Ship Safety Bulletins (SSB)

RDIMS

No

.: 8243526

Date (

Y-M-D

): 2013-05-14

We issue Ship Safety Bulletins for the marine community. Visit our Website at www.tc.gc.ca/ssb-bsn to view existing bulletins and to sign up to receive e-mail notices of new ones.

Purpose:

The purpose of this bulletin is to inform stakeholders of new regulations now in place to address air emissions from vessels over 400 gross tonnage operating in Canada. The Regulations Amending the Vessel Pollution and Dangerous Chemicals Regulations (the Amendments) were published in Part II of the Canada Gazette on May 8, 2013.

Background

The Amendments implement standards for the North American Emission Control Area (NA-ECA), energy efficiency of vessels, and a regime for Canadian vessels in the Great Lakes and St. Lawrence waters. For full text of the Amendments and the Regulatory Impact Analysis Statement, please see the Canada Gazette, Part II.

Please note some requirements for air emissions are already in place under Vessel Pollution and Dangerous Chemicals Regulations (the Regulations). As the Amendments will be incorporated into the text of the Regulations, please consult the Regulations.

The Regulations will be enforced in accordance with the Policy on Compliance and Enforcement of the Canada Shipping Act, 2001- TP13585.

With the Amendments published, Canadian regulations to implement these international standards are now in place.

Emissions Standards: Sulphur oxides

Sulphur oxides are formed during combustion from the sulphur present in the vessel’s fuel; therefore the standards are set as the percentage of sulphur content in fuel. With the advent of emission control technology, IMO also set standards based on the sulphur dioxide to carbon dioxide ratio.

For vessels inside the NA-ECA and throughout Canadian waters south of 60°N, the Amendments set a limit of 1.00% on the sulphur content of marine fuel. This will be followed by a 0.10% limit after January 1, 2015.

In waters outside of the NA-ECA, north of 60°N and including all of Hudson’s Bay, James Bay and Ungava Bay, the Amendments set the global standards under MARPOL for controlling sulphur oxides. This currently comprises a 3.50% limit on the sulphur content of marine fuel and after January 1, 2020, the Amendments set the standard to 0.50%.

Vessels over 400 gross tonnage are already required by the Regulations to carry bunker delivery notes, which stipulate the sulphur content of fuel delivered to the vessel. Pursuant to section 124(1) of the Regulations and Regulation 18.5 of Annex VI to MARPOL, the vessel’s bunker delivery note must contain the following information.

- Name and IMO Number of receiving ship

- Port

- Date of commencement of delivery

- Name, address, and telephone number of marine fuel oil supplier

- Product name(s)

- Quantity in metric tons

- Density at 15°C, kg/m3 tested in accordance with ISO 3675:1998 or ISO 12185:1996.

- Sulphur content (% m/m) tested in accordance with ISO 8754:2003.

- A declaration signed and certified by the fuel oil supplier’s representative that the fuel oil supplied is in conformity with the applicable subparagraph of regulation 14.1 or 14.4 and regulation 18.3 of Annex VI to MARPOL.

Determining compliance: Sulphur content in fuel

In most cases, an authorized representative relies on the sulphur content provided in the bunker delivery note. However, Annex VI to MARPOL also requires samples of the fuel to be kept on board. As the Authorized Representative is responsible to have compliant fuel, verification would be prudent.

Appendix VI of Annex VI to MARPOL sets out the “Fuel Verification Procedure for MARPOL Annex VI Fuel Oil Samples”, which is to be used to determine if the fuel oil delivered to and used on board ships is compliant with the sulphur limits.

The sulphur content must be tested in accordance with a test method administered by the International Standards Organization; ISO 8754:2003 which can be found at the ISO website. This test method is specified for the determination of the sulfur content of petroleum products, such as naphthas, unleaded motor gasolines, middle distillates, residual fuel oils, base lubricating oils and components. The method is applicable to products having sulfur contents in the range 0.03 % (by mass) to 5.00 % (by mass).

Petroleum fuels can vary greatly in composition depending on the stock crude and refining process they were subjected to. Therefore, variability between test results needs to be accounted for when determining if the fuel is compliant to the sulphur content standard.

The ISO test method provides an accepted variability, amounting to ±0.02% in terms of measured sulphur content or a relative variance of 5%. However, the international standards for sulphur content in marine fuel is set by Annex VI to the MARPOL Convention and are set out as absolute limits. Therefore, this must be considered when managing the natural variation of the fuel and that of laboratory measurements.

The Fuel Verification Procedure manages for a variance by setting requirements for when a test should be repeated by a second laboratory and those results included in the calculation or if the entire test should be repeated. A sample with a sulphur content found to be over the MARPOL standard and 0.59 times the reproducibility standard set by the ISO test method is deemed to have failed.

Determining compliance: Sulphur dioxide to carbon dioxide ratio

The Amendments allow for compliance to be in accordance with in the IMO Guidelines for Exhaust Gas Cleaning Systems, Resolution MEPC.184(59). This document may be accessed at the IMO web site through the Knowledge Centre, index of IMO Resolutions, under the list of MEPC Resolutions.

The Guidelines allow compliance with the sulphur content standards to be determined by the ratio of sulphur dioxide to carbon dioxide (SO2/CO2) in the vessel’s exhaust as set out in Table 1 below.

Table 1. Sulphur content compared to ratio of sulphur dioxide to carbon dioxide

| Fuel Sulphur Content (%m/m) | Ratio of SO2 (ppm) to CO2 (% v/v) |

|---|---|

| 4.50 | 195.0 |

| 3.50 | 151.7 |

| 1.50 | 65.0 |

| 1.00 | 43.3 |

| 0.50 | 21.7 |

| 0.10 | 4.3 |

The Guidelines allow compliance to be demonstrated by two schemes, A– by parameter and emissions checks and B – by continuous monitoring of emissions. Both require the vessel have a SOx Emissions Compliance Plan or SECP.

The SECP should refer to the technical manual, Exhaust Gas Cleaning System Record Book or Engine-Room logger system and Onboard Monitoring Manual. It should be noted that as an alternative, the maintenance records may be recorded in the ship’s Planned Maintenance Record System, as allowed by the Administration. Details should be provided demonstrating that the rating and restrictions for the exhaust gas cleaning unit are complied with. Required parameters should be monitored and recorded when the EGC is in operation in order to demonstrate compliance.

Emissions Standards: Nitrogen oxides

The Amendments set controls for nitrogen oxides for engines installed on vessels that have power ratings over 130 kilowatts as described in table 2 below.

Beyond this, the Amendments adopt the requirements for the management of engines to limit emissions of nitrogen oxides set out in the NOx Technical Code, 2008.

In the event a vessel undergoes a major conversion, or a new engine is installed which is substantially different from the old one, the more current standard would apply. For example, if a vessel built in 2001 undergoes a major conversion in 2014, it will then be subject to Tier II standards rather than Tier I.

Table 2. Nitrogen oxide emissions limits

| Tier I | Tier II | Tier III |

|---|---|---|

| Engines installed on vessels built between December 31, 1999 to December 31, 2010 | Engines installed on vessels built after December 31, 2010 | Engines installed on vessels built after January 1, 2016, that operate in ECAs |

|

|

|

Note: n = rated engine speed (crankshaft revolutions per minute)

Determining compliance: Nitrogen oxides

Nitrogen oxides are formed during the combustion process are nitrogen and oxygen. Therefore, unlike sulphur oxides, the basis for the emission standards stems from measurements of nitrogen oxides in the exhaust stream.

In most cases, the Authorized Representative would rely on the type approval of engines installed on their vessels that they meet the emission limits set out in Table 2 above. As well, under the NOx Technical Code, 2008, the exhaust systems would have nitrogen oxide monitoring equipment (approved by Class) and providing a record of emissions.

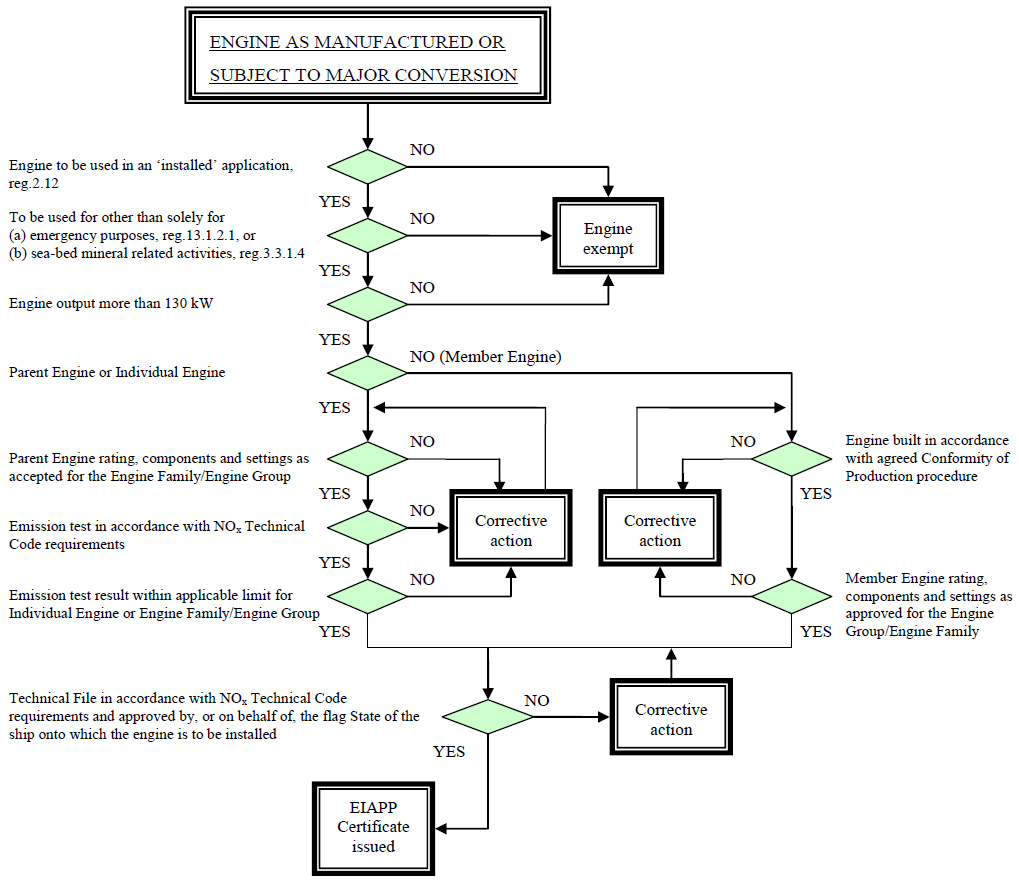

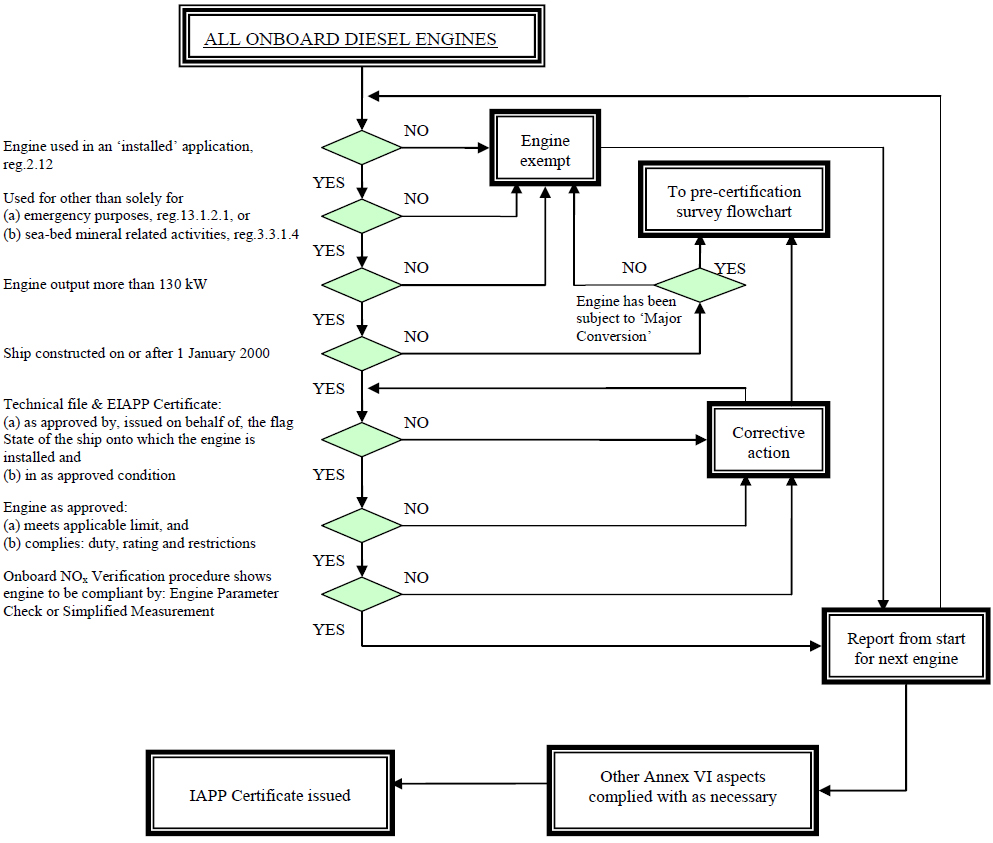

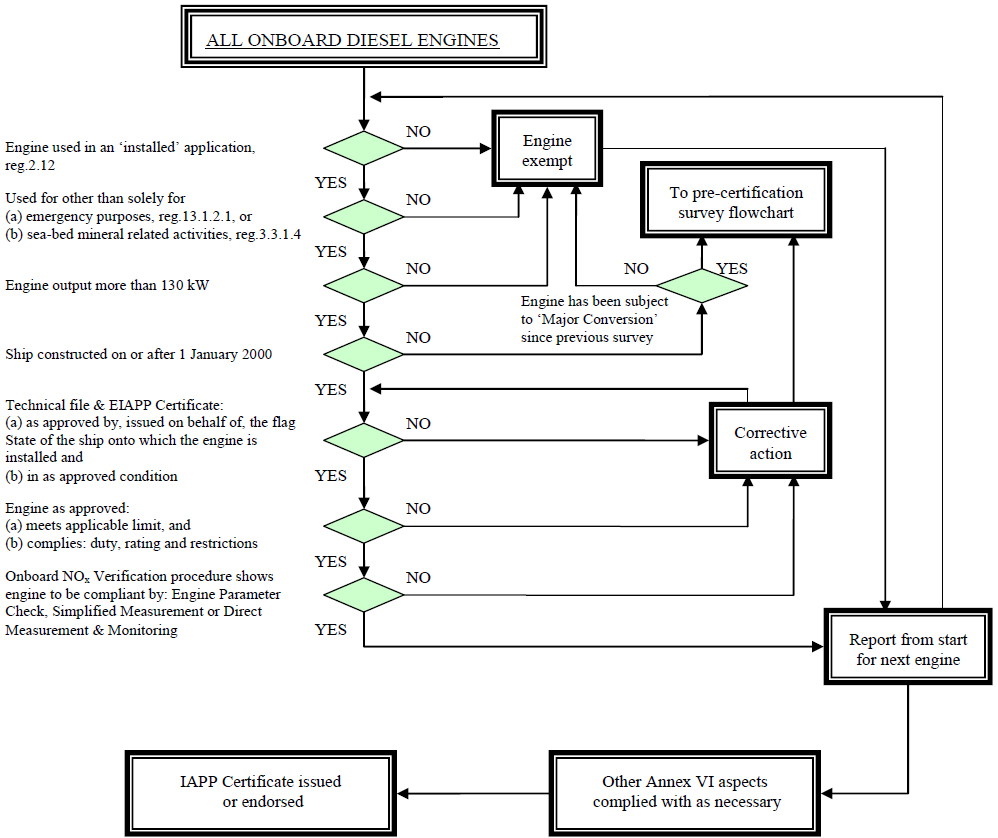

The Regulations require that the Record Book of Engine Parameters be kept on board along with a technical file of the engine. Flowcharts that provide guidance for compliance with survey and certification of marine diesel engines, as described the NOx Technical Code, 2008, are set out in Appendix 1 to this Bulletin.

Questions

Questions should be directed to:

Operations and Environmental Programs

Marine Safety and Security

Transport Canada

330 Sparks St, 10th floor,

Ottawa, Ontario K1A ON8

Email: marinesafety-securitemaritime@tc.gc.ca

Appendix: Flowcharts for survey and certification of marine diesel engines

Figure 1 – Pre-certification survey at the manufacturer’s facility

Engine as manufactured or subject to major conversion

- Is the engine to be used in an ‘installed’ application, reg. 2.12 ?

- If no, the engine is exempt.

- If yes, see question 2.

- Is the engine to be used for other than solely for:

- emergency purposes, reg.13.1.2.1, or;

- sea-bed mineral related activities, reg.3.3.1.4 ?

- If no, the engine is exempt.

- If yes, see question 3.

- Is the engine output more than 130 kW?

- If no, the engine is exempt.

- If yes, see question 4.

- Is this a parent Engine or Individual Engine?

- If no (Member Engine), see question 4.1.

- 4.1 is engine built in accordance with agreed Conformity of Production procedure?

- If no, corrective action is required.

- If yes, see question 4.2.

- 4.2 are the Member Engine rating, components and settings as approved for the Engine Group/Engine Family?

- If no, corrective action is required.

- If yes, is the technical file in accordance with NOx Technical Code requirements and approved by, or on behalf of, the flag State of the ship onto which the engine is to be installed?

- If no, corrective action is required.

- If yes, EIAPP certificate issued.

- 4.1 is engine built in accordance with agreed Conformity of Production procedure?

- If yes, see question 5.

- If no (Member Engine), see question 4.1.

- Are the Parent Engine rating, components and settings as accepted for the Engine Family/Engine Group?

- If no, corrective action is required.

- If yes, see question 6.

- Is the emission test in accordance with NOx Technical Code requirements?

- If no, corrective action is required.

- If yes, see question 7.

- Is the emission test result within applicable limit for Individual Engine or Engine Family/Engine Group?

- If no, corrective action is required.

- If yes, is the technical file in accordance with NOx Technical Code requirements and approved by, or on behalf of, the flag State of the ship onto which the engine is to be installed?

- If no, corrective action is required.

- If yes, EIAPP certificate issued.

Figure 2 – Initial survey on board a ship

All Onboard Diesel Engines

- Is the engine to be used in an ‘installed’ application, reg.2.12 ?

- If no, engine is exempt.

- If yes, see question 2.

- Is the engine to be used for other than solely for:

- Emergency purposes, reg.13.1.2.1, or;

- Sea-bed mineral related activities, reg.3.3.1.4 ?

- If no, then engine is exempt.

- If yes, see question 3.

- Is the engine output more than 130 kW?

- If no, engine is exempt.

- If yes, see question 4

- Is the ship constructed on or after January 1st 2000?

- If no, has the engine been subject to ‘Major Conversion’?

- If no, then engine is exempt.

- If yes, go to pre-certification survey flowchart.

- If yes, then see question 5.

- If no, has the engine been subject to ‘Major Conversion’?

- Is the technical file & EIAPP Certificate:

- as approved by, issued on behalf of, the flag State of the ship onto which the engine is installed and

- in as approved condition ?

- If no, corrective action is required – Go to pre-certification survey flowchart (Figure 1)

- If yes, see question 6.

- Does the engine as approved:

- Meets applicable limit, and;

- Complies: duty, rating and restrictions

- If no, corrective action is required - Go to pre-certification survey flowchart (Figure 1)

- If yes, see question 7.

- Does the onboard NOx Verification procedure show engine to be compliant by: Engine Parameter Check or Simplified Measurement?

- If no, corrective action is required - Go to pre-certification survey flowchart (Figure 1)

- If yes, then report from start for next engine – Go to beginning of flowchart (see question 1) OR other Annex VI aspects complied with as necessary IAPP Certificate issued

Figure 3 – Renewal, annual or intermediate survey on board a ship

All Onboard Diesel Engines

- Is the engine to be used in an ‘installed’ application, reg.2.12?

- If no, engine is exempt.

- If yes, see question 2.

- Is the engine to be used for other than solely for:

- Emergency purposes, reg.13.1.2.1, or

- Sea-bed mineral related activities, reg.3.3.1.4

- If no, engine is exempt.

- If yes, see question 3.

- Is the engine output more than 130 kW?

- If no, engine is exempt.

- If yes, see question 4.

- Was the ship constructed on or after January 1st 2000?

- If no, has the engine been subject to ‘Major Conversion’ since previous survey?

- If no, engine is exempt.

- If yes, go to pre-certification survey flowchart (Figure 1).

- If yes, see question 5.

- If no, has the engine been subject to ‘Major Conversion’ since previous survey?

- Are the technical file & EIAPP Certificate:

- as approved by, issued on behalf of, the flag State of the ship onto which the engine is installed, and;

- in as approved condition ?

- If no, corrective action is required – Go to pre-certification survey flowchart (Figure 1)

- If yes, see question 6.

- Does the engine as approved:

- meets applicable limit, and;

- complies: duty, rating and restrictions?

- If no, corrective action is required - Go to pre-certification survey flowchart (Figure 1)

- If yes, see question 7.

- Does the onboard NOx Verification procedure show engine to be compliant by: Engine Parameter Check or Simplified Measurement?

- If no, corrective action is required – Go to pre-certification survey flowchart (Figure 1)

- If yes, report from the start for next engine – Go to beginning of flowchart (see question 1) OR other Annex VI aspect complied with as necessary AND IAPP Certificate issued or endorsed.

The following document is available for downloading or viewing:

New Regulations for Vessel Air Emissions: Compliance with Air Emissions Standards (293

KB

)

To access the Portable Document Format ( PDF ) version you must have a PDF reader installed. If you do not already have such a reader, there are numerous PDF readers available for free download or for purchase on the Internet:

2. Marine Fuels

3. Regulations

4. Pollution Prevention

5. Compliance

Environmental Protection

613-991-3168

Marine Safety & Security

Tower C, Place de Ville

10th Floor, 330 Sparks Street

Ottawa, Ontario K1A 0N8

Contact us at: marinesafety-securitemaritime@tc.gc.ca or 1-855-859-3123 (Toll Free)