Ship Safety Bulletins (SSB)

RDIMS No.: 3655911

Date (Y-M-D): 2007-12-04

Subject: Adequacy of Single Cross-bar Type Hatch Covers

Introduction

Investigations into the loss of three vessels, most recently the commercial fishing trawler, Hope Bay on 26 February 2004, raised uncertainties about the performance of single cross bar type hatch covers that fit flush with the deck. The purpose of this Ship Safety Bulletin is to caution operators of vessels, fitted with this type of hatch, of problems associated with its incorrect operation and lack of maintenance, which may lead to leakage and major down flooding.

Description

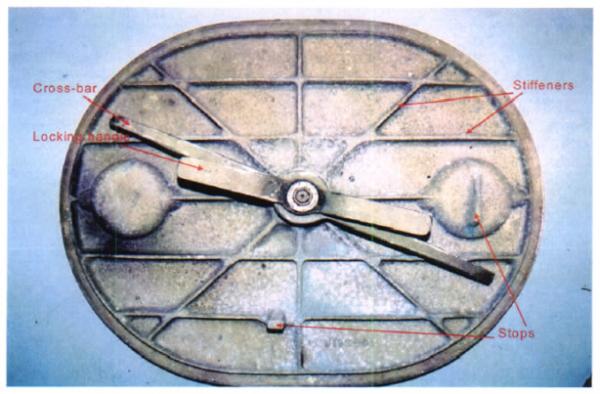

The hatch opening is oval in shape with a flush fitting hatch cover of either steel or aluminium. The hatch is correctly secured by tightening the single cross bar located on the underside of the cover such that it lands on two bearing pieces welded on the underside of the hatch seat. The two bearing pieces are 180 degrees apart on the short or minor axis of the oval opening. Operation of the hatch cover occurs by way of a central threaded spindle, which can be activated from the topside of the hatch.

The oval shaped hatch opening has a cast semi-circular groove around the perimeter. A tubular neoprene O-ring is fitted within the groove to provide a seal between the hatch cover and the hatch seat. A fibre washer seals the spindle.

Hazards

Assessment by the Transportation Safety Board of the design, operation and maintenance of the hatch cover and seating indicated that the hatch is susceptible to failure resulting in leakage and, in extreme cases, down flooding leading to the loss of stability and the loss of the vessel.

Operation of Hatch

When the operator is securing the hatch from the topside, it is not possible to confirm that the cross bar (on the underside) is correctly seated on the two bearing pieces. See photographs 1 through 4- attached. Consequently, failure to correctly fasten the hatch means the hatch is either not secured at all or only partially secured. In either instance the cover may be dislodged allowing leakage and/or down flooding.

In addition, the short lever arm of the handle makes it difficult to apply sufficient torque to tighten the hatch cover. In conjunction with the tubular nature of the O-ring, this creates a situation where the cross bar can lose its initial tension. However, caution should be taken not to over tighten, as damage to the cover and/or centre pin could occur. Furthermore, short cross bar stops, an excessive length of the spindle and too much clearance between the spindle head and cover could allow the cross bar to slip past the stops leaving the operator unaware that the hatch is not adequately secured.

Design of Hatch

The design of the cover and the cross bar does not allow uniform distribution of the tightening force and positive closure along the major or longer axis of the hatch cover. Under the influence of an applied load to a portion of the hatch cover, the cross bar could act as a fulcrum causing the opposite end of the cover to lift off the O-ring.

Also, when a load is applied uniformly across the upper surface of the cover, the weight may further compress the O-ring allowing the initial cross bar force on the bearing pieces to relax which could subsequently allow the cross bar to “walk” such that when the applied uniform load is removed, the hatch cover would not be properly secured. It should also be noted that the aluminium cover has a tendency to warp under excessive uneven loads again causing the watertight seal to be broken.

Additionally, a left hand thread of the operating spindle, clockwise-to-open, is counter-intuitive and may result in the incorrect operation of the hatch at moments of urgency.

Conclusion

Owners of vessels fitted with this type of hatch are strongly encouraged: to inspect the hatches for material defects;

- to contact the manufacturer for any operation and maintenance instructions and conduct the recommended maintenance;

- to insure that their operation will maintain watertight integrity in all conditions of operation; and

- to demonstrate to all crew members the correct operation of the hatch and to point out potential problems with its operation and maintenance.

- to demonstrate to all crew members the correct operation of the hatch and to point out potential problems with its operation and maintenance.

Photograph 1 – View of underside of manhole cover assembly.

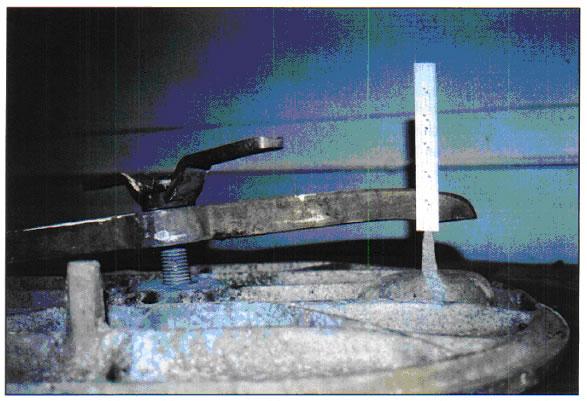

Photograph 2 - The cross bar is about 12mm above the ‘higher’ stop. It can now rotate behind the stops and the operator will be unaware that this has happened.

Photograph 3 - The cross bar was tightened by the operator from his position on deck and outside the compartment. He was completely unaware that it had come to rest on top of the wedge piece.

Photograph 4 - Position of ‘stop’ does not allow cross bar to sit over flat part of wedge piece.

The following document is available for downloading or viewing:

Adequacy of Single Cross-bar Type Hatch Covers (1.02nbsp;MB)

To access the Portable Document Format ( PDF ) version you must have a PDF reader installed. If you do not already have such a reader, there are numerous PDF readers available for free download or for purchase on the Internet:

Keywords: Questions concerning this bulletin should be addressed to:

2. Down flooding

3. Operation and maintenance

Ian Campbell

613-998-0652

Marine Safety

Tower C, Place de Ville

11th Floor, 330 Sparks Street

Ottawa, Ontario K1A 0N8

To add or change your address, contact us at: marinesafety@tc.gc.ca

Owners of commercial vessels, registered and licensed, automatically receive Bulletins.