This guide describes regulatory objectives and provides explanations, guidance and examples to help railway companies and local railway companies develop and implement their railway safety management systems (SMS) to meet the requirements of the Railway Safety Management System Regulations, 2015 (Regulations). The examples provided are for guidance purposes only. Oversight will be conducted against the requirements of the Regulations.

Notes:

- Using this document and the samples it contains is not mandatory

- Nothing in this document replaces the Regulations

On this page

Introduction

What is a Safety Management System?

A SMS is a formal framework for managing risk. It makes safety part of day-to-day railway operations.

A SMS helps companies manage the safety of their operations by requiring them to:

- identify safety concerns, assess the level of risk they represent, and take steps to reduce those risks where required;

- build a safety culture in day-to-day operations at all levels of the company;

- involve company employees by:

- collaborating or consulting with them;

- informing them of risks and how the company has dealt with these risks; and

- developing a procedure for employees to report contraventions and safety hazards to the company, and a policy for protecting employees who report contraventions and safety hazards.

SMS has become an international standard for managing safety. It can improve safety effectiveness and efficiency because it:

- promotes accountability and timely remedial actions in the management of safety, without Transport Canada prescribing one-size-fits-all requirements;

- enables companies to be more proactive by leveraging operational expertise to identify hazards, and assessing and reducing risks; and

- enables measures to be taken to reduce risks that may exceed regulatory standards.

SMS complements but does not replace the existing, robust railway safety regulatory and oversight framework. Companies must continue to meet Railway Safety Act requirements and associated regulations, rules and engineering standards. SMS can enhance safety by companies managing safety risks before Transport Canada intervenes, and before major railway safety issues emerge.

Purpose

The purpose of the Regulations is to establish the minimum requirements for a SMS that a company must develop and implement for the purpose of achieving the highest level of safety in its railway operations.

Style of the Regulation

Both the 2001 and 2015 Regulations differ from traditional prescriptive regulations because they focus primarily on management-based requirements. While the 2015 Regulations contain a series of clear rules of conduct and increased prescription, companies have the flexibility to adapt the system to their operations and find the most efficient and effective solution to continually improve safety.

The Regulations are a hybrid regulation with both prescriptive and management-based requirements.

Prescriptive regulations outline how to achieve a result. For example, a prescriptive regulation for perimeter fencing might require a company to install a fence 8 feet high. Not only would the requirement be clear to the company but evidence of its compliance would be obvious to the regulator. However, this type of regulation does not encourage, and may even restrict, innovative solutions.

Management-based regulations require regulated entities to develop and implement systems or processes designed to bring about a public policy objective. For example, a company must include a procedure for reporting a railway occurrence to company management. The regulation requires the company to develop and implement the procedure but allows for flexibility in determining the most appropriate procedure to implement based on company-specific factors.

Oversight of management-based regulations is more complex than prescriptive regulations, because inspectors determine compliance by assessing if the expected system (i.e. procedure or program) has been developed (exists) and was put in place (implemented). In some cases, Transport Canada will assess whether or not the system is effective in achieving a regulatory objective (i.e. a company must ensure that employees have certain knowledge).

Performance-based regulations focus mainly on the desired outcome or result, and set the standard to meet. In other words, the regulation defines the objective but not how to achieve it. For example, the gate arm of a warning system must descend to the resting horizontal position in 10 to 15 seconds.

Requirements

Companies must develop and implement a SMS that includes the following processes:

|

Applies to: |

Applies to: |

Applies to: |

|---|---|---|

|

Process for accountability |

Process for accountability |

- |

|

Process with respect to a safety policy |

Process with respect to a safety policy |

Process with respect to a safety policy |

|

Process for ensuring compliance with regulations, rules and other instruments |

Process for ensuring compliance with regulations, rules and other instruments |

Process for ensuring compliance with regulations, rules and other instruments |

|

Process for managing railway occurrences |

- |

- |

|

Process for identifying safety concerns |

Process for identifying safety concerns |

Process for identifying safety concerns |

|

Risk Assessment process |

Risk Assessment process |

Risk Assessment process |

|

Process for implementing and evaluating remedial action |

Process for implementing and evaluating remedial action |

Process for implementing and evaluating remedial action |

|

Process for establishing targets and developing initiatives |

Process for establishing targets and developing initiatives |

- |

|

Process for reporting contraventions and safety hazards |

- |

- |

|

Process for managing knowledge |

- |

- |

|

Process with respect to scheduling |

- |

- |

|

Process for continual improvement of the SMS |

Process for continual improvement of the SMS |

- |

The Regulations establish detailed requirements for each process, including actions companies must take and the procedures, plans and methods to develop and implement. Companies must also maintain an up-to-date index listing all their:

- processes;

- associated procedures, plans and methods; and

- positions in the company that are responsible for developing and implementing those processes, procedures, plans and methods.

Transports Canada's oversight philosophy

Transport Canada's SMS Railway Safety Inspectors will conduct two different types of oversight. They will:

- verify a company's compliance with the Regulations; and,

- assess a company's system to make sure all system components work together as intended, to meet the objective of the Regulations (i.e. continually improve the safety of the company's railway operations).

Transport Canada may apply a range of enforcement actions in the event of non-compliance with the Regulations (i.e. letter of non-compliance, administrative monetary penalty).

Where to find more information

Transport Canada Rail Safety personnel are available to provide support and advice. Railway companies and local railway companies may contact Transport Canada regional offices at the following numbers:

- Pacific Region: 604-666-0011

- Prairie and Northern Region: 204-983-5969

- Ontario Region: 416-973-9820

- Quebec Region: 514-283-5722

- Atlantic Region: 506-851-7040

For general information regarding Transport Canada's Rail Safety Program.

For general inquiries to headquarters:

Email: railsafety@tc.gc.ca

Phone: 613-998-2985

Toll-free: 1-844-897-RAIL (1-844-897-7245)

Fax: 613-990-7767

Overview of the Regulations

Scope of application

The Regulations establish the minimum SMS requirements a company must develop and implement for the purpose of achieving the highest level of safety in its railway operations. The scope of application is divided into three categories of companies within the Regulations with the list of processes to develop and implement established at the beginning of the corresponding Part or Division:

- Railway companies: section 5

- Local railway companies - main track: section 40

- Local railway companies - non-main track: section 68

Notes:

- When the Regulations use the term “Main track”, they mean a line of federal track on which the movement of railway equipment is authorized by a federal railway company. This definition is slightly different than that contained in the Canadian Railway Operating Rules (CROR).

- The definitions in the Regulations reflect current industry understanding and practices. The reference to “authorized” in the definition of “main track” is meant to distinguish between:

- yard limits, cautionary limits and train movements governed under CROR Rule 105; and

- the requirement that the operator, when entering a main track, has authority from the Rail Traffic Controller (signal, track occupancy permit or clearance).

- When the Regulations use the term “Non-main track”, they refer to a line of railway other than main track that includes sidings and rail yards.

- The two categories of local railway companies were designed to align compliance costs with underlying risks to ensure that costs disproportionate to risk were not imposed on small businesses.

A distinction between main track and non-main track was used to clarify the area of highest risk.

Development and implementation of processes

The detailed expectations for developing and implementing each required SMS process are outlined in the sections of the regulations that correspond to each process:

- Railway companies: Part 1, sections 4-38

- Local railway companies – main track: Part 2, Division 1, sections 39-66

- Local railway companies - non-main track: Part 2, Division 2, sections 67-86

The Regulations also include requirements that a company develop and implement:

- procedures that establish a step-by-step sequence of activities for dealing with certain matters;

- methods that are not necessarily a step-by-step sequence of activities but establish the manner in which certain evaluations, verifications or supervisory activities are to be carried out; and

- plans that establish the proposed time for carrying out certain activities with respect to the consultation and knowledge management requirements, and the proposed manner in which those activities are to be carried out.

When conducting oversight, Transport Canada will use the details in the applicable sections of the Regulations to determine if a company has developed and implemented each required process. For example, section 13 outlines the requirements for a process to identify and analyze safety concerns while section 14 prescribes the need for a procedure to analyze safety concerns.

Sample Template Procedure (Sample illustrates proposed format and what type of information would be included in each section of the procedure).

Company Name

- Title of the procedure

- Issue Date:

- Pages: 8 of 60

- Revision: 1

- Number: XXX

- Purpose

This section will define what the procedure is to communicate (i.e. define a method for reviewing and updating the list of regulatory instruments). - Scope

What/who does this procedure apply to with any reasonable exclusions specified (i.e. this procedure is applicable to the regulatory instruments list, as specified in the SMS Regulations, 2015, and excludes any and all instruments not under the jurisdiction of the Railway Safety Act). - Definitions and Abbreviations

Any definitions specific to this process should be listed (i.e. regulatory instrument; Railway Safety Act). - Positions Involved/Responsibilities

Identify positions, not departments, involved in this procedure to clarify responsibilities (i.e. Regulatory Affairs Director; Operations Managers). - Procedure

Provide a step-by-step sequence of activities that must be taken to achieve the objectives in the Purpose section. Ensure that it is clear who is doing what, when and why to ensure all those identified in the positions involved/responsibilities section know exactly what needs to be done and by when. Specify what equipment, if any, will be needed and cover sequential procedures and decision factors. Address the "what ifs" and safety considerations, and include any quality control points where a check will have to be done, including any approvals. - References

Provide any references to policies or other procedures that link to the process. - Records

Clearly identify what records will be generated from the procedure that will demonstrate compliance and clarify where they must be stored. - Records of revisions

List the revisions that were made to the procedure including the date and who approved

Index

Regulatory Reference

- Railway companies: section 6

- Local railway companies - main track: section 41

- Local railway companies - non-main track: section 69

All companies must keep an up-to-date index of all implemented processes referred to in sections 5, 40 or 68. For each process, the index must indicate the associated procedures, plans and methods (and date of their last revision) and the position in the company responsible for the development and implementation of those procedures, plans and methods.

- For railway companies and local railway companies operating on main track, where the accountable executive has chosen to designate a manager to develop and implement a process, the index must indicate that designated management position.

- For local railway companies operating on non-main track, the index must list the position in the railway company responsible for the process.

Sample illustrates format and all processes must be listed in company index

Sample Template: Index (Sample illustrates format and all processes must be listed in company index).

SMS Processes

- Responsible position

- Required procedures, plans and methods

- Responsible position

- Date of last revision

In writing

Regulatory Reference

- Railway companies: section 7

- Local railway companies - main track: section 42

- Local railway companies - non-main track: section 70

Companies must put every procedure, plan, and method required by the Regulations in writing and must indicate the date of its last revision. Companies may incorporate procedures, methods and/or plans into one document within or among processes provided they are in writing.

Records

Regulatory Reference

- Railway companies: sections 33-36

- Local railway companies - main track: sections 61-64

- Local Railway companies - non-main track: sections 81-84

In addition to the requirement to have procedures, plans, policies and methods in writing, railway companies and local railway companies must maintain certain records as evidence of the implementation of their SMS processes.

Specifically, railway companies must keep records of:

- the factors they took into account and the results and date of:

- the annual review of the safety policy;

- each analysis conducted using the process for identifying safety concerns; and

- each evaluation of the effectiveness of remedial actions implemented to address risks identified from a risk assessment;

- the date and subject matter of each required consultation, communication or collaboration with bargaining agents, employees or employee representative selected by employees, and the manner in which it was carried out;

- the documentation for each risk assessment conducted as required by the Regulations, including remedial action;

- the written description and explanation of initiatives to achieve annual safety targets;

- the annual report outlining the conclusions of the company's continual internal monitoring activities; and

- the audit plan, signed audit report and approved action plan.

Railway companies must keep these records for six years after the day they are created. The SMS records can be consolidated as long as regulatory requirements continue to be met.

Local railway companies operating on main track must keep records of:

- the factors they took into account and the results and date of:

- the annual review of its safety policy;

- each analysis conducted using the process for identifying safety concerns; and

- each evaluation of the effectiveness of remedial actions implemented to address risks identified from a risk assessment;

- the date and subject matter of each required communication with employees, and how it was carried out;

- the documentation for each risk assessment conducted as required by the Regulations;

- the written description and explanation of initiatives to achieve annual safety targets;

- the annual report outlining the conclusions of the company's continual internal monitoring activities; and

- the audit plan, signed audit report and approved action plan.

Local railway companies operating on main track must keep these records for six years after the day they are created.

Local railway companies operating on non-main track are required to keep records of:

- the factors they took into account and the results and date of:

- the annual review of its safety policy;

- each analysis conducted using the process for identifying safety concerns; and

- each evaluation of the effectiveness of the remedial actions implemented to address risks identified from a risk assessment;

- the date, subject matter and conduct for each required communication with employees; and

- the documentation for each risk assessment conducted as required by the Regulations.

Local railway companies operating on non-main track must keep these records for three years after the day they are created.

Filing and notification

Regulatory Reference

- Railway companies: sections 37-38

- Local railway companies - main track: sections 65-66

- Local railway companies - non-main track: sections 85-86

The Regulations outline documents the Minister may request from railway companies and local railway companies related to SMS. Companies must notify the Minister before making a change in operations that trigger a risk assessment (starting the transport of dangerous goods or changing the type of dangerous goods transported or changes that may affect the safety of the public or personnel, or the protection of property or the environment). At the request of the Minister, companies must file a risk assessment triggered by starting the transport of dangerous goods or dangerous goods different from those already transported, or by a change in operations.

Process by process

A process for accountability

Regulatory Reference

The requirement for this process applies to railway companies and to local railway companies operating on main track.

- Railway companies: section 8

- Local railway companies - main track: section 43

Regulatory Requirement

Designation of executive

8./43.(1) A railway company/local railway company [on main track] must designate an executive who is responsible for the operations and activities of the railway company/ local railway company [on main track] to be accountable for the extent to which the requirements of the safety management system are met, including its effectiveness in achieving the highest level of safety in its railway operations.

Notice to Minister

(2) The railway company/local railway company [on main track] must provide the Minister with the name of the accountable executive as soon as possible after he or she has been designated.

Declaration to the Minister

(3) The railway company/local railway company [on main track] must ensure that, within 30 days after the day on which it designates an accountable executive, the accountable executive provides the Minister with a signed declaration accepting accountability for the extent to which the requirements of the safety management system have been met.

Designation of managers

(4) The railway company/local railway company [on main track] may, in its safety management system, permit the accountable executive to designate one or more persons to develop and implement one or more of the processes required by this Part. A designated person must occupy a management position within the railway company that includes responsibilities relevant to the process or processes and the authority to make decisions with respect to that process or those processes.

Annual update

(5) If the accountable executive designates a person under subsection (4), the accountable executive must ensure that the person reports to him or her, on an annual basis, with respect to:

- any problems following the procedures or implementing the plans and methods, and the manner in which those problems have been or are being resolved or, if applicable, the reasons why they have not been or are not being resolved; and

- the effectiveness of the procedures, plans and methods in contributing to the improvement of the safety of the railway company's operations.

Guidance

A company must designate an executive who is:

- responsible for the operations and activities of the company; and

- accountable for the company meeting the regulatory requirements for SMS, including development, implementation and effectiveness.

The company must provide the Minister with the name of the accountable executive as soon as possible and, within 30 days, provide the Minister with a signed declaration from that person accepting accountability.

Note: Companies will provide the initial notification by email to RailSafety@tc.gc.ca or by mail to:

Transport Canada

Rail Safety Branch

Mailstop: ASR

427 Laurier Street West,

Ottawa, Ontario, K1A 0N5

While the accountable executive is ultimately responsible for ensuring the SMS requirements are met and implemented, they may designate an appropriate manager(s) to develop and implement one or more required processes. If the accountable executive chooses to designate a manager, two requirements apply:

- the accountable executive must ensure that the designated manager reports to him or her, on an annual basis, any problems following the procedures or implementing the plans and methods, and the effectiveness of the procedures, plans and methods. This ensures the accountable executive is aware of any issues related to the processes and the overall operation of the SMS; and

- the designated management position must appear in the company's index.

Linkages

The requirement for the designated manager to report to the accountable executive links to the process for continual improvement of the SMS, which requires companies to monitor the implementation of their SMS on a continual basis to verify that they are:

- following the required procedures; and

- implementing the required methods and plans.

If applicable, internal monitoring must include assessing:

- the cause of deficiencies in implementing the SMS;

- actions taken to remedy deficiencies; and

- the reasons why targets are not achieved.

For this reason, companies should consider the internal monitoring requirements when developing the process for accountability.

Sample Template: Declaration of Accountable Executive

- I, (full name of accountable executive), (title) of (company name) accept accountability for the extent to which (company name) meets the requirements of its safety management system.

- Signature:

- Date:

Note: Companies will provide the declaration by email to RailSafety@tc.gc.ca or by mail to:

Transport Canada

Rail Safety Branch

Mailstop: ASR

427 Laurier Street West,

Ottawa, Ontario, K1A 0N5

A process with respect to a safety policy

Regulatory Reference

The requirement for this process applies to all companies.

- Railway companies: section 9

- Local railway companies - main track: section 44

- Local railway companies - non-main track: section 71

Regulatory Requirement

Safety policy

9./44./71.(1) A company must include, in its safety management system, a written safety policy that reflects the company's commitment to promoting railway safety. The policy must be approved and signed by the accountable executive.

Annual review

(2) The company must ensure that its safety policy is reviewed annually.

Communication

(3) The company must communicate its safety policy, and any changes to the policy, to its employees.

Guidance

The written policy must be approved and signed by the accountable executive (or, in the case of local railway companies on non-main track, by an executive responsible for the company's operations and activities) and be reviewed annually. The purpose of an annual review is to ensure that the policy continues to reflect the company's safety philosophy in the context of current operations. Although the policy is a relatively high-level document, it may require revision to reflect:

- changes in the company's operations;

- changes to the company's corporate structure; or

- new safety-related programs.

A safety policy reflects a company's commitment to promoting railway safety. It encourages the development of a safety culture within the organization and outlines the company's safety philosophy, which guides related activities (i.e. objectives, policies, procedures, programs, targets and initiatives).

The company must communicate the policy and any changes to employees. Employee awareness of the company's safety policy helps to create a safety culture among employees and ensures they understand the rationale behind a company's safety activities.

Linkages

The company must keep records of the factors considered, results of the annual review, and date the review of the safety policy occurred. Companies must also keep a record of the date, subject matter and conduct of employee communication.

Railway companies and local railway companies on main track must keep records for six years while local railway companies on non-main track must keep records for three years.

Sample: Safety Policy

ABC Railway

ABC Railway, in partnership with its employees, will operate in a way that makes safety a priority in all our operations. ABC Senior Management Committee will, therefore, ensure that:

- all company decisions take into account the potential impact on the safety of our operations; and

- each employee will see safety as key to successfully fulfilling their duties.

- ABC Rail is committed to being a leader in safety and to continually improve safety through the following objectives:

- enhancing cooperation and collaboration with our employees;

- promoting a culture of safety vigilance and awareness;

- implementing effective processes and procedures that comply with all applicable legislative and regulatory requirements;

- reviewing all safety incidents and accidents and lessons learned;

- providing the leadership, organization, training and resources needed to maintain a healthy and safe working environment; and

- communicating and informing employees about safety issues.

Achieving the highest level of safety requires everyone in the company to fully understand their safety responsibilities and to commit to working towards a more proactive safety culture.

Signature and title of accountable executive

A process for ensuring compliance with regulations, rules and other instruments

Regulatory Reference

The requirement for this process applies to all companies.

- Railway companies: sections 10-11

- Local railway companies - main track: sections 45-46

- Local railway companies - non-main track: sections 72-73

Regulatory Requirement

List of instruments

10./45./72.(1) A company must include, in its safety management system, a list of the following instruments relating to railway safety:

- any regulations made under the Act that apply to the company and that are in force;

- any engineering standards approved by the Minister under section 7 of the Act or established by the Minister under subsection 19(7) of the Act that apply to the railway company and that are in effect (applies only to railway companies);

- any rules approved or established by the Minister under section 19 of the Act that apply to the company and that are in force;

- any exemptions granted under section 22 or 22.1 of the Act that apply to the company and that are in effect;

- any notices sent to the company under section 31 of the Act that contain an order and that are in effect; and

- any documents in effect by which the Minister has ordered the company to do or to not do something, including a ministerial order issued under section 32 of the Act and an emergency directive sent under section 33 of the Act.

Date and subject matter

(2) The list of instruments must include:

- in the case of an engineering standard or a rule, the date on which it was approved or established (applies only to railway companies); and

- in the case of an exemption, a notice, or a document referred to in paragraph (1)(f), the date and subject matter.

Update

(3) The company must keep the list of instruments up to date and must indicate the date of its last revision.

Procedure

11./46./73. A company must include, in its safety management system, a procedure for:

- reviewing and updating the list of instruments referred to in subsection 10(1)/45(1)/75(1); and

- verifying compliance with:

- the requirements of the regulations, engineering standards*, rules, and notices and documents containing an order, that are referred to in the list of instruments; and

- the terms of the exemptions referred to in the list of instruments.

*References to engineering standards apply only to railway companies.

Guidance

List of instruments (regulations, rules, notices, orders, exemptions, etc. relating to railway safety)

All companies must include in their SMS an up-to-date list of applicable regulatory instruments (i.e. regulations, rules, standards, orders, exemptions). The list must include all regulatory instruments approved by the Minister of Transport for a company (i.e. rules and engineering standards) and those a company is legally required to follow (i.e. regulations, other instruments). Companies should identify those instruments on their lists that do not pertain to their operations and provide an explanation.

The entire list must indicate the date of its last revision. The list must also include the date and subject matter for exemptions, notices and orders and orders. Moreover, the date when each rule and engineering standard was approved or established by the Minister must be indicated.

Information on new and amended regulations, rules and other instruments is available from the following sources:

- Transport Canada Safety Management Systems Industry Guide

https://tc.canada.ca/en/ministerial-orders-interim-orders-directives-directions-response-letters - The Railway Association of Canada (www.railcan.ca)

- Justice Canada (www.justice.gc.ca)

http://laws-lois.justice.gc.ca/eng/acts/R-4.2/

Sample List of Instruments (illustration only – actual list must contain all regulatory instruments applicable to them)

- Type of Instrument

- Regulations

- Rules

- Instrument Title

- Date and subject matter (where applicable)

- Date of Last Revision: DD/MM/YYYY

Procedure for reviewing and updating the list of instruments

Companies must include, in their SMS, a written procedure for reviewing and updating the list of instruments. The procedure ensures that the latest instruments are listed and being implemented.

The procedure for reviewing and updating the list of instruments should regularly consult official sources and actively respond to government or industry association announcements and advisories.

The procedure should provide a step-by-step sequence of how the company will:

- ensure, on a continual basis, that the list remains accurate;

- verify the accuracy of the list (Who will be responsible? How will they know? How often will they verify? Where will they obtain the information?);

- identify when an instrument is updated, compare and analyze the differences and the impact on operations (Upon notification of change and/or new release, who will be notified within the company? In what manner and how?);

- compare the requirements of the instruments to existing practices and written materials (verification of compliance procedures) to ensure that the criteria for compliance did not change (see Procedure for verifying compliance to the requirements set out by each item on the instruments list section below). If the criteria for compliance of the regulatory instrument did change, the company must make appropriate changes to existing practices and written materials;

- update the list of instruments if and when necessary;

- communicate changes to employees affected by the update; and

- assess the training needs and provide training, if and when required, to ensure continuous compliance.

Procedure for verifying compliance to the requirements set out by each item on the list of instruments

Companies must have a documented procedure on how each instrument will be monitored for compliance. This may be established in one procedure, which should specify how compliance for each regulatory instrument (step-by-step) will be achieved, or a procedure may be established for each item on the list of instruments. The procedure for verifying compliance must provide a step-by-step sequence of activities that will lead to a statement of compliance, and should clarify:

- who is doing it;

- when and how often the assessment will be done;

- the criteria for determining compliance (as per the regulatory instrument);

- action to be taken if non-compliance is detected;

- where the results of this assessment are maintained; and

- who will oversee this process to ensure that it is done as required (monitoring).

The company may keep a document that will ensure all regulatory instruments have associated procedures for verifying compliance developed, which will help them be easily located when they need to be updated. The following table could assist with this task.

Sample List of Instruments with reference to verification of compliance procedures

- Type of Instrument

- Regulations

- Rules

- Instrument Title

- Date and subject matter (where applicable)

- Verification of Compliance procedure and location (a step-by-step sequence of activities or a referenced document which contains a step-by-step-procedure

- Date of Last Revision: DD/MM/YYYY

A process for managing railway occurrences

Regulatory Reference

The requirement for this process applies only to railway companies at section 12.

Regulatory Requirement

Procedure

12.(1) A railway company must include, in its safety management system, a procedure for:

- reporting a railway occurrence to the railway company's management; and

- reviewing a railway occurrence.

Communication

(2) The railway company must communicate to its employees the procedure for reporting railway occurrences.

Guidance

A process for reporting and reviewing railway occurrences is an important part of the risk management process. Effective reporting allows a company to respond quickly to incidents. The required review of an occurrence may result in recommendations, mitigation measures and corrective action to improve safety.

The Regulations define a “railway occurrence” as an occurrence that is reportable under section 5 of the federal Transportation Safety Board Regulations (TSB Regulations). Since railway companies must already report occurrences to the Transportation Safety Board, their internal reporting and management systems should also address these occurrences.

As part of this process, companies must have a procedure for:

- reporting a railway occurrence to the railway company's management; and

- reviewing a railway occurrence.

Procedure for reporting

The procedure must, at a minimum, cover reporting “railway occurrences” and should outline:

- Who should be informed? – Each railway occurrence must be reported to the railway company's management, which may differ depending on the size and complexity of the organization. The procedure should also outline how to relay the information to the person responsible for the process for identifying safety concerns;

- How the information should be conveyed? - The procedure should include details on whether information can be reported by phone or by email, and if there is an official template to use; and

- What details should be included? - Consistency in reporting is especially important for reviewing railway occurrences and identifying safety concerns.

Procedure for reviewing a railway occurrence

Occurrences are one of the information points that railway companies must analyze as part of the process for identifying safety concerns. The objective of reviewing an occurrence should be to determine if immediate corrective action is needed and can be taken, or if an in-depth investigation should be conducted. Railway companies should not wait for the process for identifying safety concerns to highlight an issue for a risk assessment.

When developing a procedure for reviewing a railway occurrence, railway companies may consider developing a triage or escalation process, though some occurrences always warrant a higher level of analysis. For example, all occurrences resulting in serious injury or death should trigger an in-depth investigation.

Communicating to employees

Railway companies must communicate the procedure for reporting railway occurrences to employees. Awareness of the internal reporting procedure helps to ensure employees report occurrences consistently and appropriately, which contributes to an effective and timely response.

Linkages

Railway companies must keep a record of the date, subject matter and conduct of employee communication for six years.

All occurrence reports, along with related documentation, are sources of data for the company's process for identifying safety concerns.

Sample Procedure: Reviewing a Railway Occurrence

-

Step 1: Emergency Responders

Call 1-800-xxx-xxxx to report the incident as soon as it occurs. The railway company's call centre will dispatch emergency responders if necessary. Take necessary steps to assure personal safety. Report the incident to the Transportation Safety Board as soon as you can. -

Step 2: Incident Details

Record incident details on the railway company's Railway Occurrence Reporting Template. -

Step 3: Transportation Safety Board

Report the incident to the Transportation Safety Board by calling 1-800-567-6865. -

Step 4: Company Management

Report the incident to the regional manager.

Railway Occurrence Reporting Template (Single Train Occurrence)

Occurrence Details

- Date:

- Time of Occurrence:

- Train Number:

- Direction:

- Tonnage:

- Num. of loaded cars:

- Num. of empty cars:

- Length;

- Authorized Speed:

- Railway equipment operator:

- Track operator:

Occurrence location

- Province:

- Nearest City/Town:

- Track designation:

- Subdivision:

- Mileage:

Injury

- Num. of crew/employees members involved:

- Num. of passengers involved:

- Num. of other persons involved:

- Num. of fatalities:

- Num. of serious injuries:

Damage

- Num. of railway equipment damaged, or derailed:

- Unit Reporting Mark:

- Loaded (Y/N):

- Residue (Y/N):

- UN Number (if applicable):

If dangerous goods are released (otherwise, skip this section)

- Unit Reporting Mark:

- UN Number:

- Describe MOC:

- Describe condition of MOC:

- Initial quantity:

- Approx. quantity released:

Description

- Describe the local weather conditions at the time of occurrence and any climatic conditions such as snow, ice, wind, fog, dust and severe heat:

- Describe the occurrence and the extent of any resulting damage to the environment and to the rolling stock, railway and other property:

- Describe any action taken or planned to protect persons, property and the environment, including any evacuation as a result of the occurrence:

Contact Information

- Name:

- Title:

- Phone Number:

- Address:

Note: This template was developed for a single train occurrence. A railway company could develop a similar template for use in multiple train occurrences.

Sample Procedure: Reviewing a Railway Occurrence

Step 1: Schedule a Meeting

The railway company schedules a meeting within one month of the occurrence. Meeting participants could include experts related to the occurrence and affected employees.

Step 2: Review Railway Occurrence

The review team compiles all pertinent information before the meeting, including the Railway Occurrence Report and information regarding similar events and best practices.

Step 3: Root Cause

During the meeting, the review team analyzes the documentation and works to establish the root cause of the railway occurrence.

Step 4: Solution

The review team determines if current procedures and/or training need to change to prevent a repeat of the occurrence.

Step 5: Report and Implement

The review team documents their findings and recommendations, and the railway company implements the corrective actions, if necessary.

A process for identifying safety concerns

Regulatory Reference

The requirement for this process applies to all companies.

- Railway companies: sections 13-14

- Local Railway companies - main track: sections 47-48

- Local Railway companies - non-main track: sections 74-75

Regulatory Requirement

Analyses

13./47./74. A company must, on a continual basis, conduct analyses of its railway operations to identify safety concerns, including any trends, any emerging trends or any repetitive situations. The analyses must, at a minimum, be based on:

- any reports of railway occurrences/accidents;

- any internal documentation relating to railway occurrences/accidents;

- any reports of injuries;

- the results of any inspections conducted by the company or by a railway safety inspector;

- any reports of contraventions or safety hazards that are received by the company from its employees;

- any complaints relating to safety that are received by the company;

- any data [that is accessible to local railway companies] from safety monitoring technologies;

- the conclusions of the annual report referred to in subsection 29(3)/57(3) (not applicable to local railway companies on non-main track); and

- the findings of any audit reports.

Procedure

14./48./75. A company must include, in its safety management system, a procedure for conducting the analyses referred to in section 13/47/74.

Guidance

The process to identify safety concerns is a cornerstone SMS process aimed at improving the safety of railway operations. This process requires companies to have a procedure to regularly analyze safety data and feed any identified concerns into the risk assessment process.

Conducting analysis

All companies must, on a continual basis, conduct analyses of their railway operations to identify safety concerns, including any trends or emerging trends, or any repetitive situations. The word “continual” indicates that companies should conduct these analyses at a frequency that allows them to identify a trend as soon as possible. If new data is not produced, the company would be required to perform an analysis when new data becomes available.

The Regulations set out the information that companies must, at a minimum, consider as part of these analyses, which includes:

- reports of railway occurrences;

- reports of contraventions or safety hazards;

- results of any inspections; and

- the findings of any audit reports.

Note: The required information to consider varies for railway companies, local railway companies on main track, and local railway companies on non-main track.

Procedure for analysis

Companies must have a procedure for conducting the analysis of safety data. The procedure should ensure that the regulatory requirements are met by asking:

- How will the company analyze information frequently to identify safety concerns, including trends or emerging trends?

- How will the company collect and analyze all information from the required data points?

- What are the indicators of a trend? What is the threshold or definition of a “safety concern”?, and

- Who is sent the report of identified safety concerns to trigger the risk assessment?

Linkages

The company must keep records of the factors considered and the results and date of each analysis for six years (three years for local railway companies operating on non-main track).

The process for identifying safety concerns is closely linked to other SMS processes such as: the process for managing railway occurrences; the process for reporting contraventions and safety hazards; the risk assessment process; the process for establishing targets and developing initiatives; and, the process for continual improvement.

When a company identifies a safety concern, it must conduct a risk assessment that meets the requirements of the risk assessment process.

A risk assessment process

Regulatory Reference

The requirement for this process applies to all companies.

- Railway companies: sections 15-17

- Local railway companies - main track: sections 49-51

- Local railway companies - non-main track: sections 76-78

Regulatory Requirement

Risk assessment

15./49./76. (1) A company must conduct a risk assessment in the following circumstances:

- when it identifies a safety concern in its railway operations as a result of the analyses conducted under section 13/47/74;

- when it proposes to begin transporting dangerous goods, or to begin transporting dangerous goods different from those it already transports; or

- when a proposed change to its railway operations, including a change set out below, may affect the safety of the public or personnel or the protection of property or the environment:

- the introduction or elimination of a technology, or a change to a technology,

- the addition or elimination of a railway work, or a change to a railway work (applies only to railway companies),

- an increase in the volume of dangerous goods it transports,

- a change to the route on which dangerous goods are transported, or

- a change affecting personnel, including an increase or decrease in the number of employees or a change in their responsibilities or duties.

Components

(2) The risk assessment must:

- describe the circumstances that triggered the requirement to conduct the risk assessment;

- identify and describe the risks associated with those circumstances;

- identify the factors taken into account in the risk assessment, including the persons who may be affected and whether property or the environment is affected;

- indicate, for each risk, the likelihood that the risk will occur and the severity of its consequences;

- identify the risks that require remedial action; and

- identify the remedial action for each of those risks.

Consultation (only applies to railway companies)

16.(1) When identifying the risks that require remedial action and the remedial action to be implemented, a railway company must consult with the bargaining agents representing the employees of the railway company who are affected by any of those risks or, if there is no bargaining agent, with:

- the employees of the railway company who are affected by any of those risks; or

- a representative selected by the employees of the railway company.

Communication

16.(2)/50./77. The company must communicate the risks identified as requiring remedial action, and the remedial action to be implemented, to the employees of the company who are affected by any of the circumstances referred to in subsection 15(1)/49(1)/76(1).

Procedure, plan and method

17./51./78. A company must include, in its safety management system:

- a procedure for identifying the risks that require remedial action, taking into account, for each risk, the likelihood that the risk will occur and the severity of its consequences;

- a plan for the consultation referred to in subsection 16(1) (applies only to railway companies); and

- a method for evaluating the level of risk, taking into account the likelihood that a risk will occur and the severity of its consequences.

Guidance

A risk assessment is a systematic use of information to comprehend the nature, sources, causes, and chance of injury or loss measured by the likelihood that they will occur, and the severity of consequences on persons, property, the environment or other things of value to determine the level of risk. It is a proactive approach to identify the risks associated with safety concerns, potential changes in operations, and obstacles that may impede companies from achieving their objectives.

The level of detail in a risk assessment will depend on the risk, purpose of the analysis, and information and resources available.

Risk is the likelihood that an incident will happen, and potential severity of the consequences. The objective for companies conducting risk assessments before making operational changes is to analyze:

- what could happen;

- how serious it could be; and

- what could be done to prevent or reduce those risks.

Risk assessments should reduce costly and/or dangerous occurrences by compelling railway companies and local railway companies to examine the risks associated with:

- safety concerns identified through data analysis; and

- a change in operations that could impact public or employee safety, protection of property or the environment, or a change in operations related to dangerous goods (starting to transport dangerous goods or changing the type of dangerous goods transported).

A risk assessment for identified safety concerns that stem from continual analysis in section 13/47/74 is intended to address the likelihood for the safety concern to occur or reoccur, and how the trend and its associated risks can be eliminated.

Companies must notify the Minister before making a change in operations or before starting to transport dangerous goods or changing the type of dangerous goods transported. The Minister may require companies to submit documentation related to risk assessments conducted for these situations. Companies should send their notification to RailSafety@tc.gc.ca.

Companies may uncover instances of regulatory non-compliance when conducting risk assessments, which should be corrected as soon as possible.

The Regulations set out the minimum circumstances for when a company must conduct a risk assessment (triggering circumstances) but they are not exhaustive. Companies are encouraged to conduct a risk assessment whenever necessary.

The emphasis on a change in operations helps determine the potential impact on the safety of the public, employees or the protection of property or the environment. If a risk assessment was not undertaken, the company may be asked to demonstrate the factors considered that led to a conclusion that the operational change would not affect the safety of the public or personnel, property or the environment.

Components of a risk assessment

The Regulations set out the components that companies must include when conducting a risk assessment. They must:

- identify and describe the circumstances that triggered the risk assessment;

- identify and describe the risks associated with those circumstances;

- identify factors taken into account, including the potential impact on persons, property, and the environment;

- indicate the likelihood that the risk will occur and the severity of the consequences if it were to occur; and

- identify the risks that require remedial action and corresponding remedial action(s).

Consultation and communication

When railway companies are identifying risks that require remedial action and potential actions, they must consult with employees affected by those risks and have a plan for consulting employees. Consultation is more than communicating the results of the process and should involve management accounting for input provided by the bargaining agents, employees, or their representatives before making a decision.

Companies must also communicate the identified risks requiring remedial action, and the remedial action to be taken, to employees affected by any of the triggering circumstances.

Procedures

The Regulations set out the minimum components of a risk assessment and require companies to have:

- a procedure for identifying the risks that require remedial action, taking into account the likelihood the risk will occur and severity of the potential consequences;

- a plan for consulting employees (only applies to railway companies); and

- a method for evaluating the level of risk, including the likelihood and severity.

These requirements do not need to be divided into distinct documents provided there are clear, written steps that cover the required components and detail how to assess risk, consult with employees, and identify risks requiring remedial action.

Linkages

The results of the risk assessment process feed into the process for implementing and evaluating remedial action.

As part of the record-keeping requirements, companies must keep documentation related to each risk assessment conducted, including communications and consultations with employees for six years (three years for local railway companies operating on non-main track).

Summary

- Triggering circumstances

- Safety concern

- Change in operations

- Conduct of a Risk Assessment

- Describe the circumstances that triggered the process

- Identify and describe the risks

- Identify the factors to consider

- Identify the likelihood and severity

- Identify risks that require remedial actions

- Identify remedial actions

- Consultation (only for railway companies) and communication

- Keep records – six years (railway companies and local railway companies on main tracks), three years (local railway companies on non-main track)

- Consultation (only for railway companies) and communication

- Implement remedial action

- Evaluate the effectiveness of remedial action

- Consultation (only for Railway Companies)

- Keep records – six years (railway companies and local railway companies on main tracks ), three years (Local railway companies on non-main track)

- Consultation (only for Railway Companies)

- Notify the Minister of a change in operations

- Submit risk assessment documentation on Minister's request

Guidance

The following example is for guidance purposes only. Companies have the option of using any risk assessment process available as long as it meets the minimum regulatory requirements. The method to evaluate risks should contain steps similar to steps 1-5, and must address step 3. A risk assess process must include employee consultation and/or communication as required by the Regulations.

Step 1: Triggering circumstances and setting the context

A risk assessment should be conducted when one of the triggering circumstances exists.

Sample Template

Step 1 – Triggering Circumstances and Setting the Context

- The company has identified a safety concern in its railway operations. (s. 13/s.15(1)(a)/s.49(1)(a)/s. 76(1)(a))

- The company is proposing to begin transporting dangerous goods. (s. 15(1)(b)/s. 49(1)(b)/s. 76(1)(b))

- The company is proposing to transport dangerous goods different from those it already transports. (s.15(1)(b)/ s.49(1)(b)/s.76(1)(b))

- The company is proposing to make changes to its railway operations that may affect the safety of the public or personnel or the protection of property or the environment (s. 15(1)(c)/s. 49(1)(c)/s. 76(1)(c). (Select all that apply below)):

- Introduction, elimination or change of a technology.

- Addition, elimination or change to a railway work (applies only to railway companies).

- Increase in volume of dangerous goods transported.

- Change to the route on which dangerous goods are transported.

- Change affecting personnel.

- Other change (specify).

If it is a change in operation, indicate the date of the proposed change.

Description of Circumstances that Triggered the Risk Assessment (s. 15(2)(a) / 49(2)(a))

The company will gather the necessary information and experts, which should include:

- Information about the circumstances that triggered the risk assessment;

- Appropriate personnel, including subject matter experts, management and a representative of the employees who are or would be affected by the risk;

- Information about the safety requirements (rules, regulations, etc.) and safety controls the company has in place that relate to the triggering circumstances;

- Information from similar circumstances (i.e. a similar safety concern at another company that resulted in a TSB report, other industry information, or best practices relevant to the situation); and

- Information about the operational environment. The company should collect enough information to be able to consider the potential impact on people, the environment, and/or property.

Identify Internal and External stakeholders:

A stakeholder could be defined as any individual, group, or organization able to affect, be affected by, or believe it might be affected by a decision or activity.

A thorough stakeholder inventory will identify stakeholders' needs, issues and concerns. An understanding of their motivations is critical to the successful resolution of an issue. A stakeholder inventory is an important starting point for developing communication and consultation plans and strategies.

Stakeholders sample template (s. 15(2)(c)/s. 49(2)(c)/s. 76(2)(c))

Who can affect or be affected by this activity?

- Internal

- Internal stakeholders are employees, shareholders, contactors, executives, etc. within the company

- External

- External stakeholders are persons or groups from the rail industry, private corporations, municipalities, road authorities, citizens from the general public, etc.

Note: Step 1 should help the company meet the requirement of describing the circumstances that triggered the requirement to conduct the risk assessment (s. 15(2)(a), 15(2)(c)/s. 49(2)(a), 49(2)(c) /s. 76(2)(a), 76(2)(c))

Step 2: Identifying risks

After the railway company has described the triggering circumstances and understands the context, it should identify what risks could occur if the safety concern were to persist or if the operational change were to proceed. In other words, the company should ask: what could happen; how could it happen; and, what's the most serious potential outcome? At this stage, no assessment is underway but potential risks are identified.

Sample template – Identifying risks (s. 15(2)(b)/s. 49(2)(b)/s. 76(2)(b))

What are the risks associated with the circumstances?

- Possible Risk – What can happen?

- Brief Description – How can it happen?

Note: Step 2 should help the company meet the requirement of:

- identifying and describing the risks associated with those circumstances (s. 15(2)(b) /s. 49(2)(b) /s. 76(2)(b))

Step 3: Risk analysis/assessment and identification of risks requiring remedial action

In this step, the railway company takes each identified risk and assesses the likelihood that it would occur and the severity of the potential consequences.

The company should use an assessment scale for the likelihood and severity of consequences, and must document the risks assessed and factors it considered, including who may be affected and whether property and/or the environment could be affected.

A worksheet or excel spreadsheet could help with this step.

Likelihood

Likelihood is an estimate of the chance of an incident happening. It can be described using general terms or mathematical variables, such as a probability or frequency over time. Likelihood may consider factors such as:

- history - Has it happened before in the rail industry? To this company? How often?

- safety measures in place - What measures (legal obligations or voluntary actions) are in place that could prevent this risk?

Companies should develop a scale to help them consistently assess likelihood. The measurement of likelihood can be a number or word as demonstrated in the sample scale below. Companies can choose the level of granularity for the scale but many methods choose five levels.

Sample Likelihood Scale

Likelihood category

- 1 = Improbable/Very low

- 2 = Remote/Low

- 3 = Occasional/medium

- 4 = Probably/High

- 5 = Frequent/Very high

Descriptors

- 1 = Has never happened before/would be expected to happen only once every 50 years/safety controls already in place should prevent this occurrence

- 2 = Has happened somewhere before/would be expected to happen only once every 20 years/ safety controls integral to preventing this risk are in place

- 3 = Can happen/could be expected to happen once in 2 years/safety controls in place lack redundancy, contain limitations

- 4 = Has happened to the company before/could happen once a year/safety controls in place contain significant and known limitations to prevent this risk

- 5 = Happens often/could happen more than once a year/there are no safety controls in place that provide a realistic possibility of preventing this risk

Severity of Consequences

The assessment of consequences considers a broad cross-section of the most likely impacts if the identified risk occurs. During this step, companies may wish to review the factors they must consider during the risk assessment:

- Who may be affected?

- Could property be affected?, and

- Could the environment be affected?

Companies should determine the degree of impacts by primarily assessing those human, environmental and property consequences directly linked to the risk occurring and its immediate aftermath. However, experts should use sound judgment and account for cases where impacts extend over long periods when they are of a very serious nature (i.e. environmental factors).

Companies should:

- adopt a reasonable worst-case approach;

- base their assessments on expert judgment; and

- support their decisions with data wherever possible (i.e. previous incidents).

Sample Severity of Consequences Scale

Likelihood category

- 1 = Minimal

- 2 = Marginal

- 3 = Serious

- 4 = Critical

- 5 = Catastrophic

Descriptors

- 1 = First aid or minor medical treatment/little to no environmental damage/$X property damage (could be in description or dollar figures)

- 2 = Serious injury, occupational illness, lost workday/minor leak that could be contained/$X property damage

- 3 = Disabling injury, multiple injuries/environmental damage that requires response and site remediation/$X property damage

- 4 = Permanent partial disability, temporary total disability/serious environmental damage requiring site remediation and could cause long term (or large scale) environmental impacts/$X property damage

- 5 = Death or permanent disability/severe, wide scope of impact, with long term serious environmental harm/$X property damage

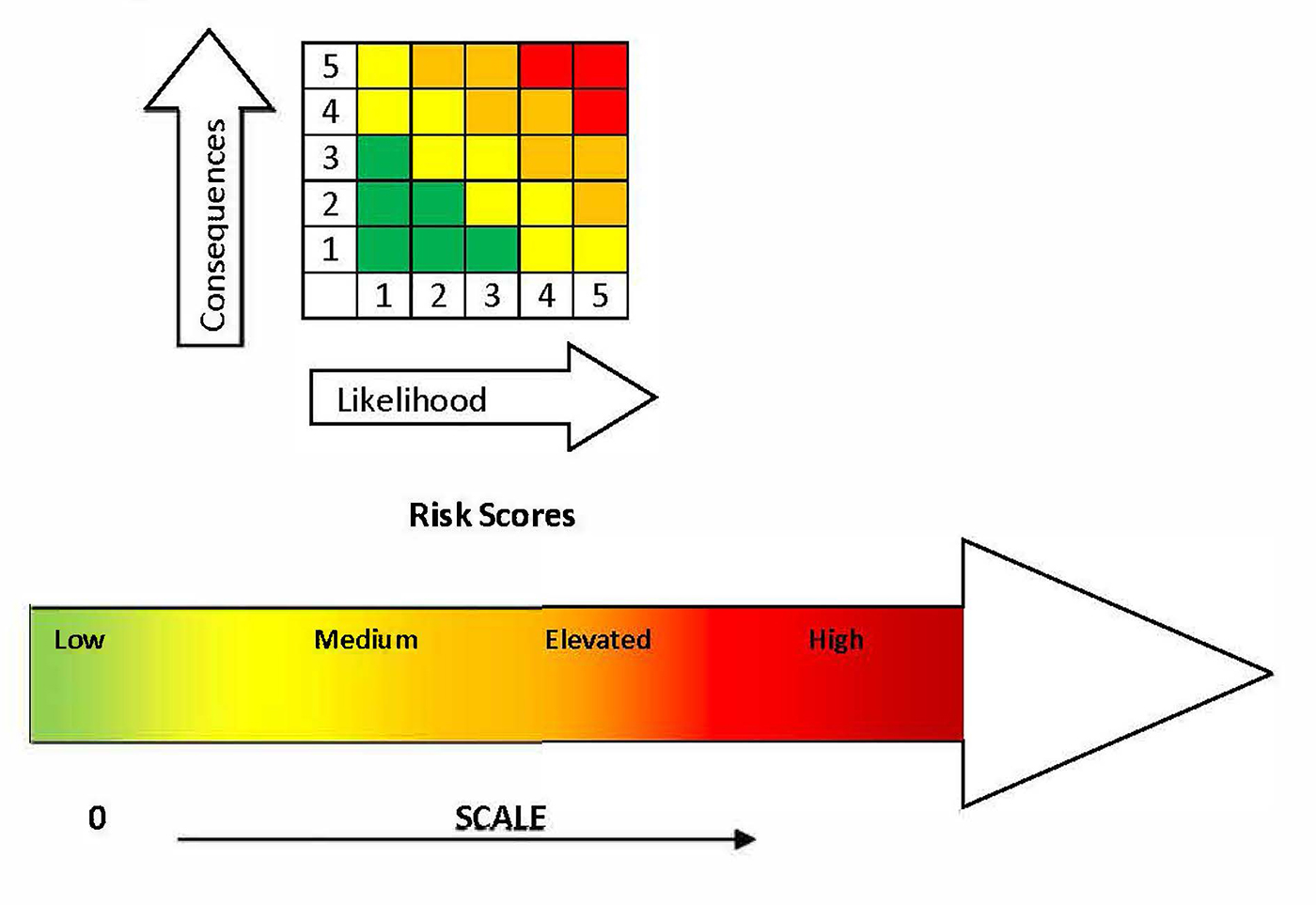

Sample Risk Level Scale

Companies must identify risks that require remedial action, and have a procedure for doing so:

- A common way is to document a risk tolerance using numeric values, colours or verbal descriptions for the likelihood and severity of consequences, and plotting the likelihood and severity of consequences on a risk level matrix. This approach helps to visually determine which risks need remedial actions and the priority for implementing remedial actions.

Companies may want to use:

- three distinct scales to clearly demonstrate that they considered human harm, environmental damage and property damage, and combine or average the level; or

- a combined scale with the factors considered documented in a worksheet.

Sample Heat Map

A heat map used to determine the risk tolerance based on the severity of consequences and the likelihood of an incident happening.

Sample Template

List each identified risk “possible risk” in step 2 for analysis in the table below. Assess the risks as per the company's method for determining level of risk. S. 17(a)/51(a)/78(a). Notes: For the assessment of property damage, companies need to add the dollar values or description for each level of the consequences scale.

Risk to Analyze

- Consequences

- Factors: describe the factors taken into account: people, property and environment s.15(2)(c)/49(2)(c)/76(2)(c)

- Likelihood s. 15(2)(d)/49(2)(d)/76(2)(d)

- Risk Level

- Remedial Action Required? Yes/No s. 15(2)(e)/49(2)(e)/76(2)(e), s. 16(1), s. 16(2) /50/77

Note: Step 3 should help the company meet the requirements of:

- identifying the factors taken into account in the risk assessment, including who may be affected and whether property or the environment is affected (s. 15(2)(c) / 49(2)(c) / 76(2)(c));

- indicating, for each risk, the likelihood that the risk will occur and the severity of its consequences (s. 15(2)(d) / 49(2)(d) / 76(2)(d), s. 15(2)(d) / 49(2)(d) / 76(2)(d));

- identifying the risks that require remedial actions (s.15(2)(e) / 49(2)(e) / 76(2)(e));

- a procedure for identifying the risks that require remedial action taking into account the likelihood that the risks will occur and the severity of their consequences (s.17(a) / 51(a) / 78(a)); and

- a method for evaluating the level of risk, taking into account the likelihood that a risk will occur and the severity of its consequences (s.17(c) / 51(b) / 78(b)).

Step 4: Identification of the remedial action(s)

Once the company has determined the risks requiring remedial action, it must identify the remedial action to address those risks. Since risk is a combination of likelihood and severity of consequences, the company could either reduce the likelihood of the risk occurring or reduce the adverse consequences if the risk occurs.

Notes:

- Companies must communicate and/or consult with employees as required in the Regulations.

- Companies may wish to keep a list of common risks and best practices for reducing risks but should not rely solely on that list. Companies should also explore new options or innovative solutions where circumstances warrant.

Sample Template – Identification of the remedial action(s) s. 15(2)(f)/49(2)(f)/76(2)(f), s. 20(a)/51(a)/78(a)

List the risks found that require remedial action from step 3 in the table below.

- Risk

- Remedial Action(s)

Best practice: Remedial action can also introduce residual risks that need to be assessed, treated, monitored and reviewed. Residual risks should be incorporated into the same treatment plan as the original risk and not treated as a new risk.

Questions to ask:

- Are there any risks remaining that are not addressed/accepted (residual) or created (new) after selecting the remedial action?

- If so, include a remedial action to address these risks into your implementation plan.

- Are there any risks present during the time between the identification of a risk and implementation of remedial action, which need to be addressed (transitional)?

- If so, create and implement a transitional risk action plan.

Note: Step 4 should help the company meet the requirements of:

- Identifying the remedial action for the risks identified as requiring remedial action (s. (15(2)(f) / 49(2)(f) / 76(2)(f)).

Sample Template – Risk assessment

Process and Form Information Section

Railway Safety Management System Regulations, 2015 – Risk Assessment Process

Notification of Change in Operations form [PDF 628 KB]

s (#) (letter) - refers to the Section in the Railway Safety Management System Regulations

This example is for guidance purposes only and use of the template is not mandatory.

Add rows to any section as required.

- Company Name:

- Date of Risk Assessment:

Step 1 – Triggering Circumstances and Setting the Context

- The company has identified a safety concern in its railway operations. (s. 13/s.15(1)(a)/s.49(1)(a)/s. 76(1)(a))

- The company is proposing to begin transporting dangerous goods. (s. 15(1)(b)/s. 49(1)(b)/s. 76(1)(b))

- The company is proposing to transport dangerous goods different from those it already transports. (s.15(1)(b)/ s.49(1)(b)/s.76(1)(b))

- The company is proposing to make changes to its railway operations that may affect the safety of the public or personnel or the protection of property or the environment (s. 15(1)(c)/s. 49(1)(c)/s. 76(1)(c). (Select all that apply below)):

- Introduction, elimination or change of a technology.

- Addition, elimination or change to a railway work (applies only to railway companies).

- Increase in volume of dangerous goods transported.

- Change to the route on which dangerous goods are transported.

- Change affecting personnel.

- Other change (specify).

If it is a change in operation, indicate the date of the proposed change.

Description of Circumstances that Triggered the Risk Assessment (s. 15(2)(a) / 49(2)(a))

Stakeholders s. 15(2)(c)/49(2)(c)/76(2)(c) - Who can affect or be affected by this activity?

- Internal

- External

Step 2 - Identifying risks (s. 15(2)(b)/s. 49(2)(b)/s. 76(2)(b)) - What are the risks associated with the circumstances?

- Possible Risk – What can happen?

- Brief Description – How can it happen?

Step 3 – Risk Analysis/Assessment

- Likelihood Scale s. 17(c) / 51(b) /78(b)

- Likelihood category

- Descriptors

- Severity Scale s. 17(c) / 51(b) /78(b)

- Severity of consequences

- Descriptors

- Risk Level Matrix (document the risk tolerance)

- Risk level

- Tolerance descriptors

List each identified risk “possible risk” in step 2 for analysis in the table below. Assess the risks as per the company's method for determining level of risk. S. 17(a)/51(a)/78(a). Notes: For the assessment of property damage, companies need to add the dollar values or description for each level of the consequences scale.

Risk to Analyze

- Consequences

- Factors: describe the factors taken into account: people, property and environment s.15(2)(c)/49(2)(c)/76(2)(c)

- Likelihood s. 15(2)(d)/49(2)(d)/76(2)(d)

- Risk Level

- Remedial Action Required? Yes/No s. 15(2)(e)/49(2)(e)/76(2)(e), s. 16(1), s. 16(2) /50/77

Step 4 - Identification of the remedial action(s) s. 15(2)(f)/49(2)(f)/76(2)(f), s. 20(a)/51(a)/78(a)

List the risks found that require remedial action from step 3 in the table below.

- Risk

- Remedial Action(s)

Step 5 – Risk Treatment - Implementation and Evaluation

- Implement remedial action (s. 18(1) / 52(1) /79(1), s 20(b) / 53(b)/90(b)

- What needs to be done?

- By whom?

- Name of person responsible for the implementation of the remedial action

- When

- Date to be implemented

- Effective Measures s. 20(b) / 53(b) /80(b)

- When and how will the effectiveness of remedial measures be determined, and name of person responsible for verification of effectiveness?

Step 6 – Monitor Impact/Follow-up

- Were the remedial actions completed as identified in Step 4? If not, why?

- Describe how the remedial actions were or were not effective (S 18(2)/52(2)/79(2), s 19)

- Is further action or assessment required? If yes, what is required, when will it be done, how and by whom?

A process for implementing and evaluating remedial action

Regulatory Reference

The requirement for this process applies to all companies.

- Railway companies: sections 18-20

- Local railway companies - main track: sections 52-53

- Local railway companies - non-main track: sections 79-80

Regulatory Requirement

Remedial action — implementation

18./52./79.(1) A company must implement remedial action with respect to the risks that it has identified in its risk assessment as requiring remedial action.

Remedial action — evaluation

(2) The company must evaluate the effectiveness of the remedial action in reducing or eliminating the risks.

Consultation (applies only to railway companies)

19. When evaluating the effectiveness of remedial action with respect to a risk, a railway company must consult with the bargaining agents representing the employees of the railway company who are affected by the risk or, if there is no bargaining agent, with:

- the employees of the railway company who are affected by the risk; or

- a representative selected by the employees of the railway company.

Procedures and plan

20./53./80. A company must include, in its safety management system,

- a procedure for selecting the remedial action to be implemented;

- a procedure for implementing the remedial action and evaluating its effectiveness; and

- a plan for the consultation referred to in section 19 (applies only to railway companies).

Guidance

Step 5 Implementation (continued from risk assessment process)

As part of the risk assessment process, companies must identify risks that require remedial action and actions to address each risk. Companies must also evaluate the effectiveness of each action.

By assessing the risk and taking the necessary remedial action before making changes to their operations, companies can proactively assess and prevent potentially dangerous situations.

Step 5 – Sample Template - Implementation and Evaluation

- Implement remedial action (s. 18(1) / 52(1) /79(1), s 20(b) / 53(b)/90(b)

- What needs to be done?

- By whom?

- Name of person responsible for the implementation of the remedial action

- When

- Date to be implemented

- Effective Measures s. 20(b) / 53(b) /80(b)

- When and how will the effectiveness of remedial measures be determined, and name of person responsible for verification of effectiveness?

Note: Step 5 should help the company meet the requirements of:

- implementing remedial action with respect to the risks that it has identified in its risk assessment as requiring remedial action (s.18 (1) / 52(1) / 79(1)); and

- including a procedure for implementing the remedial action and evaluating its effectiveness (s.20(b) / 53(b) / 80(b)).

Step 6: Monitor impact/follow-up

A company must keep a record of the factors considered and results of each evaluation of effectiveness, including the date the evaluation took place.

Step 6 – Same Template - Monitor Impact/Follow-up

- Were the remedial actions completed as identified in Step 4? If not, why?

- Describe how the remedial actions were or were not effective (S 18(2)/52(2)/79(2), s 19)

- Is further action or assessment required? If yes, what is required, when will it be done, how and by whom?

Note: Step 6 should help the company meet the requirements of:

- evaluating the effectiveness of the remedial action in mitigating or eliminating the risks (s.18(2)/52(2)/ 79(2)).

Consultation

When evaluating the effectiveness of the remedial action, railway companies must:

- consult with employees affected by the risk (or their bargaining agents or representatives); and

- have a plan for consultation.

Consultation should involve management seeking and accounting for employee views before making a decision, not simply communicating the results of the process.

A plan for consulting employees when evaluating effectiveness

Railway companies must have a plan for consulting employees affected by the risk (or their bargaining agent or representative) when evaluating the effectiveness of remedial action. The company could incorporate this plan into the procedures below provided it is a clearly documented how employees are included in the evaluation.

Railway companies must also keep a record of the date, subject matter and conduct of the consultation for six years.

Procedure for selecting the remedial action

This procedure and the procedure for implementing the remedial action and evaluating its effectiveness are closely linked to the risk assessment process. The risk assessment process requires a company to have a procedure for identifying the risks that require remedial action and to identify the remedial action to take. The procedure for selecting remedial action should outline the steps to:

- engage appropriate personnel and subject matter experts;

- identify multiple options and best practices;