Chapter 5 - Ground Crew Supplement

Role of Ground Crew

- Your role in "The Clean Aircraft Concept" starts before you get to the apron. If the conditions that promote icing are present, you have to be alert before you get out there. When in doubt, ask the weather office for the most up-to-date forecasts. Find out what kind of temperatures and precipitation aircraft will experience on the apron. If precipitation is forecast, find out what kind.

- Check your manuals for the correct de-icing procedures for the various aircraft you'll be servicing. Some aircraft have specific control surface settings for de-icing. The pilot should know them and you should be familiar with these recommendations as well.

- Ground Crew are an important part of the flight team. The aircraft crew usually meet before a flight and good pilots involve everyone in the watch for contamination. But cabin and cockpit crew can't see all the aircraft surfaces from inside the aircraft. You have to be their eyes and hands.

Trained Personnel

- Only properly trained personnel shall be employed in the aircraft de/anti-icing process in accordance with the Approved Ground Icing Program. Personnel are required to read, understand and follow the precautions listed in the fluid manufacturer's product information bulletin (known as the Material Safety Data Sheet - MSDS), and on the product label, prior to using these materials.

Initial Training

- At a minimum, initial training for ground deicing crews and maintenance personnel must cover the following (additional training may be required for larger and more complex organizations):

- Company policy

- Effects of Contamination

- Weather conditions requiring de/anti-icing

- De/Anti-icing Vehicle and Equipment

- Fluids & Fluid Application methods and techniques

- HOT considerations

- Inspection Procedures

- Safety

Recurrent Training

- At a minimum, recurrent training for ground deicing crews and maintenance personnel must cover the following (additional training may be required for larger and more complex organizations):

- A review of current de-icing and anti-icing operations and inspection procedures;

- A review of any changes to the program;

- A review of the latest available research and development on ground de-icing and anti-icing operations; and

- Issuance of an information circular prior to commencement of winter operations to all involved personnel. The circular must review procedures and present any new information.

- All trained personnel must be tested on all information covered in their respective initial and recurrent training programs.

- An air operator that contracts de-icing/anti-icing services from another organization is responsible for ensuring that the training program of the contractor and application of de-icing/anti-icing operation standards meet the operator's own AGIP criteria. The operator is responsible for documenting the contractor's procedures and training.

Recommended Practices

- The fluids must be used in accordance with the Approved Ground Icing Program. Application should respect the fluid manufacturers instructions and be applied in accordance with the most recent version of the SAE Aerospace Recommended Practice (ARP) 4737.

Record Keeping

- An accurate, detailed record keeping system must be in place to allow easy access to all information pertaining to the deicing/anti-icing operation and fluids management. Care must be taken to ensure that not only is the information is accurate but also that it is recorded in a timely fashion and retained for a minimum of two years.

Fluid Description

- Aircraft deicing/anti-icing fluids consist of four types. They are Type I, II, III, and IV. The various types all have different physical and chemical properties and their use is aircraft specific.

- Deicing fluids are typically ethylene glycol, diethylene glycol or propylene glycol based fluids containing water, corrosion inhibitors, wetting agents and dye. These fluids are formulated to assist in removing ice, snow and frost from the exterior surfaces of aircraft. They also provide a short period of anti-icing protection.

- Anti-icing fluids are similar in composition except that they also contain polymeric thickeners. They are formulated to prevent formation of unabsorbed frozen contamination for a longer period of time than deicing fluids; however, the protection is still for a limited period of time.

Note: It is the heat contained by the Type l (de-ice) fluid and the hydraulic pressure (high pressure spray) that removes the frozen contaminants. The glycol provides some protection during precipitation conditions until Type ll, III or IV fluid is applied.

Colour

- Colours are used as a visual aid in the application of fluids to aircraft surfaces. SAE fluid specifications indicate the appropriate colour for each of the Types of fluids, as follows:

- Type I fluids: Orange colour.

- Type II fluids: Colourless or a pale Straw colour.

- Type III fluids: TBA.

- Type IV fluids: Emerald Green colour.

Note: If the colour of the fluid being applied to the aircraft is NOT the colour anticipated, the procedure should be stopped and the situation investigated.

Qualified Fluids

- A list of qualified de-icing and anti-icing fluids and the HOT tables are included in the current Ground Icing Operations Update TP 14052E. If reliable holdover times are to be achieved, only qualified fluids, stored, dispensed and applied in accordance with the manufacturers' instructions are acceptable. The qualified fluids have undergone laboratory testing to quantify their protection endurance and to confirm aerodynamic acceptability during simulated take-off conditions.

- Qualified fluids have undergone laboratory testing to meet performance specifications and to confirm their aerodynamic acceptability. They have also been subjected to endurance time tests from which the holdover guidelines have been developed. Chemical property tests are also conducted. The operator is ultimately responsible for ensuring that only qualified fluids are used.

- It is expected that additional fluids will be qualified from time to time. Operators are encouraged to contact suppliers or manufacturers to determine the qualification status of any de-icing or anti-icing fluid that does not appear in the CBAAC. However, the operator will be required to prove that fluids not on the approved list have been properly tested.

Industry Fluid Specifications

- The Society of Automotive Engineers (SAE) and the International Standards Organization (ISO) have specifications for ADFs and AAFs. The ISO specifications are derived from the SAE specification and are therefore usually dated. Transport Canada recognizes only the most up-to-date SAE specifications, and all fluids applied to aircraft must meet these specifications.

Note: The status of ISO ground icing related documents has become uncertain, therefore only current SAE Specifications and documents are recognized by Transport Canada.

- The SAE specifications are SAE Aerospace Material Specification (AMS) 1424, entitled: "Aircraft Deicing/Anti-icing Fluid SAE Type I"; and, SAE AMS 1428, entitled: "Deicing/Anti-icing Fluid SAE Type II, III and IV".

- Users should request certificates of conformance to these SAE specifications from the fluid manufacturers.

Freezing Point

- The freezing points are determined by the American Society for Testing Materials (ASTM) D 1177 method, which measure the temperature of the first ice crystal formation.

- Frequent determinations of the freezing point of fluids are required to ensure that the desired freezing point is maintained.

- As the concentration of the fluid is increased from 0% upwards, by volume, the freezing point decreases. At some point as the concentration is increased towards 100%, the freezing point starts to increase. The reason for this tendency is that a solution has a lower freezing point than a pure solvent.

Refractometer Use in Determining a Glycol Based Fluid's Freezing Point

- The freezing point can be measured directly, using a method such as ASTM D 1177, however, this method is cumbersome for use in the field. The freezing point of fluids can be easily monitored in the field by measuring their refraction. The magnitude of the refraction is related to the concentration of glycol contained in the solution and therefore to the fluid freezing point.

- The fluid manufacturers should be consulted for further operational information on the procurement and the training required for refractometer use in the field.

FPD Fluid Strength When Applied

- The ratio of FPD ingredients to water, or fluid strength, is a significant factor in the de-icing fluid properties. HOT tables present guidelines for holdover times achieved by SAE Type I, SAE Type II, Type III and Type IV fluids as a function of fluid strength, weather conditions and outside air temperature (OAT).

Caution:

Do not use pure (100%) ethylene glycol or pure propylene glycol fluids in non-precipitation conditions. The reasons for this caution are explained below:

- Pure ethylene glycol has a much higher freezing point than ethylene glycol diluted with water. Slight temperature decreases can be induced by factors such as cold-soaked fuel in wing tanks, reduction of solar radiation by clouds obscuring the sun, wind effects, and lowered temperature during development of wing lift;

- Undiluted propylene glycol, having a strength of about 88% glycol at temperatures less than -10°C (+14°F), is quite viscous. In this form, propylene glycol based fluids have been found to cause lift reductions of about 20%.

- Propylene glycol FPD fluids are not intended to be used in the undiluted state unless specifically recommended by the aircraft manufacturer.

- Check the concentrations of the fluids you have available and know how they react under various conditions. If you do a quality assurance test as part of your procedure, don't skimp. If the test results are borderline, get help from your supervisor. Check with your supervisor, operations or maintenance to get the most up-to-date information available.

FPD Temperature Buffer

- Temperature buffer is the temperature difference between the freezing point of the fluid as applied, and the ambient temperature. Remember from Part One that this buffer allows for absorption of precipitation.

- Generally, the holdover time is increased with an expansion of the temperature buffer. Therefore, if the choice is available, use the maximum buffer. However, greater buffers require the use of more glycol, which is more costly and which increases the burden for collection and processing of FPD spillage and runoff. FPD fluid mixtures and their attendant buffers should be determined after consideration of the following factors in the listed order of priority:

- Safety;

- Environmental impact;

- Cost.

- For SAE Type I fluids, the freeze point buffer of the anti-icing should be as great as possible but not less than 10°C (18°F).

- For SAE Type II, III and IV, the freeze point buffer should not be less than 7°C (13°F).

Guidelines on the Use of Representative Surfaces

The decision to take off following the pre-take-off inspection is the responsibility of the PIC.

- The Air Operator's Ground Icing Operations program must specify the ground and flight crew training to be conducted regarding the purpose, procedures and limitations with respect to Representative Surfaces. Training on the assessment procedures to be followed to determine whether or not the fluid has failed should be included in the program.

- This technique may be used when the aircraft manufacturer has identified representative aircraft surfaces which can be readily and clearly observed by flight crew during day and night operations, and which are suitable for judging whether or not critical surfaces are contaminated.

- When the aircraft is deiced and anti-iced, it is desirable for the representative surface to be treated first during the final application of fluid. Whether or not this procedural methodology is appropriate for any particular aircraft design needs to be determined.

- Representative Surfaces may not be particularly effective during conditions when clear ice is forming on the aircraft's critical surfaces. Clear ice is even difficult to identify under ideal lighting conditions from outside the aircraft. Additional aircraft type specific procedures, such as tactile inspections, may be required.

- Other surfaces which are visible from inside the aircraft should also be inspected whenever possible, in addition to the Representative Surfaces. For example, under very good lighting conditions it may be possible to examine the surface of the wing beyond the Representative Surface.

- For large aircraft where it is necessary for one pilot to leave the flight deck in order to accomplish the pre-take off contamination inspection, there is the potential for the disruption of "checklist flow". The operator's ground icing plan should therefore specify at what point the inspection should take place in order to minimize any such disruption.

- Flight crew must be made aware that the use of representative surfaces for contamination detection may not be feasible in poor weather under very poor lighting conditions. The presence of contaminants on the cabin or cockpit windows may also make it difficult to properly observe the Representative Surfaces. Under conditions such as these it is prudent to have an external inspection conducted, to return for deicing and anti-icing or to delay the flight until conditions improve and a safe take off can be assured.

- Air Operators that have established a program in accordance with TC Ground Icing Operations Standards may have representative aircraft surfaces designated and approved for their aircraft. Representative surfaces that can be clearly observed by flight crew from inside the aircraft may be suitable for judging whether or not critical surfaces are contaminated.

- Many operators have painted a portion of the representative surface in a darker colour to aid in the visual detection of contamination. Some have designated representative surfaces on both sides of the aircraft in the event that, due to strong wind during taxi, one side of the aircraft becomes contaminated before the other.

- Research has indicated that fluid failure occurs last at the mid chord sections of wings. Therefore, whether painted or not, areas located at mid chord sections of wings and previously used for checking fluid conditions are not suitable for evaluating fluid failure and should no longer be used exclusively as representative surfaces. Tests have shown that first fluid failure occurs in the areas of the leading and trailing edges on aircraft with leading edge devices and that first fluid failure occurs in the areas of the spoilers, wing tip and the trailing edges on hard wing aircraft. (Note: The leading edges should always be checked because they are critical to aircraft performance.)

- Pre-take-off contamination inspections should be concentrated on the leading edge close to the fuselage (the wing high lift area) and ahead of the aileron (the roll control area) where these are visible. Dependent upon aircraft configuration, wing spoilers may also be used to provide an indication of fluid condition.

- In addition to the representative surface, other aircraft critical surfaces which are visible from inside the aircraft should be inspected for contamination whenever possible.

- The operational advantage of a check from inside the aircraft is obvious in this circumstance. However, as stated in the TC standard, the operator's program must specify the conditions, such as weather, lighting and visibility under which such an inspection may be conducted. In some cases, even the presence of residual deicing and anti-ice fluid on cabin windows may make a proper visual check difficult or impossible.

- In any event, flight crew personnel should be aware that the use of a representative surface for contamination detection might not be feasible in some circumstances. A return to the deicing facility will be the only safe alternative, if any doubts exist, regarding the condition of the aircraft.

The decision to take off following the pre-take-off inspection is the responsibility of the PIC.

Deicing and Anti-icing Procedures

- Most aircraft ground icing related accidents have occurred when the aircraft was not de-iced prior to take-off. The de-icing process is intended to restore the aircraft to a clean configuration so neither degradation of aerodynamic characteristics nor mechanical interference from contaminants will occur.

- Common practice over many years of experience is to deice and, if necessary, anti-ice an aircraft as close to the time of take-off as possible. Various techniques of aircraft ground de-icing and anti-icing have been developed. The most common technique is to use FPD fluids in the ground de-icing process and to anti-ice with a protective film of FPD fluid to delay formations of frost, ice or snow.

Deicing/Anti-icing Fluid on the Cockpit Windscreen

- The inherent properties of the fluids often results in the aircraft windshield wipers being rather inefficient at removing the fluids from the windscreen. In fact, the wipers will often merely smear the fluid resulting in a smudged windscreen, which makes it extremely difficult for the pilots to see out of the cockpit, especially during nighttime operations.

- Deicing Operators should be aware of this phenomenon and realize that even small amounts of deicing fluid covering flight deck windows can cause pilots to lose visual contact with the operation taking place around the aircraft. If this situation occurs, especially when hand signals are used as the only means to communicate, the communication between the pilot and the deicing operator may be impossible, and the overall safety of the operation may be compromised.

- In some instances it will not be possible to prevent deicing fluid build-up on the windscreens; however, the deicing operator should be aware of the negative implication of this situation. When an aircraft has been given depart clearance from the pad, the actual departure may need to be delayed while the pilot attempts to remove the fluid using windshield wipers, or while he waits for the fluid to run down the windscreen and thin out for better forward visibility. The very fact that deicing spray can reduce visibility from the cockpit down to nil, makes a compelling argument for the use of a hard wire or radio communication link between the PIC and the deicing crew.

Adequate Nighttime Flood Lighting

- Deicing an aircraft in a dimly lit, low visibility environment can be both difficult and unsafe. The ability to enter and exit the deicing area safely is hampered, especially at night when conditions like blowing snow has reduced visibility. The lighting should be sufficiently bright to allow for "day like" operations to take place. Nighttime lighting should be shielded to prevent glare for pilots of aircraft taxiing, landing or taking off in close proximity to the deicing facility.

- Good flood lighting, whether it is permanently fixed, portable or vehicle mounted, should be installed in consideration of the following points:

- Adequate nighttime lighting at the deicing facility will allow pilots to see clearly and therefore follow the hand signals of the Deicing Operator.

- Deicing crews will require sufficient nighttime flood lighting to enable them to provide the best possible deicing/anti-icing treatment.

- Pilots will also need a well lit environment within which to conduct a pre-take-off contamination inspection.

Fluid Application Procedures

- SAE document ARP 4737 and the fluid manufacturers recommendations should be consulted in establishing sound operations de/anti-icing procedures.

- The deicing/anti-icing operation should be performed as close in time to the takeoff procedure as possible. This generally means that the location chosen on an airport for deicing is as near to the end of the operational runway as is possible.

- De/anti-icing near the beginning of departure runways reduces the interval between the anti-icing process and take off. It is this interval that determines whether takeoff can be achieved prior to fluid failure. Once the fluid has failed, the aircraft must be de/anti-iced again. Under no circumstances shall a second application of anti-icing fluid be applied over a contaminated anti-icing fluid layer.

- Research has indicated that if the fluid is not applied correctly, the HOT Guideline values are not achievable.

Caution:

Types II, III & IV fluids, in particular, must be applied using specialized equipment. If these fluids are not applied in the correct manner and with the correct equipment, as recommended by the fluid manufacturer, they will NOT function as designed and will therefore NOT provide the expected protection as indicated in the HOT tables.

Fluid application procedures from SAE ARP 4737 Caution and Fluid Application Reminder, are outlined in the Table entitled: "Type I Deicing Fluid Application Procedures for Type I fluids", and in the Table entitled: "SAE Type II/IV Anti-Icing Fluid Application procedures" for Types II, III and IV fluids, available at the Transport Canada HOT website.

- Depending on the prevalent weather conditions, available equipment, technology, fluids and the desired holdover time, a one step or a two step de/anti-icing procedure may be appropriate. The aircraft must be treated symmetrically for aerodynamic reasons, as recommended in ARP 4737.

- Individual aircraft manufacturers provide guidance on specific anti-icing or deicing procedures for their particular aircraft models. An Air Operator must obtain and follow the aircraft manufacturers' guidance.

- It is also necessary for the Air Operator to understand aircraft deicing and anti-icing standard practices, such as those published in SAE document ARP 4737. The Regulations, Standards and Guidance published by Transport Canada must also be followed.

- The effectiveness of anti-icing fluid in protecting the aircraft's critical surfaces from the adherence of frozen contaminants is dependant upon the correct execution of the deicing process. The proper procedures and equipment must be employed to ensure that when both deicing and anti-icing with fluids have been accomplished the aircraft is safe for take off. This assurance requires that a thoroughly qualified and trained deicing crew accomplish the tasks.

- Cold soaked wings can be considerably below the ambient temperature therefore frost can build up in localized wing areas. When active frost is anticipated, SAE Type II or IV may be applied to the surfaces to prevent frost accumulation. Both wings should receive a symmetrical treatment for aerodynamic reasons.

Note: The following guidance is general in nature and is not intended to be fluid manufacturer specific.

One-step Deicing/Anti-icing

- Generally, in Canada the use of a one step process suggests that there isn't any active precipitation occurring at the time of deicing. However, in Europe the one step method is used with Type II & Type IV anti-icing fluids in a diluted and heated state, and applied with a specialized nozzle. Also, in Canada's Northern communities, given the extremely low temperatures, the only fluid option has been the Type I fluids, and a one step procedure is sometimes used despite the associated short Hold Over Times.

- The thickened fluids, Types II, III & IV, should not be used unheated on an aircraft contaminated with any snow ice or frost. The aircraft surfaces must first be cleaned before application of an unheated fluid Two-step Deicing/Anti-icing.

Two-step Deicing/Anti-icing

- Generally is used when the aircraft is contaminated and when precipitation is active. If a two step procedure is used, the first step is typically performed using a deicing fluid; however, alternate deicing technology or mechanical methods may be used depending upon circumstances.

- The selection of fluid type and concentration depends on the ambient temperature, the weather conditions and the desired holdover time. When performing a two-step process, the freezing point of a fluid used for the first step must not be less than 3°C above ambient temperature. The freezing point of a SAE Type I fluid used for one-step or as the second step of the two-step operation must be at least 10°C below the ambient temperature. The second step must be completed as quickly as possible following first step fluid application (not more than 3 minutes). The two step process may need to be performed area by area.

- When deicing fluid is used in step 1, the application of the second step fluid will flush away the first step fluid and leave a film of anti-icing fluid which is designed to be of adequate thickness. If freezing of the deicing fluid has occurred, step 1 must be repeated. Refer to SAE ARP 4737 document for additional details.

- SAE Type I fluids have limited effectiveness as an anti-icing fluid due to their short holdover time. SAE Type II or IV fluids used as deicing/anti-icing agents may have a temperature application limit of -25°C. The application limit may be lower provided a 7°C buffer between the freezing point and the ambient temperature is maintained and the fluid has been demonstrated to be aerodynamically acceptable at this ambient temperature.

First Step:

- Apply heated ADF until all of the frozen contaminants have been removed from the aircraft's critical surfaces. The ADF fluid is typically heated so that it will arrive at the application nozzle at around 60-82°C (140-180°F).

- No frozen contaminants shall remain after application of an ADF, including under the fluid.

- Aircraft surfaces should be treated symmetrically for aerodynamic reasons.

Second Step:

- Apply the AAF to aircraft surfaces before any freezing of the ADF occurs. Typically the application of AAF should occur within 3 minutes of deicing with an heated ADF.

Caution:

- The effectiveness of Types II, III and IV fluids can be seriously diminished if proper procedures are not followed when applying it over Type I fluid. Consult the fluid manufacturer for further information.

- Ensure Type IV fluids are applied evenly and thoroughly and that an adequate thickness has been applied in accordance with the fluid manufacturer's recommendations.

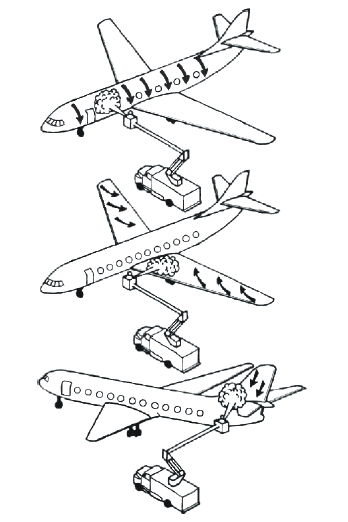

- Figure 2 demonstrates how an aircraft must be systematically and symmetrically de-iced and anti-iced in weather conditions conducive to icing. Each aircraft surface requires a specific cleaning technique.

- Generally, the fuselage should be de-iced and anti-iced from the top down. Clearing the top of the fuselage manually instead of by spraying requires that personnel use caution not to damage protruding equipment (e.g., antennae) while deicing. Spraying the upper section with heated FPD fluid first allows the fluid to flow down, warming the sides of fuselage and removing accumulations. This is also effective when deicing the windows and cockpit windshield of the aircraft. Direct spraying of these surfaces can cause thermal shock, resulting in cracking or crazing of the windows. Deicing the top of the fuselage is especially important on aircraft with an aft-mounted centreline engine. The ingestion of ice or snow can result in compressor stalls or engine damage.

- The radome or nose of the aircraft should be de-iced to eliminate snow or ice accumulations from being projected into the crew's field of vision during take-off. The nose also contains navigation and guidance equipment; therefore, it must be cleared of accumulations to ensure proper operation of the sensors.

- The cargo and passenger doors must also be de-iced and anti-iced to ensure proper operation. All hinges and tracks should be inspected to ensure that they are free of accumulation. Although accumulation may not impair operation on the ground, it may freeze at flight altitude and prevent normal operation at the aircraft's destination. Frozen accumulation may also cause damage and leakage on cargo and passenger door latches and seals.

- Sensor orifices and probes along the fuselage (e.g., static ports, pitot tubes, air intakes or temperature sensors) require caution during the application of FPD fluid. Direct spraying into these openings can damage the equipment, or residues could result in faulty readings.

- The wings are the main lifting surfaces of the aircraft and must be free of contamination to operate efficiently. An accumulation of frost, ice or snow on the wing changes the airflow characteristics, reducing its lifting capabilities, increasing drag, increasing stall speed and changing pitching moments. The weight increase is slight and its effects are secondary to those caused by surface roughness.

- On many aircraft, de-icing of the wing begins at the leading edge wing tip, sweeping in the aft and inboard direction. This procedure avoids increasing the snow load on outboard wing sections, which under some very heavy snow conditions could produce excessive wing stresses. This method also reduces the possibility of flushing ice or snow deposits into the balance bays and cavities.

- The various aircraft types that will be de-iced at a station need to be identified. The operators must be very familiar with any unique deicing considerations based upon aircraft type.

Figure 2. Systematic and Symmetrical Deicing of Aircraft

- If ice accumulation is present in areas such as flap tracks and control cavities, it may be necessary to spray from the trailing edge forward. Also, under some weather or ramp conditions, it is necessary to spray from trailing edge. Consult the aircraft manufacturer for specific details.

- It is important for operators to consider the configuration of their aircraft during de-icing. Manufacturers may indicate that their aircraft need to be in a specific configuration during the de-icing and anti-icing process. However, if an aircraft is in a clean configuration, that is with all high lift devices retracted, during de-icing the operator needs to consider what untreated areas of the wing are subsequently exposed to freezing precipitation once the devices are extended/deployed. The areas under a leading edge flap or slat, if not protected by anti-icing fluids, have the potential of becoming a contaminated critical surface prior to take-off. Air operators need to consider this scenario and may need to develop additional procedures to ensure that the aircraft is taking off in an uncontaminated condition.

- Two possible options include: delaying slat/flap deployment until just prior to take-off; and deploying the devices prior to de/anti-icing so that the surfaces under these devices are treated.

- The tail surfaces require the same caution afforded the wing during the de-icing procedure. It is important that both sides of the vertical stabilizer and rudder be de-iced because it is possible for directional control problems to develop on certain aeroplanes if the contamination is removed from one side only. The balance bay area between moveable and stationary tail surfaces should be closely inspected. For some aircraft, positioning the horizontal stabilizer in leading-edge-down position allows the FPD fluid and contaminants to run off rather than accumulate in balance bays. For some aircraft, the horizontal stabilizer must be in the leading-edge-up position. Consult your manuals for complete information.

- Balance bays, control cavities and gap seals should be inspected to ensure cleanliness and proper drainage. When contaminants do collect in the surface juncture, they must be removed to prevent the seals from freezing and impending the movement of the control surface.

No Spray Zones

- Operators need to clearly understand where they can or can not spray de/anti-icing fluids. Examples of no spray zones include, but are not limited to:

- Engine inlets and openings;

- APU inlets;

- Engine exhaust openings;

- Aircraft brakes;

- Flight deck windows;

- Cabin windows;

- Passenger door handles;

- Static ports;

- Pitot heads;

- Air data sensors;

- Avionics vents; and

- Aircraft manufacturer specified "no spray" areas.

- The above list includes items where direct spraying is not recommended; whereas indirectly washing the item with deicing fluid is acceptable (e.g. cabin windows). Consideration must also be given to factors which continuously vary with time, such as: the number and types of vehicles in use, a one step or a two step process, local weather conditions, local operational peculiarities, and so on.

- Operators must be very familiar with any unique deicing considerations based upon aircraft type.

De-icing the Engine Area

- Minimal amounts of FPD fluid should be used to de-ice the engine area and auxiliary power unit (APU). FPD fluids ingested in the APU can cause an auto shutdown, overspeed or rotors burst (which can lead to a fire) as well as, smoke and vapours to enter the cabin. Engine intake areas should be inspected for the presence of ice immediately after shutdown. Accumulations should be removed while the engine is cooling and before installation of plugs and covers. Any accumulation of water must be removed to prevent the compressor from freezing.

- For turbo-jet engines, FPD fluids should not be used for de-icing internal components. Fluid residue on the engine fan or compressor blades can reduce engine performance or cause stall or surge. In addition, this could increase the possibility of glycol vapours entering the aircraft through the engine bleed air system.

- Most turbo-jet and turbo-prop engine manufacturers recommend that thrust levers be advanced periodically to an N1 rpm of 70 to 80% while the aircraft is in ground operations to prevent ice accumulation that can result in reduced thrust, dynamic imbalance of the fan or compressor or excessive induction of shed ice. Pilots are made aware of these operating procedures in training. All procedures should comply with the procedures established by the manufacturer.

Ground Deicing/Anti-Icing With Main Engines Running

- A number of aircraft and engine manufacturers have published information on the advisability of deicing/anti-icing with the main engines running, and when permitted, the procedures to be followed in order to protect the engines.

- Experience shows that problems can be minimized if precautions are taken to limit the ingestion of deicing/anti-icing fluid by the engines. The following procedures, which must be adapted to the specific aircraft type, were developed to protect the aircraft during deicing/anti-icing with the main engines running:

- Operate as few engines as possible during the deicing process;

- Operate at the lowest practicable power setting;

- If possible select air conditioning 'OFF';

- Avoid spraying fluid directly into the engine, APU, and air conditioning system intakes;

- Avoid a large run-off of fluid from adjacent surfaces into the intakes, e.g., from a vertical stabilizer into a tail-mounted engine or APU;

- Minimize the generation of spray in the vicinity of the intakes.

Fluid Application

Spray Pressure

- During the deicing process, it is a combination of temperature and fluid velocity that dictate the efficiency with which the frozen contaminants are dislodged from the aircraft's surfaces. This is most effectively accomplished with a nozzle spray angle of approximately 45 degrees. The contaminants which are not removed from the surfaces by the initial impact of the fluid are melted off, or debonded, by virtue of the thermal energy contained in the heated deicing fluid.

- Excess pressure can result in fluid velocities out of the nozzle that can cause impact damage to aircraft components. The aircraft manufacturer should be consulted to ensure that any proposed deicing procedur When applying anti-icing (AAF) fluids to the aircraft surfaces only correct pumping equipment must be used to avoid shearing the fluid and thereby destroying the fluid's HOT capacity. The fluid manufacturer should be contacted to determine what methods should be employed in the application of their fluids.

Proper Coverage

- Proper fluid coverage is absolutely essential for proper fluid performance. It is imperative that the personnel applying the fluid are properly trained and that a consistent fluid application technique is utilized. Adequate fluid quantities must be expended to accomplish the de/anti-icing tasks. Proper training will help ensure that the de/anti-icing task is accomplished in a manner that utilizes the fluids most effectively and that the aircraft is subsequently rendered safe for flight.

- The deicing with fluids process is not completed until the aircraft's critical surfaces are completely free from frozen contamination. This can only be accomplished with the use of a sufficient quantity of deicing fluid to complete the task.

- For the purpose of deicing, hot Type I fluid is generally applied directly onto the total aircraft surface to be de-iced. If applied only to the front part of the wing, allowing it to flow back to the aft part, the fluid will cool down significantly as it moves on the surface of the wing making it less effective, or even ineffective in melting frozen contamination on the aft part of the wing.

- It is considered imperative that the leading edges of the wings and control surfaces be thoroughly cleaned of any contaminant. No frozen precipitation or contamination can be allowed to remain underneath the deicing fluid. Hot deicing fluid must be applied in sufficient quantity that the remaining fluid on the surfaces to be protected has a freezing point at least 10°C below Outside Air Temperature (OAT). As the fluid is applied, it is being diluted by the melted ice, snow or whatever frozen accumulation it is removing. Its freezing point is thus increased.

- Sufficient hot deicing fluid must be applied to make sure that fluid diluted by melted slush, snow or ice is flushed away. This is best accomplished by applying the fluid from the high point on the wing to the low point on the wing. Typically from wing tip to wing root.

- The anti-icing with fluids process is not properly accomplished if an insufficient amount fluid has been used and which results in incomplete or inadequate coverage of the surfaces to be treated.

- For the second step of a two step procedure, a sufficient amount of aircraft anti-icing fluid must be applied that can completely cover the surfaces and form an adequate coating. The HOT table values are based upon the application of sufficient fluid. Insufficient coverage results in a thin layer and reduced protection of uncertain duration.

- The application process should be continuous and as short as possible. Anti-icing should be carried out as near to the departure time as possible in order to utilize available holdover time. While thickness will vary in time over the profile of the wing surface, the anti-icing fluid should be distributed uniformly. In order to control the uniformity, all horizontal aircraft surfaces should be visually checked during application of the fluid. The amount of fluid required, will be visually indicated by the fluid just beginning to run off the leading and trailing edges of the surfaces.

- For a typical ethylene based Type IV fluid, between 1 mm and 3 mm thickness layer is required. It takes 2 litres of fluid to cover 1 square metre to a depth of 2 mm. Since application is never perfect, it will take more than 2 litres/square metre to achieve this 2 mm fluid thickness (In non-metric units, it will take at least 2 U.S. gallon/40 sq. ft. to achieve 0.08 inches). Conversion factors:

- litre = 0.5284 U.S. gallon;

- mm = about 0.08 inch; and

- 1 square metre = 10.76 square feet.

Note: For more detailed information on specific fluids, contact the de/anti-icing Fluid manufacturer.

Heat Loss

- The heated ADF should be dispensed as close to the surface to be deiced as possible. Application of heated fluid from a distance results in the significant cooling of the fluid enroute to the aircraft surfaces which will reduce the fluid's ability to remove frozen contaminants. The thermal energy contained in heated ADF fluids has been shown to be a principle factor in the efficient removal of frozen contaminants from the aircraft's surfaces. Therefore, within limits, the hotter the fluid is when it reaches the aircraft's surfaces, the more effective it will be in removing the contaminants. The deicing operator training program will need to emphasize correct techniques to get the best performance from the fluid in use.

Areas to be Covered

- The application strategy should adopt standard techniques while considering unique procedures necessary for specific aircraft design differences. Where possible, mechanical removal of snow, ice or slush accumulations should be considered as well as the proper execution of such procedures.

- All windows and doors of the aircraft must be closed during spraying, engine may be shut down or idling and air-conditioning and/or APU air must be off, unless otherwise recommended by the airframe and engine manufacturer.

- A spray to provide an even and uniformly distributed film should be used in a continuous process of application.

- The surfaces to be treated are typically:

- Wing leading and trailing edges;

- Wing and controls upper surfaces;

- Horizontal stabilizer and elevator upper surfaces;

- Vertical stabilizer and rudder; and

- Fuselage upper surfaces on aircraft with rear fuselage mounted engines, depending on amount and type of precipitation.

- Care must be taken to ensure that ice, snow and slush has not accumulated or has not been overlooked in critical places such as the flight control hinge areas, auxiliary power unit (APU) intake or between stationary and moveable surfaces. The front and rear sides of fan blades must be checked prior to start-up when engines are not running. Clear ice can form below a layer of snow or slush and can be hard to detect therefore the surface of the aircraft must be carefully examined after deicing. Care must be taken to avoid inadvertently spraying fluid directly onto the cabin and cockpit windows, doors and emergency exits, or into the intake of a running APU.

- In general, deicing treatment must be done in a leading edge to trailing edge direction. Failure to follow this methodology may result in contamination being forced into the wing or stabilizer openings where it could re-freeze and jam control systems and thereby result in an unsafe condition.

Note: T-tail aircraft. These types of aircraft have the potential to tip due to the imbalance caused when the wings are clean and the tail surfaces have a heavy accumulation.

Excessive Application

- Excess application can become a safety problem. The tarmac surfaces become slippery because of the fluid and the clean up process become onerous and expensive. Any accumulation of fluid on the ground must be cleaned up and disposed of in a safe and environmentally friendly manner.

- Proper training of deicing crews will help minimize waste and deicing costs.

Inspection for Contaminants

- As part of the walk-around, the aircrew will be looking very closely at the aircraft. If it's snowing or raining, an icy wing looks just like a wet wing.

- You as ground crew must check your own area closely. The best testing tools are your eyes and your hands. If a surface looks suspect and conditions are ripe for freezing contamination, run your hand across the surface. If it is wet, you'll slosh water around. But if you feel thick water or a mild, gritty feeling, you are feeling snow and water or ice crystals and water. Light sheet ice is sometimes found over a coating of water. It will break or shift around when you feel it. Heavy ice, sticking to the aircraft, will feel pebbly, or feel too smooth. Heavy ice also looks slightly cloudy. Some ice is rough and hard to see through to the aircraft skin, while other ice is smooth and as clear as water. Snow accumulation is obvious: it looks like snow. But some areas of certain aircraft can fool you. For example, most jet engine intakes have a built-in heater to keep the intake clear of ice in flight and on the ground. If melted ice in the intake is allowed to refreeze (while overnight, for example) and snow falls on that refreezing water, you'll find what looks like some snow in the intake. Run your hand through it and you'll find a hard lump of ice with a fine cover of snow sitting in the intake.

Representative Aircraft Surfaces

Note: Transport Canada no longer maintains a list of approved representative aircraft surfaces.

- Air carriers that have established a program in accordance with GOFR 622.11 may have representative aircraft surfaces designated and approved for their aircraft. Representative surfaces that can be clearly observed by flight crew from inside the aircraft may be suitable for judging whether or not critical surfaces are contaminated. Guidelines for the approval of representative surfaces have been developed.

- Many operators have painted a portion of the representative surface in a darker colour to aid in the visual detection of contamination. Some have designated representative surfaces on both sides of the aircraft in the event that, due to strong wind during taxi, one side of the aircraft becomes contaminated before the other.

- Research has indicated that fluid failure occurs last at the mid chord sections of wings. Therefore, whether painted or not, areas located at mid chord sections of wings and previously used for checking fluid conditions are not suitable for evaluating fluid failure and should no longer be used exclusively as representative surfaces.

- Pre-take-off contamination inspections should be concentrated on the leading edge in conjunction with the trailing edge of the wing. Dependent upon aircraft configuration, wing spoilers may also be used to provide an indication of fluid condition.

- In addition to the representative surface, other aircraft critical surfaces which are visible from inside the aircraft should be inspected for contamination whenever possible.

- While not recommended, if ground operations are to be conducted in freezing precipitation conditions, TC strongly recommends the use of Type II, III or IV anti-icing fluids (in accordance with the aircraft manufacturer's instructions) in order to take advantage of their superior protection characteristics.

The decision to take off following the pre-take-off inspection is the responsibility of the PIC.

Collection and Disposal

- Fluid runoff from deicing operations shall be contained, collected and disposed of in accordance with federal, provincial and municipal regulations and guidelines. Please note that laws and regulations governing disposal may change. It is the responsibility of the user to assure that disposal is appropriate and is in compliance with legal requirements.

Environmental Impact

- The local Environment Canada representative should be contacted for information on the detailed requirements for protection of the environment from the adverse effects of deicing fluids.

- Aircraft deicing or anti-icing fluids that are allowed to enter surface waters can have an adverse effect on aquatic life. For this reason, it is recommended that the runoff from deicing operations be contained and diverted to either a water treatment system or a glycol reclamation system.

- A portion of the deicing fluid applied to the aircraft surfaces during deicing operations drains onto the apron surface and subsequently enters drainage runoff or percolates into subsurface soils.

- Although some glycol has been found in the air and groundwater, the most significant environmental concern is associated with storm water discharges to surface waters. As glycol has a high biochemical oxygen demand (BOD), the discharge of untreated runoff containing aircraft deicing fluids into receiving waters creates an unacceptable pollution problem and a potential hazard to aquatic life.

- To ensure that airport effluent does not negatively impact on the environment, a number of airports throughout Canada have implemented a program of sampling and analyzing storm water. Water quality programs have also been established at Local Airport Authorities and Canadian Airport Authorities. Although existing environmental legislation does not specifically require water monitoring, federal, provincial, and municipal laws do specify water quality standards and guidelines to be followed by industry.

- To ensure responsible environmental management of glycol based chemicals used in deicing operations the Air Operator, Service Provider and local Airport Authority shall prepare detailed glycol management plans and procedures.

Fluid Contamination

- Fluid contamination can generally be avoided by following established procedures and practices. The following is a list of considerations that should be undertaken as a minimum.

New Equipment

- New equipment placed into service should be thoroughly cleaned. Pay particular attention to new deicing trucks, which are often shipped with an antifreeze solution in the pump and piping system. Drain the system and rinse with clean water before filling the truck with deicing fluid and introducing it into service.

Weatherproof Covers

- Make certain that the tank covers of the trucks and the storage tanks are weatherproof and do not allow water into the tank; however, recognize that proper venting is still required. If it is suspected that water or contaminants have entered the tanks, check the product in the tanks to ensure that it meets specification(s) and if necessary thoroughly clean the tanks and ensure that the covers are repaired to a weatherproof state.

Internal Inspection of Tanks

- Some deicing/anti-icing trucks have the anti-icing fluid tank sharing a common wall with the deicing fluid tank. Some tank walls can develop cracks, allowing deicing and anti-icing fluids to mix. The presence of even small amounts of deicing fluid in the anti-icing fluid can cause significant anti-icing fluid performance and thus effect the HOT times. Valves and hoses can also leak and allow fluid mixing or contamination. Routine inspection is required to help prevent these issues from arising.

Transfer of Fluid

- Transfer of fluid from deicing equipment into storage tanks should not be accomplished without appropriately testing the fluid. If the fluids were contaminated this action would result in the contamination of the fluid in the storage tank.

Dedicated Equipment

- Use dedicated storage and handling facilities for deicing fluids. Make certain that loading and unloading lines are clean. Routine inspections are required.

Labeling

- Conspicuously label storage tanks, loading and transfer lines, valves, deicing/anti-icing truck tanks, and pumps for instant identification to minimize the risk of product contamination. Before transferring any fluid, check the label on both the source and receiving vessels, as required by WHMIS regulations.

Forbidden Mixtures

- Do not mix deicing fluids with any other product unless approved by the fluid manufacturer.

Occupational Safety and Health (OSH)

- We should all be aware of the potential effect on health of de-icing and anti-icing fluids. Proper precautions must be taken during the de-icing and anti-icing process to ensure the well being of passengers and flight crew. Passengers and crew should be shielded from all FPD fluid vapours by turning off all cabin air intakes during the de-icing and anti-icing process. Exposure to vapours or aerosols of any FPD fluid may cause transitory irritation to the eyes. Exposure to ethylene glycol vapours in a poorly ventilated area may cause nose and throat irritations, headaches, nausea, vomiting, and dizziness.

- All glycols cause some irritation upon contact with the eyes or the skin. Although the irritation is described as "negligible", chemical manufacturers recommend avoiding skin contact with FPD fluids and wearing protective clothing and equipment when performing normal de-icing and anti-icing operations.

- Ethylene and diethylene glycol are moderately toxic for humans. Swallowing small amounts of ethylene or diethylene glycol may cause abdominal discomfort, pain and dizziness, and can affect the central nervous system and kidneys. Because the glycol contained in FPD fluids is considerably diluted with water and other additives, it is unlikely that de-icing personnel could ingest a lethal amount accidentally in the normal performance of their duties. Detailed information on health effects and proper safety precautions for any commercial FPD fluid is contained in the material safety data sheet for that fluid. This sheet is available from the fluid manufacturer and should be on file with the operator providing the de-icing or anti-icing service.

Techniques for Implementing the Clean Aircraft Concept

- Establish training programs to update crewmembers on the hazards of winter operations, adverse effects of ice formations on aircraft performance and de-icing and pre-take-off procedures during ground icing operations.

- Establish training programs for maintenance or other personnel who perform aircraft de-icing to ensure thorough knowledge of the adverse effects of ice formations on aircraft performance and flight characteristics, critical components, specific ground de-icing and anti-icing procedures for each aircraft type, and the use of ground de-icing and anti-icing equipment including detection of abnormal operational conditions.

- Establish quality assurance programs to ensure that FPD fluids being purchased and used are of the proper characteristics, that proper ground de-icing and anti-icing procedures are utilized, that all critical areas are inspected, and that all critical components of the aircraft are clean prior to departure.

- Perform thorough planning of ground de-icing activities to ensure that proper supplies and equipment are available for forecast weather conditions and that responsibilities are specifically assigned and understood. This is to include service contracts.

- Monitor weather conditions very closely to ensure that planning information remains valid during the ground de-icing or anti-icing process and subsequent aircraft operations. Type or concentration of FPD fluids, de-icing or anti-icing procedures, and departure plans should be altered accordingly.

- When applicable, use two stage de-icing process where ice deposits are first removed, and secondly all critical components of the aircraft are coated with an appropriate mixture of FPD fluid to prolong the effectiveness of the anti-icing.

- Ensure thorough co-ordination of the ground de-icing and anti-icing process so that the final treatments are provided just prior to take-off.

- Ensure communication with the de-icing/anti-icing crew is maintained at all times. It is essential that the PIC know exactly what surfaces are being treated and when de-icing/anti-icing operations are complete and crews are clear.

- When feasible, provide and use remote sites near the take-off position for de-icing, anti-icing and final inspection, to reduce the time between de-icing and take-off.

- Use multiple aircraft de-icing or anti-icing units for faster and more uniform treatment during precipitation.

- Use FPD fluids that are approved for use by the aircraft manufacturer. Some fluids may not be compatible with aircraft materials and finishes, and some may have characteristics that impair aircraft performance and flight characteristics or cause control surface instabilities.

- Do not use substances that are approved for use on pneumatic boots (to improve de-icing performance) for other purposes unless the aircraft manufacturer approves such uses.

- Use FPD fluid types and concentrations that will delay ice formations for as long as possible under the prevailing conditions.

Critical Surface Inspections

- Critical surface inspections should be performed immediately after final application of the fluid to verify that the aircraft critical surfaces are free of contamination. (Refer to the Ground Icing Operations Standards if applicable to your operation.) Areas to be inspected depend on the aircraft design and should be identified in a critical surface inspection checklist. The checklist should include, at a minimum, all items

- Wing leading edges, upper surfaces, and lower surfaces;

- Vertical and horizontal stabilizing devices, leading edges, upper surfaces, lower surfaces, and side panels;

- High lift devices such as leading edge slats and leading or trailing edge flaps;

- Spoilers and speed brakes;

- All control surfaces and control balance bays;

- Propellers;

- Engine inlets, particle separators, and screens;

- Windshields and other windows necessary for visibility;

- Antennae;

- Fuselage;

- Exposed instrumentation devices such as angle of attack vanes, pitot-static pressure probes and static ports;

- Fuel tanks and fuel cap vents;

- Cooling and APU air intakes, inlets, and exhausts; and

- Landing gear.

- Once it has been determined through the critical surface inspection that the aircraft is clean and adequately protected, the aircraft should be released for take-off as soon as possible. This procedure is especially important in conditions of precipitation or high relative humidity.

Emergency Service

Transport Canada maintains a 24-hour emergency service for all chemical products (Call CANUTEC at 1-888-CANUTEC, *666 by cellular phone (in Canada only) or call collect to 613-996-6666).

Many fluid manufacturers also have a 24-hour emergency service for their products. The user should obtain the manufacturer's emergency phone number for ready reference.

DO NOT WAIT, if in doubt, call a specialist for advice.

Conclusion

Ground de-icing and anti-icing procedures vary greatly depending primarily on aircraft type, type of contamination accumulation on the aircraft and FPD fluid type. Ground crew should become familiar with applicable Canadian Aviation Regulations and Standards, the procedures recommended by the aircraft manufacturer in the Aircraft Flight Manual, Maintenance Manual and, where appropriate, the Aircraft Service Manual. As well, they should comply with all Company Operations Manual provisions.

You may reproduce this training package as required and it can be found at:

https://tc.canada.ca/en/aviation/licensing-pilots-personnel/flight-crew-licences-permits-ratings/study-reference-guides-sample-examinations.

Copies of the current Transport Canada Ground Icing Operations Update (TP 14052) and the Holdover Time Guidelines may be obtained from your Regional Commercial and Business Aviation representative or the following website:

https://tc.canada.ca/en/aviation/general-operating-flight-rules/holdover-time-hot-guidelines-icing-anti-icing-aircraft.

For further information regarding Ground Icing issues please refer to the latest Commercial and Business Aviation publication titled "Guidance for Aircraft Operations under Icing Conditions", and can be downloaded from the following website:

https://tc.canada.ca/en/aviation/general-operating-flight-rules/holdover-time-hot-guidelines-icing-anti-icing-aircraft.

NASA Glenn Research facility has developed numerous in-flight icing media, which address problems, encountered while in-flight such as, tailplane stall, Supercooled Liquid Drops (SLD), aircraft icing certification criteria plus computer based icing training sessions. They are available from: http://icebox-esn.grc.nasa.gov/.

Or by writing to the following address:

Icing Branch

NASA GRC

21000 Brookpark Rd.

MS 11-2

Cleveland, OH 44135

216-433-3900

216-977-7469 (fax)

The videos When in Doubt... Small Aircraft, Large Aircraft, and Ground Crew, and accompanying training packages, as well as the copies of the current CBAAC's and Transport Canada Ground Icing Operations Update (TP 14052) may be obtained from the Civil Aviation Communication Center at:

Toll Free: 1-800-305-2059

In the National Capital Area: (613) 993-7284.

Chapter 6 - Aircraft Critical Surface Contamination Examination Questions

To assist air operators in establishing Surface Contamination Training, Transport Canada has made available this training package concerning the adverse effect of critical surface contamination on aircraft performance.

This publication is to be used with reference to the Canadian Aviation Regulations (CARs) Parts VI and VII, Ground Icing Operations Update TP 14052E, the Aeronautical Information Publication (A.I.P.) - Canada, and industry publications.

When developing a knowledge verification examination to meet the CARs requirements, air operators may select appropriate questions from this publication and add questions specific to their operation. References are given to assist in determining the correct response to each question.

Comments or suggestions with respect to this publication should be referred to:

Transport Canada

Place de Ville, Tower C

Ottawa, Ontario, Canada

K1A 0N8

Telephone: (613) 998-8168

Facsimile: (613) 990-6215

email: tom.dunn@tc.gc.ca

1.0 Air Law, The Clean Aircraft Concept

1.01 Frost, ice or snow on top of deicing or anti icing fluids

- is not considered as adhering to the aircraft and a take off may be made.

- must be considered as adhering to the aircraft and a take off should not be attempted.

- is only considered as adhering to the aircraft when Vr speeds are below 100 kt.

- is not considered as adhering if the aircraft has been de iced and then anti iced.

1.02 Where conditions are such that frost, ice or snow may reasonably be expected to adhere to the aircraft, no person shall take off or attempt to take off in an aircraft unless

- it has been de iced.

- it has been inspected immediately prior to take off to determine whether any frost, ice or snow is adhering to any of its critical surfaces.

- its skin temperature is warm enough to ensure that adhering frost, ice or snow will slide off on take off.

- its power and runway length are sufficient to allow acceleration to Vr plus 10% before rotation.

1.03 Prior to take off, the PIC cannot confirm that the aircraft is "clean". Take off

- may be commenced provided the maximum holdover time has not been exceeded.

- may be commenced provided the anti ice fluid used was of the type that prevents ice or snow from sticking to the critical surfaces.

- may be commenced provided the amount of frost, ice, or snow does not exceed that specified in the company operations manual.

- must not be attempted until confirmation is obtained that the aircraft is clean.

1.04 One engine is kept running during a quick turn around in icing conditions because you are unable to restart it with existing internal or external power. When taxiing for take off, you are advised that there is a significant amount of wet snow on the aircraft. As your operating instructions require both engines to be shut down for deicing, you should

- take off but delay rotation until Vr plus 10%.

- take off as wet snow will slide off as the aircraft becomes airborne.

- taxi back to the apron, shut down the engine you are able to restart and have the critical surfaces carefully de iced.

- cancel the flight until proper equipment is available or necessary repairs made.

1.05 The only positive assurance that an aircraft is "clean" prior to take off can be achieved by

- confirmation from the crew chief that the fluid used has the required holdover time.

- ensuring the aircraft is not subjected to excessive ground delays.

- close inspection by the PIC or designated flight crew member.

- ensuring take-off is within the applicable holdover time table.

1.06 Who may inspect an aircraft immediately prior to take off to determine whether any frost, ice or snow is adhering to any of its critical surfaces?

The PIC and

- a flight crew member of the aircraft designated by the PIC to carry out the inspection.

- the operations officer.

- the deicing crew.

- a person designated by the operator who has received the required surface contamination training.

- any Aircraft Maintenance Engineer.

- A, B, C, D, E.

- A, B, C, D.

- A, B, C.

- A, D.

1.07 When a crew member of an aircraft observes frost, ice or snow adhering to the wings of an aircraft before take off, the crew member

- shall immediately report that observation to the PIC.

- need not report that observation if the aircraft has recently been de iced.

- shall immediately report that observation to the designated crew member.

- unless designated, need not report that observation.

1.08 Before commencing take off the PIC is advised that there is frost, ice or snow adhering to the wings of the aircraft.

The PIC

- may take off without a further wing inspection if the aircraft has been recently de iced.

- shall request a go/no go decision from company operations.

- shall request the deicing crew to inspect the wings before take off.

- or another flight crew member designated by the PIC shall inspect the wings before take off.

1.09 No person shall commence a flight in an aircraft

- unless it has been de iced if frost, ice, or snow conditions exist.

- unless assured that adhering frost, ice or snow will slide off on take off.

- if frost, ice, or snow is adhering to any of its critical surfaces.

- if frost, ice, or snow adhering to the critical surfaces cannot be removed on take off by the aircraft deicing systems.

1.10 An air carrier shall provide training to crew members on the adverse effects of aircraft surface contamination

- biannually.

- on initial hiring and annually.

- biennially.

- on initial hiring only.

1.11 Persons other than crew members who require annual training on the adverse effects of aircraft surface contamination are those

- designated by the air carrier to carry out inspections in relation to the identification, reporting and inspection of surface contamination.

- involved in flight operations safety awareness programs.

- baggage handlers and refuellers who service the air carrier's aircraft.

- designated by the air carrier to de ice its aircraft.

1.12 Candidates taking the training program on adverse effects of aircraft surface contamination

- need not have their results recorded.

- shall be tested orally on the use of deicing and anti icing equipment.

- shall be tested to verify they understand and are able to apply the concepts taught.

- shall write an examination on the concept and use of deicing and anti icing equipment.

1.13 Persons who are involved in flight operations and who are not required to undergo periodic training on the adverse effects of aircraft surface contamination shall be

- advised of their responsibility for inspection of surface contamination.

- designated as backup for identification and reporting of surface contamination.

- tested on their understanding of reporting and inspection concepts.

- given a safety awareness program on the subject.

1.14 A flight attendant observes snow adhering to the wings of an aircraft. The flight attendant

- shall report that observation to the head flight attendant.

- shall immediately report that observation to the PIC.

- need not report that observation if the aircraft was de iced.

- need not report that observation if the aircraft was anti iced.

1.15 The PIC notes that frost caused by cold soaking fuel is adhering to the underside of the wings. Take off may

- not be attempted until the aeroplane is de iced.

- not be attempted under any circumstances as the frost, if removed, will quickly reform.

- be made at the discretion of the PIC.

- be made provided it is conducted in accordance with the aircraft manufacturer's instruction.

1.16 A take off with frost adhering to the underside of a wing may

- not be made under any circumstance.

- be made if it is conducted in accordance with the aircraft manufacturer's instructions.

- be made providing the grains of frost are no larger than .004 inches in diameter.

- be made providing the affected area has been treated with an undiluted Type I fluid.

1.17 Who may inspect an aircraft immediately prior to take off to determine whether any frost, ice or snow is adhering to any of its critical surfaces?

- The PIC.

- A flight crew member of the aircraft who is designated by the PIC.

- A person designated by the operator of the aircraft who has received the required surface contamination training.

- All of the above.

1.18 Select the correct statements regarding the use of representative aircraft surfaces.

- The operator's Ground Icing Operation Program must specify the conditions under which they may be used to comply with the Pre Take Off Inspection.

- They must be areas that can be clearly observed by the flight crew.

- Their surfaces should not be altered in any way that makes them appear different from the surrounding surfaces.

- A maximum of one surface will be approved for each aircraft.

- They may be used after the holdover time is exceeded to decide if a take off may be made.

- A, B, C, E.

- A, B, E.

- A, C, D.

- B, D, E.

1.19 What are the requirements to allow operators in Canada with rear-mounted engines to take off with hoar frost on the fuselage?

- The fuselage shall be de-iced if other contaminants are present.

- A copy of the exemption shall be attached to the aircraft deicing/anti icing procedures in the operations manual.

- Hoar frost shall be the only contaminant on the fuselage.

- All the above.

2.0 Theory and Aircraft Performance

2.01 Aircraft certified for flight in known icing conditions have been designed and have demonstrated system capability of providing adequate protection against the adverse effects of airframe icing

- both in flight and on the ground.

- in flight only.

- on the ground only.

- under all inflight icing conditions.

2.02 Stall warning systems are calibrated to give an effective warning

- in icing conditions if all components are heated.

- in icing conditions when the backplate is heated.

- under all conditions.

- under clean wing conditions.

2.03 Aircraft performance may be seriously affected by frost, ice or snow on the wings and control surfaces primarily because of the

- increase in gross weight.

- disruption of smooth airflow.

- strong possibility that the control hinges will freeze.

- adverse movement of the C of G.

2.04 Frost, ice or snow on a wing will

- increase the stall speed but will not affect the rate of climb.

- decrease the stall speed and reduce the rate of climb.

- increase the stall speed and reduce the rate of climb.

- not affect the stall speed or the rate of climb.

2.05 Contamination on an aircraft wing is dangerous primarily because

- the aircraft may become airborne in ground effect but be unable to climb.

- drag will prevent the aircraft accelerating to take off speed.

- its weight will cause the centre of pressure to move forward and reduce the rate of climb.

- of all of the above factors.

2.06 Frost, ice or snow formation on the leading edge and upper surface of a wing, having a thickness and surface roughness similar to medium or coarse sandpaper, can reduce the wing lift by as much as ... and increase drag by as much as ...

- 10%, 20%.

- 30%, 40%.

- 50%, 75%.

- 75%, 100%.

2.07 The adverse effects of frost, ice or snow on aircraft include

- decreased thrust and lift, and increased drag and stall speed.

- trim changes and altered stall characteristics.

- altered handling qualities.

- all of the above.

2.08 Frost, ice or snow on an aircraft may

- increase the stall speed but the stall characteristics remain the same.

- increase the drag but take off acceleration remains unaltered.

- decrease the lift and alter stall and handling characteristics.

- decrease thrust and stall speed.

2.09 A significant part of the loss of wing lift can be attributed to

- under wing contamination.

- leading edge contamination.

- flap contamination.

- trailing edge contamination.

2.10 The use of SAE Types II and IV fluids on large aircraft

- will not cause any performance degradation or require weight or other take off compensation.

- will require weight and take off compensation for all those with a Vr of 100 kt and below.

- should be restricted to those with a Vr above 100 kt.

- should be restricted to those with a Vr above 85 kt.

2.11 The use of SAE Types II and IV fluids could cause significant performance degradation for aeroplanes with rotation speeds

- of 85 kt to 100 kt only.

- of 85 kt and below only.

- above 100 kt.

- of 100 kt and below.

2.12 One of the key determinants in using anti icing fluids on a particular aeroplane is the

- time taken to accelerate to Vr.

- time taken to accelerate to V1.

- distance travelled to accelerate to V2min.

- distance travelled to accelerate to V3.

2.13 Who should determine what effect SAE Types II and IV fluid dryout, remaining on the aircraft, will have on aircraft performance or handling qualities during flight?

- The fluid manufacturer.

- The aircraft manufacturer.

- The aircraft operator.

- The deicing contractor.

2.14 Undiluted propylene glycol, having a strength of about 88% glycol, at temperatures less than 10°C has been found to cause lift reductions of about

- 10%.

- 20%.

- 30%.

- 40%.

2.15 Frost and ice could form or snow could adhere to the surface of an aircraft if its skin temperature is

- at or below freezing and the surrounding air is above freezing.

- below freezing and the surrounding air is cool and humid.

- at or below freezing and the surrounding air is well below freezing.

- all of the above.

2.16 After extended flight at a temperature of -20°C, an aircraft arrives for a quick turn around at an aerodrome where the temperature and dew point are 10°C and 9°C respectively. The pilot could expect

- blockage of the fuel vent system.

- ice formation over the entire wing surface.

- no adverse problems.

- frost to form in the area of the wing fuel tanks.

2.17 An aircraft which has been de iced in a heated hanger is rolled out into sub zero temperatures. The pilot should be particularly alert for

- freezing of wet surfaces or pooled water.

- frost formation.

- sublimation of water vapour into ice crystals.

- all of the above.

2.18 When aircraft are operating on slush or wet surfaces, ground crew should be particularly alert for contamination of

- the wheel wells.

- the underside of the aircraft.

- the control surfaces.

- all of the above.

2.19 An aircraft is refuelled with sub zero temperature fuel in conditions of high humidity. The pilot could expect

- clear ice to form around integral fuel cells.

- frost to form around integral fuel cells.

- no icing or frost problems.

- frost to form around integral fuel cells only if the ambient air temperature is below zero.

2.20 After extended flight at a temperature of -20°C, an aircraft arrives for a quick turn around at an aerodrome where there is light drizzle with a temperature of +8°C. The pilot could expect

- no adverse problems.

- ice to form on top of the wing in the area of the fuel tanks.

- frost to form on top of the wing in the area of the fuel tanks.

- ice to form on the bottom of the wing and frost to form on the top.

2.21 When an aircraft that has experienced frost formation on the wing because of the cold soaking phenomenon is de iced,

- the maximum holdover table values are applicable.

- the frost tends to reform quickly, even when removed.

- no further deicing will be required.

- the minimum holdover table values are applicable.

2.22 A very critical cold soaking phenomenon situation arises at aerodromes where there is

- drizzle with an ambient temperature around +15°C.

- rain with an aircraft skin temperature of +8°C.

- dry snow with an aircraft skin temperature between +8°C and +14°C.

- wet snow with an ambient temperature around 0°C.

3.0 Deicing/Anti-icing Fluids

3.01 Holdover time is

- a fixed time for fluid breakdown specified by the manufacturer.

- a fixed time for fluid breakdown specified by the ISO and SAE standards.

- the estimated time that an application of deicing/anti icing fluid is effective in preventing frost, ice or snow from adhering to treated surfaces.

- the estimated time to fluid shear from the aircraft surfaces.

3.02 The term "holdover time" as applied to anti icing or deicing fluids is the

- recommended maximum storage time in approved containers.

- recommended maximum time the fluid should be allowed to remain on the aircraft surface to avoid corrosion.

- estimated spray application time.

- estimated time the fluids will prevent frost, ice, or snow from forming or accumulating on the treated surface of an aircraft.

3.03 Pure 100% ethylene glycol should not be used for deicing in non precipitation conditions because

- the freezing point is higher than fluids with a proper glycol/water ratio.

- this fluid is highly corrosive unless diluted with water.

- undiluted, it is highly flammable.