This report presents the opinion of the TERMPOL Review Committee (TRC) who have reviewed the project proposal and drafted the report. TERMPOL Review Report conclusions and recommendations do not relieve Pieridae Energy Limited, Goldboro LNG Limited and the vessels associated with the project from an obligation to fully follow all current legislative and regulatory requirements, amended from time to time, that apply to shipping safety and to the protection of the environment.

On this page

- Foreword

- Executive Summary

- 1.0 Introduction

- 2.0 Indigenous Engagement

- 3.0 Analysis

- 4.0 Conclusion

- Appendix 1: findings and recommendations

- Appendix 2: Documents submitted for TERMPOL review process

- Appendix 3: Design vessels

- Appendix 4: Terminal and navigation information

- Appendix 5: Goldboro LNG Navigation Simulation Study

- Appendix 6: Glossary

- Appendix 7: Acronyms and Abbreviations

- Appendix 8: List of references

Foreword

The TERMPOL Review Report on the Goldboro LNG Project was prepared by representatives from the following departments and authorities:

- Transport Canada:

- Marine Safety & Security Footnote 1

- Environment and Climate Change Canada:

- Environmental Assessment and Marine Programs

- Department of Fisheries and Oceans:

- Canadian Coast Guard

- Canadian Hydrographic Service

- Oceans and Coastal Management

- Atlantic Pilotage Authority

- County of Guysborough

Please note that this TERMPOL Review Report is not a statement of government policy. Do not assume that the government endorses the proposed project in whole or in part. This report reflects the opinions of the TERMPOL Review Committee (TRC) who reviewed the project proposal and prepared the report. Footnote 2

TERMPOL Review Report conclusions and recommendations do not relieve Pieridae Energy Limited, Goldboro LNG Limited and the vessels associated with the project from an obligation to fully follow all current legislative and regulatory requirements, amended from time to time, that apply to shipping safety and to the protection of the environment.

Julie Gascon

Director General

Marine Safety and Security

Transport Canada

Executive Summary

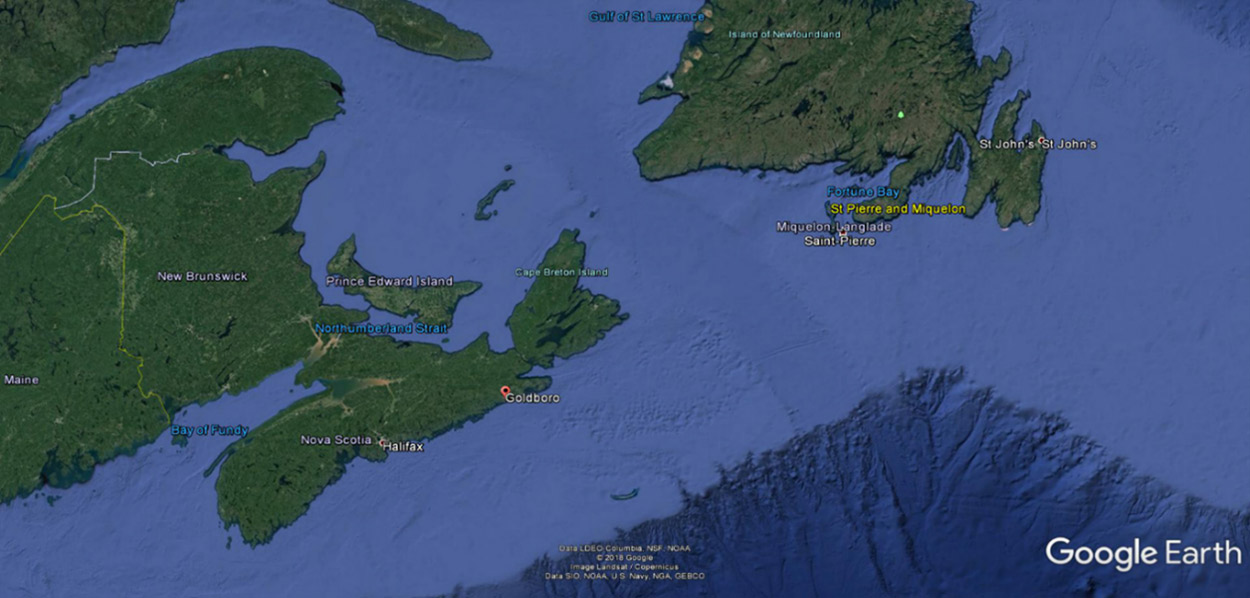

Pieridae Energy (Canada) Ltd. (Pieridae, the Proponent) wants to develop and operate a Liquefied Natural Gas (LNG) facility for storage and export at a site in Country Harbour, in Guysborough County, near Goldboro, NS.

Pieridae's design for the facility will berth LNG vessels with a cargo capacity of up to 266,000 m3 Footnote 3. The operation will result in the export of about 9.6 million tonnes per annum (MTPA) of LNGFootnote 4, with in a maximum 206 LNG vessels entering Country Harbour every year (7 to 13 shipments per month)Footnote 5. Pieridae does not expect changes to existing shipping routes or expect to have LNG vessels that hold more than 266,000 m3.

Transport Canada (TC) provides a voluntary, technical review process of marine terminal systems and transshipment sites known as TERMPOLFootnote 2. It measures the navigational risks associated with placing and operating marine terminals for tankers carrying bulk oil, chemicals, liquefied gas and other dangerous cargoes. A TERMPOL Review Committee (TRC) uses the review process to evaluate proposed projects.

In 2014, after obtaining an environmental assessment approval under the province of Nova Scotia's environmental review regime, Pieridae asked TC for a TERMPOL review. The NS approval was subject to meeting conditional requirements which included undergoing a TERMPOL review and implementing all recommendations.

A TRC was set up with members from TC, Fisheries and Oceans Canada (DFO), Environment and Climate Change Canada (ECC), the Atlantic Pilotage Authority (APP) and the County of Guysborough. They determined the scope of the review and asked Pieridae to submit studies that could help demonstrate how it could carry out the marine transportation components of the project safely, taking into account current Canadian laws and regulations, industry best practices, marine programs and services.

In 2016, Pieridae provided a studyFootnote 6 prepared by Amec Foster Wheeler, as a part of its submission. To help prepare other studies for the submission, Pieridae commissioned HR Wallingford Ltd. to conduct a General Risk Analysis and Ship Manoeuvering Simulations.

On July 26, 2018, Pieridae submitted the Information Report to Satisfy the Requirements of TERMPOL for the Goldboro LNG Export Facility to the TRCFootnote 7. The submission contained the following information:

| 3.1 | Introduction |

| 3.2 | Marine Traffic Survey |

| 3.3 | Route Analysis, Approach Characteristics and Navigability Survey |

| 3.4 | Special Under keel Clearance Survey |

| 3.5 | Transit Time and Delay Survey |

| 3.6 | Casualty Data Survey |

| 3.7 | Vessel Specifications |

| 3.8 | Site Plans and Technical Data |

| 3.9 | Cargo Transfer and Transshipment Systems |

| 3.10 | Channel, Manoeuvring and Anchorage Element |

| 3.11 | Berth Procedures and Provisions |

| 3.13 | General Risk Analysis and Intended Methods of Reducing Risk |

| 3.14 | Outline of Port Information Book |

| 3.15 | Outline of Terminal Operations Manual |

| 3.16 | Contingency Planning |

| 3.18 | Hazardous and Noxious Substances Considerations |

Members of the TRC also participated in the vessel manoeuvring simulations in Howbery Park, Wallingford, United Kingdom. The last report, Goldboro LNG, Navigation Simulation Study, was submitted to the TRC on April 2, 2019.

The committee studied Pieridae's proposal from the point of view of their respective mandates, regulatory authorities, responsibilities and expertise.

The committee expects the project to follow all current legal and regulatory requirements that apply to marine safety and protection of the environment. Canada has several regulatory safety measures in place to help make sure large vessels that enter Canadian waters follow both international and Canadian requirements, and do not pose a risk to safety or the environment. Under these requirements, marine terminals, LNG vessels and their operations, including those planned for Pieridae's Goldboro facility, must meet the safety and environmental protection requirements of international agreements and Canada's marine safety regulatory regime while in waters of Canadian jurisdiction.

Canadian and international requirements deal with areas including:

- Safe vessel design and construction, including requirements for safe manning

- Crew qualifications and training

- Working conditions

- Safety management systems

- Radio communications equipment

- Equipment for safe navigation, including electronic chart display and information systems (ECDIS) and automatic identification systems (AIS)

- Voyage planning

- Vessel reporting

- Rules to prevent collisions

LNG carriers will also have to follow Pieridae's vessel acceptance process and terminal procedures.

Although any project can pose some degree of risk, the TRC has not identified any major concerns for Pieridae's LNG carriers, operations, the proposed route, navigability, other waterway users or the marine terminal operations. After reviewing Pieridae's submission, the TRC has made 52 recommendations and proposed actions for Pieridae Energy Ltd. to undertake before the proposed terminal becomes operational. In combination with Pieridae's commitments, they will provide a higher level of safety for LNG vessel operations.

While the TRC does not consider the increase in marine traffic levels to be a safety issue, it supports additional measures that are consistent with the best practices of fully operational LNG terminals, including the LNG facility in Saint John, NB. These include:

- Applying thorough vetting and compatibility criteria before allowing a vessel at the terminal

- Using tugs with the right characteristics to escort the LNG carriers to and from their berths

- Setting limiting environmental criteria for arrivals, departures and cargo transfer

- Updating CHS charts and nautical publications for the area before terminal operations begin

- Having all licensed marine pilots for the area go through simulation or manned model training before terminal operations begin

- Considering safety zones around the LNG carriers and the terminal for an improved level of safety for the vessels, lives and nearby property. This is consistent with best practices at similar, fully operational LNG terminals.

All of the TRC's findings and recommendations are listed in Appendix 1.

1.0 Introduction

1.1 Project background and description

In 2014, after reviewing Pieridae's environmental assessmentFootnote 8 submitted, Nova Scotia‘s Minister of the Environment, approved the Goldboro LNG Project, subject to several conditions.

Condition 2.11 of the environmental assessment states:

"Completion of the TERMPOL Review Process in consultation with TC, Marine Safety and Security (MSS), to adequately assess the risks associated with the Goldboro LNG Marine Terminal.

The Approval Holder must implement and adhere to all recommendations of the TERMPOL Review Process unless otherwise approved by NSE."

Pieridae started a TERMPOL Review Process with TC in November 2013 and agreed on the scope and depth of the studies. Pieridae provided the final portion of the submission on April 2, 2019.

On October 31, 2018, the Nova Scotia Utility and Review Board issued a permit to construct a Liquefied Natural Gas (LNG) export facility in Goldboro, Nova Scotia, subject to conditions including providing copies of permits and approvals from other authorities.

Through the Goldboro LNG Project (the Project), Pieridae is proposing to build and operate a facility and marine terminal, for the storage and export of LNG.

LNG is natural gas in its liquid state. It's mostly made of methane, but also includes heavier hydrocarbons and traces of other compounds. When cooled to about ‑160°C, at atmospheric pressure, natural gas becomes a clear, colourless, and odourless liquid. LNG is cryogenic, non-corrosive and non-toxic. The process to turn LNG into a liquid removes the water, oxygen, carbon dioxide and sulfuric compounds from the natural gas. As a liquid, the volume of natural gas is reduced by 600 times, which makes it easier to transport overseas. After shipping, the LNG is re-heated and turned back into gasFootnote 9 .

The International Maritime Organization (IMO) classifies LNG as a hazardous and noxious substance (HNS). The IMO defines HNS as any substance other than oil that, if released into the marine environment, would likely harm humans, living resources and marine life or interfere with other use of the seaFootnote 10. TC has applied the definition of LNG as a hazardous and noxious substance in this report.

If the project goes ahead, the Goldboro LNG facility will export up to 10 MTPA of LNG and be able to load vessels between 125,000 m3 to 266,000 m3. Goldboro LNG will:

- Receive natural gas by a dedicated pipeline.

- Liquefy the gas.

- Store the LNG on site.

- Load it onto carriers (LNGCs).

- Ship it around the world.

The LNGCs docking at the Goldboro facility will be chartered tankers, owned by independent owners. The LNGC owners will be responsible for making sure the vessels are safe.

When operating in waters under Canadian jurisdiction, LNGCs must also follow all regulations. In addition, LNGCs will have to follow Pieridae's own vessel acceptance process and terminal procedures.

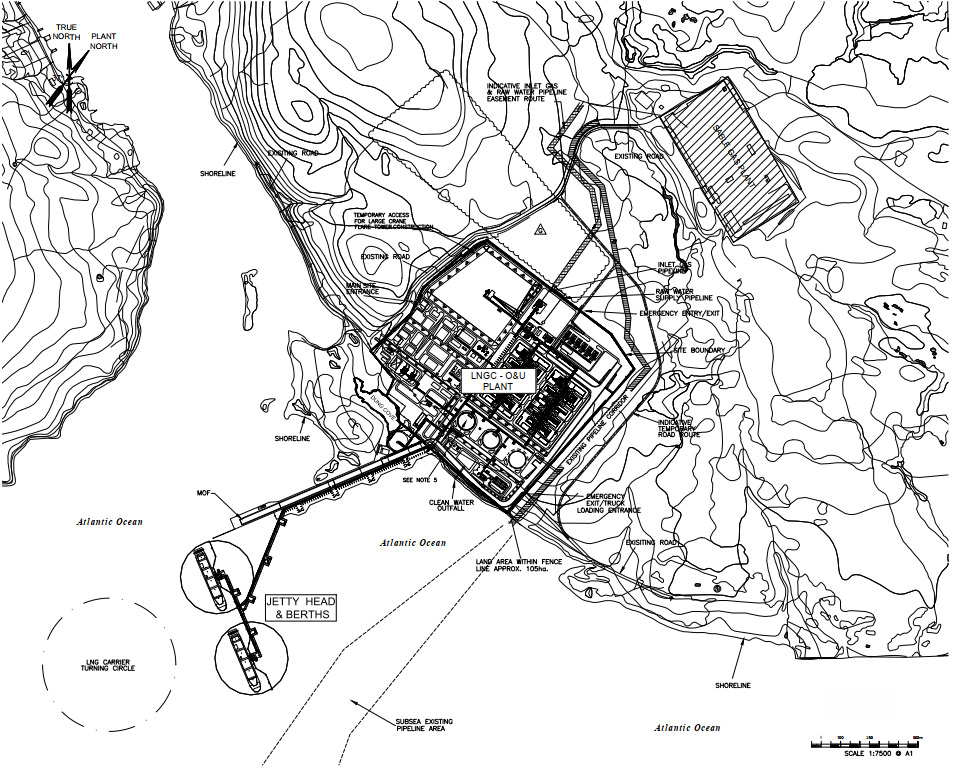

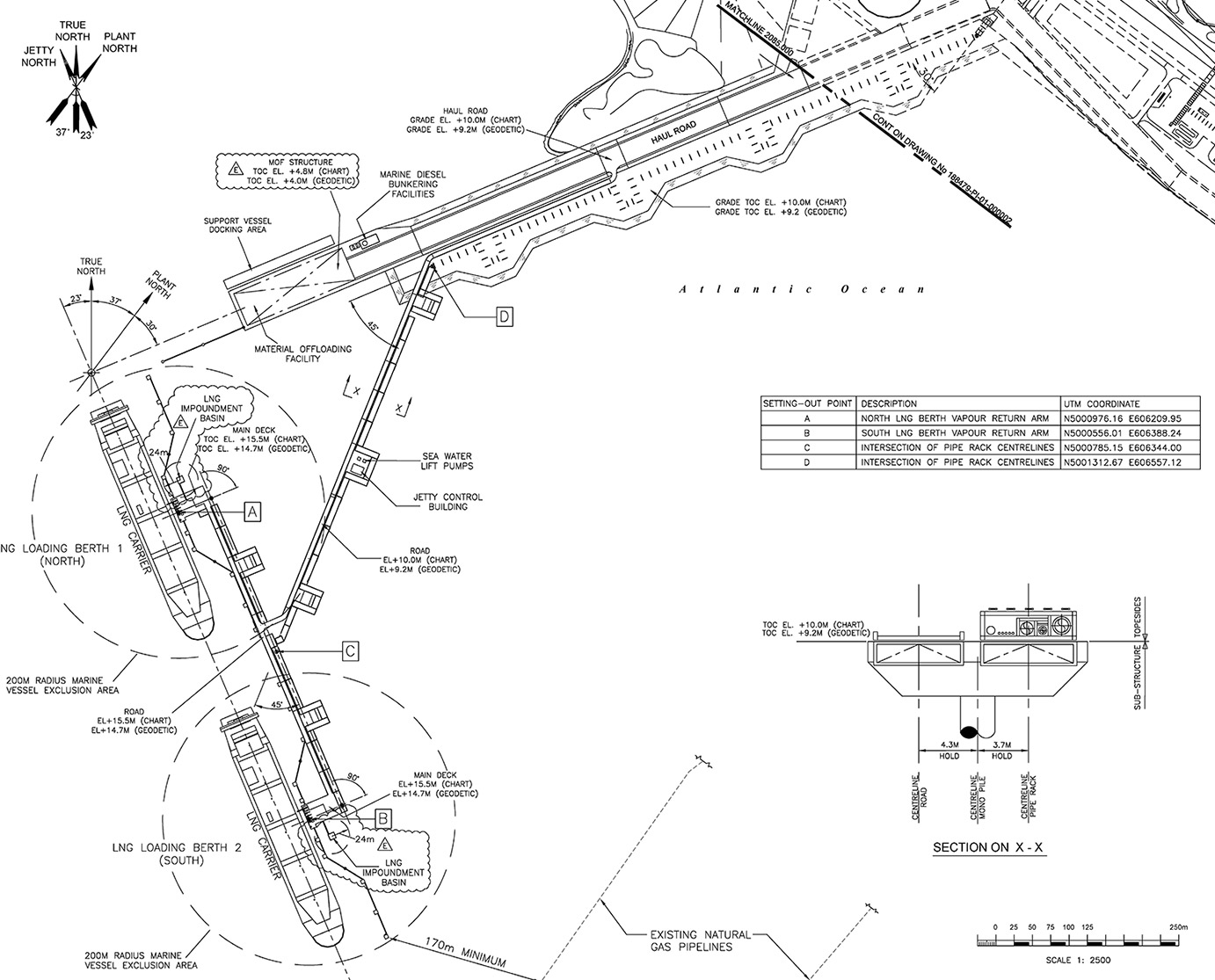

The proposed terminal layout, as detailed in the submission, will be made up of a causeway from the shore to two berths. The berths are designed to handle two LNGCs:

- Berth 1 (north) can moor vessels with 125,000 m3 to 266,000 m3 capacity.

- Berth 2 (south) can moor vessels with 125,000 m3 to 220,000 m3 capacity.

You can find the proposed layout in Section 3.3.1 and Appendix 4.

1.2 TERMPOL Review Process

TERMPOL refers to the Technical Review Process of Marine Terminal Systems and Transshipment Sites. TERMPOL guidelines are described in TERMPOL Review Process, 2014 Edition (TP 743).Footnote 2

TERMPOL is a voluntary review process for companies (proponents) that want to build and operate marine terminal for bulk handling of oil, chemicals and liquefied gases. The review focuses on the marine transportation parts of a project (i.e. when a vessel enters Canadian waters, navigates through channels, approaches berths at a marine terminal, and loads or unloads bulk oil, gas or chemicals).

The goal of this process is to improve those parts of a proposal that could, in certain circumstances, damage a vessel's hull while navigating or during cargo transfer at the terminal.

A proponent will submit TERMPOL studies set out in the TERMPOL Review Process, 2014 Edition, TP 743, to:

- Identify major hazards in the context of the proposed operation.

- Evaluate the risks from these hazards.

- Identify ways to reduce the risks to an acceptable level using the best available technology and practices.

Through the technical review process, a proponent works with a TRC chaired by TC and made up of members from departments and authorities with relevant expertise or responsibilities.

The TRC examines the proposal and considers:

- Studies, surveys and technical data provided in support of TP 743.

- Current and anticipated national and international regulations to make sure vessels are safely operated.

- Current marine transportation activities along the proposed shipping route.

The proponent considers a range of subjects, including:

- Navigational safety of the vessel's route(s)

- Services that help with safe navigation, such as

- fixed and floating aids

- vessel traffic services

- electronic position fixing systems

- Requirements for pilotage, tug escort and radio communications along the route(s)

- If the vessel is well suited to navigating the proposed route(s) and docking at the berth

- Operational safety of the vessel's cargo containment and handling

- Whether the vessel's berth and related terminal service requirements are adequate

- Possible effects of increased shipping on regional shipping networks, including fishing, recreational boating and vessels that don't need to carry an automatic identification system (AIS)

- Pollution concerns related to the additional vessels

- Risks to communities along the route(s)

- Pollution prevention, contingency planning and emergency response

The Committee reviews the TERMPOL submission and provides a report that includes:

- An executive summary, analysis, findings and recommendations

- Reports on specific topics to address any site-specific circumstances

The success of the TERMPOL Review Process depends on the proponent following the procedures in TP 743 and the quality of the data submitted to the TRC. The proponent is responsible for making sure that the studies meet industry and international standards.

The TRC "recommendations" are proposed actions to improve safety beyond existing regulations. As such, they relate to areas that the proponent can control. "Findings" are observations made to capture, reinforce or comment on key commitments made by the proponent. They are sometimes used to highlight actions underway or to note something related to a particular program or regulation.

The TERMPOL Review Process does not replace the safety, security, and environmental requirements of any Acts or Regulations that are in effect, nor is it a process to approve or reject a project. It should be noted for the purpose of this document that the referred to legislation and regulations may have changed since the implementation of the Goldboro terminal and therefore, it is expected that the proponent adhere to the most updated acts and regulations pertaining to this project.

The TERMPOL process is not a regulatory instrument. No approvals or permits are issued as a result of the TERMPOL review or report. As such, the TERMPOL report should not be interpreted as a statement of government policy or federal government endorsement. Although TERMPOL report findings and recommendations are not binding, a proponent may integrate the suggested improvements into their engineering, planning and design.

The Environmental Assessment8approval issued by the Nova Scotia Environment Department (NSE) included several conditions. Condition 2.11 requires the proponent to complete a TERMPOL Review Process to evaluate the project's risks and then carry out any recommendations, unless otherwise approved by NSE.

Notes:

- Recommendations cannot reduce the regulatory requirements of the Canada Shipping Act, 2001 (CSA, 2001) and any other applicable legislation.

- No approvals or permits are issued as a result of a TERMPOL Review. However, government authorities and other agencies can use the TERMPOL Review Report to identify:

- Problems and opportunities to improve maritime safety

- Any impact on marine services and programs

- The TRC and its relevant departments and organizations are not responsible for enforcing the conditions put in place by the environmental assessment.

1.3 Scope of a TERMPOL review

The scope of a TERMPOL Review Processwill vary according to the nature and location of each project.

The proponent, in consultation with the TRC, will select the most appropriate scope for the project to determine the geographic area, studies, surveys, technical data and timelines for the review. The proponent must also keep in mind pre-existing shipping activities and unique circumstances in the area.

Other considerations include:

- Will the terminal handle bulk oil, chemicals, liquefied gases, or other noxious and hazardous cargo?

- Is the project a new or existing terminal?

- Is the project proposed for an area that is not already a well-established shipping route?

- Are the project vessels larger than vessels currently in the area?

- Is this new cargo, not currently shipped out of the area?

- Is the project located outside the limits of a Canada Port Authority?

- Is this the first TERMPOL review for the region? If so, are the operations, vessels or cargo different from the previous review?

- Will the project result in a significant increase in vessel traffic?

- Have the safety risks been properly assessed in the scoping area of the project?

The TERMPOL review is a stand-alone process, separate from any environmental assessment. It does not look at the environmental impacts of a project, including those caused by accidents or malfunctions.

TERMPOL reviews do not determine standards for the terminal's site, design, construction or operation nor do they examine land infrastructures like natural gas receiving and LNG production facilities.

TERMPOL reviews are separate from the requirements under the Canadian Navigable Waters Act (CNWA)Footnote 11.Under the CNWA, proponents must apply for an approval if they want to construct, place, alter, repair, rebuild, remove or decommission a major work in, on, over, under, through or across any navigable water. The project must not affect the safety of navigation in that waterway.

In contrast, the TERMPOL review process looks at the marine transportation parts of a project within the context of the existing marine regulations, programs, and services, and considers new measures that could be put in place when the project begins operations.

1.4 Methodology for the Review of the Goldboro LNG Project

Pieridae Energy Ltd (Pieridae) formally requested a TERMPOL Review in a letter to TC on November 4, 2013. After the request was accepted, representatives from Pieridae and the TRC met to decide on the right scope for the surveys and studies.

The TRC members represented:

- TC MSS

- DFO Canada: CHS, Oceans and Coastal Management, Canadian Coast Guard (CCG) - Navigational Programs, Incident Management, and Integrated Business Management Services.

- ECC: Environmental Assessment and Marine Programs

- APA

- County of Guysborough

Pieridae prepared its submission according to theTERMPOL Review Process TP 743, 2014 EditionFootnote 2. The Technical Review Committee evaluated the documents to identify information gaps and to provide feedback.

As set out in the TERMPOL Review Guidelines, Pieridae submitted the studies, surveys and technical data identified in the Table 1.3-1for TRC review and analysis:

| Number | Title of the TERMPOL Study |

|---|---|

| 3.2 | Marine Traffic Survey |

| 3.3 | Route Analysis, Approach Characteristics and Navigability Survey |

| 3.4 | Special Under keel Clearance Survey |

| 3.5 | Transit Time and Delay Survey |

| 3.6 | Casualty Data Survey |

| 3.7 | Vessel Specifications |

| 3.8 | Site Plans and Technical Data |

| 3.9 | Cargo Transfer and Transshipment Systems |

| 3.10 | Channel, Manoeuvre and Anchorage Elements |

| 3.11 | Berth Procedures and Provisions |

| 3.13 | General Risk Analysis and Intended Methods of Reducing Risks |

| 3.14 | Port Information Book (outline) |

| 3.15 | Terminal Operations Manual (outline) |

| 3.16 | Contingency Planning |

| 3.18 | Hazardous & Noxious Substances Considerations |

Pieridae and the TRC agreed to omit two studies that do not apply to the project:

- 3.12 - Single Point Mooring Provisions

- 3.17 - Oil Handling Facilities Requirements

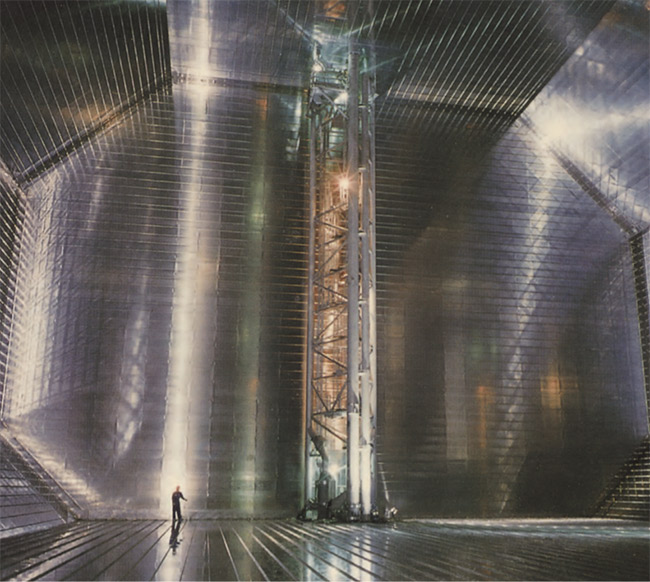

Pieridae worked with HR Wallingford Ltd. in Howbery Park, Wallingford, UK, to conduct LNGC ship manoeuvring simulations to:

- Validate its terminal design and configuration.

- Validate tug characteristics and composition.

- Test environmental limits for safe operation.

- Evaluate the adequacy of existing aids to navigation.

The simulations were performed in November, 2018 by a team from the APA, TC MSS, Pieridae and HR Wallingford Ltd. More information on the simulation report can be found in Section 3.2.3.2.

The TRC reviewed the draft surveys and studies between July 2018 and May 2019 and provided feedback to Pieridae for amendments/additions to their submission information.

The results of the TRC's review are presented in the Analysis section of this report under the following five sections:

- Vessel information

- Route information

- Terminal operations

- Risk assessment and contingency planning

- LNG and oil spill preparedness and response

The TRC based the analysis and commentary in this report on the information, documentation, and technologies available at the time it was written. There may be a need to re-evaluate some aspects of this analysis if there is a long delay in the start of operations or if Pieridae makes changes to the proposal.

This TERMPOL Review Report recommendations and findings apply specifically to the marine safety elements of Pieridae's proposed Goldboro LNG Project and are intended to reduce risks, using the best available technology and practices.

Please read this report along with the TERMPOL Review Process, 2014 Edition (TP 743) and the studies submitted by the proponent. For a copy of the proponent's studies, contact:

Pieridae Energy Ltd

1718 Argyle St Suite 730

Halifax NS B3J 3N6

Tel: 902-492-4044

Fax: 902-492-5200

Email: info@pieridae.com

2.0 Indigenous Engagement

Several communities and Indigenous organizations may be affected by or have a direct interest in the Goldboro LNG Project. The scoping area is used for traditional activities including hunting, fishing and gathering.

In their proposal, Pieridae detailed their engagement with local Indigenous groups between 2013 and 2018. They've also committed to continue these conversations as the project moves forward and reaches key milestones. Although the Duty to Consult was initially triggered by the requirements from Nova Scotia's environmental assessment, parts of the TERMPOL Review also factored into Pieridae's consultation.

As part of the completed environmental assessment, Pieridae has committed to work proactively with Indigenous groups to define and agree to a Collaboration Benefits Agreement, which the proponent claims will aim to ensure the active involvement of First Nations in the development and operation of the project.

During the TERMPOL review process, TC provided regular updates to local Indigenous groups as well as other provincial and federal departments. TC will make Pieridae's TERMPOL Review Report on the Goldboro LNG Projectavailable to the public.

TC may hold technical briefings with Indigenous groups and local waterway users to:

- Give them an overview of the TERMPOL report.

- Provide an opportunity for questions and answers.

- Explain how the review committee reached its conclusions.

3.0 Analysis

3.0 Introduction

The TERMPOL Report reflects the TRC's analysis of Pieridae's plans and management of risk. The "safety enhancements" Pieridae has committed to were important parts of the TRC's assessment of the Project's safety. The TRC expects the proponent to manage these risks.

The report includes recommendations and findings that apply to LNG carriers, proposed routes and terminal safety. The TRC encourages the proponent to act on the recommendations included in this report. While the proponent can implement some recommendations, others will involve speaking to various authorities. Pieridae should make sure to give themselves enough lead time in case discussions are needed before acting on some recommendations.

If Pieridae changes any parts of the project, operational parameters, or characteristics, it is important to notify the right authorities to give them enough time for their review.

The Project's LNGCs and their operations must follow all Canadian and International laws that apply, including:

- The Canada Shipping Act, 2001; which is the main law that governs safety in marine transportation and protects the marine environment from vessel-source pollution in Canada. The CSA, 2001applies to all vessels operating in Canadian waters, Canadian vessels worldwide and in some cases, to foreign vessels within the Exclusive Economic Zone.

- The Atlantic Pilotage Regulations under the Pilotage Act, which created compulsory pilotage areas along Canada's Atlantic Coast.

- The Marine Transportation and Security Act (MTSA) manages marine transportation security and applies to vessels, ports and marine facilities in Canada, Canadian vessels outside of Canada, and marine installations and structures.

Finding 1. The TRC recognizes that Pieridae will have to discuss timelines with all relevant authorities for acting on the recommendations outlined in this report.

Recommendation 1. The TRC recommends that Pieridae notify the relevant authorities if it wishes to alter any parts of the project, operational criteria, or characteristics, so the authorities can review any safety impacts that would result from the changes.

3.1 Vessel information

3.1.1 General

Specialized LNG carriers (LNGC) will transport LNG from the Goldboro terminal to market. According to PieridaeFootnote 12, its marine terminal will handle vessels ranging from 125,000 m3 to 266,000 m3. The LNGCs will be chartered, foreign-flagged vessels and they must follow all international, flag state and Canadian Acts, Regulations and Conventions that apply to the vessel at the time of inspection. Based on the smallest vessel expected, they will have to meet the full range of requirements with no size-related exemptions.

Canada has incorporated parts of two international agreements, the International Convention for the Safety of Life at Sea (SOLAS) and International Convention for the Prevention of Pollution from Ships (MARPOL) into the Canada Shipping Act, 2001, and require vessels to follow them. For example:

- Critical shipboard systems like steering, power and navigation systems must have back-ups available on board so that the failure of one system does not jeopardize the safety of the vessel. (SOLAS, Chapter IV and V).

- SOLAS requires a full set of navigational equipment for safe and accurate navigation.

- All LNGCs must have enough lifesaving equipment made up of lifeboats, life rafts, lifejackets, life rings and distress signals, etc. They must also have a fire plan on board with details of essential firefighting equipment.Footnote 13

- SOLAS requires vessels to have an emergency towing arrangement on board.Footnote 14

- All LNGCs must carry a shipboard oil pollution emergency plan approved by the Administration.Footnote 15

- Air Emissions: Goldboro is located in the North American Emissions Control Area (NA-ECA), which requires that the marine fuel used by vessels within the NA-ECA cannot contain more than 0.1% Sulphur. The 0.1% Sulphur limits came into effect on January 1, 2015.Footnote 16

The construction of a LNGC must comply with the requirements of the Flag State as well as the appropriate instruments of IMO conventions and codes. LNGCs must also comply with the version of the International Code for Construction and Equipment of Ships Carrying Liquid Gases in Bulk (IGC Code) in force at the time of their construction, and the guidelines of classification societies. Guidelines and recommendations are also issued by the Oil Company International Marine Forum (OCIMF) and the Society of International Gas Tanker and Terminal Operators (SIGTTO).

IGC Code includes requirements for the following items and controls:

- Cargo containment construction materials

- Cargo pressure and temperature control

- Environmental control

- Fire protection and extinguishment

- Personnel protection

- Capacity limits for cargo tanks

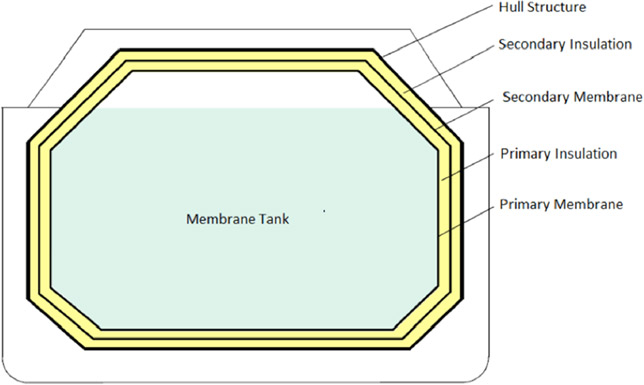

The membrane system uses insulation built directly into the hull of the vessel, along with a membrane covering inside the tanks to maintain their integrity. The ship's hull directly supports the pressure of the LNG cargo. The membrane system uses the entire volume of a ship's hull and is cheaper to build. These vessels have better visibility from the bridge windows than the spherical design and will not be as affected by wind.

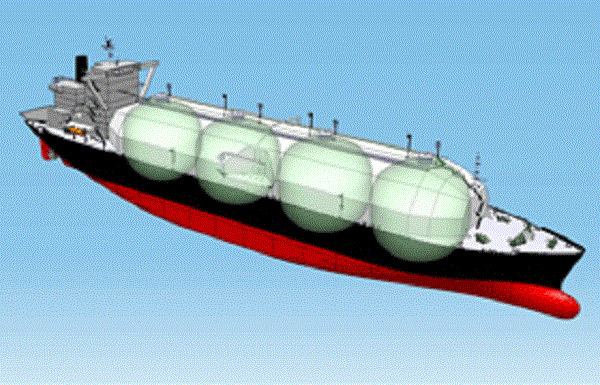

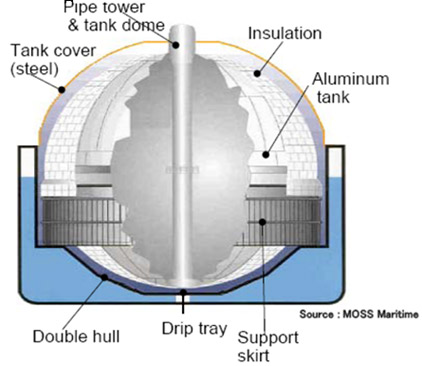

Independent, self-supporting tanks, such as the Kvaerner-Moss system, use free-standing, insulated spherical tanks supported at the equator by a continuous cylindrical skirt. The tank and the hull of the vessel are two separate structures. They are not affected by possible damage to vessel's hull. The Kvaerner-Moss design is generally found on smaller LNGCs.

Pieridae submitted data for four sizes of vessel that may call at GoldboroFootnote 17:

| Vessel Capacity | 125,000 m3 | 177,000 m3 | 216,000 m3 | 266,000 m3 |

|---|---|---|---|---|

| Containment | Spherical | Spherical/ Membrane | Membrane | Membrane |

| LOA (m) | 285.3 | 300 | 315 | 345 |

| LBP (m) | 273.4 | 286.5 | 302 | 332 |

| Beam (m) | 43.7 | 52 | 50 | 53.8 |

| Moulded Depth (m) | 25 | 28 | 27 | 27 |

| Loaded Draft (m) | 11.5 | 11.7 | 12 | 12 |

| Ballast Draft (m) | 10 | 9.5 | 9.4 | 9.6 |

| Loaded Displacement (mt) | 102,804 | 128,533 | 146,054 | 178,564 |

| Ballast Displacement (mt) | 82,500 | 98,887 | 111,900 | 141,990 |

| Loaded Longitudinal Wind Area (m2) | 6,450 | 9,918 | 7,130 | 8,759 |

| Loaded Transverse Wind Area (m2) | 783 | 1,943 | 1,510 | 1,612 |

| Ballast Longitudinal Wind Area (m2) | 6,865 | 10,478 | 8,000 | 9,552 |

| Ballast Transverse Wind Area (m2) | 850 | 2,055 | 1,650 | 1,741 |

Recommendation 2. The TRC recommends that Pieridae identify all specific Canadian requirements that are not currently part of International Conventions, Codes or standards. Pieridae should emphasize these requirements within the Port Information Bookfor vessels calling at the Goldboro LNG terminal.

3.1.2 Tanker vetting procedures

All foreign tankers calling at a Canadian port are subject to inspections. TC inspects tankers during their first call to a Canadian port, and at least once each year afterwards.

Inspectors make sure they follow Canadian requirements and relevant international conventions. Canada considers LNGCs as tankers for inspection purposes.

Classification societies (like Lloyd's Register, American Bureau of Shipping, DNV-GL, etc.) have the expertise to inspect, verify and certify that vessels are built, maintained and operated according to recognized rules, regulations and standards.

The Port State Control program is an international regime that allows foreign vessels to be boarded and inspected to make sure that major international maritime conventions are respectedFootnote 18. TC uses the program to enforce the CSA, 2001, the Marine Transportation and Security Act and other international conventions.

The Oil Companies International Marine Forum (OCIMF) provides guidance for a tanker inspection program's content and application under the Ship Inspection Report (SIRE), a voluntary inspection process. Member companies ask for vessel inspections by an accredited SIRE inspector. There is a cascading division of responsibility in SIRE for ensuring compliance with the applicable regulations. The shipper vets the ship owner before nominations. The marine terminal operator will then vet the nominated tankers to make sure they are compatible with the terminal layout, facilities and equipment. Industry members' adherence to the SIRE programme promotes continuous improvement.

OCIMF's Tanker Management Self-Assessment (TMSA) encourages companies to measure their safety management systems against key performance indicators and provides a minimum expectation (level 1) plus three increasing levels of best practice guidance. Self-assessment results can be used to develop improvement plans to support continuous improvement of their vessel management systems. Companies are encouraged to regularly compare their self-assessment results against the TMSA key performance indicators and create plans for improvement. Making sure that their policies and procedures align with industry best practices helps companies improve their performance and reach high standards of safety and pollution prevention.

Since the TMSA is generally accepted by the tanker sector, many Protection and Indemnity Associations (P&I Clubs) and terminals have begun to request the TMSA from other types of vessels. The self-assessment covers the followingFootnote 19:

- Leadership and the Safety Management System

- Recruitment and Management of Shore-Based Personnel

- Recruitment Management and Wellbeing of Vessel Personnel

- Vessel Reliability and Maintenance including Critical Equipment

- Navigational Safety

- Cargo, Ballast, Tank Cleaning, Bunkering, Mooring and Anchoring Operations

- Management of Change

- Incident Reporting, Investigation and Analysis

- Safety Management

- Environmental and Energy Management

- Emergency Preparedness and Contingency Planning

- Measurement, Analysis and Improvement

- Maritime Security

The Chemical Distribution Institute—Marine (CDI-M) provides annual inspection reports on the world's fleet of chemical and liquid petroleum gas tankers. In 2018, over 600 ship owners and 5400Footnote 20 chemical and gas carriers participated in this effort. There are over 70 CDI-M accredited inspectors that conduct inspections in ports around the world. Vessels that have a CDI-M report on the active database are listed in the European Quality Ship Information System (EQUASIS). Port State Control members participating in EQUASIS have access to the database that lets them get information from ship inspection reports.

Pieridae has stated that it will establish a vetting and approval process that evaluates an LNG carrier's ability to call and load at the Goldboro LNG terminal safely and efficiently.Footnote 21 This procedure is divided into two different activities:

- "Compatibility with the Terminal" - checks of the physical aspects of the LNGC against the terminal's requirements.

- "Quality Assurance of the LNGC and LNGC Operator" - assesses the ability of the LNGC to comply with safety and environmental standards.Footnote 21

The vetting procedure would also cover:

- Safety and security at the berth.

- LNG carrier verification prior to berth.

- Details of the cargo and carrier during loading.

- Crew qualifications.

- Terminal safety and operational procedures.

The Society of International Gas Tanker and Terminal Operators (SIGTTO) has developed a Ship-Shore Compatibility Questionnaire to make sure that tankers are appropriately configured for the terminal.Footnote 22 Pieridae has stated that all vessels calling at Goldboro will meet all relevant International and Canadian vetting requirements and will have a valid Ship Inspection Report programme (SIRE) certificate.Footnote 23

Finding 2. Tanker vetting, the Ship Inspection Report Programme and Chemical Distribution Institute-Marine processes are generally accepted tools that terminals and LNG companies use to check compliance and improve safety.

Recommendation 3. The TRC recommends that Pieridae introduce and apply vetting standards, ensure all vessels calling at its terminal have an up-to-date Ship Inspection Report Programme certificate (SIRE) and meet the terminal's compatibility criteria. Pieridae should incorporate its vetting standards within the Port Information Book.

Recommendation 4. The TRC recommends that Pieridae requires all vessels calling at their marine terminal to follow the Tanker Management Self-Assessment program from the Oil Companies International Marine Forum (OCIMF).

Recommendation 5. The TRC recommends that Pieridae use the Ship-Shore Compatibility Questionnaire as published by the Society of International Gas Tanker and Terminal Operators (SIGTTO) at the pre-fixing stage to see if a vessel can be safely berthed at the terminal.

3.1.3 Ballast water management

The Goldboro LNG project will involve LNGCs up to 266,000 m3, which will likely carry sea water as ballast. Every foreign vessel must follow Canada's Ballast Water Control and Management Regulations as well as the International Convention for the Control and Management of Ships' Ballast Water and Sediments.Footnote 24

Vessels that take on ballast water outside Canada must have a ballast water management plan in place. They cannot release foreign ballast water into Canadian waters unless it has been managed by:

- Exchanging it at sea.

- Treating it onboard.

- Pumping it ashore for treatment; or

- Retention on board.

Canadian regulations go beyond the International Convention by asking that ballast be exchanged at least 200 nm from shore and in water that is at least 2000 metres deep. IMO convention on ballast requires the exchange of ballast water at least 200 nm from shore but only 200 metres depth.

A vessel must send a "Ballast Water Reporting Form" to TC as soon as the ballast water management is completed and before entering waters under Canadian jurisdiction. Vessels can be inspected by TC MSS to make sure they are following the Ballast Water Control and Management Regulations, as amended from time to time.

3.1.4 Vessel and crewing standards

All LNGCs must meet theStandards of Training, Certification and Watch Keeping Convention (STCW), Classification Society and Flag State surveys, and follow all international and Canadian laws.

The STCW Convention sets the minimum international qualification standards for any person working on board a vessel. It includes certification and training requirements for all jobs aboard a vessel, including:

- Hours of rest for seafarers

- Certificates of Competency for able seafarers, for both deck and engine departments

- Training and refreshing requirements

- Required security training

- Additional medical standards

- Specific blood or breath alcohol limits

The Marine Personnel Regulations (MPR) are regulations made under the Canada Shipping Act, 2001. Part 2 of MPR applies to Canadian vessels and foreign vessels in Canadian waters. It requires:

- Senior officers (master, chief mate, chief engineer or second engineer) on board an LNGC to have a Specialized Liquefied Gas Tanker Training certificate/endorsement.

- Any crew member with specific duties in liquefied gas transfer operations to have a Liquefied Gas Tanker Familiarization certificate/endorsement.

Pieridae needs to make sure carriers meet all required elements of the MPR under the CSA, 2001, including any future updates.

The SOLAS requires that all "vessels shall be sufficiently and efficiently manned."Footnote 25 When the minimum safe manning of a vessel is determined, several principles are applied to make sure the safety is not compromised at any time.

The SIGTTO has published two documents about crew qualifications:

- SIGTTO LNG and LPG Experience Matrix Guidelines for UseFootnote 26, to help with the safety management of crews on board LNG and LPG vessels

- LNG Shipping Competency Standards

The proponent will need to ensure that crews of the LNGCs that call at the proposed Goldboro terminal are experienced and trained for the specific cargo and vessel they operate.Footnote 27 As such, all applicable shipboard personnel should have the training required to meet the SIGTTOLNG Shipping Competency Standardsand theSIGTTO LNG and LPG Experience Matrix Guidelines for Use.

Finding 3. Pieridae did not include any Marine Personnel Regulations requirements for crews training and qualification in its submission.

Recommendation 6. The TRC recommends that all shipboard personnel be trained to meet SIGTTO's LNG Shipping Competency Standardsand the SIGTTO LNG and LPG Experience Matrix Guidelines for Use.

3.2 Route information

3.2.1 Overall route

The proposed Goldboro LNG terminal would be located on the eastern shore of Nova Scotia at the entrance of Country Harbour and Isaacs Harbour. It is only accessible from deep sea so no alternative routes were considered. Most LNG carriers calling at the proposed facility would arrive from Europe (Belgium, Spain and France are key markets.Footnote 28) Maritime access to the proposed terminal is safe and unrestricted for all the design vessels, with the approach and departure routes generally 20m or deeper. You can find additional information in Appendix 4.

The scoping area of the proposed facility extends from Dover, NS (61° west longitude) to Sherbrooke, NS (62 ° west longitude) for a total of 76 km (47 nm) along the coast, and out to the boundary of the Canadian Territorial Sea (to a distance of 12 nautical miles).

In April 2016, Pieridae submitted a studyFootnote 6 prepared by Amec Foster Wheeler, as a part of its submission. The study was not updated but relevant sections were added to an Annex in module 3.3 Route Analysis, Approach Characteristics and Navigability Survey, submitted to the TRC on July 26, 2018.

Pieridae also submitted a Manoeuvring Simulations Report in module 3.10 — Channel and Manoeuvring and Anchorage Elementsand Goldboro LNG — Navigation Simulation Studyconducted by HR Wallingford Ltd.

In the immediate area of the proposed terminal, there are two sub-sea natural gas pipelines that are no longer in operation:

- The Sable Offshore pipeline, owned by ExxonMobil

- The Deep Panuke Offshore pipeline, owned by Encana Corporation

ExxonMobil, the main operator of the Sable Offshore Energy Project, stopped shipping natural gas ashore on December 31, 2018Footnote 29. Encana Corporation stopped shipping gas ashore on May 7, 2018, for their activities at Deep Panuke. These pipelines should be fully decommissioned by 2021Footnote 30 and will reduce the risk associated with the passage and berthing of the LNGCs.

Pieridae's studies do not take the decommissioning of the sub-sea pipelines into account. The end of operations for Sable Offshore and Deep Panuke will have an effect on the proposed mitigations that vessels would have to take while navigating in the area. Pieridae will need to re-evaluate the risks associated with the navigation in the area and the risk mitigation measure as well. For example, Pieridae has proposed that all LNG vessels should have the anchor up and secured, once the pilot is on board and one tug has been made fast. This measure might not be necessary if the pipelines are not in use.

Finding 4. The two existing offshore pipelines that moved natural gas to the former Goldboro Gas Plant will likely remain. Both Encana Corporation and ExxonMobil have submitted applications to the Canada Energy RegulatorFootnote 31 to abandon the pipelines and have started decommissioning them. Both companies have explained that the pipelines would be pigged and flushed, filled with seawater, and left inert on the seafloor.

Recommendation 7. The TRC recommends that Pieridae evaluate the proposed risk mitigation measures related to the abandoned Encana and ExxonMobil sub-sea gas pipelines located near the terminal; in particular, the risks associated with a LNG carrier dropping anchor over the sub-sea pipelines and make the related updates to its Port Information Book and Terminal Operational Manual.

3.2.2 Navigation and safety

3.2.2.1 General

Like all vessels entering Canadian waters, LNGCs bound for the proposed Goldboro LNG terminal must meet all navigation safety requirements found in the Canada Shipping Act, 2001, andthe Canada Marine Act and their regulations. They must comply with the regulations for the entire time they are in waters under Canadian jurisdiction.

These regulations require the Master of the vessel to:

- Have the proper navigational charts, nautical publications, and navigation and communications equipment on board.

- Develop a passage plan that takes into account the available water depth over the entire transit to make sure there is enough under keel clearance at all times.

- Before arriving at the pilot boarding station and departing from the berth, check that the vessel's navigation, control and propulsion systems are fully functional, by: Footnote 32

- Running engine(s) astern

- Checking the steering (testing the full arc of swing of the rudder[s]); and

- Testing:

- Communication systems

- RADARs

- Other electronic navigation equipment

- Other wheelhouse equipment

- Anchor

- Mooring equipment

- Emergency towing system available for escort tug operations

LNGCs would approach the terminal from deep sea without much interaction with other vessels except for manoeuvring to follow the Convention on the International Regulations for Preventing Collisions at Sea (COLREGs) until it reaches the anchorage or pilot station (if the harbour is to be deemed a mandatory pilotage area).

3.2.2.2 Vessel Traffic Services

All Goldboro LNGCs will need to report to CCG's Marine Communications and Traffic Services (MCTS):

- When 96 hours away from Canadian Waters, as set out in Marine Transportation Security Regulations (SOR/2004-144)Footnote 33 provisions. Among other security enquiries, the vessel must declare any deficiencies in its security equipment and systems, including its communications systems.

- When 24 hours away from Canadian Waters, as set out in Eastern Canada Vessel Traffic Services Zone Regulations (SOR/89-99)Footnote 34 provisions. Vessels must declare, in addition to details about statutory certification and liability coverage, any defects in the ship's hull, main propulsion or steering systems, RADARs, compasses, radio equipment, anchors or cables.

MCTS centres also monitor shipping within Vessel Traffic Services (VTS) zones under the Vessel Traffic Services Zones Regulations. Every ship of 20 metres or more in length and every ship engaged in towing or pushingany vessel must report to an MCTS officer. The vessel must comply with the reporting requirements set out in the regulations. The exchange of information between vessels and a shore-based centre helps promote safe and efficient navigation and increases environmental protection.

Currently, there is no vessel traffic routing system in the Goldboro LNG project scoping area (such as a traffic separation scheme), nor is there any VTS monitoring (including RADAR coverage and VHF working frequency radio coverage), as the traffic density does not require such measures.

The HR Wallingford General Risk Analysis produced several intended measures and procedures to reduce any risks to an acceptable level. Vessel traffic management was one of the measures suggested in the study. This is discussed further in Section 3.4.2.

3.2.2.3 Aids to navigation

Aids to navigation are devices or systems, external to a vessel, that:

- Help mariners determine the vessel's position and course.

- Warn of dangers or obstacles.

- Indicate the best or preferred route.

The Canadian aids to navigation systemFootnote 35 is made up of visual, aural and electronic aids to navigation. Visual aids include buoys, day beacons, day marks and lights. Aural aids are sound producing devices that warn mariners of danger in low visibility conditions. These include fog signals on shore and buoy mounted bells and whistles that are activated by wave action. Most aural aids operate when visibility is reduced to less than two nautical miles. Electronic aids include radar reflectors, radar beacons, the Differential Global Positioning System, "virtual" aids to navigation and the Automatic Identification System (AIS).

The CCG is mandated, though not required, to provide aids to navigation in Canadian waters, with the exception of waterways served by Parks Canada.

The existing aids to navigation system in Country Harbour and Isaacs Harbour meet the needs of current marine traffic. Aids are not provided for the benefit of a single user or to mark access to a private facility. As this is considered a single user, any costs related to additional aids would be at the expense of Pieridae.

Finding. The TRC notes that the harbour is well marked with buoys and meets the needs of the current marine traffic. Any proposed changes, or additions, to the aids to navigation system requires input from the CCG, Aids to Navigation Program, to make sure that the level of service is maintained for existing users in the area.

3.2.2.4 Pilotage

Around the world, many maritime countries use specialized marine pilots to navigate ships through their waterways. Licensed pilots conduct vessels to make sure that ships are navigated and berthed safely in challenging areas. They are familiar with the coastlines, inland waters, shoals, harbours, ports, weather, tides, shipping regulations and restrictions of the pilotage area in which they are licensed. Pilots are also familiar with the different propulsion systems, hull design, and rudder characteristics of different vessels and how they react at various speeds and weather conditions.

The four Pilotage Authorities in Canada responsible for setting requirements for, and providing marine pilotage services in, all geographic areas of the country are the Atlantic Pilotage Authority (APA), the Great Lakes Pilotage Authority, the Laurentian Pilotage Authority, and the Pacific Pilotage Authority. They regulate the requirements for compulsory pilotage within which certain classes of vessels, including oil tankers, must take a marine pilot with local knowledge on board before entering a harbour or busy waterway.

The APA continues to monitor and assess all areas within its mandate to determine any change in factors and circumstances that may have an impact on safety. If such a change is determined to warrant closer review, the Authority will employ an outside facilitator to conduct a Pilotage Risk Management Methodology (PRMM).

Pieridae explained that vessels would approach the terminal location under the conduct of a pilot by passing the fairway buoy "TT" on the vessel's port side. The vessel would keep its heading until the vessel begins its turn to approach the jetty, with help from tugs. During the manoeuvring simulations, pilots suggested a set of range light/leading lights be placed for the transit of the narrows at approaches to the proposed terminal location (Refer to the Section 3.2.3.3 and Appendix 5 for more details.)

The proposed Goldboro LNG terminal is not situated in a compulsory pilotage area. Pieridae has recommended that Goldboro be included as a mandatory pilotage area. This is discussed further in section 3.4.2.5.

Finding 6. The proposed Goldboro LNG terminal is not located in a compulsory pilotage area.

Recommendation 8. The TRC recommends that Pieridae request a Pilotage Risk Management Methodology review prior or during construction of the terminal.

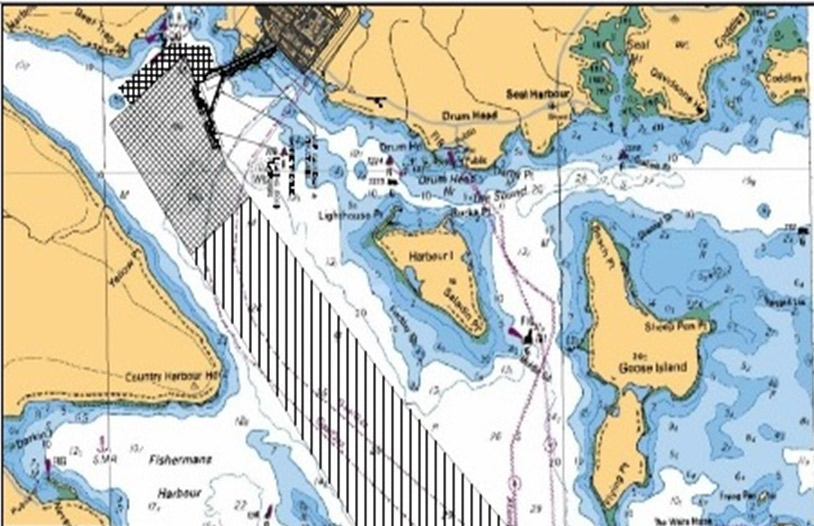

3.2.2.6 Nautical charts

Vessels calling at the proposed Goldboro terminal would use CHS charts 4234, 4321 and 4227 or equivalent chart recognized by the International Hydrographic Organization (IHO). CHS is the federal government agency in charge of marine charting. CHS is responsible for producing and maintaining charts and other products that support safe navigation in Canadian waters.Footnote 36 The Goldboro LNG Navigation Simulation Study recommended that charts should be updated so that Country Harbour is centered, instead of its current location at the edge of the chart. CHS stated that they need to chart any proposed anchorages, berths, exclusion zones and any changes/additions to aids to navigation related to the proposed facility. Given the nature and scope of the project, the chart revision could take up to four years. CHS would have to reassess the existing chart schemes. A new large-scale "docking" inset may be needed to support navigation at the LNG terminal. Electronic charts and nautical publications would also have to be updated to support navigation at the terminal, once the terminal design, lighting, exclusion zones and aids to navigation are finalized.

If the Goldboro LNG project is confirmed, Pieridae must officially notify CHS. All proposed and as-built plans should be forwarded to the CHS at Pieridae's earliest opportunity. Notifications and proposed plans can be sent to:

CHS Atlantic

Attention:

Hydrographic Data Centre

1 Challenger Drive

Dartmouth NS B2Y 4A2

Finding 7. CHS would be impacted by a large new marine terminal.

Finding 8. The TRC recognizes that the present charts of the area are inadequate for the safe navigation of the predicted increase and type of vessel traffic.

Recommendation 9. The TRC recommends that Pieridae consult with CHS to prepare and submit the charting survey data at the earlier stage possible as the process for charting could take 3 to 4 years.

3.2.2.7 Environmental conditions

The Chicago Bridge & Iron Company (CB&I) commissioned a metocean studyFootnote 37 , on behalf of Pieridae Energy for the Goldboro project in 2015, to document the average and extreme local weather and sea conditions that could be expected at the proposed terminal location. The study area extends up to 20 km from the proposed terminal location in all directions. Pieridae has included the 2015 study results in their 2018 submission.

Waves, tides and currents

The area's highest tide can reach 2.2 metres and the lowest tide 0.2 metresFootnote 38. Table 3.2.2.7-1 is a sample from the tide table for Isaacs Harbour, showing the highest high and lowest low tides for 2019.

| Day | Time | Height (m) |

|---|---|---|

| January 22, 2019 | 9:12 PM | 2.2 |

| January 23 2019 | 9:51 PM | 2.2 |

| March 21, 2019 | 8:33 PM | 2.2 |

| March 22, 2019 | 9:07 PM | 2.2 |

| August 3, 2019 | 9:28 AM | 2.2 |

| August 4, 2019 | 10:06 AM | 2.2 |

| August 31, 2019 | 8:32 AM | 2.2 |

| September 1, 2019 | 3:05 AM | 0.2 |

| September 1, 2019 | 9:08 AM | 2.2 |

| September 2, 2019 | 9:43 AM | 2.2 |

| September 29, 2019 | 8:09 AM | 2.2 |

| September 30, 2019 | 8:44 AM | 2.2 |

The average sea level in the area rises at a rate of about 3.15 mm/year, roughly 0.315 m in 100 years. CB&I determined that the worst case scenario, for a 100 year return period would be +3.3 m above chart datum (+2.2 m of astronomical high tide, +0.3 sea level rise and +0.8 m of storm surge event).

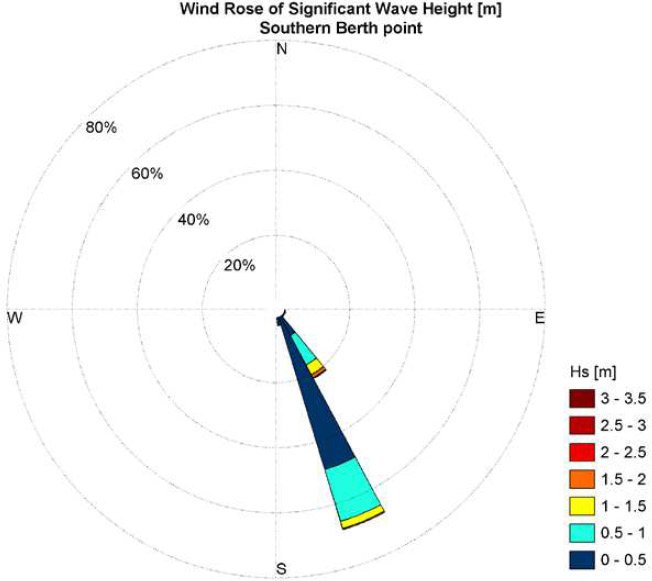

Wave heights outside the entrance to Country Harbour, by Goose Island, average 1.35 m from the south and can be as high as 8.24 m (5 cases reported in 61 years)Footnote 37. Wave conditions near the proposed Goldboro LNG terminal are smaller and shorter due to the sheltering effect of the land surrounding the berth. The southern berth is more affected than the northern berth; although, in general the wave height is less than 1 metre, with rare cases above 1 m and a maximum of 3 m (0.03%). In summer, waves are smaller and from the south-southwest; in the colder months waves are bigger and from the south.

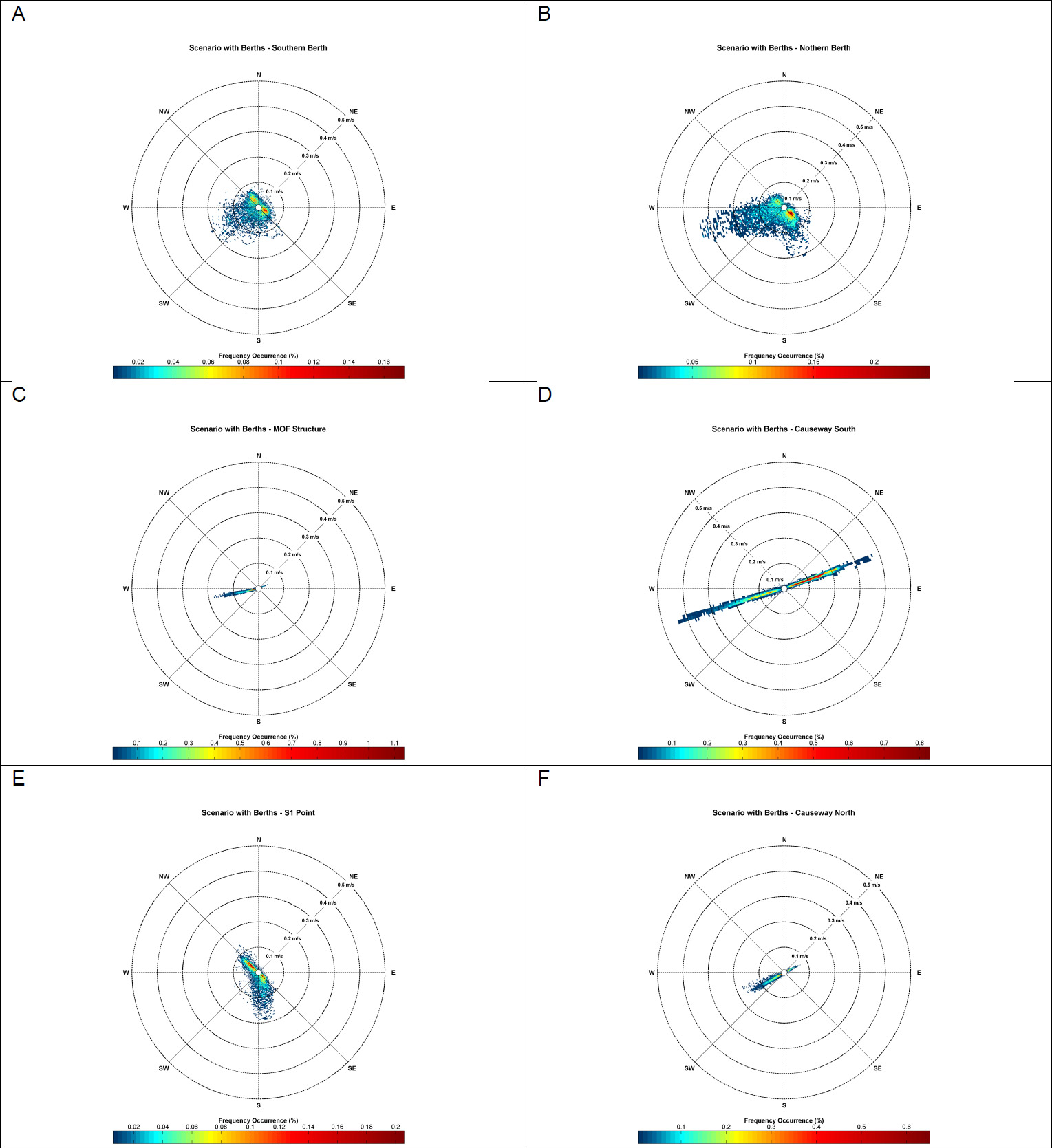

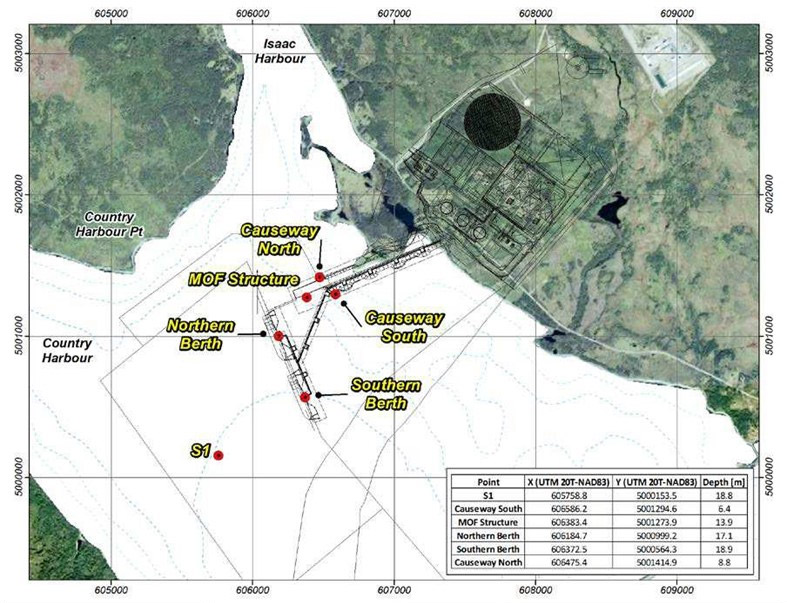

The study also detailed the currents expected at the terminal location. Through modelling post-construction, Pieridae has calculated the maximum current expected at the Causeway South to be 0.44 m/sFootnote 37, which is highest current velocity predicted at the proposed terminal location. Figure 3.2.2.7-3 shows the directional frequency of the currents at six points:

- Southern berth, maximum expected current 0.21 m/s (0.4 Kts)

- Northern berth, maximum expected current 0.34 m/s (0.66 Kts)

- Material Offloading Facility (MOF) Structure, maximum expected current 0.18 m/s (0.35 Kts)

- Causeway south, maximum expected current 0.44 m/s (0.86 Kts)

- Point "S1", maximum expected current 0.19 m/s (0.37 Kts)

- Causeway north, maximum expected current 0.17 m/s (0.33 Kts)

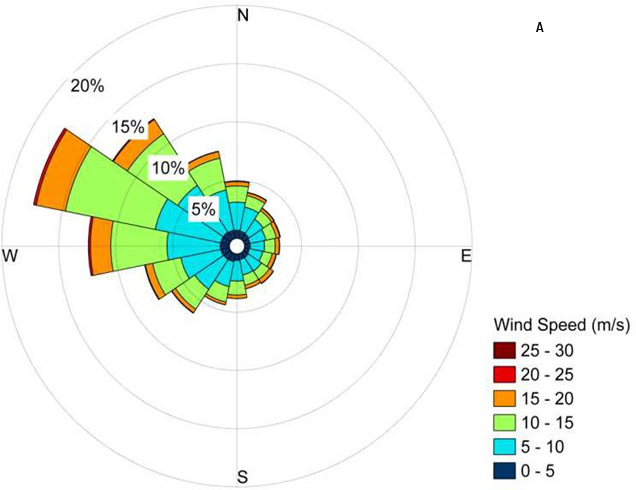

Winds and storm events

The prevailing winds in the area are westerly — southwesterly in the warmer months and northwesterly in cold months. At the project site, the direction of wind varies from southwest and west-southwest. The maximum wind velocity in the 61 years covered by the study was 26 m/s (93.6 km/h), which occurred in spring.

According to records for seasonal wind conditions, the strongest average wind speeds occur in winter. The average speed is 9.71 m/s (35 km/h) compared to 5.13 m/s (18.5 km/h) in summer. In general, storms with winds over 12.86 m/s (46 km/h) are more frequent during winter and can last up to 5 days.

Fog

The project site lies in an area that is often affected by fog. Fog is more common during the warmer months and will reduce visibility which can cause delays to the terminal's shipping activities. According to Environment and Climatic Change Canada, close to half of mornings in June and July have reduced visibility due to fog in the area. This figure drops drastically in the winter with an average of 16% foggy days.

Finding 9. The TRC believes that installing a smart buoy [Ocean Data Acquisition System (ODAS) / weather buoy)] near the proposed pilot station would provide a real-time analysis of metocean conditions.

Recommendation 10. Pieridae should decide on funding sources for the smart buoy [Ocean Data Acquisition System (ODAS buoy/weather buoy)], in consultation with Environment and Climate Change Canada.

Recommendation 11. Pieridae should confirm the metocean limiting conditions, including factors affecting visibility that would affect operations and include them in the Port Information Book and Terminal Operations Manual.

3.2.2.8 Winter Conditions

Freezing spray

Freezing spray is an environmental risk during the cold winter months when temperatures can drop to -10°C and wind-chill values can drop below -25°CFootnote 39. Freezing spray can create ice build-up on marine infrastructure such as the vessel's hull, decks, guy wires, cables, anchors, deck equipment, etc. that may affect the vessel's stability or deck operations. A freezing spray warning is issued when ice build-up from freezing spray is expected to reach moderate levels, between 0.7 and 2 centimetres per hour (cm/h), or severe levels of more than 2 cm/h.Footnote 40

Sea ice

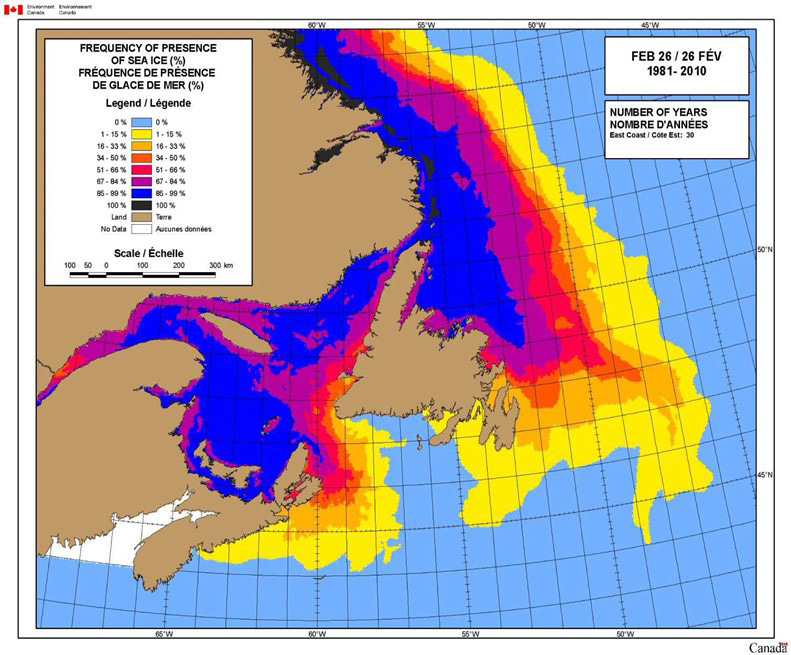

According to the Canadian Ice Service, sea ice in the area is highest from January to March. The highest likelihood of sea ice in the area is 15% for March, with a maximum likely thickness of 30 cm. The odds decrease to 10% for January and February. When sea ice is present, the coverage would be 50% or less. Figure 3.2.2.8-1 shows the frequency (%) of sea ice over 30 years.

In the past, there have been extreme ice events that fall outside the expected conditions. In February 2003 sea ice up to 120 cm was seen in the area. In April 1987 pack ice was carried by currents along the coast of Nova Scotia, then strong southerly winds sent the 2 - 2.5 meter thick ice into the coastal ports. This impacted commercial shipping significantly.

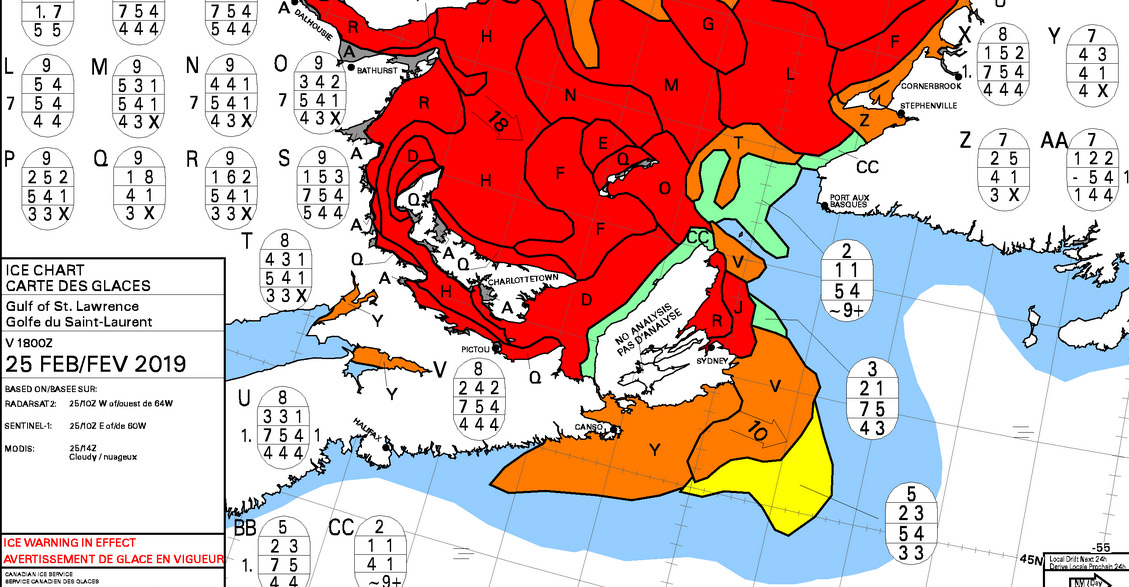

During the winter of 2019, ice concentration in the area was heavier than average. On February 25th, the total ice concentration was 7/10 in area "Y", with 4/10 covered with grey ice (10 cm to 15 cm thick) in medium-sized floes (100 to 500 metres wide) and 3/10 of new ice (under 10 cm thick). Figure 3.2.2.8-2 shows an excerpt of the ice chart with its ice egg codes.

Description

Excerpt of the Ice Chart for the Gulf of St. Laurence (Goldboro is located in the 'Y' orange area)

(Goldboro is located in the "Y" orange area)

Risk of ice damage exists on the east coast of Canada during winter and spring. As this can affect the safety of marine personnel, the marine environment and vessels sailing in ice-covered waters, TC developed the Joint Industry-Government Guidelines for the Control of Oil Tankers and Bulk Chemical Carriers in Ice Control Zones of Eastern Canada, TP 15163, in November 1979Footnote 41.

These guidelines do not apply to LNG carriers, only to laden oil tankers and bulk chemical carriers. However, the TRC recommends that LNGCs calling at the proposed terminal follow the guidelines, to lower the risk of ice damage.

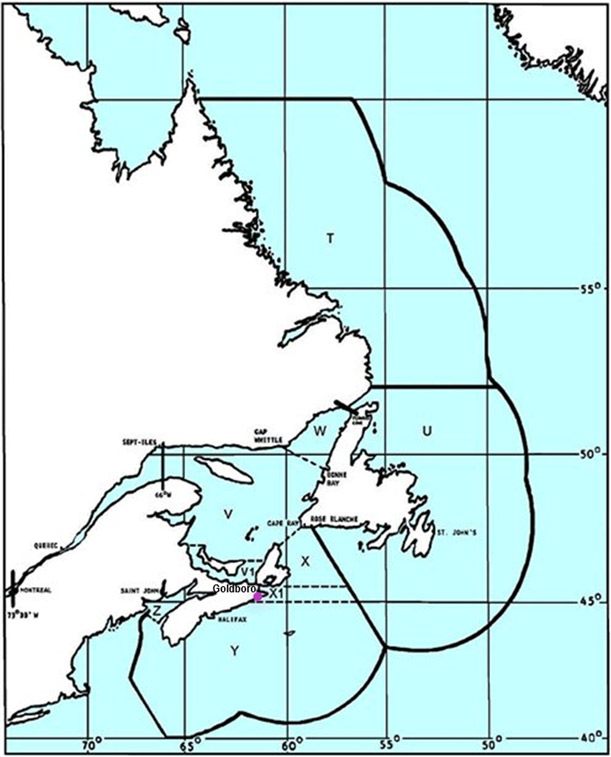

Eastern Canadian waters south of Latitude 60º N are divided into Ice Control Zones. The Canadian Coast Guard Ice Operations Centre declares an Ice Control Zone "active" when it finds that ice conditions in a zone are dangerous to shipping.

In 2012, the guidelines were changed to include Ice Control Zone "X1" for Chedabucto Bay and the Strait of Canso. Zone "X1" is defined as all waters in Zone X between Latitude 45 30'N and 45°00'N, running eastwards from the shoreline. Country Harbour, Isaacs Harbour and Goldboro are located in Ice Control Zone "X1".

Ice Control Zone "X1" was active from February 25 to March 27, 2019 so all oil tankers and chemical carriers had to carry an "Ice Advisor" on board when travelling through the zone.

The TRC noted that Pieridae does not agree that LNGCs visiting the Goldboro Terminal should be required to follow the guidelines.

"We note that these guidelines are applicable to oil tankers and bulk chemical carriers. It is our view that an LNG carrier is not, as declared by the IBC Code, a chemical carrier nor is it an oil tanker, therefore the JIGs do not apply. However, Pieridae agrees that it would be prudent to include provisions in the Port Information Booklet advising the procedures to be followed in the event that ice is reported in the area that a LNG carrier is due to traverse. We intend to develop these procedures in the next phase of the project development and we would welcome TC's involvement during this process."Footnote 42

Finding 10. The TRC believes that LNG carriers would be safer if they have an "Ice Advisor" on board when travelling in ice covered waters.

Recommendation 12. The TRC recommends that Pieridae require all LNG carriers that call at the proposed terminal to follow the Joint Industry-Government Guidelines for the Control of Oil Tankers and Bulk Chemical Carriers in Ice Control Zones of EasternCanada in an active ice control zone as if the vessels were laden oil tankers.

3.2.3 Navigability and vessel operations

3.2.3.1 Transit Time and Delay Survey

In the December 2015 submission, Pieridae presented the LNG Berth Utilisation and Down Time Analysis. The study used a mathematical model to:

- Examine the potential down time for marine operations (vessel arrival, loading and departure) due to local weather (visibility, wind, waves and sea ice).

- Estimate the yearly down time for marine operations.

The TRC noted the following limiting conditions were included in the mathematical model, which used base data from metocean and other studiesFootnote 43:

- Vessel inbound transit and berthing:

- Off shore waves < 3.0m

- Waves at berth < 2.0m

- Wind speed < 25kts

- Visibility > 1.0nm

- Sea ice <25%, thickness <15cm

- Vessel un-berthing and outbound transit:

- Off shore waves < 3,0m

- Waves at berth < 2,0m

- Wind speed < 30kts

- Visibility > 1,0nm

- Sea ice <25%, thickness <15cm

- Cargo transfer – stop loading:

- Waves at berth >2,0m

- Wind speed >30kts

- Cargo transfer – disconnect marine loading arm:

- Waves at berth >2,0m

- Wind speed >35kts

The following table shows results from the LNG Berth Utilisation and Down Time Analysis. Large vessels would use the berths less often than smaller vessels so the number of transits would be lower. Large vessels can load more LNG per call and would be more efficient.

The smaller vessels spend more time at each berth as the time spent includes non-LNG product loading operations such as government clearances, safety checks, tank gauging, etc.

| Annual Utilization | Design Vessel | ||

|---|---|---|---|

| Small vessel (120,000 m³) | Medium vessel (175,000 m³) | Large vessel (266,000 m³) | |

| Minimum number of vessels per year | 190 | 128 | 84 |

| Maximum number of vessels per year | 206 | 137 | 91 |

| Annual use (% of year) | 63% | 50% | 42% |

3.2.3.2 Navigation Simulation Study

Pieridae's submission included a report on vessel manoeuvring simulations provided by HR Wallingford Ltd. The Goldboro LNG Navigation Simulation StudyFootnote 44, performed during November 19–24, 2018 looked at:

- The safety aspects of LNGCs (up to 266,000 m3 in capacity) navigating to and from the proposed terminal and vessel berth.

- The safety aspects when using 4 azimuth stern drive (ASD) tugs with 70 tons bollard pull capacity, using industry standard tethered escort techniques.

In particular, the study aimed to:

- Confirm the Goldboro LNG terminal design and configuration for the proposed LNGCs.

- Make sure there are enough tug with tractor abilities/bollard pulls to perform escort and berthing operations.

- Confirm the upper environmental limits (wind speed/direction, tidal current conditions and restricted visibility) for transit and berthing/un-berthing operations.

- Identify tug reserve power requirements during LNGC accidents and or tug failures.

- Evaluate the adequacy of existing navigation aids and propose new aids or the relocation of existing aids.

HR Wallingford created a geographic model of the terminal and surrounding area, using the layout which was developed during the Front End Engineering Design Phase (FEED) studies completed in 2015.Footnote 45 The FEED studies were also used for other base data like wind, current, wave, etc.

The simulation team was made up of representatives from Pieridae, two marine pilots from the APA, two representatives from TC MSS and HR Wallingford representatives (including one marine pilot and one tug master).

Accident scenarios are critical in choosing the best tug configuration for Goldboro terminal section and were included in the simulations runs. Some of the emergencies that were part of the simulation included:

- Aborted arrival

- Accelerated departure

- Outbound voyage with rudder failure

- Arrival berth with failure of vessel's engine

- Dead ship departure

- Arrival berth with tug failure

During the session, HR Wallingford conducted 41 simulations, including 28 completed standard manoeuvres, covering 13 arrivals and 15 departures. Of the 28 manoeuvres, 21 were successful, 6 were rated as marginal and one was considered a fail. The "fail" was due to the combination of tugs being unable to push the LNGC off the north berth due to significant wave heights (2 meters).

"Marginal" outcomes were for the following scenarios:

- Aborted arrival to the north berth mooring starboard side to

- Accelerated departure from port side on the north berth using one tug

- Accelerated departure from port side on the north berth using 2 tugs

- Accelerated departure from starboard side on the north berth using 2 tugs

Overall, the simulations showed that there was enough space and tug power available to allow the berthing manoeuvre to be stopped with the vessel under control, and for the vessel to move to a temporary anchorage area with tug assistance.Footnote 44

Based on the simulations, the team reached the following conclusions:

- Tests confirmed that access to and from the proposed terminal is safe and unrestricted. There is enough space for vessels to be moved onto and off a berth, without interacting with a moored vessel on the next berth. There is enough, naturally deep space available to allow the ship handler to swing to port or starboard on arrival, for either berth.

- The jetty berthing line is reasonably aligned with the dominant wave direction but tugs operating in push mode at the vessel's hull are fully exposed to waves. As expected, the key constraint on marine operations was found to be the performance of tugs in higher wave conditions, particularly when tugs were operating in push mode.

- The 70 ton bollard pull ASD tugs were found to be effective in push mode up to 1 metre wave height conditions, particularly when combined with tugs working on lines using render recovery winches.

- Tests also showed that, when tugs were operating in appropriate wave conditions and steady wind speeds of 25 knots or less, the wind direction was unimportant.

- No additional floating aids to navigation were needed. Although, tests clearly showed that leading lights (range lights or sector lights) would be helpful so recommendations were made to improve the aids to navigation.

See Appendix 5 for the full list of conclusions and recommendations of the Goldboro LNG Navigation Simulation Study report which were supported by the simulation team.

The TRC considered each recommendation from the Goldboro LNG Navigation Simulation Study and developed findings and recommendations for Goldboro terminal, which are included in section 3.4.2 Intended Methods of Reducing Risks.

Findings 11. The TRC agrees that the overall conclusions, recommendations and supplementary considerations of HR Wallingford's Navigation Simulation Study would improve the safety of marine navigation in the TERMPOL scoping area.

3.2.4 Marine traffic considerations

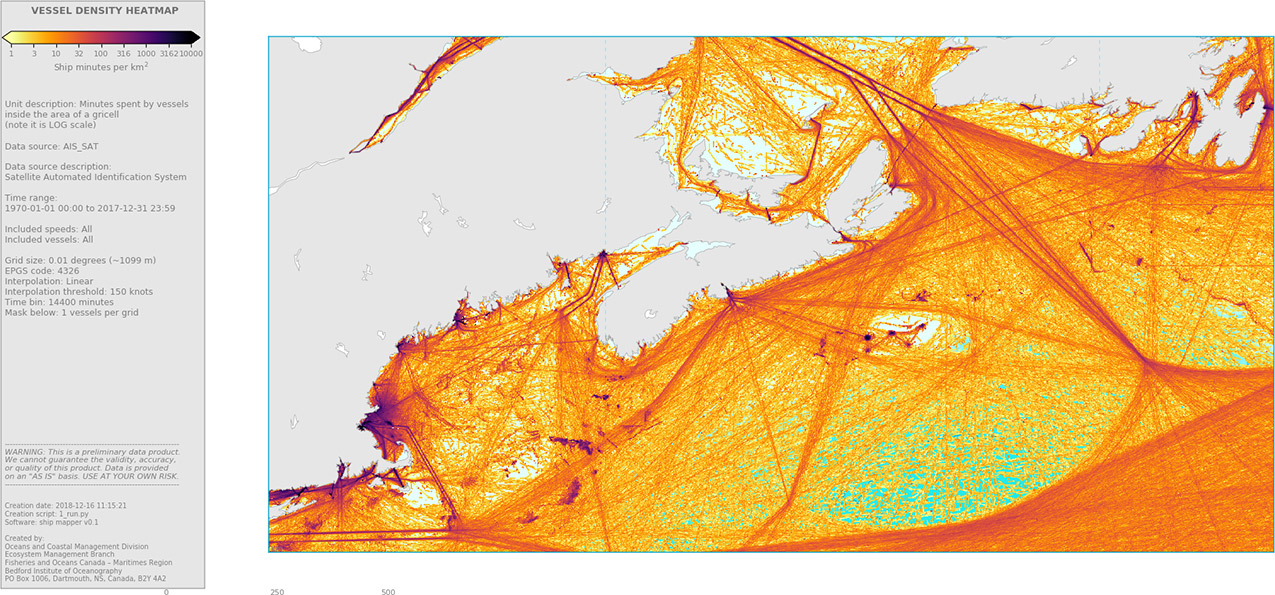

Pieridae submitted their Marine Traffic Survey using data from the Atlantic Pilotage Authority 2017 Annual Report, Statistics Canada, Oceans and Coastal Management (Fisheries & Oceans Canada), the US Department of Defense, National Geospatial Intelligence Agency and the marine traffic website "marinetraffic.com". The traffic study did not include vessels not required to carry AIS.

Traffic from the Goldboro project will develop in two phases — the construction phase and the operational phase. The construction phase will have additional vessel traffic. As of the writing of this document, Pieridae had not yet decided on the terminal's construction method, land-based, sea-based, or both. The TRC expects construction will require tugs, work boats, barges and project cargo vessels, but exact details are not yet available.

The operational phase of the project is expected to see, at maximum, 206 vessel calls (412 vessel movements), assuming that the carriers have a 125,000 m3 capacity. The design vessels for this project are up to 266,000 m3, and as such, would create fewer vessels calls, which would in turn reduce any increase of vessel traffic. The number of vessel movements in the area is directly related to the size of the LNGCs that will call at the terminal. The proposed design vessels are listed in Appendix 3.

The Marine Traffic Survey showed that there is not a lot of vessel traffic in the scoping area of the project. It also noted the absence of ports with any significant marine traffic between Halifax and Port Hawkesbury.Footnote 46

For the offshore "Scotian Shelf" portion of the LNGC transits, the TRC expects that project LNGCs can be easily be absorbed in the existing network. LNGCs are subject to strict vetting processes by charterers so the TRC were not concerned that the project vessels would increase the risk to the network.

Most of the Atlantic coastal traffic is located well offshore to avoid any natural hazards. This would give enough room for any vessels the LNGCs might encounter. While the exact routing has yet to be confirmed, LNGCs will generally avoid busy areas (like Halifax and the Strait of Canso).

The Nova Scotia inshore coast will have more traffic than the offshore part. The inshore data collection is not as robust as the offshore portion, as not all inshore traffic needs to carry Automatic Identification Systems (AIS), and the area is in the range of recreational boaters and fishing vessels.

Recreational traffic is expected to be low as there are no big population centres in the area. There are a few small fishing harbours but none have a large number of vessels. Nevertheless, this portion of the transit will have seasonal changes in traffic density, directly related to the local fishing seasons, mainly lobster and snow crab. This traffic will be a combination of local fishing vessels and fishing vessels from other ports.

Pieridae's proposal did not address the impact of the project on local communities. However, they have an ongoing communication plan, local engagement activities and a working group set up with local fishermen that will continue throughout the LNG plant's operational life.

There are no special operational areas that need to be considered for this project, other than the charted military exercise areas, which extend along much of the Nova Scotia coast. Whenever the Royal Canadian Navy has exercises within those areas, there will be a Navigational Warning (NAVWARN) issued via the eNavigation web portal and broadcast over the MCTS radio network. The TRC recommends that the proponent make sure that all LNGCs calling at the proposed terminal have all relevant Navigational Warnings prior entering Canadian waters.

All vessels must follow Navigation Safety Regulations, pursuant to the Canada Shipping Act, 2001. These regulations govern the carriage of Automatic Identification Systems (AIS).

TC is considering changing AIS carriage requirements to improve vessel monitoring by Canadian authorities and by other nearby vessels through the amendments to the Navigation Safety Regulations, 2020Footnote 47 The TRC recognizes this will also improve the situational awareness for vessels travelling around the project area, given the expected increase in project-related traffic.

Finding 12. The TRC recognizes that not all vessels operating in the area are required to be fitted with AIS.

Finding 13. For the offshore part of the LNG carrier's transit, the additional vessels can be easily absorbed in the existing network. LNGCs are subject to a strict vetting process by charterers so the TRC is not concerned that the project vessels will increase the risk to the network.

Finding 14. Pieridae has an ongoing communication plan and is engaging with local communities, including all water users. There is also a working group with local fishermen which will continue throughout the plant's operational life.

Recommendation 13. The TRC recommends that Pieridae investigate the "non-AIS" vessels that travel in the scoping area and pay close attention to seasonal fishing operations.

Recommendation 14.The TRC recommends that Pieridae expands its study on the impact to coastal communities.

Recommendation 15.The TRC recommends that Pieridae continue its engagement through the working group with the local fishermen.

Recommendation 16.The TRC recommends that Pieridae make sure that vessels calling Goldboro terminal have all relevant Navigational Warnings before they enter Canadian waters. This will make sure there are no conflicts with any Royal Canadian Navy exercises or other activities in the area.

3.3 Terminal Operations

3.3.1 Marine terminal

The marine facilities associated with the Project will include an LNG jetty made up of a single marine trestle spanning from the causeway structure to a t-head with two LNG loading platforms. They will also include a Material Offloading Facility (MOF), which will be used for delivery of construction materials and equipment for the construction of the terminal. Once the construction phase is complete, the MOF will be converted into a support vessel berth, mooring the necessary support vessels for the operation of the terminal.

The cargo loading berths will be able to accommodate vessels ranging in size from 125,000m³ to 266,000m³ capacity, which is the most likely vessels to call at the terminal on a regular basis. Table 3.3.1-1 lists the proposed Terminal Characteristics.

| Description | Value |

|---|---|

| Berth 1 - vessel sizes | 125,000 - 266,000m3 |

| Berth 2 - vessel sizes | 125,000 - 220,000m3 |

| Minimum distance of flange face to side of vessel | 2.8m |

| Maximum distance of flange face to side of vessel | 3.8m |

| Transverse drift perpendicular from berth (away/towards) | +3.0m/-1.8m |

| Total drift parallel to the berth (fore/aft) | +/-3.0m |

| Minimum flange spacing on vessel manifold | 3.0m |

| Maximum flange spacing on vessel manifold | 4.0m |

| Minimum rail height | 1.0m |

| Minimum distance of vessel flange axis to deck | 4.2m |

| Maximum distance of vessel flange axis to deck | 5.6m |

| Manifold | 16-20 1"/ASME CL150/SS |