Table of Contents

- Preface

- 1. Introduction

- 2. Application - Definition of confined space, definition

- 3. Employer's Confined Space Obligations When Working in a Cargo Hold

- 4. Types and list of cargoes to which condition (c) of the definition of confined space is always present

- 5. Confined space regulatory requirements (part 14 of the MOHSR)

- 6. Confined space entry procedures (part 13 of the MOHSR)

- 7. Other hazards – Hazard Prevention Program (part 7 of the MOHSR)

- 8. General precautions

- 9. Significant points

- Appendix A: Solid Bulk Cargo Declaration

- Appendix B: Example of Access Holds

- Appendix C: IMO Permit Form

- Appendix D: Safety Data Sheet

- Appendix E: Group B Bulk Cargo List

- Bibliography

Preface

This publication is intended for members of the federal marine industry, who are involved in ship loading and unloading operations. The goal is to provide clarifications on the requirements for entry into cargo holds in connection with the definition of confined space in Part 1 of the Maritime Occupational Health and Safety Regulations, which is under Part II of the Canada Labour Code (Code).

This document covers the following points:

- 1) the responsibilities of the employer and employees regarding confined space regulations under the Code and the Maritime Occupational Health and Safety Regulations;

- 2) the risks of entering and carrying out operations in cargo holds;

- 3) workplace assessment and compliance; and

- 4) the tools and best practises to adopt.

1. Introduction

Recent research by the International Maritime Organization (IMO) [Document CCC 6/INF.7; June 10, 2019] listed at least 106 accidents reported between 1999 and December 2018, in which at least 140 people, 90 seafarers (65%) and 50 shore workers (35%), lost their lives from asphyxiation, poisoning from toxic gases, explosion, or fire on ships carrying solid bulk cargoes.

Transport Canada recorded 10 additional deaths further to this research, between December 2018 and June 2020, and it is also likely that several other cases were not identified. These accidents occurred while entering a cargo space where the atmosphere presented hazardous conditions. Despite clear guidelines from shipping companies to their crews, obligations from international regulations, and federal regulatory requirements to protect anyone boarding ships to perform their jobs, preventable accidents are still occurring in Canada.

2. Application - Definition of confined space, definition

The definition of a confined space is found in Part 1 of the Maritime Occupational Health and Safety Regulations (SOR 2010-120), and is defined as follows:

confined space means an enclosed or partially enclosed space that:

- a) is not designed or intended for human occupancy, except for the purpose of performing work;

- b) has restricted means of access and egress; and

- c) may become hazardous to any person entering it owing to

- its design, construction, location or atmosphere,

- the materials or substances in it, or

- any other conditions relating to it. (espace clos)

In evaluating the risks, the qualified person appointed by the employer may refer to all aspects of Part XI Confined Spaces as provided in the Canada Occupational Health and Safety Regulations (COHSR).

2.1 Identification of a cargo hold as an enclosed space

For a cargo hold to be considered an enclosed space, it must meet all 3 of the confined space definition contained within the Maritime Occupational Health and Safety Regulations (MOHSR). This is demonstrated below.

A totally or partially enclosed space which, at the same time:

A ship's cargo hold is, by configuration, a fully enclosed space when the hatch covers (bilge covers) and access covers are fully closed and partially enclosed when the hatch covers and access covers are open.

- a) is not designed or intended for human occupancy, except for the purpose of performing work;

Cargo holds are not designed for regular and continuous occupation by workers. They are designed to temporarily stow or transport a product, materials or substances.

- b) has restricted means of access and egress;

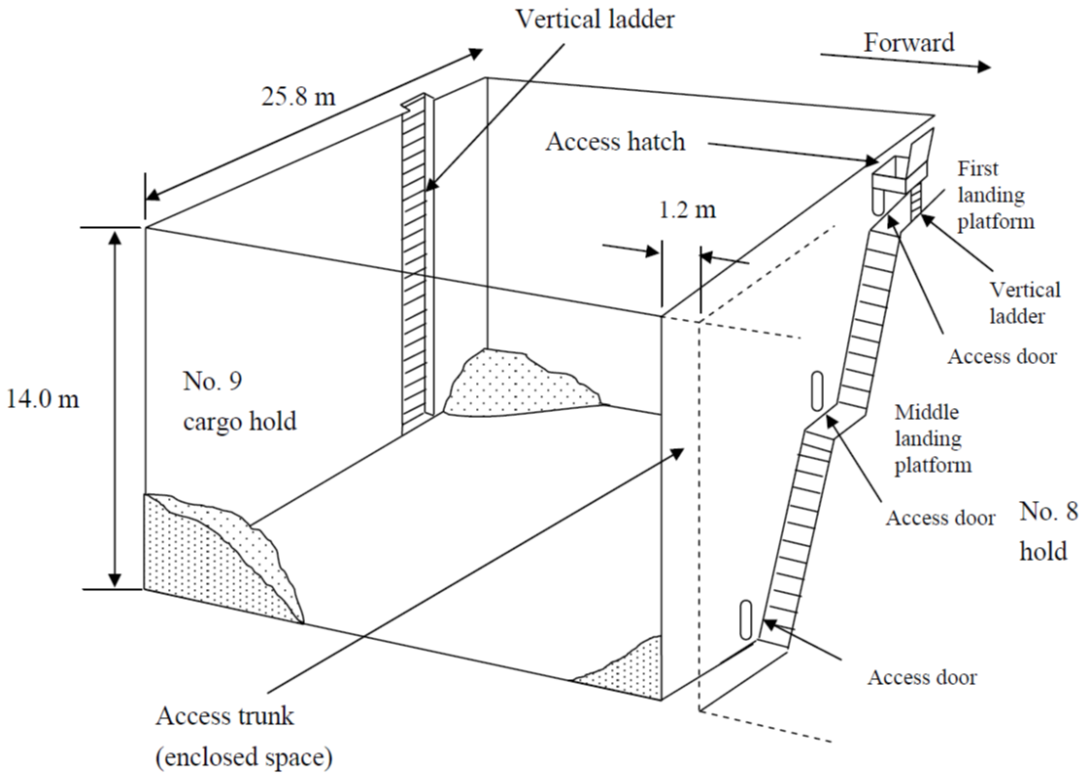

Access to enter a cargo hold can be limited by their size and location. In some cases, the dimensions of the openings may not exceed 450 mm (17.5 inches) of clearance. Access or egress routes are limited, making it difficult to provide first aid, evacuation, rescue or other emergency response. Usually there are two accesses, one at each end of the hold. One consists of a straight ladder with several landings, directly attached to the bulkhead of the hold, and the other consists mostly of short ladders combined with a large staircase (straight or spiral). These stairs are often covered or located between two bulkheads to protect the structure from the impact of cargo and machinery during loading and unloading operations.

Appendix B has some photos showing examples of the restricted access routes to the cargo holds.

- c) may become hazardous to any person entering it owing to:

- its design, construction, location or atmosphere,

- the materials or substances in it, or

- any other conditions relating to it.

Note: The adequacy of ventilation may be determined by the qualified person taking a risk-based approach.

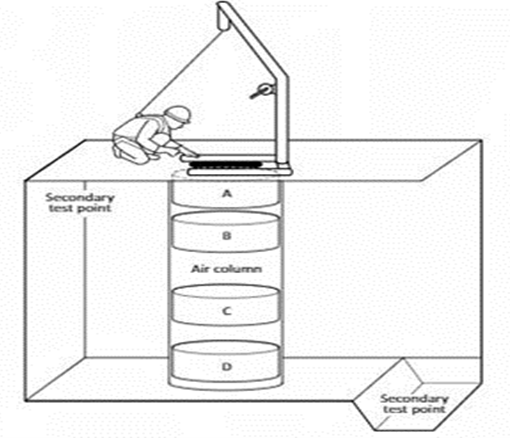

- The configuration of the access to the cargo hold can make it difficult or impossible to circulate air to the entrances and to areas adjacent or connected to them. It may not be possible to properly check the atmosphere from the exterior entrance to the accesses, when the construction of these accesses has been designed in stages (see photos in Appendix B). If you encounter such a situation, you should proceed step by step. The shape of the cargo hold is similar to a pit, typically 14 metres (about 50 feet) deep. The design of the cargo holds means that fresh air does not move freely between the access ducts and the bottom of the cargo hold, despite the presence of ventilation ducts. When a person uses access ladders or stairs, there is also a risk of slipping, bumping or falling if the structural integrity of these means of access is compromised.

-

Lethal gases may be present inside a cargo hold if it contains or has contained chemical or organic substances that have decomposed or overheated. In general, cargoes of an organic or metallic nature that appear to be harmless in the open air can cause a decrease in oxygen levels or produce toxic gases, such as carbon monoxide (CO) or other gases that can contribute to a hazardous atmosphere. Sometimes there is a structure that houses the access to the holds (often called a stow), which can be used as storage space. This structure as well as the access could contain such gases, which could affect the quality of the atmosphere. It should not be assumed that a space is safe because the hatch covers of the hold are open.

Another example is the presence of fumigants (pesticides) in a cargo hold. Fumigated cargo can poison the air in the space where the hatch entrance is located or in the space leading to the hold. Even if a fumigated hold has been ventilated, pockets of toxic gas may still be present inside the hold. The air inside may also be too rich in oxygen, which increases the risk of fire or an explosion if an ignition source is present or introduced. These hazards should be considered when the qualified person performs their assessment.

- It is also possible that leaks on the vessel may be present through cracks in various pipes and valves (e.g., suction points on the bottom of holds). A crack in a bulkhead, or a defective weld or hole caused by corrosion, can allow dangerous gases to pass through without the crew being aware. In addition, a previously tested space deemed to be safe could present risks when machinery with an internal combustion engine is used inside the cargo hold. Exhaust gases (carbon monoxide or carbon dioxide), in combination with the handling of oxidizing bulk cargoes, can compromise and rapidly change the quality of the atmosphere.

In short, a cargo hold meets the definition of an enclosed space. The employer shall assess the risks to which persons are likely to be exposed, establish entry procedures and ensure that the risk is controlled at all times and maintained within the exposure limits for hazardous substances specified by the American Conference of Governmental Industrial Hygienists (ACGIH) as required by Part 20 of the MOHSR.

3. Employer's Confined Space Obligations When Working in a Cargo Hold

According to the order of priority in section 122.2 of the Code, employers must eliminate hazards, then reduce them if they cannot be eliminated, then implement safe work procedures, and finally provide appropriate equipment, material and protective devices to ensure the health and safety of workers.

The qualified person or marine chemist shall assess the confined space (cargo hold) before a person is permitted to enter, establish entry procedures and procedures for evacuation in the event of an emergency (MOHSR Parts 14 and 21). A work permit must be issued (Part 13 of the MOHSR). It is mandatory for the employer to provide training and procedures for the use of personal protective equipment (Part 10 of the MOHSR).

The employer must consult with the Policy Health and Safety Committee (where one exists) or the Workplace Health and Safety Committee or its representative to:

- Identify and assess known and foreseeable hazards related to accessing and working in a cargo hold;

- Determine preventive measures and safe work procedures;

- Train all persons in safe working procedures on how to safely use and wear the protective equipment and gear required to access a cargo hold and during loading and unloading operations on a vessel; and,

-

Review the effectiveness of the program whenever the risk conditions change and at least once every 3 years (Part 7 of the MOHSR).

Note: Technical aspects such as training requirements may be determined by the qualified person taking a risk-based approach.

3.1 Confined space hazards when working in a cargo hold

Note: Confined space hazards may be determined by the qualified person using a risk-based approach. Engulfment hazards may not be present in all circumstances.

There are at least four types of risks to consider:

- 1) Lack of awareness of the risks associated with the physical configurations of the holds and its restricted access;

- 2) The risk of asphyxiation due to the presence of a dangerous atmosphere (lack of oxygen, explosion or fire, etc.);

- 3) Conditions causing a change in air composition during handling operations (presence of gases, particles, etc.);

- 4) The danger of being swallowed or crushed by the moving cargo.

1) The configuration of the cargo hold, and its accesses can be problematic. On board bulk carriers, the ventilation ducts for the holds are often located in the upper part of the structure, leaving the lower part ventilated only through the opening in the hatch covers. Always observe the configuration of the hold before entering it. If you have such a configuration, confirm that the entrance is secure with your supervisor.

2) In a cargo hold, the greatest risk is asphyxiation due to the presence of a dangerous atmosphere. Oxygen depletion is often caused by various chemical or biological reactions between the cargo and the ambient air. According to the available data, most fatal accidents related to lack of oxygen occur in enclosed stairways. These spaces usually have no ventilation system and may be blocked at the other end by cargo.

|

% of oxygen in the air |

Effect |

|---|---|

| 23.5% | Enriched atmosphere, disorientation, breathing, and vision problems |

| 19.5% | Minimum acceptable oxygen level |

| 15 to 19.5% | Coordination of movements affected |

| 12 to 14% | Breathing is faster. Judgement is affected |

| 10 to 12% | Breathing increases and lips turn blue |

| 8 to 10% | Fainting, nausea, unconsciousness, vomiting |

| 6 to 8% | 8 min.: fatal; 6 min.: 50% fatal; 4 to 5 min.: survivable |

| 4 to 6% | Coma in 40 sec. Dead in 3 mins |

(Source The Standard Club, A master’s guide to Enclosed Space Entry)

Warning: never use pure oxygen for ventilation

3) In addition to the problems that lack of ventilation can cause, certain conditions can change in a hold during operations. The presence of large quantities of dust can make the atmosphere hazardous, especially if the dust is flammable (e.g., grain dust) and can be harmful to the worker's health. If a water mist is used to keep the dust inside the hold, it may trap the machinery exhaust longer in the hold. Some cargoes in contact with water can release toxic gases. It is essential to consult the safety data sheet before starting cargo operations.

4) Swamping or crushing can occur when a person enters a hold and can be submerged, suffocated, or trapped by falling loose material. Loose or granular bulk materials stowed in a hold, such as some grains, can engulf a person when operating on this type of equipment. Some bulk cargoes can agglomerate and form a kind of bridge that can collapse (see pictures below).

4. Types and list of cargoes to which condition (c) of the definition of confined space is always present

Note: The qualified person may assess the hazards using a risk-based approach.

The International Maritime Solid Bulk Cargo Code (IMSBC Code) and its successive editions require shippers to provide the ship's master with information on the nature of the cargo and the potential hazards involved in its carriage and handling during loading and unloading operations. This information is recorded on the “Shipper's Declaration for Solid Bulk Cargoes" (a sample of this form with the information to be included is provided in Appendix A) and will also be accompanied by a "Safety Data Sheet (Appendix D)."

It is very important to know the characteristics of the cargo and the potential dangers that are present before entering a hold. The following types of cargo (4.1 to 4.6) meet condition (c) in a systematic manner.

4.1 Solid bulk cargoes in Group B (or a combination of Group B and another group)

Group B cargoes have chemical hazards (gas release, heating, etc.). They are described in Chapter 9 of the IMSBC Code. This Code has safety data sheets for each type of bulk cargo and includes some of their characteristics. The alphabetical list of Group B cargoes (or a combination of Group B with another group) specified in this Code can be found in Appendix E of this document. The complete list of solid cargoes with English-French-Spanish translation of all cargo names can be found in Appendix V of the IMSBC Code.

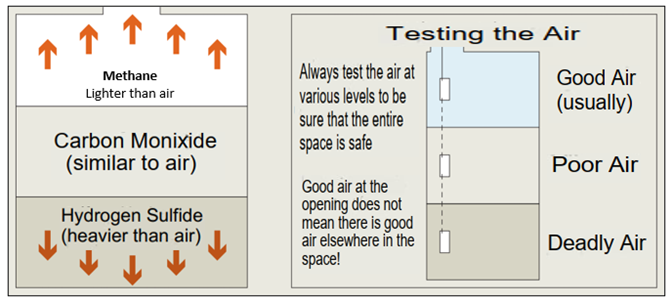

4.2 Coal

Coal is a Group B bulk cargo. Coal also causes a decrease in oxygen levels and is involved in most of the fatal accidents during handling operations. Two dangerous characteristics of coal are the emission of methane (a flammable gas) and carbon monoxide. Due to the potential presence of methane gas, it is imperative that a smoking ban be enforced for all workers when a coal shipment is being handled. In the past, levels indicating only 4% oxygen have been measured in cargo hold accesses. Always consult the safety data sheet (example in Appendix D) for the characteristics of a coal shipment, as these may vary depending on the origin of the shipment (the mine where the coal was mined).

4.3 Grain and grain products

Grain and grain products in bulk may appear harmless in the open air, but when stowed inside a cargo hold they can present similar risks as Group B cargoes. It all depends on the type of grain and its characteristics. The dangers of this type of cargo are flammability, toxicity, oxygen depletion, and self-heating. In addition, there is a risk of being buried, especially when grains clump together after absorbing moisture. This causes the formation of walls/floating cargo that no longer flow and may fall and bury a person.

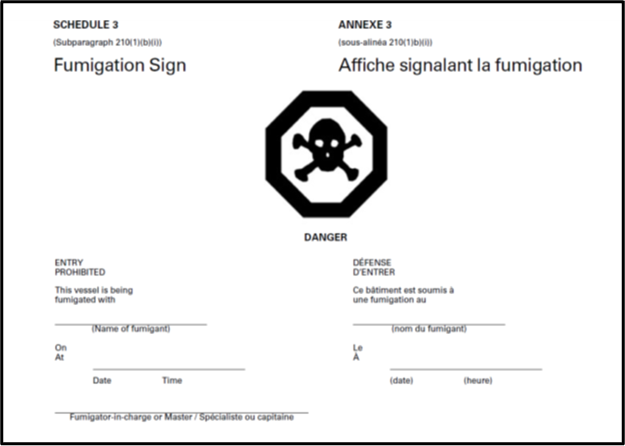

4.4 Fumigated cargo

Many cargoes, especially grains and grain products and wood, are treated with fumigants to prevent contamination by insect pests. Although the holds are degassed when the ship arrives at its destination, pockets of toxic gas may still be present in some areas. Many deaths have occurred as a result of entering a space that was improperly degassed or contaminated by a leak of fumigant from an adjacent fumigated space. Any worker who sees a sign indicating that a space has been or is being fumigated must check with their supervisor to ensure that the space has a safe atmosphere before entering it.

4.5 Shipments of wood or wood pellets

Wooden cargoes are subject to oxidation, which lowers the oxygen level in the hold. This reaction produces carbon monoxide (CO), which is an odourless, tasteless gas that does not irritate the eyes or respiratory tract. This gas is also flammable and deadly in high concentrations (ACGIH limit is 25 ppm for eight hours). In some accidents, oxygen percentages as low as 6% have been recorded; at this level death is very quick.

4.6 Metal concentrates and scrap metal shipments (including trimmings, chips, etc.)

Metal concentrate shipments are subject to the oxidation process, so the level of oxygen in the atmosphere will be reduced. In the case of scrap metal cargoes, oxidation is accelerated if the cargo is wet or damp. The riskiest area is the access to the cargo holds, especially if they are closed (see photos in Appendix B: Example of Access Holds).

5. Confined space regulatory requirements (Part 14 of the MOHSR)

Subsection 171(1) requires the employer to have a marine chemist or other qualified person assess any hazardous substance in the confined space and determine what tests are required to establish the likelihood of employees being exposed hazards. The qualified person may assess these hazards using a risk-based approach.

The person shall verify that the concentrations of any chemical agent do not exceed the limits of the exposure values established by the most recent version of American Conference of Governmental Industrial Hygienists (ACGIH) (Part 20 of the MOHSR) and that the concentration of hazardous substances, other than chemical agents, present in the air does not present a risk. The percentage of oxygen must be maintained at no less than 19.5% and no more than 23% during the time a person is in the cargo hold.

5.1 Content of the report

The qualified person shall complete and sign an assessment report that contains the following information [subsection 171(3)]:

- a) the name of the vessel;

- b) the location of the enclosed space on the vessel;

- c) the results of the assessment of the concentrations of hazardous substances (chemical and others) and the percentage of oxygen;

- d) type, model, and serial number of any instrument used, including the date of calibration;

- e) the risk assessment of the confined space;

- f) work procedures and instructions for entry, inside the cargo hold and exit;

- g) the required protective equipment (Part 10 of the MOHSR);

- h) the emergency procedures to be followed in the event of an accident, an activated alarm device, including the evacuation procedure.

Note: The length of time that the assessment is valid for may be determined by the qualified person.

5.2 Additional requirements – Cargo Hold attendant

The qualified person should consider all the requirements specified in the regulation. Below are some points to consider.

Before a permit is issued, the requirements in sections 166 and 168 must be met and recorded in the qualified person’s report. Under paragraphs 171(2)(a) to (c) or 173(1)(b) to (e), a cargo hold attendant will be required [173(3)], if appointed by the qualified person and where the following conditions cannot be complied with:

- a) The concentration of any chemical agent to which a person is exposed will not exceed the ACGIH exposure limit value;

- b) The concentration of hazardous substances—other than chemical agents—in the air of the confined space does not present a risk to the health and safety of the person in the space;

- c) The percentage of oxygen in the confined space is between 19.5% and 23% by volume

or

- a) That the material cannot swallow or engulf a person [173(1)(b) and (c)].

- b) That the mechanical or electrical equipment does not cause a hazard, [173(1)(d)].

- c) The entrances and exits are large enough to safely pass through while wearing the protective equipment, [173(1)(e)].

The qualified person must establish an access control system for the entrances. The supervisor must be qualified, stand outside the confined space, and be in communication with the person inside the confined space. The person inside the confined space must have an adequate alarm device to summon help. The required emergency equipment must be close to the entrance and ready for use. Training in emergency evacuation procedures as well as first aid training is required. The emergency evacuation procedures may be determined by the qualified person using a risk-based approach.

6. Confined space entry procedures (Part 13 of the MOHSR)

6.1 Work permit content

The employer is required to issue a written work permit to every qualified person before they begin work in the confined space (section 166 of the MOHSR). The work permit must include the following information (section 167 of the MOHSR):

- a) the name of the person issuing the permit;

- b) the name of the holder;

- c) the validity period;

- d) the type of work to be performed and its location;

- e) the assessment of the risk factors inherent in the performance of the work and the resulting instructions, in particular:

- the work procedures to be followed,

- if applicable, identification of the equipment to be locked out in accordance with CSA Standard CAN/CSA-Z460-05, Control of Hazardous Energy: Lockout and Other Methods,

- a description of the safety tests to be carried out before, during, and after the execution of the work,

- the particulars of the labels or signs to be used, if any,

- the protective equipment to be used, if any,

- procedures to follow in case of emergency,

- a description of the locations, work, and electrical equipment to which the instructions apply,

- reference to any other work permits that may affect the work procedures to be followed or the procedures to be followed in an emergency.

The work permit is signed by the holder and the employer, who explains to the holder the conditions of the permit, as well as the rights and obligations arising from it, and is informed/trained on all procedures and instructions to be followed. When the permit expires, all persons should leave the space. A new entry will be permitted upon issuance of another permit (section 168 of the MOHSR).

6.2 Records

The assessment (Part 14 of the MOHSR) and the permit (Part 13 of the MOHSR) must be retained by the employer for a period of two years.

7. Other hazards – Hazard Prevention Program (Part 7 of the MOHSR)

According to Part 7 of the MOHSR, the employer must develop a hazard prevention program in conjunction with the OHS committee or representative to prevent accidents, injuries and illnesses in the workplace. The program must include methods of risk identification and assessment, prevention measures, and employee training. The employer must review the effectiveness of the program, including confined space entry, at least every three years and whenever the hazard conditions have changed or new hazard information becomes available.

All workers involved in cargo handling operations on board a ship shall be trained by the employer in relation to the following:

- a) The employer's hazard prevention program and how it applies to workers who have access to cargo holds;

- b) Steps to follow before entering a cargo hold, proper entry and exit procedures;

- c) The known and foreseeable hazards to which they may be exposed during handling operations, and the training required in the use of personal protective equipment;

- d) Control equipment for the level of oxygen and other possible gases and protection needed before entering a hold and during the work to be done.

The employer and employee must certify in writing that the training was provided and received in a logbook and the logbook must be kept for a period of two years.

In addition, the employer should consider subsection 238(1) of Part 19 Materials Handling and Storage – section 3.

Each enclosed work area in which materials handling equipment with an internal combustion engine is used shall be ventilated to prevent the concentration of carbon monoxide (25 ppm) in the ambient air from exceeding the exposure limit values set out in the most recent edition of the document published by the American Conference of Governmental Industrial Hygienists, entitled Threshold Limit Values (TLVs) and Biological Exposure Indices (BEIs).

For each enclosed work area in which materials handling equipment with an internal combustion engine is used, the employer must keep a record of the date, time, location, and results of carbon monoxide testing.

8. General precautionsFootnote 1

Access hatches or doors to cargo spaces should always be assessed prior to entry and checked especially when access is not required.

A hatch cover or access hatch that is left open may be mistaken for an indication that the atmosphere is safe. Some form of barricades or a chain with a warning sign is useful to prevent unauthorized access.

A qualified terminal or stevedoring company representative must determine if it is safe to enter a cargo hold by ensuring that:

- Potential hazards have been identified and assessed;

- The space was adequately ventilated to remove toxic or flammable gases and to ensure that an adequate level of oxygen was continuously present in the cargo hold;

- The atmosphere of the hold and its accesses was checked with calibrated instruments;

- The space is safe for entry and is well lit;

- A communication system has been established between all parties for the duration of the entry and that this system has been verified;

- If necessary, a supervisor was posted at the entrance to the hold;

- Rescue equipment has been placed nearby ready for use and that rescue procedures are in place, known and understood;

- Personnel are equipped with the proper PPE for entry and the tasks to be performed in the hold; and,

- The permit was issued and signed for the entry of workers in each hold.

Only trained personnel may enter the cargo holds, stand guard at the entrance, or be a member of a salvage team. Training should include at least:

- Identification of hazards to be faced when entering a cargo hold;

- How to recognize the signs that have an adverse effect on health when entering; and,

- Knowledge of the protective and emergency equipment necessary to perform work with a specific cargo.

Any equipment used in conjunction with entry (PPE, life-saving equipment, etc.) into a hold must be in good condition and ready for use.

8.1 Ventilation before entering a cargo hold

Natural ventilation may not be sufficient. If contaminants or low oxygen levels are present during the atmosphere check, mechanical ventilation should be considered prior to entering the cargo hold access. One way to ensure that fresh air replaces contaminated or oxygen-deficient air is to use a fan with a large diameter hose. By placing the flexible duct in the vicinity of the bottom of the access space, fresh air should spread throughout the space to reach and maintain a safe atmosphere.

If the configuration of the space does not allow you to install the vent properly, lower it to the lowest accessible point without entering the space and start venting. If you have to enter the space to install the ventilation duct, don't take any chances:

- a) Use appropriate instruments to check the air quality at different heights (e.g., in the upper, middle, and lower parts) and other isolated corners before entering;

- b) Wear a self-contained breathing apparatus while everything is being installed;

- c) Never enter without the supervision of another person;

- d) When everything is in place, get out before starting the ventilation; and

- e) Repeat these steps (a, b, c, and d) to the last level.

Some equipment manufacturers provide you with tables indicating the minimum ventilation time for a given space (in m3 or ft3) according to the capacity of your ventilation system.

8.2 Measuring the atmosphere

Access to cargo holds should not be allowed until an atmosphere check has been carried out by a qualified person with instruments calibrated and approved for the nature of the cargo. The atmosphere check should confirm that all areas are safe to enter. The holds and their access should be checked for:

- The level of oxygen

- Flammable vapours and gases

- Toxic gases and fumes

The atmosphere may be different at different locations in the confined space

Continuous monitoring should be considered if the atmosphere in the hold is subject to change. The wearing of a personal detection device (badge - portable detector) capable of detecting the level of oxygen or other dangerous gases may be mandatory. This matter may be determined by the qualified person.

When measuring the atmosphere, do not do so when the ventilation is on, as the readings of your device may be distorted.

When taking your measurements, do so at different levels to get a better picture of the space being audited. At each checkpoint/level, leave your instrument at that level for an appropriate period of time depending on the depth of the reading (consult your instrument's technical data), to give you an accurate idea of the atmosphere's composition at each level.

The use of a flexible hose must correspond to the depth of the cargo hold. Lethal gases are usually heavier than the ambient air and are found at the bottom of the hold. Moreover, it is likely that even with mechanical ventilation, it is not possible to remove some of the gases. The same goes for some lighter-than-air gases, which may not come out, even if the access or hatch covers are open.

Always consult the cargo's safety data sheet to assess what types of gases may be present. Some gases may not be detected by your device. Detection devices designed to detect specific gases should be used.

Verification devices used must be calibrated according to the manufacturer's instructions and a date must be recorded to indicate the next calibration. A device that has exceeded its calibration date should not be used. In addition, a check of each device must be done before each entry into a confined space.

8.3 Precautions during cargo hold entry

- Make sure you wear the personal protective equipment required by your employer including a personal gas detection device and that it has been checked, calibrated, and programmed with the appropriate alarm settings;

- Make sure the space is well lit;

- Keep in touch with the workplace responsible person;

- If you feel dizzy or sense that something is wrong, exit the space immediately;

- Always have the proper PPE for the type of cargo you are handling;

- Continuously monitor the atmosphere by wearing your personal detection device during the entire time you are working in the hold. Wear your device so that it is not covered by your clothing;

- The person in charge of the work area and the qualified person should check the atmosphere during handling operations to detect changes that may occur during operations. If the air quality deteriorates, the hold shall be evacuated;

- In any case, if you see an unconscious person in an access or in a hold, do not go in, ask for help immediately and start the emergency procedure. Several lives were and can be lost in an unplanned rescue attempt.

9. Significant points

The warning signs on the vessel

If, as a worker, you need to access a workplace and you notice this:

(Source: IMO SIGNS CATALOGUE, A-SPE Europe sp. J.)

- Do not enter—a checklist must be completed and signed by a qualified person;

- Make sure that an entry permit has been completed and that your name is on it. The checklist and the entry permit can be on the same document (example in Appendix C);

- If a crew member opens an access with symbols similar to those shown above, do not enter immediately. Wait for confirmation from your supervisor, as the atmosphere must be checked before entering;

- Always carry a portable oxygen detector (detection badge). If the alarm sounds during entry, exit immediately;

- Do not rely on the crew members to tell you whether the compartment is safe or not. Atmospheric assessment should be a joint venture between the terminal and the ship. The terminal must complete its own evaluation and entry permit.

9.1 Other information – The BLU Code

Since 1998, international measures have been in place to promote the exchange of information between the ship and the terminal representative. These measures are explained in detail in the IMO Code of Practice for the Safe Loading and Unloading of Bulk Carriers (BLU Code and Manual). One of the highlights of this Code is the checklist that must be completed prior to the start of operations by the terminal and the ship upon arrival of the ship at the dock. Two of the standard questions on this list are:

12. Has the shipper provided the master with the properties of the cargo in accordance with the requirements of chapter VI of SOLAS?

13. Is the atmosphere safe in holds and enclosed spaces to which access may be required, have fumigated cargoes been identified, and has the need for monitoring of atmosphere been agreed by ship and terminal?

Consequently, the Master of the vessel must be in possession of the information required to identify the hazards associated with the cargo he is carrying and must transmit it to the terminal.

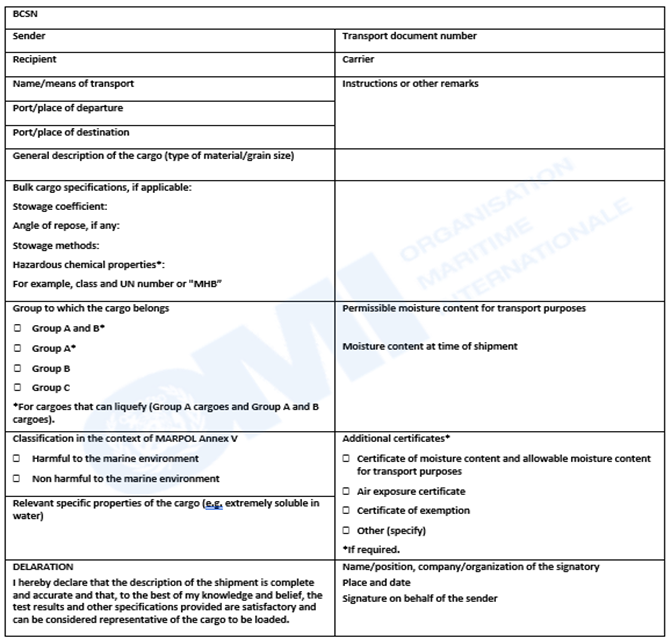

Appendix A: Solid Bulk Cargo DeclarationFootnote 3

According to section 4.2.2 of the IMSBC Code, the following cargo information must be confirmed in writing and by appropriate transport documents before loading.

- The Bulk Cargo Shipping Name (BCSN) when the cargo is listed in this Code. Other designations may be used in addition to the BCSN;

- The cargo group (A and B, A, B or C);

- The IMO class of the cargo, if applicable;

- The IMO number preceded by the letters "UN" of the cargo, if applicable;

- The total quantity presented for transport;

- The stowage ratio;

- The need for securing and the methods of securing, if applicable;

- The possibilities of slippage, including the angle of repose, if any;

- In the case of a cargo of concentrate or other cargo that may liquefy, additional information, in the form of a certificate, on the moisture content of the cargo and its permissible moisture content for transport purposes

- The likelihood of liquid base formation (see section 7.2.3 of the Code);

- Toxic or flammable gases that may be released from the cargo, if any;

- Flammability, toxicity, corrosion effects and the ability of the cargo to cause oxygen depletion, if applicable;

- Self-heating properties of the cargo and the need for securing, if applicable;

- Properties when releasing flammable gases in contact with water, if any;

- Radioactive properties, if any;

- Information on whether or not the cargo is classified as harmful to the marine environment in accordance with Appendix I to Annex V of the International Convention for the Prevention of Pollution from Ships, 1973, as modified by the Protocol of 1978 relating thereto, as amended; and

- any other information required by the national authorities.

Items 7 and 11 to 16 should be considered when planning handling operations by the supervisors of the crews that will be handling the loading/unloading.

Cargo declaration form for solid bulk cargoes

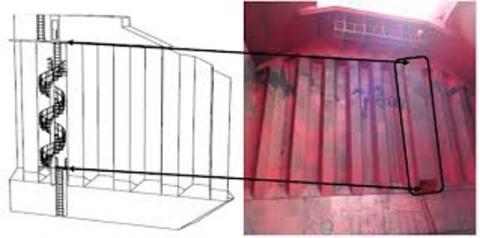

Appendix B: Example of Access Holds

The entrance to these access holds is usually well defined.

Spiral ladder is often protected by partitions (right image), is often poorly lit and poorly ventilated (air does not circulate when the cargo covers the lower part).

Access ladder located between two wedges with different landings. Usually very small, poorly lit, and a poorly ventilated space. This type of ladder is not visible from either side of the wall.

(Source: Marine Accident Investigation Section, Marine Department of Hong KongFootnote 4)

Appendix C: IMO Permit Form - Sample

|

General |

|||

|---|---|---|---|

| Location/name of the enclosed space: | |||

| Reason for entry: | |||

| Validity of the permit | Date and time | To | Date and time |

|

Part 1 – Pre-entry preparation |

|||

| Was the space effectively ventilated by mechanical means? | Yes | No | |

| Has the space been isolated by closing off any pipes, ducts, or valves or by turning off the power supply? | Yes | No | |

| Has the space been cleaned where necessary? | Yes | No | |

| Has the atmosphere been tested and is it safe to enter? | Yes | No | |

|

Result of the readings of the detection device before the entry |

|||

|

Potential hazards |

Permitted limits |

Data collected |

|

| Oxygen rate in %. | Min. 19.5% to max. 23% | ||

| Carbon monoxide (CO) | 35 PPM | ||

| Hydrogen sulphide (H2S) | 10 PPM | ||

| Flammable or combustible gases (LEL) | Max 10% LEL | ||

| Temperature | |||

| Others | |||

| Realized by: | Date and time: | ||

| Model and number of the gas detector: | |||

| Are arrangements in place to do frequent atmosphere checks when the space is occupied and after breaks? | Yes | No | |

| Have measures been taken to effectively ventilate the confined space while it is occupied? | Yes | No | |

| Is access to the confined space and lighting adequate? | Yes | No | |

| Is life-saving and resuscitation equipment nearby or at the workplace? | Yes | No | |

| Has a person been designated to provide constant surveillance at the entrance to the confined space? | Yes | No | |

| Has the person in charge of the workplace been notified that a person or a crew is going to enter the confined space? | Yes | No | |

| Has a system of communication between all parties has been established and understood by all personnel who will have access to the confined space? | Yes | No | |

| Have emergency and evacuation procedures been established and understood by personnel who will have access to the confined space? | Yes | No | |

| Has the equipment used been inspected and is in good condition before entering the confined space? | Yes | No | |

| Are the personnel wearing the correct personal protective equipment and have the necessary equipment to perform the task? | Yes | No | |

|

Part 2 – Pre-entry checks |

|||

| I have received instructions and permission from the supervisor or a responsible person to enter the confined space. | Yes | No | |

| Part 1 of this licence has been satisfactorily completed by the supervisor or person in charge. | Yes | No | |

| I have accepted and understand the communications procedures. | Yes | No | |

| I agreed to report to the person responsible for monitoring me every insert number minutes. | Yes | No | |

| Evacuation and emergency procedures have been agreed upon and are included. | Yes | No | |

| I am aware that the space must be evacuated immediately if the ventilation stops or if atmosphere tests show a change in the established safe limits. | Yes | No | |

|

Part 3 – Self-contained breathing apparatus and other equipment |

|||

| Persons entering the confined space are familiar with the breathing apparatus. | Yes | No | |

| The self-contained breathing apparatus was checked as follows: | |||

|

Yes | No | |

|

Yes | No | |

|

Yes | No | |

| The means of communication have been checked and the emergency signals are known. | Yes | No | |

| All personnel entering the space are equipped with a harness. | Yes | No | |

Signatures after completing sections 1 to 3

Supervisor/Person in Charge:

Date:

Time:

Supervisor (as per risk assessment):

Date:

Time:

Person entering the confined space:

Date:

Time:

|

Part 4 – Staff entry |

||

| Name: | Time of entry: | Time of exit: |

|

Part 5 – Completion of task or operations |

||

| Work completed | Date: | Time: |

| Staff exited the confined space | Date: | Time: |

| Informed supervisor | Date: | Time: |

Signature after completing parts 4 and 5

Supervisor/Person in Charge:

Date:

Time:

THIS PERMIT BECOMES INVALID FOLLOWING A CHANGE OF CONDITIONS IN THE CHECKLIST OR IF THE VENTILATION STOPS

Appendix D: Safety Data Sheet

(Source: Canadian Centre for Occupational Health and Safety [CCOHS])

In the case of solid bulk cargo, it is rather rare to see this sheet, but the shipper may have provided a copy to the captain at the time of loading.

| Sections and headings of an SDS | Specific information | |

|---|---|---|

| 1 | Identification |

|

| 2 | Hazard identification |

|

| 3 | Composition/information on ingredients |

NOTE: Rules regarding the protection of confidential business information may apply. |

| 4 | First Aid |

|

| 5 | Measures to be taken in case of fire |

|

| 6 | Actions to be taken in case of spills |

|

| 7 | Handling and storage |

|

| 8 | Exposure controls/personal protection |

|

| 9 | Physical and chemical properties |

|

| 10 | Stability and reactivity |

|

| 11 | Toxicological data |

Comprehensive but concise description of the various toxic health effects and data to target these effects, including:

|

| 12 | Ecological dataFootnote 9 |

|

| 13 | Product disposal informationFootnote 10 | Information on safe handling for disposal and disposal methods, including contaminated packaging. |

| 14 | Transport informationFootnote 11 |

|

| 15 | Regulatory informationFootnote 12 | Safety, health, and environmental regulations applicable to the product in question |

| 16 | Other information | Date of most recent revision of the SDS |

(Source: CCOHS website)

Appendix E: Group B Bulk Cargo List

|

Material |

Groupe/Group |

Matière |

|---|---|---|

| Alumina hydrate | A et/and B | Hydrate d’alumine |

| Aluminium dross | B | Laitier d’aluminium |

| Aluminium ferrosilicon powder un 1395 | B | Alumino-ferrosilicium en poudre un 1395 |

| Aluminium hydroxide | A et/and B | Hydroxyde d’aluminium |

| Aluminium nitrate un 1438 | B | Nitrate d’aluminium un 1438 |

| Aluminium remelting by-products un 3170 | B | Sous-produits de la refusion de l’aluminium, un 3170 |

| Aluminium salt slags | B | Scories salines d’aluminium |

| Aluminium silicon powder, uncoated un 1398 | B | Silico-aluminium en poudre, non enrobé un 1398 |

| Aluminium skimmings | B | Crasse d’aluminium |

| Aluminium smelting by-products un 3170 | B | Sous-produits de la fabrication de l’aluminium un 3170 |

| Aluminium smelting/remelting by-products, processed | A et/and B | Sous-produits de la refusion de l’aluminium, traités |

| Ammonium nitrate un 1942 | B | Nitrate d’ammonium un 1942 |

| Ammonium nitrate based fertilizer un 2067 | B | Engrais au nitrate d’ammonium un 2067 |

| Ammonium nitrate based fertilizer un 2071 | B | Engrais au nitrate d’ammonium un 2071 |

| Amorphous sodium silicate lumps | B | Morceaux de silicate de sodium amorphe |

| Bakery materials | B ou/or C | Produits de boulangerie |

| Barium nitrate un 1446 | B | Nitrate de baryum un 1446 |

| Barley malt pellets | B ou/or C | Malt d’orge en boulettes |

| Beet, expelled | B ou/or C | Betterave, triturée |

| Beet, extracted | B ou/or C | Bettrave, sous-produit de l’extraction |

| Boric acid | B | Acide borique |

| Bottom ash | A et/and B | Cendres résiduelles (voir cendres de mâchefer) |

| Bran pellets | B ou/or C | Son en boulettes |

| Brewer’s grain pellets | B ou/or C | Drêches de brasserie en boulettes |

| Brown coal briquettes | B | Charbon brun en briquettes |

| Calcined pyrites | A et/and B | Pyrites calcinées |

| Calcium fluoride | A et/and B | Fluorure de calcium |

| Calcium nitrate un 1454 | B | Nitrate de calcium un 1454 |

| Calcium oxide | B | Oxyde de calcium |

| Canola pellets | B ou/or C | Canola en boulettes |

| Castor beans un 2969 | B | Graines de ricin un 2969 |

| Castor flake un 2969 | B | Graines de ricin en flocons un 2969 |

| Castor meal un 2969 | B | Farines de ricin un 2969 |

| Castor pomace un 2969 | B | Tourteaux de ricin, un 2969 |

| Charcoal | B | Charbon de bois |

| Chile saltpetre | B | Salpêtre du chili |

| Chilean natural nitrate | B | Nitrate naturel du chili |

| Chilean natural potassic nitrate | B | Nitrate de potassium naturel du chili |

| Citrus pulp pellets | B ou/or C | Pulpe d’agrumes en boulettes |

| Clinker ash | A et/and B | Cendres de mâchefer |

| Coal | B et/and A | Charbon |

| Coal tar pitch | B | Brai de goudron de houille |

| Coconut | B ou/or C | Noix de coco |

| COPRA (dry) UN 1363 | B | Coprah (sec) un 1363 |

| Copra, expelled | B ou/or C | Coprah, trituré |

| Copra, extracted | B ou/or C | Coprah, sous-produit d’extraction |

| Corn gluten | B ou/or C | Gluten de maïs |

| Cotton seed | B ou/or C | Graines de cotonnier |

| Direct reduced iron (a) Briquettes, hot-moulded |

B | Fer obtenu par réduction directe (a) (briquettes moulées à chaud) |

| Direct reduced iron (b) Lumps, pellets, cold-moulded briquettes |

B | Fer obtenu par réduction directe (b) (morceaux, pellets, briquettes moulées à froid et tournures de fer indiennes) |

| Direct reduced iron (c) By-product fines |

B | Fer obtenu par réduction directe (c) (fines en tant que sous-produit) |

| Dolomitic quicklime | B | Chaux vive dolomitique |

| D.r.i. | B | Not applicable in french |

| Expellers | B ou/or C | Expellers |

| Ferrophosphorus | B | Ferrophosphore |

| Ferrophosphorus briquettes | B | Ferrophosphore en briquettes |

| Ferrosilicon un 1408 | B | Ferrosilicium un 1408 |

| Ferrosilicon | B | Ferrosilicium |

| Ferrous metal borings un 2793 | B | Rognures de métaux ferreux un 2793 |

| Ferrous metal cuttings un 2793 | B | Ebarbures de métaux ferreux un 2793 |

| Ferrous metal shavings un 2793 | B | Copeaux de métaux ferreux un 2793 |

| Ferrous metal turnings un 2793 | B | Tournures de métaux ferreux, un 2793 |

| Fishmeal, stabilized un 2216 | B | Farine de poisson stabilisée un 2216 |

| Fishscrap, stabilized un 2216 | B | Déchets de poisson stabilisés un 2216 |

| Flue dust, containing lead and zinc | A et/and B | Cendres volantes contenant du plomb et du zinc |

| Fluorspar | A et/and B | Spath fluor |

| Garbage tankage | B | Détritus organiques |

| Gluten pellets | B ou/or C | Gluten en boulettes |

| Granulated nickel matte (less than 2% moisture content) | B | Matte de nickel en granules (teneur en humidité inférieure à 2 %) |

| Ground nuts, meal | B ou/or C | Farine d’arachide |

| Hominy chop | B ou/or C | Hominy chop |

| Iron oxide, spent un 1376 | B | Oxyde de fer résiduaire un 1376 |

| Iron sponge, spent un 1376 | B | Tournures de fer résiduaire, un 1376 |

| Iron swarf | B | Copeaux de fer |

| Lead nitrate un 1469 | B | Nitrate de plomb un 1469 |

| Lignite | B | Lignite |

| Lime (unslaked) | B | Chaux (vive) |

| Linted cotton seed | B | Graines de cotonnier avec linter |

| Linseed, expelled | B ou/or C | Graines de lin, triturées |

| Linseed, extracted | B ou/or C | Graines de lin, sous-produits de l’extraction |

| Logs | B | Grumes |

| Magnesia (unslaked) | B | Magnésie (vive) |

| Magnesia lightburned | B | Magnésie calcinée légère |

| Magnesia calcined | B | Magnésie calcinée |

| Magnesia caustic calcined | B | Magnésie calcinée caustique |

| Magnesium nitrate un 1474 | B | Nitrate de magnésium un 1474 |

| Maize, expelled | B ou/or C | Maïs, trituré |

| Maize, extracted | B ou/or C | Maïs, sous-produit de l’extraction |

| Matte containing copper and lead | B | Matte contenant du cuivre et du plomb |

| Meal, oily | B ou/or C | Farines oléagineuses |

| Metal sulphide concentrates | A et/and B | Concentrés de sulfures métalliques |

| Metal sulphide concentrates, corrosive un 1759 | A et/and B | Concentrés de sulfures métalliques, corrosifs un 1759 |

| Metal sulphide concentrates, self-heating un 3190 | A et/and B | Conentrés de sulfures métalliques, autochauffants un 3190 |

| Mill feed pellets | B ou/or C | Sous-produits de meunerie en boulettes |

| Monoammonium phosphate (m.a.p.), mineral enriched coating | B | Monophosphate d’ammonium, revêtement enrichi en minéraux |

| Monocalciumphosphate (mcp) | A et/and B | Phosphate monocalcique |

| Niger seed, expelled | B ou/or C | Graines de niger, triturées |

| Niger seed, extracted | B ou/or C | Graines de niger, sous-produits de l’extraction |

| Oil cake | B ou/or C | Tourteaux oléagineux |

| Palm kernel, expelled | B ou/or C | Amande de palmiste, triturée |

| Palm kernel, extracted | B ou/or C | Amande de palmiste, sous-produit de l’extraction |

| Peanuts, expelled | B ou/or C | Cacahuètes, triturées |

| Peanuts, extracted | B ou/or C | Cacahuètes (sous-produit de l’extraction) |

| Peat moss | A et/and B | Tourbe horticole |

| Pellets, cereal | B ou/or C | Céréales en boulettes |

| Pencil pitch | B | Brai en crayon |

| Petroleum coke (calcined) | B | Coke de pétrole (calciné) |

| Petroleum coke (uncalcined) | B | Coke de pétrole (non calciné) |

| Pitch prill | B | Brai en grains |

| Pollard pellets | B ou/or C | Recoupette en boulettes |

| Potassium nitrate un 1486 | B | Nitrate de potassium un 1486 |

| Potassium nitrate/sodium nitrate (mixture) | B | Nitrate de potassium/nitrate de sodium (en mélange) |

| Prilled coal tar | B | Goudron de houille en grains |

| Pulp wood | B | Bois à pâte |

| Pyrites, calcined | A et/and B | Pyrites calcinées |

| Pyritic ash | A et/and B | Cendres pyriteuses |

| Quicklime | B | Chaux vive |

| Radioactive material, low specific activity (lsa-i) un 2912 | B | Matières radioactives de faible activité spécifique (lsa-i), sables, concentrés de minéraux, un 2912 |

| Radioactive material, surface contaminated objects (sco-i) un 2913 | B | Matières radioactives, objets contaminés superficiellement (sco-i), un 2913 |

| Rape seed, expelled | B ou/or C | Graines de colza, triturées |

| Rape seed, extracted | B ou/or C | Graines de colza, sous-produits de l’extraction |

| Rice bran | B ou/or C | Son de riz |

| Rice broken | B ou/or C | Brisures de riz |

| Rough ammonia tankage | B | Déchets organiques ammoniacaux |

| Roundwood | B | Rondins (bois) |

| Safflower seed, expelled | B ou/or C | Graines de carthame, triturées |

| Safflower seed, extracted | B ou/or C | Graines de carthame, sous-produits de l’extraction |

| Saltpetre | B | Salpêtre |

| Sand, mineral concentrate, radioactive material, low specific activity (lsa-i) un 2912 | A et/and B | Matières radioactives de faible activité spécifique (lsa-i), sables, concentrés de minéraux un 2912 |

| Sawdust | B | Sciure de bois |

| Saw logs | B | Bois débité |

| Seed cake, containing vegetable oil un 1386 (a) mechanically expelled seeds, containing more than 10% of oil or more than 20% of oil and moisture combined. | B | Tourteaux contenant de l’huile végétale, un 1386 A) graines triturées par procédé mécanique contenant plus de 10 % d’huile ou plus de 20 % d’huile et d’humidité combinées. |

| Seed cake, containing vegetable oil un 1386 (b) solvent extraction and expelled seeds, containing not more than 10% of oil and when the amount of moisture is higher than 10%, not more than 20% of oil and moisture combined. | B | Tourteaux contenant de l’huile végétale un 1386 B) sous-produits de l’extraction au solvant ou graines triturées contenant au maximum 10 % d’huile et, si la teneur en humidité est supérieure à 10 %, pas plus de 20 % d’huile et d’humidité combinées. |

| Seed cake un 2217 | B | Tourteaux, un 2217 |

| Seed cakes and other residues of processed oily vegetables | B | Tourteaux et autres résidus de végétaux huileux traités |

| Seed expellers, oily | B ou/or C | Expellers oléagineux |

| Silicomanganese (low carbon) | B | Silicomanganèse (à faible teneur en carbone) |

| Sodium nitrate un 1498 | B | Nitrate de sodium un 1498 |

| Sodium nitrate and potassium nitrate mixture un 1499 | B | Nitrate de sodium et nitrate de potassium en mélange un 1499 |

| Solidified fuels recycled from paper and plastics | B | Combustibles solidifiés recyclés à partir de déchets composés de papier et de plastique |

| Soyabean, expelled | B ou/or C | Graines de soja, triturées |

| Soyabean, extracted | B ou/or C | Graines de soja, sous-produits de l’extraction |

| Spent cathodes | B | Cathodes usées |

| Spent potliner | B | Revêtement usé des cuves |

| Steel swarf | B | Rognures d’acier |

| Strussa pellets | B ou/or C | Strussa en boulettes |

| Sugarcane biomass pellets | B | Biomasse de la canne à sucre |

| Sulphide concentrates | B | Concentrés sulfurés |

| Sulphur un 1350 (crushed lump and coarse grained) | B | Soufre un 1350 (concassé en morceaux et en poudre à gros grains) |

| Sunflower seed, expelled | B ou/or C | Graines de tournesol, triturées |

| Sunflower seed, extracted | B ou/or C | Graines de tournesol, sous-produits de l’extraction |

| Swarf | B | Rognures |

| Tankage | B | Déchets organiques |

| Tankage fertilizer | B | Engrais à base de déchets organiques |

| Timber | B | Bille de bois |

| Toasted meals | B ou/or C | Farines grillées |

| Vanadium ore | B | Minerai de vanadium |

| Woodchips | B | Copeaux de bois |

| Wood pellets containing additives and/or binders | B | Granulés (pellets) de bois contenant des additifs et/ou liants |

| Wood pellets not containing any additives and/or binders | B | Granulés (pellets) de bois ne contenant aucun additif ou liant |

| Wood products – general | B | Produits du bois – généralités |

| Wood torrefied | B | Bois torréfié |

| Zinc ashes un 1435 | B | Cendres de zinc un 1435 |

| Zinc, dross, residue or skimmings | B | Zinc, crasses, résidus, laitier |

| Zinc oxide enriched flue dust | A et/and B | Cendres volantes enrichies aux oxydes de zinc |

Bibliography

Adam Allan C. & Captain Michael Lloyd, Enclosed Space Equipment, September 2012, Seaways, Page 4.

Canadian Standards Association, CSA Z1006-F16 (R2020), Management of work in confined spaces, Toronto, CSA, 2016, 117 pages.

CCC 5/INF.12, AMENDMENTS TO THE IMSBC CODE AND SUPPLEMENTS, Safe handling of solid bulk cargoes submitted by IBTA, June 14, 2018, IMO, London, Page 24.

Code of Safe Working Practices for Merchant Seafarers 2015 edition – Amendment 5, October 2020, Chapter 15: "ENTERING DANGEROUS (ENCLOSED) SPACES", Maritime & Coast Guard Agency UK, 5th Edition, October 2020, 543 pages.

Confined Space Practice, recommendation No.72 – Rev.3, Dec. 2018, IACS, 2018, 31 pages.

Enclosed Spaces Entry, The Shipowners’ Protection Limited, December 2007, 40 pages.

Enclosed Space Entry Awareness, Captain Harry Gale FNI, Seaways, September 2011, 3 pages.

Enclosed Space Design, Adam Allan & Capt. Michael Lloyd FNI, Seaways, September 2011, 4 pages.

Enclosed Space Fatalities – Why?, 2018, CHIRP Maritime, London, 6 pages.

Entry Into Enclosed Spaces: Still an On-Going Cause of Crew Deaths, March 2019, Maritime Mutual Insurance Association (NZ) Ltd., 4p.

Gard Alert: Enclosed space entry training, Guard P&I Club, December 2014, 3 pages.

Guidance on Enclosed Space Entry and Rescue (Based on guidance in the ICS Tanker Safety Guide (Chemicals)), International Chamber of Shipping, August 2015, 19 pages.

International Safety Guide for Tankers and Terminals (ISGOTT), chapter 10 "Enclosed Space Entry", Oil Companies International Marine Forum (OCIMF), Witherby Seamanship, June 2006, 450 pages.

Confined Spaces – A Guide for Health and Safety Officers, May 2004, HRSDC – Labour Program, 50 pages.

Loss Prevention Briefing, Enclosed Spaces, The North of England P&I Association, April 2016, 17 pages.

MSC.1/Circ.1477, GUIDELINES TO FACILITATE THE SELECTION OF PORTABLE ATMOSPHERE TESTING INSTRUMENTS FOR ENCLOSED SPACES AS REQUIRED BY SOLAS REGULATION XI-1/7, June 9, 2014, IMO, London, 4 pages.

Olsen & Olsen, Fresh Air in Dark Places, 1st Ed., Livingston UK, Witherby Seamanship International Ltd., August 2010, 107 pages.

Resolution A.1050 (27), revised recommendations for entering enclosed spaces aboard ships, November 30, 2011, IMO, London, 13 pages.

Risk Management - Entry into enclosed spaces – ships’ cargo spaces (IIL/3), February 2010, ICHCA International Limited & TT Club, 4 pages.

Safe Rescue in Confined Spaces for Firefighters, CNESST, May 2017, 12 pages.

SIP007 – Guidance on Loading and Unloading of Dry Bulk Cargo, October 2010, Port Skills and Safety UK, London, 23 pages.

SIP015 - Guidance on Confined Spaces in Ports, April 2014, Port Skills and Safety UK, London, 17 pages.

Spencer, Chris., A Master’s Guide To: Enclosed Space Entry, February 2012, Standard P&I Club, London, 60 pages.

Standard Club – Guide to Enclosed Space Entry, The Standard Club, August 2017, 32 pages.

Guidance on Confined Spaces – Cargo hold

(PDF, 7.36 MB)