On this page

- 1. Introduction

- 2. Risk associated with marine carriage of grain in bulk

- 3. Scope of inspection (What to expect during inspection)

- 3.1 Main step

- 3.2 Notification and request for the readiness to load inspection

- 3.3 Start of inspection

- 3.4 Safety of inspectors on board the ship

- 3.5 Readiness to Load inspection process

- 3.6 Issuance of the Certificate to Readines to Load

- 3.7 Changes to the approved loading plan

- 3.8 Notification and request for the fitness to Proceed inspection

- 3.9 Fitness to Proceed inspection process

- 3.10 Issuance of the Fitness to Proceed Certificate

- 3.11 Deviations from the approved loading plan

- 4. Specific requirements

1. Introduction

Safely loading, stowing and securing cargoes is one of the most important factors in preparing a ship for safe voyage. Cargoes like grain in bulk present high risks because of their ability to flow freely.

The risks of marine transportation of grain are further elevated due to the fact that in Canada those cargoes account for a significant part of Canadian export in terms of quantity. To minimize these risks, a mandatory inspection program was established for ships loading grain in Canadian ports.

This guidance is published to help ship Masters prepare for inspections in order to save as much time and effort as possible, while also successfully completing the inspection process.

In Canada, safe loading, stowing and securing of cargo is regulated by the Cargo, Fumigation and Tackle Regulations (CFTR) created under the Canada Shipping Act, 2001.

The master of a ship loading grain in bulk must also make sure that their ship meets the requirements of the International Grain Code, and any relevant parts of the SOLAS Convention (CFTR s. 123).

Section 128 of the CFTR requires that ships loading grain in bulk be inspected.

2. Risks associated with marine carriage of grain in bulk

2.1 Shift of grain due to its ability to flow

Unless cargo holds are properly loaded, excessive void spaces will occur. As the cargo settles these voids will become larger. As the ship rolls the cargo tends to shift to fill the void spaces on one side or the other. This shift of cargo will produce a list which can become severe if the ship doesn’t have sufficient stability to withstand it.

For this reason, ships are required to have approved loading plans which must be followed when loading grain. Special precautions must be taken to make sure that the ship has stability to withstand a shift or to secure any grain surfaces which may shift.

2.2 Contamination

Grain can be easily contaminated by residue from previous cargo, insects or by contact with water or oil. Although not always directly related to the safety of the ship it’s still an important aspect of the initial inspection. If the grain gets wet, it may self-heat over time.

For phytosanitary aspects refer to the inspection by the Canadian Food Inspection Agency referred to in the “What to expect during inspection” section below.

3. Scope of inspection (What to expect during an inspection)

The information in this section provides a general overview of the inspection process. It will be followed by a detailed description of inspection stages and the items that need to be verified to successfully obtain a Certificate of Readiness to Load and Fitness to Proceed Certificate.

Commercial considerations do not affect inspection

Transport Canada will conduct inspections pursuant to the CFTR. Any limitations imposed due to commercial considerations will not be regarded as an overriding factor for the process of assigning an Inspector and inspecting the ship. This applies as much to the issuing of the Readiness to Load Certificate, Fitness to Proceed, or written statement.

3.1 Main steps

- The ship Master or Agent informs the respective Transport Canada Center about the intended loading and applies for inspection for the purpose of receiving a Certificate of Readiness to Load

- Before the ship’s arrival, in order to minimize inspection time, an Inspector contacts the ship and asks for electronic copies of the documents listed in the “Master - Inspection Checklist - Grain

- The Inspector will also provide the “Master - Inspection Checklist – Grain” at the time of pre-arrival review. This will help the Master to prepare the ship

- At the agreed time, the Inspector will carry out the inspection for issuing a Certificate of Readiness to Load

- Once an inspection has been successfully completed, the Inspector will issue a Certificate of Readiness to Load to allow loading

- Loading starts

- Once loading is complete, the ship Master or Agent will notify the respective Transport Canada Center and apply for an inspection to obtain a Fitness to Proceed Certificate

- At an agreed time, the Inspector will carry out the inspection for issuing a Fitness to Proceed Certificate

- Once the inspection has been successfully completed, the Inspector will issue a Fitness to Proceed Certificate

3.2 Notification and request for the readiness to load inspection

Before a ship begins loading grain in bulk in a Canadian port the CFTR requires the Master or Agent to notify the respective Transport Canada Center and apply for a Certificate of Readiness to Load.

The ship’s agent will contact the respective Transport Canada Center and ask for a readiness to load inspection, providing accurate information about the date, time, ship’s name, and terminal.

In response to this request, an Inspector will contact the ship and ask for electronic copies of the documents listed in the “Master - Inspection Checklist – Grain”.

3.3 Start of inspection

An Inspector will verify the condition of the ship at the agreed time and determine whether the ship complies with all applicable requirements of the regulations and can safely load, stow, and carry the intended cargo.

3.4 Safety of inspectors on board the ship

The ship Master must take all necessary steps to ensure safety of the Inspector. This includes providing safe access to the ship, any enclosed space, cargo holds, and decks. There must be proper lighting and ventilation. The ship must provide a sufficient and competent crew to accompany the Inspector.

To provide safe access to cargo holds, please refer to IMO Resolution A.1050(27) - Revised recommendations for entering enclosed spaces aboard ships. At all times, an empty cargo hold is considered by Transport Canada as an enclosed space.

3.5 Readiness to Load inspection process

The following paragraphs expand on what to expect during the inspection for a Certificate of Readiness to Load.

The Master must make sure that the load line marks are clearly readable and marked according to the ship’s Load Line Certificate. The Inspector will visually verify the marks and check the general condition of the external hull.

While inspecting the ship, the Master will provide copies of the ship’s certificates and relevant documents approved by the ship’s flag authority or a recognized organization (such as Classification Society) on behalf of the ship’s flag authority.

Occasionally, a ship that has recently changed ownership and / or country of registration may arrive with approval documents issued by its former flag administration. The Inspector will not issue a Readiness to Load Certificate until the ship’s present administration has rectified the situation. When inspecting a ship for the issuance of a Certificate of Readiness to Load, the Inspector will make sure that the ship meets the stability requirements according to Chapter VI of SOLAS and the International Grain Code.

The Master must present the Inspector with a completed copy of a Canadian Grain Stability Calculation formFootnote 1. To complete the form correctly, please refer to the Annex attached to it. The stability calculations of the ship must meet the stability requirements identified in the Grain Code. The Inspector may issue a Certificate of Readiness to Load based on the positive results of this calculation.

After examining the documents and certificates, the Inspector will verify all spaces in which cargo will be loaded.

The Inspector should work with the Canadian Food Inspection Agency Inspector to determine whether the cargo spaces are fit to carry grain. As stated in paragraph 128(2)(e) of the CFTR, the Certificate of Readiness to Load can only be issued if a document of compliance is issued to the ship by the Canadian Food Inspection Agency (for more information please see paragraph 58(2)(a) of the Plant Protection Regulations).

When inspecting the cargo spaces, the Inspector will carefully examine bulkheads, wing tanks and topside tanks for any sign of damage or leaks. Rust stains or damp streaks generally indicate that cracks may exist. In this case repairs may be necessary. The inspection will include the double bottom tank tops, sounding or filling pipes and ships side plating for possible leaks. Any signs of structural damage (like indentations or distortion) may warrant further examination. The detection of a heavy corrosion area will be considered suspect. Bilge wells must be clear of obstruction and any foreign objects and must be covered by burlap or other suitable material secured in place.

The Inspector may ask the Master to test the bilge pumping arrangement to ensure it works properly. Hatch coamings and seals on hatches will be carefully examined. The Cargo spaces must be clean and dry.

3.6 Issuance of the Certificate of Readiness to Load

If the ship is found compliant with all applicable requirements, based on inspection result, a Readiness to Load Certificate will be issued.

If some requirements have not been met, the Inspector will give the Master a written statement detailing the elements to be rectified. A Certificate of Readiness to Load will only be issued once non-conformities have been rectified.

When the deficiencies are rectified and the ship is ready, the Master or Agent must notify the respective Transport Canada Center and ask for an inspection to issue the Certificate of Readiness to Load.

3.7 Changes to the approved loading plan

If, before the start or in the course of loading, the previously approved plan changes, the Master must notify the respective Transport Canada Center, prepare and submit a new stability calculation to the Inspector before completion of loading to check the calculation and issue a new Certificate of Readiness to Load.

3.8 Notification and request for the Fitness to Proceed inspection

At the completion of loading grain in bulk, the CFTR require the Master or Agent to contact the respective Transport Canada center and ask for an inspection to issue a Fitness to Proceed Certificate to the ship.

The Transport Canada Centre must be provided with accurate information about the date, time, ship’s name and terminal.

3.9 Fitness to Proceed inspection process

An Inspector will inspect the ship at the agreed time and determine whether the cargo stowage is loaded in compliance with all applicable requirements of the regulations and if the ship is fit to proceed to sea for the intended voyage.

The Inspector will verify the drafts, forward, aft and amidship (both side) , taking into account the applicable correction for water density.. The Inspector will make sure that the loading was done according to the approved loading plan and check proper stowage, levelling and securing of the cargo.

Please note that in the Great Lakes Basin no Fresh Water Allowance is permitted under any circumstances.

3.10 Issuance of the Fitness to Proceed Certificate

Based on the positive results of the inspection, the Inspector will issue a Fitness to Proceed Certificate.

3.11 Deviations from the approved loading plan

If the ship is found to be overloaded or deviating from the conditions in the approved loading plan, the Inspector will not issue a Fitness to Proceed Certificate.

The Inspector will inform the master of the outstanding requirements to be complied with before a Fitness to Proceed Certificate can be issued.

4. Specific requirements

4.1 Bilges

Bilge wells and strainer plates in the cargo spaces must be in good order. Bilge wells must be dry, free from extraneous material and covered by burlap or by other appropriate material to allow water outside the bilges to drain to the bilge sections while preventing the cargo from entering the bilges.

Bilge lines, sounding pipes and other service lines within the cargo spaces must be in good order. Cargo space fittings must be protected from damage. Sounding the bilges may be used to detect the absence of damage on cargo space fittings.

4.2 Multi-port loading

In case of multi-port loading, the stability calculations for different topping off conditions for all subsequent ports of topping off must be verified during the inspection in the first port of loading. The objective is to confirm that the proposed scenarios meet the requirements applicable to all stages of the voyage.

4.3 Stability calculations

Stability calculations must include the bunker. Any operation that takes place during the voyage before the first port of discharge must be included in the appropriate section of the calculation. Adequate stability must be maintained throughout the intended voyage.

Please note that in Canada stability calculations for any filled compartment must be based on the 100% full cubic capacity and corresponding maximum VCG (Vertical Center of Gravity) of the compartment whether the cargo is trimmed or not. Untrimmed moments shall always be used unless the filled compartment has been trimmed.

When a ship part loaded with grain needs to proceed to another Canadian port for topping-off within designated sheltered waters, the ship may sail with reduced stability based on the stability calculations verified and accepted by the Inspector for more information please refer to the CFTR, section 125.

4.4 Grain-tightness of cargo spaces

Grain leaking from one cargo compartment into another would change the ship’s initial loaded condition and make the stability calculations invalid. To avoid grain leakage, make sure that all structural boundaries of cargo compartments are grain tight. Although this isn’t a problem with permanent divisions, temporary or movable bulkheads will require special attention.

For a ship with moveable bulkheads, they must be installed and sealed according to the instructions approved by the Flag Administration / recognized organization (such as classification society).Footnote 2

4.5 Structural strength and limitations

Ships are designed with certain limitations deliberately imposed on their operations to maintain their structural integrity. The use of scenarios not shown in the approved loading manual may cause structural failure due to excessive stresses.

In particular, overstressing local structural members can occur even when the ship's loading instrument calculations indicate that the hull girder still water shear forces (SWSF) and still water bending moments (SWBM) are within their permissible limits.

Exceeding the permissible limits specified in the ships' approved loading manual may lead to overstressing of the ship's structure and may result in failure of the hull structure. Thus, when deviating from the cargo load conditions contained in the ship's approved loading manual, you must make sure not to exceed both the overall (SWSF and SWBM) and local structural limits.

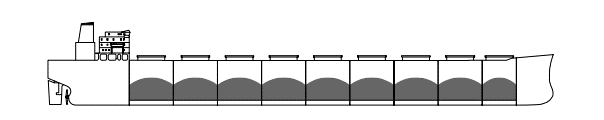

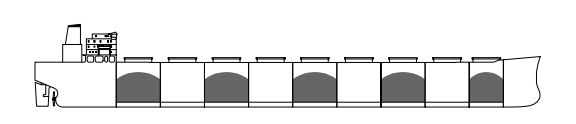

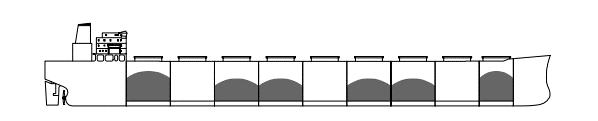

Overstressing the local structural members may occur in case of non-homogeneous hold loading such as alternate hold loading and block loading (see Figure 1). Alternate hold loading refers to loading in odd-numbered holds with even-numbered holds remaining empty (or vice versa). Block loading refers to stowing cargo in a block of 2 or more adjoining holds with holds adjacent to such blocks remaining empty.

To prevent overstressing hull structures, prepare proposed loading plans and sequences according to the loading conditions in the ship’s approved loading manual.

Ships loading bulk cargoes must not load or carry cargo in load configurations that are not specifically authorized in the approved loading manual, which must be used in conjunction with the approved loading instrument.

To avoid potential delays during inspections the approved loading manual should be updated to include additional approved loading conditions. Otherwise, a special approval from an organization recognized by the Flag Administration (Classification Society) should be provided for a particular loading condition before the Inspector issues a Certificate of Readiness to Load. Unauthorized loading condition is a deviation from the approved stability manual, even though the ship's loading instrument calculation indicates that the ships' SWSF / SWBM are within the permissible limits.

Alternatively, the ship can be provided with a set of approved local loading criteria which define the maximum cargo weight as a function of the ship's mean draft for each cargo hold and block of cargo holds. In this case, you must make sure that the amount of cargo carried in each hold satisfies the cargo or ballast weight and draught limits specified by the local loading criteria and the hull girder SWSF and SWBM values are within their permissible limits.

Figure 1. Loading conditions

- Homogeneous hold loading - cargo is evenly distributed in all holds.

- Alternate hold loading in odd cargo holds (fully loaded condition) – approximately double the cargo weight per hold is loaded in the odd numbered holds.

- Block loading – cargo is loaded in blocks of two or more adjoining holds with adjacent holds remaining empty.

4.6 Structural integrity

All decks, hatch covers, hatch coamings and cargo holds must have no cracks and / or deformations and shall be in a satisfactory condition.

Cargo hold inspection includes but is not limited to the following items:

- safe means of access to cargo holds (to be in good order)

- structural members to show no sign of cracks, leaks, excessive corrosion, deformation or damage

- bilge wells (to be clean and dry)

- integrity of bilge wells’ covers

- protection of bilge wells (burlap or geotextile membrane)

- pumping arrangement (to be operational)

- water ingress alarms (to be operational)

- sounding pipes (to be in good order)

- ventilation systems (to be operational)

- hatch coamings and seals (to be in good order)

- hatch cover locking devices (to provide for secure and weathertight closing of hatch covers)

- grain tightness of the cargo spaces (to avoid leakage of grain from the cargo spaces)

4.7 Miscellaneous

Operational oxygen analysis and gas detection instruments must be available on board together with the certificate of approval and the detailed instructions for their use (CFTR s.123(1), SOLAS VI / 3.1)

Cargo hold water level indicators / detectors must be operational (SOLAS XII / 12).

Loading instruments must be approved by the Flag Administration / Recognized Organization (Classification Society) on behalf of the Flag Administration, and operational (CFTR s.126 (2), SOLAS / C - XII / R11).

The ship must comply with the International Grain Code throughout the intended voyage.