Attention:

Owners, operators and maintainers of Bombardier Inc. Challenger 601 Aircraft using Bombardier Maintenance Steering Group 3 (MSG-3) Program

| File Classification No.: | Z 5000-35 |

|---|---|

| RDIMS No.: | 16590483 |

| Document No.: | CASA 2020-13 |

| Issue No.: | 01 |

| Effective Date: | 2020-12-07 |

Purpose:

The purpose of this Civil Aviation Safety Alert (CASA) is to provide awareness that the Bombardier MSG-3 program does not include an inspection task for the dual brake control valve (BCV) assembly. The task (reference: 32-43-21-216) is only found in Time Limits/Maintenance Checks (TLMC) documents PSP601-5 and PSP601A-5 for the MSG-2 program aircraft.

Background:

Following a Challenger 601 runway overrun accident, a failed BCV spring was found to be a contributing factor. The failure of the BCV spring resulted in the loss of brake function on the corresponding wheel. The affected aircraft was maintained using the Bombardier MSG-3 program.

During the investigation, it was found that BCV inspection criteria have not been consistently applied throughout the Challenger 601 fleet and some Challenger 601 operators have not included a BCV inspection task as part of their maintenance programs.

Maintenance programs approved in accordance with the Challenger 601 MSG-3 program, as defined by Service Bulletin (SB) 601-0590, are not likely to include BCV inspection task 32-43-21-216, which is included in the original MSG-2 program. The TLMC manual (PSP601-5-26) referenced in the SB, does not include this task. Therefore, any operator using this TLMC manual as a basis for their approved maintenance program may not have included a BCV inspection task.

The MSG-3 analysis noted that task 53-ZL-00-204 is applicable, however this is a general visual zonal inspection and makes no mention of inspecting the BCV. The inspection interval is 120 months and the method of inspection provides no timely or meaningful awareness of the BCV’s condition.

The original Challenger 600/601 models, using the MSG-2 methodology, have a 300 hour BCV inspection because the failure is hidden from the crew and there is no component life. The MSG analysis therefore required an on-condition inspection in the form of a 300 hour inspection. Some operators, due to their operational requirements, performed this BCV inspection as a pre-flight item even though the Maintenance Review Board (MRB) assigned a 300 hour interval. It is worth noting that the original certification of the Challenger 600 required that the BCV condition be known prior to dispatching the aircraft.

The more recent 604/605/650 aircraft models were certified and delivered in conjunction with MSG-3 inspection programs. They do not include the BCV inspection task because BCV failure on these models is not hidden as these aircraft have more extensive engine indicating and crew alerting systems (EICASs) which alert the crew of brake system failures.

Earlier 600/601 models that do not have an EICAS that alerts in the event of BCV failure and are maintained in accordance with the Bombardier MSG-3 program are at increased risk of being operated with an undetected failure of a BCV spring.

Recommended action:

Transport Canada recommends incorporating the BCV inspection for all Bombardier Challenger 601 model aircraft by performing the following:

-

Check if your maintenance program is based on the Bombardier approved MSG-3 program defined by SB 601-0590, which uses TLMC PSP601-5-26 as a basis of the aircraft maintenance program.

-

If the aircraft is using this MSG-3 program, review and amend the approved maintenance schedule (program) by incorporating the BCV inspection tasks detailed in the applicable TLMC documents listed below:

For CL-600-2A12 (CL601-1A) incorporate TLMC task 32-43-21-216 which is found in TLMC PSP601-5, Part 5 Revision 46 or later revisions.

For CL-600-2B16 (CL601-3A /-3R) incorporate TLMC task 32-43-21-216 which is found in TLMC PSP601A-5, Part 5 Revision 42 or later revisions.

-

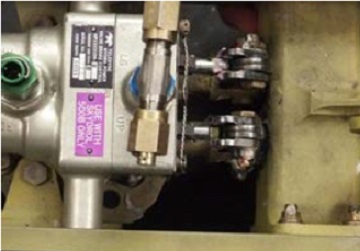

The inspection task is required every 300 hours and estimated to take no more than 5 minutes to complete, including inspection access. A failed BCV spring is indicated by different lengths of the pushrods and can be identified when the pushrod is displaced inward and does not contact the roller of its associated input linkage.

Contact office:

For more information concerning this issue, contact a Transport Canada Centre; or contact Daniel Haughton, Continuing Airworthiness in Ottawa, by telephone at 1-888-663-3639, facsimile at 613-996-9178 or by e-mail at cawwebfeedback@tc.gc.ca.

Original signed by

Rémy Knoerr

Chief, Continuing Airworthiness

National Aircraft Certification

The Transport Canada Civil Aviation Safety Alert (CASA) is used to convey important safety information and contains recommended action items. The CASA strives to assist the aviation industry's efforts to provide a service with the highest possible degree of safety. The information contained herein is often critical and must be conveyed to the appropriate office in a timely manner. The CASA may be changed or amended should new information become available.

Broken Brake Control Valve (BCV) Spring

(PDF, 89 KB)