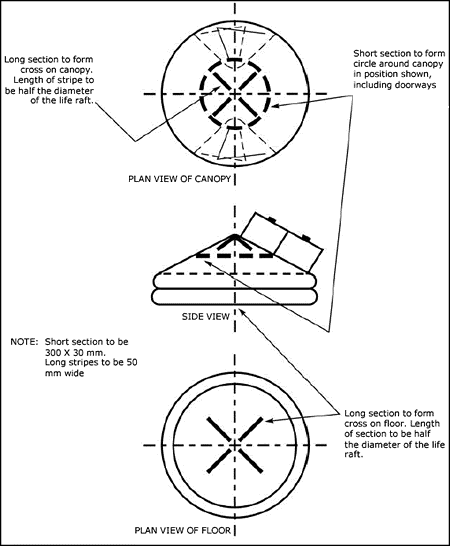

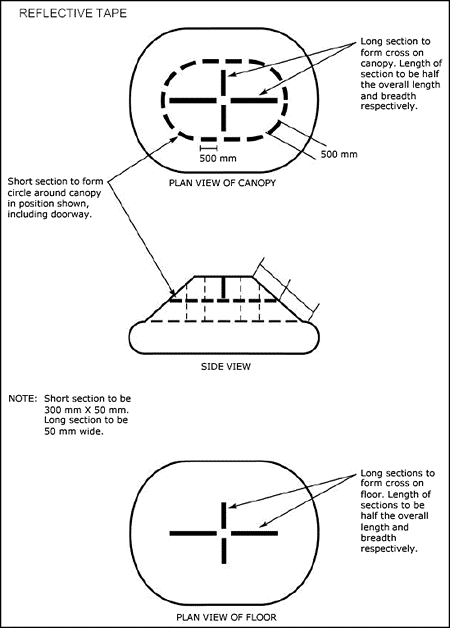

4.3.14.1 Every coastal liferaft must have affixed to it a retro-reflective medium that meets the requirements of paragraph 1.2.2.7 of the LSA Code and must be arranged as shown in diagrams 1 and 2 of this Part.

4.3.14.2 Except in the case of the medium forming crosses on the top and bottom of the coastal liferaft, a retro-reflective medium must be in sections of not less than 50 mm in width and not less than 300 mm in length, and spaced so that the distance between the centres of adjacent sections is not more than 500 mm.

4.3.14.3 The retro-reflective medium sections must be fitted on the outside:

4.3.14.3.1 around the canopy at half of its height;

4.3.14.3.2 on top of the canopy at its centre in the form of a cross, which sections are to be half of the length and half of the breadth of the coastal liferaft; and

4.3.14.3.3 on the bottom of the coastal liferaft at its centre and in the form of a cross, similar in size to that mentioned in section 4.3.14.2 above.

4.3.15 Sea anchor

4.3.15.1 Every sea anchor with which a coastal liferaft is required to be equipped must meet the requirements of paragraph 4.1.5.1.5 of the LSA Code.

Diagram 1: Typical round liferaft – Arrangement of retroreflective tape

Diagram 2: Typical oval liferaft – Arrangement of retroreflective tape

4.4 Coastal liferafts’ inflation system

4.4.1 The coastal liferaft must be constructed so that it is capable of being inflated by one person.

4.4.2 Means must be provided whereby a topping-up pump or bellows can be used to maintain pressure in the coastal liferaft chambers.

4.4.3 The gas cylinder and operating head for the inflation of the coastal liferaft must be stowed and secured to the outside of the liferaft.

4.4.4 The inflation hose or manifold must be attached to a vacuum-packed coastal liferaft by means of a quick release coupling.

4.4.5 The gas used for the inflation of a coastal liferaft must be of a non-toxic type and provide a high rate of inflation and must not form enough ice at the outlet during expansion to compromise compliance with the tests requirements in Part C of this Standard.

4.4.6 The neck of the cylinder must be threaded to receive a valve unit that will retain the gas in the cylinder and in conjunction with the operating head, release the gas at the desired moment in a controlled manner to satisfy all test conditions as detailed in Part C of this Standard.

4.4.7 The gas release mechanism for a cylinder used in the inflation of a coastal liferaft must:

4.4.7.1 operate in such a manner that a pull on the operating line opens a valve and releases gas;

4.4.7.2 incorporate means of retaining the valve in the open position after it has been operated, and an indicator that shows whether the operating head has been operated;

4.4.7.3 in the case where the cylinder valve and operating head are separate components, be a detachable operating head screwed onto the valve unit in the neck of the cylinder, and the handing of the thread must be arranged so that when the operating head is screwed on, there is no tendency to slacken the valve in the cylinder; and

4.4.7.4 be watertight.

4.4.8 Means must be provided to prevent chafing of the coastal liferaft fabric by the operating head.

4.4.9 A high-pressure hose or manifold must be provided to convey the gas from the cylinder to the inflatable chambers of the coastal liferaft.

4.4.10 The hose assembly, where fitted, must:

4.4.10.1 have a minimum bursting pressure of at least 50% greater than the gas delivery pressure;

4.4.10.2 be capable of operating over a temperature range of -45°C to +70°C;

4.4.10.3 be capable of being bent through 180° over a form having a radius of 5 cm, after conditioning at -50°C;

4.4.10.4 after having been bent as described in section 4.4.10.3 above, be capable of passing the hydraulic test as prescribed in Part C of this Standard; and

4.4.10.5 have its hose clean and free from particles or any foreign matter.

4.4.11 Non-return valves must be provided at each point where gas for the inflation of a coastal liferaft enters an inflatable chamber from the cylinder or another inflatable chamber.

4.4.12 Each chamber of a coastal liferaft must be capable of withstanding a pressure equal to three times the nominal pressure and prevented from reaching a pressure exceeding twice the nominal pressure by being fitted with a safety relief valve or having a limited gas supply.

4.4.13 Means must be provided for fitting the top-up pump or bellows provided with the coastal liferaft equipment.

4.4.14 The safety relief valve must:

4.4.14.1 function to allow gas to escape should the pressure exceed that which would be safe for the chambers to carry; and

4.4.14.2 reset to maintain the nominal operating pressure to maintain the rigidity of the chambers.

4.4.15 Deflation arrangements must be fitted for deflating the fully inflated coastal liferaft for re-packing and vacuum sealing, the capacity of which is not to exceed the minimum required for re-packing and vacuum sealing.

Chapter 5 Emergency boats

5.1 General requirements

5.1.1 Emergency boats must meet the requirements of paragraphs 1.2.2.7, 4.4.1.1, 4.4.1.2, 4.4.1.3.2, 4.4.6.1, 4.4.6.9, 4.4.7.1 to 4.4.7.3, 5.1.1.3, 5.1.1.6 to 5.1.1.10 and 5.17.13.1 of the LSA Code and the modifications in this section.

5.1.2 For the purpose of paragraph 4.4.1.1 of the LSA Code, emergency boats do not need to meet the launching trim conditions.

5.1.3 For the purpose of paragraph 4.4.1.2 of the LSA Code, the marking must also include the emergency boat’s dimensions.

5.1.4 For the purpose of paragraph 4.4.6.9 of the LSA Code, the starter batteries must be fitted in a watertight enclosure separate from the motor and provided with a fitted top that has vents for necessary gas venting.

5.1.5 For the purpose of paragraph 4.4.7.1 of the LSA Code, the position of each drain valve must be clearly indicated.

5.1.6 For the purpose of paragraph 5.1.1.3 of the LSA Code, emergency boats must not be less than 2.5 m, be capable of carrying at least four people, and constructed of rubber, steel, aluminum, fibrous glass-reinforced plastics (GRP) or any other material that provides equivalent or superior physical properties and durability in a marine environment.

5.1.7 For the purpose of paragraph 5.1.1.8 of the LSA Code, the minimum and maximum powers for the motor must be included in the emergency boat manuals, and the inboard or outboard motor can be type approved separately.

5.1.8 For the purpose of paragraph 5.1.1.9 of the LSA Code, such arrangements for towing must have a safety factor of 6:1.

5.1.9 For the purpose of paragraph 5.17.13.1 of the LSA Code, the substance used for marking must not contain ingredients harmful to the fabric.

5.1.10 The propulsion system of an emergency boat must meet the requirements of paragraph 4.4.6.12 of the LSA Code, with instructions in English and French.

5.1.11 An emergency boat must provide seating that:

5.1.11.1 are thwarts, side benches or fixed chairs or is on the deck space;

5.1.11.2 does not interfere with the positive stability of the emergency boat; and

5.1.11.3 can support the total mass of the number of persons for which it is designed, assuming each person to have a mass of 82.5 kg.

5.1.12 Emergency boats can accommodate, at a maximum, the number of persons all wearing lifejackets that can be seated in the seating referred to in section 5.1.11 above, without interfering with the means of propulsion of the emergency boat or the operation of any of its equipment.

5.1.13 Emergency boats must be provided with a steering mechanism.

5.1.14 An inboard motor for an emergency boat must not be gasoline-driven.

5.2 Additional requirements for rigid emergency boats

5.2.1 Rigid emergency boats must meet the requirements of paragraphs 4.4.1.4, 4.4.1.6, 4.4.4, and 4.4.5.2 of the LSA Code with the modifications in section 5.2.2 below.

5.2.2 Rigid emergency boats can be fitted with a foam-filled or inflated collar if the collar:

5.2.2.1 is subdivided into no less than three separate compartments, one on each side of the boat and one around the bow area;

5.2.2.2 is fitted in such a way that the boat maintains positive stability when it is loaded with its full complement and equipment and one of the compartments of the collar is damaged;

5.2.2.3 in the case of an inflated collar:

5.2.2.3.1 meets the requirements of sections 7 and 8 of the Life Saving Equipment Regulations, and

5.2.2.3.2 have a non-return valve fitted to each buoyancy compartment to allow the boat to be inflated by hand. The non-return valve of each buoyancy compartment must enable the boat to be inflated by compressed air or gas, or both, and be so arranged or fitted as to prevent accidental deflation; and

5.2.2.4 in the case of a foam-filled collar, is filled with foam that is non-granular and is not adversely affected by salt water or oil.

5.3 Additional requirements for inflated emergency boats

5.3.1 Inflated emergency boats must meet the requirements of paragraphs 4.2.2.1 and 5.1.3 of the LSA Code, excluding paragraphs 5.1.3.3, 5.1.3.4, and 5.1.3.7, with the modifications in sections 5.3.2 to 5.3.6 below.

5.3.2 All cordage must be attached to the inflated rescue boat so that, if the cordage is accidentally detached, the buoyancy compartments are not damaged.

5.3.3 For the purpose of paragraph 5.1.3.2.2 of the LSA Code, the ambient temperature is between 18℃ and 22℃ and all the pressure relief valves of the boat are closed.

5.3.4 The main buoyancy chamber that forms the periphery of an inflated emergency boat must be divided into no fewer than three airtight buoyancy compartments, the capacity of each not exceeding 40% of the total chamber capacity.

5.3.5 Rigid flooring must be fitted to inflated emergency boats to provide a firm deck that protects the keel and any fabric that may form the bottom of the boat.

5.3.6 Inflated emergency boats must meet the requirements of paragraph 4.2.2.3 of the LSA Code.

5.4 Emergency boat equipment

5.4.1 Emergency boats must carry Class B (SOLAS) emergency packs, as described in paragraph 4.1.5.3 of the LSA Code.

Chapter 6 Launching appliances for emergency boats

6.1.1 The launching appliance of an emergency boat must be fitted with a release mechanism meeting the requirements of paragraph 4.4.7.6 of the LSA Code.

6.1.2 A launching appliance used to lower and hoist an emergency boat can be manually powered.

6.1.3 A launching appliance used to lower and hoist an emergency boat must be:

6.1.3.1 operated from a position on the vessel’s deck that has a clear range of visibility to the water at the side of the vessel; and

6.1.3.2 capable of lowering and hoisting an emergency boat that is loaded with its equipment and a launching crew of at least two persons. Where the launching appliance of an emergency boat is strong enough to lower only the boat and its launching crew, without its equipment, the device must be clearly marked with the words “LOWER WITH LAUNCHING CREW ONLY” and “N’ABAISSER QU’AVEC L’ÉQUIPAGE DE MISE À L’EAU”.

Part C Testing and evaluation of Canadian life-saving appliances (Non-SOLAS)

Chapter 1 General

1.1 General requirements for testing of life-saving appliances

1.1.1 Except as otherwise provided in this Part, the tests found in Resolution MSC.81(70) – Revised Recommendations on Testing of Life-saving Appliances, as amended from time to time, apply to the appliances addressed hereafter.

Chapter 2 Personal life-saving appliances

2.1 Lifebuoys

2.1.1 Paragraph 1.1 – Lifebuoys – Lifebuoys specification – of Part 1 of Resolution MSC.81(70) is replaced with the following:

2.1.1.1 It is verified by measurement, weighing and inspection that:

2.1.1.1.1 the lifebuoy dimensions meet the requirements of section 2.1.1 of Part B of this Standard;

2.1.1.1.2 the lifebuoy weight capacity and its weight meet the requirements of sections 2.1.2 and 2.1.3 of Part B of this Standard; and

2.1.1.1.3 if the lifebuoy is provided with a buoyant lifeline, the buoyant lifeline must meet the requirements of section 2.1.5 of Part B of this Standard.

2.1.2 For the purpose of the requirements of paragraph 1.3 – Lifebuoys – Drop test – of Part 1 of Resolution MSC.81(70), the drop test on concrete from a height of 2 m is mandatory for each lifebuoy.

2.1.3 Instead of the requirements of paragraph 1.6 – Lifebuoys – Flotation test – of Part 1 of Resolution MSC.81(70), every lifebuoy must be floated in fresh water with not less than 7.5 kg of iron freely suspended from it for a period of 24 hours.

2.1.4 At the end of the 24-hour period, each lifebuoy is to remain floating at essentially the same level as at the commencement of the test.

2.2 Lifejackets

2.2.1 Class 1 lifejackets must be tested in accordance with the requirements of CAN/CGSB-65.7 – Lifejackets.

2.3 Immersion suits

2.3.1 Immersion suits must be tested in accordance with ANSI/CAN/UL 15027-3 Standard for Immersion Suits – Part 3: Test methods.

2.4 Anti-exposure suits

2.4.1 Anti-exposure suits must be tested in accordance with ANSI/CAN/UL 15027-2 Standard for Immersion suits – Part 2: Abandonment suits, requirements including safety.

2.5 Personal flotation devices

2.5.1 Personal flotation devices (PFD) must be tested in accordance with:

2.5.1.1 Underwriters Laboratories, Inc. UL 1180 Standard for Fully Inflatable Recreational Personal Flotation Devices; or

2.5.1.2 Level 70 performance devices from ANSI/CAN/UL 12402-5 Standard for Personal Flotation Devices – Part 5: Buoyancy Aids (Level 50) – Safety Requirements.

Chapter 3 Visual signals

3.1 Hand flares

3.1.1 Hand flares must be tested in accordance with the requirements of paragraph 4.7 – Pyrotechnics – rocket parachute flares, hand flares and buoyant smoke signals – Hand flares test – of Part 1 of Resolution MSC.81(70), and specimens submitted for testing must be representative of the device as regularly manufactured and marketed.

3.2 Multi-star flares

3.2.1 Multi-star flares must be tested in accordance with the requirements of paragraph 4 – Pyrotechnics – rocket parachute flares, hand flares and buoyant smoke signals – of Part 1 of Resolution MSC.81(70), with the modifications listed in sections 3.2.1.1 to 3.2.1.5 below, and specimens submitted for testing must be representative of the device as regularly manufactured and marketed.

3.2.1.1 Temperature tests

3.2.1.1.1 In addition to the requirements of paragraph 4.2.1 – Temperature tests – of Part 1 of Resolution MSC.81(70), the samples must not ignite spontaneously or decompose during the conditioning tests.

3.2.1.1.2 In addition to the requirements of paragraph 4.2.2 – Temperature tests – of Part 1 of Resolution MSC.81(70), samples of multi-star flare signals must not have a temperature increase of more than 5℃ at the time of the test.

3.2.1.1.3 In addition to the requirements of paragraph 4.2.3 – Temperature tests – of Part 1 of Resolution MSC.81(70), samples of multi-star flare signals must not have a temperature drop of more than 5℃ at the time of the test.

3.2.1.1.4 For the purpose of the requirements of paragraph 4.2.4 – Temperature tests – of Part 1 of Resolution MSC.81(70), samples must function effectively at 23℃ +/- 2℃.

3.2.1.1.5 In addition to the requirements of paragraph 4.2 – Temperature tests – of Part 1 of Resolution MSC.81(70), an insulated container for the transportation of the samples for testing in accordance with sections 3.2.1.1.2 and 3.2.1.1.3 above, from the refrigerating or heating chamber to the test location, is acceptable provided that all possible steps are taken to minimize any change of temperature. A maximum variation of +/- 5°C is acceptable. The refrigerating and heating chambers must be provided with thermostatic control devices to maintain an even temperature.

3.2.1.2 Water and corrosion resistance test

3.2.1.2.1 For the purpose of the requirements of paragraph 4.3 – Water and corrosion resistance test – of Part 1 of Resolution MSC.81(70), multi-star flares must be subjected to a salt-spray test (20% natrium chloride solution) at a temperature of 35℃ +/- 3℃ for at least 100 hours and the test must be conducted in accordance with the requirements of ISO Standard 3768-1976 or ASTM B-117.

3.2.1.2.2 In addition to the requirements of paragraph 4.3 – Water and corrosion resistance test – of Part 1 of Resolution MSC.81(70), samples of multi-star flare signals, including the firing device and cartridges if any, must function effectively after being immersed for one minute under 1 m of water.

3.2.1.3 Handling safety test

3.2.1.3.1 In addition to the requirements of paragraph 4.4 – Handling safety test – of Part 1 of Resolution MSC.81(70), samples of multi-star flare signals must be included in the pyrotechnic testing.

3.2.1.4 Visual safety inspection

3.2.1.4.1 For the purpose of the requirements of paragraph 4.5.1 – Safety inspection – of Part 1 of Resolution MSC.81(70), the indelibly markings can be diagrams.

3.2.1.4.2 In addition to the requirements of paragraph 4.5.6 – Safety inspection – of Part 1 of Resolution MSC.81(70), pyrotechnics must be clearly and permanently marked with the lot number and date of manufacture.

3.2.1.4.3 In addition to the requirements for inspections for markings and waterproofing specified in section 3.2.1.4.1 above, inspections must be conducted before and after the conditioning requirements of sections 3.2.1.1 and 3.2.1.2 above, for temperature, water and corrosion resistance, respectively.

3.2.1.5 Additional testing requirements for multi-star flares

3.2.1.5.1 Altitude burning period – samples of the devices must be fired vertically and, by means of accurate measuring instruments, the following must be determined:

3.2.1.5.1.1 the altitude at which the stars are ejected;

3.2.1.5.1.2 the length of the burning period of the stars; and

3.2.1.5.1.3 the interval between ignitions of individual stars, if more than one star is produced by a single firing.

3.2.1.5.2 Rapid fire – if the flare fires a single star, it must be determined that a second star can be fired rapidly after the first star. The time interval between firings must be noted.

3.2.1.5.3 Luminosity – samples of the flare must be tested to determine the average luminous intensity.

3.2.1.5.4 Flame colour – tests must be conducted to determine the colour of the stars is a vivid red as defined by section 11 of the publication Color: Universal Language and Dictionary of Names (Special Publication 440, National Bureau of Standards).

3.2.1.5.5 Test procedures are as follows:

3.2.1.5.5.1 The tests in sections 3.2.1.5.1 and 3.2.1.5.2 above must be conducted in clear conditions with a minimum of wind deflection.

3.2.1.5.5.2 The tests in sections 3.2.1.5.3 and 3.2.1.5.4 above must be conducted by a suitable laboratory using a non-reflective chamber and a suitably calibrated photometer.

Chapter 4 Survival craft

4.1 Tests for reduced capacity liferafts

4.1.1 Reduced capacity liferafts must be tested in accordance with paragraph 5 – Liferafts – rigid and inflatable – of Part 1 of Resolution MSC.81(70).

4.1.2 Buoyancy material for rigid liferafts must be tested in accordance with paragraphs 6.2.2 to 6.2.7 – Lifeboat buoyant material test – of Part 1 of Resolution MSC.81(70).

4.2 Tests for inflatable rescue platforms

4.2.1 The tests required by paragraphs 5.17.3 to 5.17.6 – Additional tests applicable to inflatable liferafts only – Inflation test – of Part 1 of Resolution MSC.81(70), are replaced by an inflation test at a temperature of 0°C as follows:

4.2.1.1 The packed platform, complete with its equipment, must be placed into a cold chamber until the core of the platform reaches a temperature of 0°C.

4.2.1.2 Upon attaining the 0°C temperature, the platform must be inflated by pulling the painter to become boardable, (i.e., when buoyancy tubes are inflated to full shape and diameter) either:

4.2.1.2.1 within the cold chamber; or

4.2.1.2.2 within a period of five minutes after removal from the cold chamber.

4.2.1.3 The device must begin to inflate and reach its nominal pressure within three minutes from when the painter is pulled. Upon completion of inflation, there must be no seam slippage, cracking or other defects in the platform, and it must be ready for use upon completion of inflation in all respects.

4.3 Tests for coastal liferafts

4.3.1 Drop Test

4.3.1.1 The coastal liferaft must be subjected to the drop test in paragraph 5.1.2 of Part 1 of Resolution MCS.81(70), with the following modifications:

4.3.1.1.1 the liferaft, in its operationally packed condition, must be suspended and dropped from a height of 5 m into the water; and

4.3.1.1.2 if the liferaft must be stowed at a height greater than 5 m, it must be dropped from the height at which it must be stowed.

4.3.1.2 Upon completion of the drop test the coastal liferaft, in its operationally packed condition, must be left floating for at least 30 minutes.

4.3.1.3 After the 30-minute period required by section 4.3.1.2 above, the coastal liferaft must be inflated by pulling the painter and must:

4.3.1.3.1 inflate upright; and

4.3.1.3.2 inflate in the time specified in sections 4.4.1 to 4.4.4 of this Part.

4.3.1.4 Upon completion of inflation, the coastal liferaft and its container must be removed from the water and the container must be subjected to a thorough inspection for damage as required by section 4.3.1.5 below.

4.3.1.5 Damage to the coastal liferaft container, if the liferaft is normally within it when launched, is acceptable if the damage does not affect the operational efficiency of the coastal liferaft.

4.3.2 Jump test

4.3.2.1 It must be demonstrated that a person can jump on to the coastal liferaft from a height above the floor of at least 4 m without damaging the liferaft.

4.3.2.2 The test subject is to weigh not less than 82.5 kg and be wearing hard bottom shoes with smooth soles and no protruding nails.

4.3.2.3 The number of jumps performed must be equal to the total number of persons which the coastal liferaft can accommodate.

4.3.3 Towing test

4.3.3.1 It must be demonstrated that the fully laden coastal liferaft is capable of being towed at a speed of 3 knots in calm water for at least 1 km. Towing must be by a line attached to the liferaft’s towing connection with the sea anchor streamed.

4.3.4 Mooring out tests

4.3.4.1 The coastal liferaft must be loaded with mass equal to the mass of the total number of persons which it is to carry and its equipment and moored in a location at sea or in a seawater harbour.

4.3.4.2 The costal liferaft must remain afloat for a period of not less than 15 days. The pressure can be topped up once a day using the manual pump or bellows; however, within any 24-hour period the liferaft must retain its shape.

4.3.4.3 Upon completion of the mooring out period, the coastal liferaft must not have sustained any damage that would impair its performance.

4.3.4.4 Upon completion of this test, the coastal liferaft must be subjected to the pressure test in section 4.4.5 of this Part.

4.3.5 Painter system test

4.3.5.1 The line used as a painter for a coastal liferaft must be tensile tested and have a breaking strength of not less than 7.5 kN.

4.3.5.2 The weak link used in the coastal liferaft painter system must be tensile tested and have a breaking strength of 2.2 kN (± 0.4 kN).

4.3.6 Lighting system test

4.3.6.1 Coastal liferaft canopy lights and interior liferaft lights must be subjected to the testing and evaluation requirements in paragraph 10 – Position-indicating lights for life-saving appliances – of Part 1 of Resolution MSC.81(70).

4.3.7 Loading and seating test

4.3.7.1 The freeboard of the coastal liferaft in the light condition, including its full equipment but no personnel, must be recorded prior to this test.

4.3.7.2 The freeboard of the coastal liferaft must be recorded, with the complement, having an average mass of 82.5 kg and each wearing an anti-exposure suit that meets the requirements of section 2.4.1 of Part B of this Standard, on board and seated.

4.3.7.3 It must be established that all the seated persons, as specified in section 4.3.7.2 above, have space and headroom and it must be demonstrated that the various items of equipment can be used within the coastal liferaft in this condition.

4.3.7.4 The freeboard of the coastal liferaft on an even keel must not be less than 300 mm when loaded with the complement and equipment.

4.3.8 Boarding test

4.3.8.1 The boarding test must be carried out in a swimming pool by a team of not less than four persons, who are of mature age, of differing physiques. At least one subject must be less than 82.5 kg.

4.3.8.2 For this test, persons described in section 4.3.8.1 above must be clothed in shirts and trousers or coveralls and wearing anti-exposure suits that meet the requirements of section 2.4.1 of Part B of this Standard, or a Transport Canada-approved immersion suit.

4.3.8.3 Prior to boarding the coastal liferaft, each person must swim 100 m and upon reaching the liferaft, attempt to board it immediately.

4.3.8.4 Each person must attempt to board the coastal liferaft individually with no assistance from the other swimmers or persons already on board. The water must be of sufficient depth to prevent any external assistance when boarding.

4.3.8.5 Coastal liferaft boarding arrangements will be considered satisfactory if three of the four persons board the liferaft unaided and the fourth boards with the assistance of the others.

4.3.9 Stability test

4.3.9.1 A coastal liferaft’s carriage capacity must be determined by the complement sitting on one side and then at one end if the liferaft is not circular in shape. In both cases, there must be positive freeboard from the waterline to the top surface of the uppermost main buoyancy tube at its lowest point.

4.3.9.2 The stability of a coastal liferaft must be determined as follows:

4.3.9.2.1 two persons each wearing an anti-exposure suit must board the empty liferaft;

4.3.9.2.2 it must then be demonstrated that the two persons can assist from the water a third person, also wearing an anti-exposure suit, who feigns unconsciousness; and

4.3.9.2.3 the third person must have their back towards the liferaft so that they cannot assist the rescuers.

4.3.9.3 In this test, it must be demonstrated that the water pockets of the coastal liferaft counteract the upsetting moment on the liferaft, and that there is no danger of the liferaft capsizing.

4.3.10 Manoeuvrability test

4.3.10.1 It must be demonstrated that the coastal liferaft, when loaded with its complement and equipment, is capable of being propelled a distance of over 25 m in calm conditions with the paddles provided as part of the standard equipment.

4.3.11 Swamp test

4.3.11.1 It must be demonstrated that the coastal liferaft, when in a fully swamped condition, can support the number of persons it is to accommodate and remain seaworthy.

4.3.11.2 The coastal liferaft must not deform when loaded and fully swamped.

4.3.11.3 This test must be carried out in at least 10 waves of at least 0.3 m high. Waves can be produced by the wake of a boat or other suitable means.

4.3.12 Canopy closure test

4.3.12.1 To ensure the effectiveness of the canopy closures to prevent water entering the coastal liferaft, a hose test, or another equally effective method must be undertaken.

4.3.12.2 As a result of this test, there must be no accumulation of water inside the coastal liferaft.

4.3.13 Wind tunnel test

4.3.13.1 The coastal liferaft, in its packed condition with entrances open but without its container, must be inflated in a wind velocity of 30 m/s and left in this condition for at least 10 minutes. When necessary, securely lash the liferaft down in place during this test.

4.3.13.2 In the wind conditions specified in section 4.3.13.1 above, the coastal liferaft must be rotated 30° to the left and to the right of the starting position and return to the starting position where it must be inspected for damage as per section 4.3.13.4 below.

4.3.13.3 The coastal liferaft must again be subjected to the wind conditions specified in section 4.3.13.1 above for not less than five minutes in each of the following conditions:

4.3.13.3.1 with the entrance to the wind open and the other entrances closed, if there is more than one entrance;

4.3.13.3.2 with the entrance to the wind closed and the other entrances open, if there is more than one entrance; and

4.3.13.3.3 with all entrances closed.

4.3.13.4 On completion, there must be no detachment of the arch support or canopy from the upper buoyancy tube or other damage, which affects the function of the coastal liferaft.

4.3.14 Damage test

4.3.14.1 It must be demonstrated that in the event of any one of the buoyancy compartments being damaged or failing to inflate, the intact compartment or compartments support the complement seated in their positions, or an equally distributed mass, with positive freeboard over the coastal liferaft’s periphery.

4.3.15 Righting test

4.3.15.1 For this test, the inflated coastal liferaft loaded with its equipment pack must be inverted in the water.

4.3.15.2 All entrances, ports, and other openings in the coastal liferaft canopy must be opened to allow the infiltration of water into the canopy when capsized.

4.3.15.3 The canopy must be allowed to be completely filled with water, if necessary, by partially collapsing the canopy support. Unless the coastal liferaft is self-righting, it must remain in this condition for at least 10 minutes before righting is attempted.

4.3.15.4 The righting test must be carried out by the same team as required for the boarding test, as specified in section 4.3.8.1 and 4.3.8.2 above.

4.3.15.5 Each person must attempt to right the coastal liferaft unaided.

4.3.15.6 The water must be of sufficient depth to give no external assistance to the swimmers when mounting the inverted coastal liferaft.

4.3.15.7 The righting arrangement will be considered satisfactory if each person rights the coastal liferaft unaided, there is no damage to the structure of the liferaft and the equipment pack remains secured in place.

4.3.15.8 A coastal liferaft that is proved capable of righting itself when inflated upside down is not required to undergo the righting test.

4.3.16 Material test

4.3.16.1 A coastal liferaft’s material must be tested in accordance with paragraph 5.17.13 – Material test – of Part 1 of Resolution MSC.81(70).

4.4 Tests for coastal liferafts’ inflation system

4.4.1 Inflation test

4.4.1.1 A coastal liferaft, packed in each type of container, must be inflated by pulling the painter and the times must be recorded for each of the following steps:

4.4.1.1.1 for the liferaft to become boardable, that is with buoyancy tubes inflated to full shape and diameter;

4.4.1.1.2 for the liferaft cover to be erect; and

4.4.1.1.3 for the liferaft to reach its nominal pressure when tested at:

4.4.1.1.3.1 ambient temperature between +18°C and +20°C;

4.4.1.1.3.2 a core temperature of -10°C; and

4.4.1.1.3.3 a temperature of +35°C.

4.4.2 Ambient inflation (+18°C to +20°C) Test

4.4.2.1 The coastal liferaft must achieve total inflation in not more than one minute when inflated in an ambient temperature between +18°C and +20°C.

4.4.3 Cold inflation (-10°C) Test

4.4.3.1 The coastal liferaft must be subjected to an inflation test at a temperature of -10°C as follows:

4.4.3.1.1 the packed liferaft, complete with its equipment, must be placed into a cold chamber until the core of the packed liferaft reaches a temperature of -10°C; and

4.4.3.1.2 upon attaining a core temperature of -10°C, the liferaft can be:

4.4.3.1.2.1 inflated within the cold chamber; or

4.4.3.1.2.2 removed from the cold chamber and inflated within a period of five minutes after removal, by pulling the painter.

4.4.3.2 The coastal liferaft must begin to inflate and reach its nominal pressure within a period of three minutes after pulling the painter. Upon completion of inflation there must be no seam slippage, cracking or other defects, and the liferaft must be ready for use in all respects.

4.4.4 Hot inflation (+35°C) Test

4.4.4.1 For the inflation test at +35°C, the packed coastal liferaft must be placed in a heating chamber at a temperature of +35°C for at least seven hours. Upon removal from the heating chamber the liferaft must be immediately inflated by pulling the painter.

4.4.4.1.1 The coastal liferaft must begin to inflate and reach its nominal pressure within a period of one minute from pulling the painter. Upon completion of inflation, there must be no seam slippage, cracking, swelling or other defects, and the liferaft must be ready for use in all respects.

4.4.4.1.2 Upon inflation, the gas pressure relief valves must be of sufficient capacity to prevent damage to the coastal liferaft by excess pressure.

4.4.5 Pressure test

4.4.5.1 Each inflatable compartment in the coastal liferaft must be tested to a pressure equal to 3 times the nominal pressure, and upon completion, there must be no evidence of seam slippage, cracking or other defects in the liferaft.

4.4.5.2 The pressure relief valves must be tested to show that the pressure inside the inflated chambers of the coastal liferaft cannot reach twice the nominal pressure of the liferaft, and upon completion, there must be no evidence of seam slippage, cracking or other defects in the liferaft.

4.4.6 Hose assembly test

4.4.6.1 Each complete hose assembly must have a test pressure of 126.5 kg/cm2 applied hydrostatically for at least one minute.

4.4.6.2 There must be no leakage from the hose or end fitting of the assembly after the test.

4.4.6.3 Upon completion of the test, each hose must be:

4.4.6.3.1 dried by blowing air through it; and

4.4.6.3.2 checked for length.

4.4.6.4 A certificate from the manufacturer of the hydraulic hose attesting to these requirements is acceptable.

Chapter 5 Emergency boats

5.1 Tests for emergency boats

5.1.1 Impact test

5.1.1.1 The emergency boat must be subjected to the impact test in paragraphs 6.4.1 and 6.4.2 – Davit-launched lifeboat and drop test – Impact test – of Part 1 of Resolution MSC.81(70), with the following modification:

5.1.1.1.1 The emergency boat, in a free-hanging position, must be pulled laterally to a position so that when released, it will strike a rigid vertical surface at a velocity of at least 1.5 m/s.

5.1.2 Seating strength test

5.1.2.1 The emergency boat must be subjected to the seating strength test in paragraph 6.6.1 – Lifeboat seating strength test – Davit-launched lifeboats – of Part 1 of Resolution MSC.81(70) with a modification of mass of 82.5 kg.

5.1.3 Manoeuvrability test

5.1.3.1 The emergency boat must be subjected to the manoeuvrability test in paragraph 7.1.8 – Rigid rescue boats – Manoeuvrability test – of Part 1 of Resolution MSC.81(70), with the following modifications:

5.1.3.1.1 it must be fitted with its engine and all equipment;

5.1.3.1.2 the complement, all wearing immersion suits, must board the emergency boat and be properly seated; and

5.1.3.1.3 all equipment on board must be tested to demonstrate that it can be operated without difficulty or interference.

5.1.4 Loading test

5.1.4.1 The emergency boat must be subjected to the loading test in paragraphs 7.2.4 and 7.2.5 – Inflated rescue boats – Loading tests – of Part 1 of Resolution MSC.81(70).

5.1.5 Inboard engine fuel consumption test

5.1.5.1 The emergency boat must be subjected to the operation of engine and fuel consumption test in paragraphs 7.4.2.1 and 7.4.2.2 – Rigid fast rescue boats – Operation of engine and fuel consumption test – of Part 1 of Resolution MSC.81(70).

5.1.6 Engine-out-of-water test

5.1.6.1 If the engine is a water jet type, the emergency boat must be subjected to the test in paragraph 6.10.5 – Lifeboat operational test – Engine-out-of-water test – of Part 1 of Resolution MSC.81(70).

5.1.7 Submerged engine test

5.1.7.1 The emergency boat must be subjected to the test in paragraph 6.10.6 – Lifeboat operational test – Submerged engine test – of Part 1 of Resolution MSC.81(70).

5.1.8 Outboard engines

5.1.8.1 Outboard engines must demonstrate that they can be readily started out of the water.

5.2 Additional tests for rigid emergency boats

5.2.1 Flooded stability test

5.2.1.1 The test must demonstrate that the emergency boat has positive stability in the water when:

5.2.1.1.1 loaded with a distributed mass equal to the number of persons for which it must be approved and its equipment; and

5.2.1.1.2 in a loaded condition, filled with water to represent flooding which would occur when holed in any one location below the waterline, assuming buoyancy material and no other damage. Several tests must be conducted if holes in different areas would create different flooding conditions.

5.2.2 Overload test

5.2.2.1 The rigid emergency boat must be subjected to the tests in paragraph 7.1.4 – Rigid rescue boats – Overload test – of Part 1 of Resolution MSC.81(70).

5.2.3 Drop test

5.2.3.1 The rigid emergency boat must be subjected to the drop test in paragraph 6.4.3 – Davit-launched lifeboat impact and drop test – drop test – of Part 1 of Resolution MSC.81(70), with the following modifications:

5.2.3.1.1 the loaded emergency boat must be suspended so that the lowest part of the boat is at least 3 m above the surface of the water; and

5.2.3.1.2 on completion of the drop test the emergency boat must be inspected and no damage must have occurred which would affect the efficient functioning of the boat.

5.2.4 Freeboard and stability test

5.2.4.1 In addition to the test prescribed in paragraphs 6.8.4 and 6.8.5 – Lifeboat freeboard and stability tests – Freeboard test – of Part 1 of Resolution MSC.81(70), for a rigid emergency boat, one half of the complement, all wearing immersion suits, must be seated in a proper seating position on one side of the centreline.

5.2.5 Buoyant material tests

5.2.5.1 Where inherent buoyancy material is required, that material must be subjected to the tests prescribed in paragraphs 6.2.2 to 6.2.7 – Lifeboat material tests – Lifeboat buoyant material test – of Part 1 of Resolution MSC.81(70).

5.3 Additional tests for inflated emergency boats

5.3.1 Drop test

5.3.1.1 In addition to the requirements prescribed in paragraphs 7.2.2 and 7.2.3 – Inflated rescue boats – Drop tests – of Part 1 of Resolution MSC.81(70), the inflated emergency boat, complete with all its equipment and with a mass equivalent to its engine and fuel in the position of its engine and fuel tank, must be dropped into the water from a height of at least 3 m.

5.3.2 Righting test

5.3.2.1 The emergency boat must be subjected to the righting test in paragraph 7.1.7 – Rigid rescue boats – Righting test – of Part 1 of Resolution MSC.81(70).

5.3.3 Manoeuvrability test

5.3.3.1 The emergency boat must be subjected to the manoeuvrability test in paragraph 7.1.8 – Rigid rescue boats – Manoeuvrability test – of Part 1 of Resolution MSC.81(70).

5.3.4 Stability test

5.3.4.1 The emergency boat must be subjected to the stability test in paragraphs 7.2.6 and 7.2.7 – Inflated rescue boats – Stability test – of Part 1 of Resolution MSC.81(70).

5.3.5 Damage test

5.3.5.1 The emergency boat must be subjected to the damage test in paragraphs 7.2.8 and 7.2.9 – Inflated rescue boats – Damage test – of Part 1 of Resolution MSC.81(70).

5.3.6 Swamp test

5.3.6.1 The emergency boat must be subjected to the swamp test in paragraph 7.2.11 – Inflated rescue boats – Swamp test – of Part 1 of Resolution MSC.81(70).

5.3.7 Overload tests

5.3.7.1 The emergency boat must be subjected to the overload tests prescribed in paragraph 7.2.12 – Inflated rescue boats – Overload tests – of Part 1 of Resolution MSC.81(70).

5.3.8 Detailed inspection

5.3.8.1 The emergency boat must be subjected to the detailed inspection in paragraph 7.2.16 – Inflated rescue boats – Detailed inspection – of Part 1 of Resolution MSC.81(70).

5.4 Production tests for inflated emergency boats

5.4.1 Buoyancy tubes air inflation tests

5.4.1.1 Every buoyancy tube with all its valves, deflation plugs and fittings must be inflated to 17.78 g/cm2 (177.8 mm water gauge) above the maximum blow-off pressure of the relief valves, the valves being plugged, and allowed to stand for 30 minutes.

5.4.1.2 After the procedure described in section 5.4.1 above has been carried out:

5.4.1.2.1 the pressure in the inflated tube must be adjusted to the designed working pressure and the tube left for at least 30 minutes for any stretch to recover; and

5.4.1.2.2 the pressure in the inflated tube must again be adjusted to the designed working pressure of the relief valves and the pressure drop after 60 minutes, corrected for any temperature change in accordance with section 5.4.1.2.4 below, must be recorded.

5.4.1.2.3 Where a buoyancy tube of an inflated boat is subdivided by bulkheads or diaphragms, the pressure in each compartment must be adjusted to the designed working pressure of the relief valves and the pressure drop after 15 minutes, corrected for any temperature change in accordance with section 5.4.1.2.4 below, must be recorded.

5.4.1.2.4 The results of the pressure drop readings of the air inflation tests must be corrected for any variation of the temperature in the vicinity of the buoyancy tube during the test, within a permissible limit of 3℃ as follows:

5.4.1.2.4.1 if there is a temperature rise, 0.004 kg/cm2 (38 mm water gauge) must be subtracted for every degree Celsius; and

5.4.1.2.4.2 if there is a fall in temperature, 0.004 kg/cm2 (38 mm water gauge), must be added for every degree Celsius.

5.4.1.2.5 The maximum permissible corrected drop in pressure referred to in sections 5.4.1.2.3 and 5.4.1.2.4 above must not exceed 2.54 g/cm2 (25.4 mm water gauge) from the designed working pressure.

5.4.1.2.6 Tests of other inflation compartments such as thwarts or keels, as applicable, must be as specified in the manufacturer’s construction specifications for the boat.

5.4.1.2.7 Where, during a manometer pressure test of an inflated buoyancy tube, the ambient temperature varies more than 3℃, the results of the test must be disregarded, and the test must be repeated.

Chapter 6 Testing for launching appliances for emergency boats

6.1.1 Launching appliances for emergency boats must be tested in accordance with paragraph 8.1 – Testing of davits and launching appliances – of Part 1 of Resolution MSC.81(70).

TP 14475 – Canadian Life Saving Appliance Standard

(PDF, 1.1 MB)

GC Catalogue No. T29-59/2023E-PDF

ISBN 978-0-660-69572-3

TP 14475E