D. Track structure

Scope: This subpart prescribes minimum requirements for ballast, crosstie, track assembly fittings, and the physical condition of rails.

I. Ballast: General

Unless it is otherwise structurally supported, all track must be supported by material which will:

- transmit and distribute the load of the track and railroad rolling equipment to the subgrade;

- restrain the track laterally, longitudinally, and vertically under dynamic loads imposed by railway rolling equipment and thermal stress exerted by the rails;

- provide adequate drainage for the track; and

- maintain proper track cross-level, surface, and alignment.

II. Crossties

- Crossties shall be made of a material to which rail can be securely fastened.

- Each 39 foot segment of track shall have:

- a sufficient number of crossties which in combination provide effective support that will:

- hold gauge within the limits prescribed in C. 2.3;

- maintain surface within the limits prescribed in C. 6; and

- maintain alignment within the limits prescribed in C. 3.

- the minimum number and type of crossties specified in paragraph(c) of this section effectively distributed to support the entire segment; and

- At least one crosstie of the type specified in paragraph (c) of this section that is located at a joint location as specified in paragraph(d) of this section.

- a sufficient number of crossties which in combination provide effective support that will:

- Each 39 foot segment of track shall have the minimum number of crossties as indicated in the following table:

Track Class Tangent track, turnouts and curves Tangent track and curved track less than or equal to 2 degrees Turnouts and curved track greater than 2 degrees Class 1 5 6 Class 2 8 9 Class 3 8 10 Class 4 and 5 12 14

c.1 Notwithstanding (c) above, until May 31, 2024, for crossties other than concrete, each 39 foot segment of:- Class 1 track shall have five crossties;

- Class 2 track shall have eight crossties;

- Class 3 track shall have 10 crossties; and

- Class 4 and 5 track shall have 12 crossties.

- Crossties, other than concrete, counted to satisfy the requirements of item (c) of this section shall not be:

- broken through;

- split or otherwise impaired to the extent the crossties will allow the ballast to work through, or will not hold spikes or rail fasteners;

- so deteriorated that the tie plate or base of rail can move laterally more than 1/2 inch relative to the crossties; or

- cut by the tie plate through more than 40 percent of a tie’s thickness.

- Concrete crossties counted to satisfy the requirements of item (c) of this section shall not be:

- Broken through or deteriorated to the extent that the stressing tendon material is visible;

- So deteriorated or broken off in the vicinity of the shoulder or insert so that the fastener assembly can either pull out or move laterally more than 3/8 inch relative to the crosstie;

- So deteriorated that the base of either rail can move laterally more than 3/8 inch relative to the crosstie on curves of 2 degrees or greater; or can move laterally more than 1/2 inch relative to the crosstie on tangent track or curves of less than 2 degrees;

- So deteriorated or abraded at any point under the rail seat to a depth of 1/2 inch or more;

- So deteriorated such that the crosstie's fastening or anchoring system, including rail anchors is unable to maintain longitudinal rail restraint, or maintain rail hold down, or maintain gauge due to insufficient fastener toeload; or

- Configured with less than two fasteners on the same rail except where fastener placement impedes insulated joints from performing as intended, the fastener may be modified or removed, provided that the crosstie supports the rail.

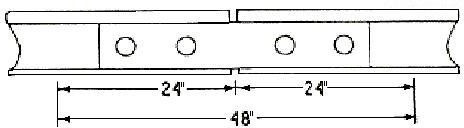

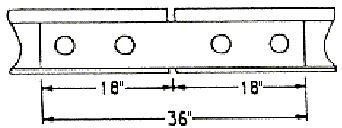

- Class 1 and Class 2 track shall have one crosstie whose centerline is within 24 inches of the rail joint location, and Classes 3 through 5 track shall have one crosstie whose centerline is within 18 inches of the rail joint location. The relative position of these ties is described in the following diagram:

Classes 1 through 2

Each rail joint in Classes 1 and 2 track shall be supported by at least one crosstie in paragraph (c) of this section whose centerline is within the 48 inches shown above.

Classes 3 through 5

Each rail joint in Class 3 through 5 track shall be supported by at least one crosstie specified in paragraph (c) of this section whose centerline is within 36 inches shown above.

III. Defective Rails

- When a rail in track contains any of the defects listed in the following table, operation over the defective rail is not permitted until:

- the rail is replaced or repaired; or

- the remedial action prescribed in the table is initiated:

| Defect | Length of Defect (inch) | Percent of Rail Head Cross-Sectional Area Weakened by Defect | If Defective Rail is not Replaced, Take this Remedial Action Prescribed in Note | ||

|---|---|---|---|---|---|

| More than | But not more than | Less than | But not less than | ||

| Transverse fissure | 20 | B | |||

| 100 | 20 | B | |||

| 100 | A | ||||

| Compound fissure | 20 | B | |||

| 100 | 20 | B | |||

| 100 | A | ||||

| Detail fracture Engine burn fracture Defective weld |

20 | C | |||

| 100 | 20 | D | |||

| 100 | A or E and H | ||||

| Horizontal split head Vertical split head |

0 | 2 | H and F | ||

| 2 | 4 | I and G | |||

| 4 | B | ||||

| (1) | (1) | A | |||

| Split web Piped rail Head web separation |

0 | ½ | H and F | ||

| ½ | 3 | I and G | |||

| 3 | B | ||||

| (1) | (1) | A | |||

| Bolt hole crack | 0 | ½ | H and F | ||

| ½ | 1½ | G | |||

| 1½ | B | ||||

| (1) | (1) | A | |||

| Broken base | 0 | 6 | E | ||

| 6 | A or E and I | ||||

| Ordinary break | A or E | ||||

| Damaged rail | C | ||||

(1) Break out in rail head.

Notes:

- * Assigned person to visually supervise each operation over defective rail.

- Limit operating speed over defective rail to that as authorized by the track supervisor or other supervisory personnel.

- Apply joint bars bolted only through the outermost holes to defect within 20 days after it is determined to continue the track in use. In the case of Classes 3 through 5 track, limit operating speed over the defective rail to 30 mph until angle bars are applied; thereafter limit speed to 60 mph or the maximum allowable speed under Subpart A Classes of Track: Operating Speed Limits for the class of track concerned, whichever is lower.

- Apply joint bars bolted only through the outermost holes to defect within 10 days after it is determined to continue the track in use. In the case of Classes 3 through 5 track, limit operating speed over the defective rail to 30 mph or less as authorized by a track supervisor or other supervisory personnel until angle bars are applied; thereafter limit speed to 60 mph or the maximum allowable speed under Subpart A Classes of Track: Operating Speed Limits for the class of track concerned, whichever is lower.

- Apply joint bars to defect and bolt in accordance with V (d) and (e).

- Inspect rail 90 days after it is determined to continue the track in use.

- Inspect rail 30 days after it is determined to continue the track in use.

- Limit operating speed over defective rail to 60 mph or the maximum allowable speed under Subpart A, Classes of Track: Operating Speed Limits for the class of track concerned, whichever is lower.

- Limit operating speed over defective rail to 30 mph or the maximum allowable speed under Subpart A, Class of Track: Operating Speed Limits, for the class of track concerned, whichever is lower.

* Where there is an ordinary break; or a complete break in which there is a sign of a transverse fissure or compound fissure or defective weld, movements over these rail breaks may take place under the following conditions:

- All persons performing these duties have been properly trained.

- Unsupervised movement over a rail break can only be performed where the rail break is at a significant distance from a location where a person's vehicle can be stored, for example, where there is no other track, grade crossings or other road nearby, or access on foot is impeded by adverse weather conditions such as snow, ice or cold temperatures. In addition, unsupervised movement over rail break must also comply with the requirements of following items: (1) and (3) to (9).

- Movements must not be permitted to operate over the rail break when any of the following conditions exist:

- the rail break is in a tunnel or on an open deck bridge;

- the rail break is within 150 m of an unanchored open deck bridge;

- the rail break occurs in an area of unstable grade;

- the offset (overhang) is greater than 2 inches (50 mm);

- the gap is greater than 3½ inches (89) mm;

- in the case of a joint area, the break extends beyond the limits of the joint bar; or

- the rail break occurs in an area in which the engineer in charge has specified that movements over rail breaks are not permitted.

- Where joint bars are installed with at least one bolt through the centre of the rail break, movements may operate over the rail break at a speed not exceeding10 miles per hour.

- Where the rail break is not on a ballast deck bridge and the gap size is too small to allow for the installation of joint bars with one bolt through the centre of the rail break (i.e. less than 1 1/8 inches), movements may operate over the rail break at a speed not exceeding 5 miles per hour.

- The condition of the rail break, splice bars, and supporting ties, must be inspected prior to each movement over the break.

- Speed restrictions must be applied in accordance with the applicable operating rules.

- Records of these rail breaks must be kept for a period of at least 1 year including:

- the mileage and subdivision where each rail break occurred;

- the measured gap and offset at the rail break; and

- the type of rail defect.

- Repairs must be completed within 24 hours from the time that the defect is first inspected.

- As used in this section:

- "Transverse Fissure" means a progressive crosswise fracture starting from a crystalline centre or nucleus inside the head from which it spreads outward as a smooth, bright, or dark, round or oval surface substantially at a right angle to the length of the rail. The distinguishing features of a transverse fissure from other types of fractures or defects are the crystalline centre or nucleus and the nearly smooth surface of the development which surrounds it.

- "Compound Fissure" means a progressive fracture originating in a horizontal split head which turns up or down in the head of the rail as a smooth, bright, or dark surface progressing until substantially at a right angle to the length of the rail. Compound fissures require examination of both faces of the fracture to locate the horizontal split head from which they originate.

- "Horizontal Split Head" means a horizontal progressive defect originating inside of the rail head, usually one quarter inch or more below the running surface and progressing horizontally in all directions, and generally accompanied by a flat spot on the running surface. The defect appears as a crack lengthwise of the rail when it reaches the side of the rail head.

- "Vertical Split Head" means a vertical split through or near the middle of the head, and extending into or through it. A crack or rust streak may show under the head close to the web or pieces may be split off the side of the head.

- "Split Web" means a lengthwise crack along the side of the web and extending into or through it.

- “Piped Rail" means a vertical split in a rail, usually in the web, due to failure of the shrinkage cavity in the ingot to unite in rolling.

- "Broken Base" means any break in the base of a rail.

- "Detail Fracture" means a progressive fracture originating at or near the surface of the rail head. These fractures should not be confused with transverse fissures, compound fissures, or other defects which have internal origins. Detail fractures may arise from shelly spots, head checks, or flaking.

- "Engine Burn Fracture" means a progressive fracture originating inspots where driving wheels have slipped on top of the rail head. In developing downward they frequently resemble the compound or even transverse fissures with which they should not be confused or classified.

- "Ordinary Break" means a partial or complete break in which there is no sign of a fissure, and in which none of the other defects described in this paragraph are found.

- "Damaged Rail" means any rail broken or injured by wrecks, broken, flat, or unbalanced wheels, slipping, or similar causes.

IV. Rail Surface Management

- Rail Surface Management

- Each railway company must develop and adhere to a Rail Surface Management Plan that:

- Defines, as a minimum, the following rail surface conditions: crushed heads, flattened rail, corrugation, and rail end batter for which companies must inspect; and

- Each railway company must maintain records, for a minimum of 1 year, to demonstrate that the requirements of the Rail Surface Management Plan are being adhered to.

- Each railway company with a key route or track over which trains operate at Class 3 speed or higher must have the Rail Surface Management Plan approved by a professional engineer.

- Each railway company must file a copy of their Rail Surface Management Plan with Transport Canada. Any subsequent revisions to the plan must be filed with Transport Canada before the revisions become effective.

- Each railway company must maintain records, for a minimum of 1 year, to demonstrate that the requirements of the Rail Surface Management Plan are being adhered to.

- Each railway company must develop and adhere to a Rail Surface Management Plan that:

- Rail End Mismatch

Any mismatch of rails at joints may not be more than that prescribed by the following table:

|

Class of Track |

On the top of the rail ends |

On the gauge side of the rail |

|

1 |

¼ |

¼ |

|

2 |

¼ |

3/16 |

|

3 |

3/16 |

3/16 |

|

4,5 |

1/8 |

1/8 |

V. Rail Joints

- Each rail joint, insulated joint, and compromise joint must be of the proper design and dimensions for the rail on which it is applied.

- If a joint bar on Classes 3 through 5 track is cracked, broken, or because of wear allows vertical movement of either rail when all bolts are tight, it must be replaced.

- If a joint bar is cracked or broken between the middle two bolt holes it must be replaced.

- In the case of conventional jointed track, each rail must be bolted with at least two bolts at each joint in Classes 2 through 5 track, and with at least one bolt in Class 1 track.

- In the case of continuous welded rail track, each rail must be bolted with at least two bolts at each joint.

- Each joint bar must be held in position by track bolts tightened to allow the joint bar to firmly support the abutting rail ends and to allow longitudinal movement of the rail in the joint to accommodate expansion and contraction due to temperature variations. When out-of-face, no-slip, joint-to-rail contact exists by design, the requirements of this paragraph do not apply. Those locations are considered to be continuous welded rail track and must meet all the requirements for C continuous welded rail track prescribed in this part.

- No rail or angle bar having a torch cut or burned bolt hole may be used.

VI. Tie Plates

In Classes 3 through 5 track where timber crossties are in use there must be tie plates under the running rails on at least eight of any 10 consecutive ties.

VII. Rail Anchoring

A sufficient number of anchoring devices will be applied to provide adequate longitudinal restraint.

VIII. Rail Fastenings

Each 39 foot segment of rail shall have a sufficient number of fastenings to effectively maintain gauge within the limits prescribed in C. 2.

IX. Continuous Welded Rail (CWR)

- Each railway company must develop and adhere to a CWR Management Plan that includes comprehensive installation, inspection and maintenance requirements;

- Each railway company with CWR track on a key route or over which trains operate at Class 3 speed or higher must have the CWR Management Plan approved by a professional engineer.

- Each railway company must file a copy of their CWR Management Plan with Transport Canada. Any subsequent revisions to the plan must be filed with Transport Canada before the revisions become effective.

- Each railway company must maintain records, for a minimum of 1 year, to demonstrate that the requirements of the CWR Management Plan are being adhered to.

X. Rail Wear

- Railway companies must develop and adhere to a Rail Wear Management Plan that includes rail wear limits for each section (weight) of rail in service and prescribes the action(s) to be taken when rail approaches or exceeds limits; and

- Railway companies with a key route or track over which trains operate at Class 3 speed or higher must have the Rail Wear Management Plan approved by a professional engineer.

- Railway companies must file a copy of the Rail Wear Management Plan with Transport Canada. Any subsequent revisions to the plan must be filed with Transport Canada before the revisions become effective.

- Railway companies must maintain records, for a minimum of 1 year, to demonstrate that the requirements of the Rail Wear Management Plan are being adhered to.

XI. Turnouts and Track Crossings Generally

- In turnouts and track crossings, the fastenings must be intact and maintained so as to keep the components securely in place. Also, each switch, frog, and guard rail must be kept free of obstructions that may interfere with the passage of wheels.

- Classes 4 through 5 track must be equipped with rail anchors through and on each side of track crossings and turnouts, to restrain rail movements affecting the position of switch points and frogs.

- Each flange way at turnouts and track crossings must be at least 1 ½ inches wide.

XII. Switches

- Each stock rail must be securely seated in switch plates, but care must be used to avoid canting the rail by over tightening the rail braces.

- Each switch point must fit its stock rail properly, with the switch stand in either of its closed positions to allow wheels to pass the switch point. Lateral and vertical movement of a stock rail in the switch plates or of a switch plate on a tie must not adversely affect the fit of the switch point to the stock rail.

- Each switch point be maintained so that the outer edge of the wheel tread cannot contact the gauge side of the stock rail.

- The heel of each switch rail must be secure and the bolts in each heel must be kept tight.

- Each switch stand and connecting rod must be securely fastened and operable without excessive lost motion.

- Each throw lever must be maintained so that it cannot be operated with the lock or keeper in place.

- Each switch position indicator must be clearly visible at all times.

- Unusually chipped or worn switch points must be repaired or replaced. Metal flow must be removed to insure proper closure.

XIII. Frogs

- The flange way depth measured from a plane across the

- wheel-bearing area of a frog on Class 1 track may not be less than 1 3/8 inches, or less than 1½ inches on Classes 2 through 5 track.

- If a frog point is chipped, broken, or worn more than five-eighths inch down and 6 inches back, operating speed over the frog may not be more than 10 miles per hour.

- If the tread portion of a frog casting is worn down more than three-eighths inch below the original contour, operating speed over that frog may not be more than 10 miles per hour.

- Where frogs are designed as flange-bearing, flange way depth may be less than that shown for Class 1 if operated at Class 1 speed.

XIV. Spring Rail Frogs

- The outer edge of a wheel tread may not contact the gauge side of a spring wing rail.

- The toe of each wing rail must be solidly tamped and fully and tightly bolted.

- Each frog with a bolt hole defect or head-web separation must be replaced.

- Each spring must have a tension sufficient to hold the wing rail against the point rail.

- The clearance between the hold-down housing and the horn may not be more than one-fourth of an inch.

XV. Self-Guarded Frogs

- The raised guard on a self-guarded frog may not be worn more than three-eighths of an inch.

- If repairs are made to a self-guarded frog without removing it from service, the guarding face must be restored before rebuilding the point.

XVI. Frog Guard Rails

The guard check in frogs must be within the limits prescribed in the following table:

|

Class of Track |

Guard check gauge - The distance between the gauge line of a frog to the guard lineFootnote 1 of its guard rail or guarding face, measured across the track at right angles to the gauge line,Footnote 2 may not be less than - |

|---|---|

|

1 |

4 feet 6 1/8 inches |

|

2 |

4 feet 6 1/4 inches |

|

3, 4 |

4 feet 6 3/8 inches |

|

5 |

4 feet 6 1/2 inches Footnote 3 |